Table of Contents

Advertisement

Quick Links

Operation and Parts

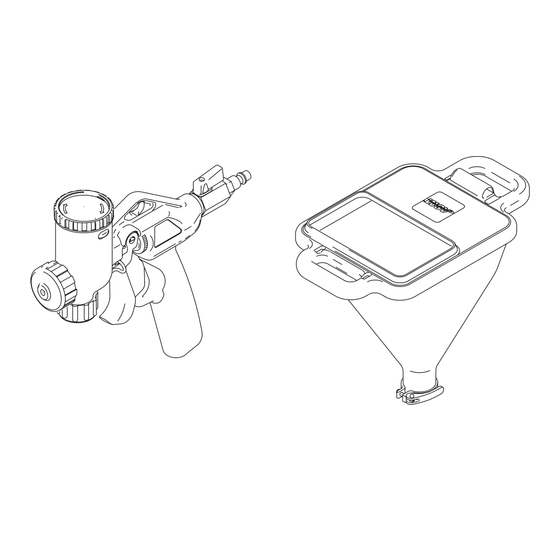

Texture Gun & Hopper

For Water-Based Materials Only

Model 246409 Series A, B, and C

100 psi (7 bar, 0.7 MPa) Maximum Working Air Pressure

60 psi (4.1 bar, 0.41 MPa) Maximum Working Fluid Pressure

Read warnings and instructions.

Related Manuals

309799

309800

TI2445a

309798F

ti3145a

Advertisement

Table of Contents

Need help?

Do you have a question about the B Series and is the answer not in the manual?

Questions and answers