Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Danfoss FT1244

- Page 1 Operator’s Manual Danfoss FT1244 Crimp Machine...

-

Page 2: Table Of Contents

Electrical Schematic ........................14-15 Obsolate Data Notice The calibration method for some early model crimp machines used fittings that are no longer supplied by Danfoss Corporation. Therefore, some of the data on the following pages may be considered obsolete, such as machine settings (i.e. 1401 socket data). -

Page 3: Introduction

Introduction The Danfoss FT1244 Crimp Machine is designed for the distributor or O.E.M. who needs production style crimping capacity. The FT1244 is a hydraulically operated machine that will crimp Danfoss standard crimp fittings; -3 through -32*, including four spiral hose. The FT1244 will crimp both straight and standard elbow fitting assemblies. -

Page 4: Preoperation Procedures

Preoperation Procedures CAUTION: THIS MACHINE IS TOP HEAVY! Uncrate the FT1244 crimp machine and inspect the machine for possible shipping damage. The following components are in the tool box. 1 can of high efficiency PTFE grease (Danfoss part number FF91455) -

Page 5: Operating Instructions

Select the crimp dies specified in the PowerSource Crimp Spec Tool at danfoss.com/crimp for the selected hose style and size. Liberally lubricate all sliding surfaces of the crimp dies with high efficiency PTFE grease (Danfoss part number T-400-G). Do not lubricate the crimping surface of the dies. - Page 6 (Det. 4) against the spacer. Crimp the fitting, pull out the spacer, push Det. 3 back against Det. 4 and remove elbow.. Illustration 2 6 | © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. AQ439269330776en-000101...

- Page 7 The crimp diameter specifications are listed in the PowerSource Crimp Spec Tool at danfoss.com/crimp for crimp spec details. The exact micrometer settings may vary from one machine to another due to manufacturing tolerances. Furnished in the back of this manual is a sheet of approximate micrometer settings for the first crimp.

- Page 8 (the socket is precrimped to the nipple to establish the required crimp length). Refer to the PowerSource Crimp Spec Tool at danfoss.com/crimp for crimp spec details which outlines the required crimping information. Scribe a mark on the socket at the nipple end at the desired dimension as indicated in the PowerSource Crimp Spec Tool at danfoss.com/crimp for crimp spec details.

-

Page 9: Maintenance

Maintenance Normal maintenance of the FT1244 crimp machine requires a light film of oil coating over all the exposed black surfaces, crimp ring die, contact surface lubricated with high efficiency PTFE grease (Danfoss part number T-400-G), and a maintained oil level within the hydraulic power unit oil reservoir (one inch below the top of the reservoir). -

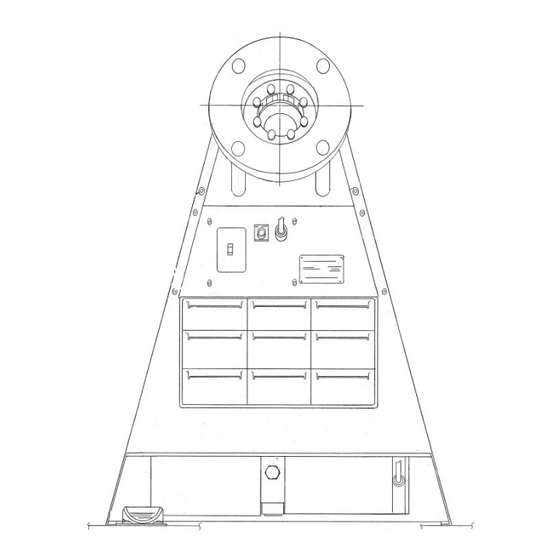

Page 10: Machine Breakdown

Danfoss FT1244 Crimp Machine Operator’s Manual Machine Breakdown 10 | © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. AQ439269330776en-000101... - Page 11 FF9236-045 1/4-20 Thin Self-Locking Nut FT1244-3-61 Adjustment Screw FF9228-0408S 1/4-20 x .50 Soc Hd Cap Screw with Nylon insert FT1244-3-69 Guard (not shown) FT1244-3-70 Guard Decal (not shown) AQ439269330776en-000101 © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. | 11...

-

Page 12: Hydraulic Breakdown

Danfoss FT1244 Crimp Machine Operator’s Manual Hydraulic Components 12 | © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. AQ439269330776en-000101... - Page 13 Danfoss FT1244 Crimp Machine Operator’s Manual DETAIL NUMBER PART NUMBER DESCRIPTION NUMBER REQUIRED FT1244-2-6 Power Unit 2062-6-6S Danfoss Adapter FL1348GGG0240 Danfoss Hose Assembly 203103-6-6S Danfoss Adapter 2081-6S Danfoss Adapter 2024-4-6S Danfoss Adapter AQ439269330776en-000101 © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. | 13...

-

Page 14: Electrical Schematic

Danfoss FT1244 Crimp Machine Operator’s Manual Electrical Schematic 14 | © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. AQ439269330776en-000101... - Page 15 FT1244-2-5-15 Limit Switch Electric Cord FT1244-2-5-16 Wall Plug FT1244-2-5-18 Electric Cord Connectors FT1244-2-5-19 Fuse (1 Amp) *Items 7 through 15 & 18 are not shown on electrical schematic. AQ439269330776en-000101 © Danfoss FT1244 Crimp Machine Operator’s Manual | 2023.05. | 15...

- Page 16 Phone: +86 21 3418 5200w Danfoss can accept no responsibility for possible errors in catalogs, brochures, and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

Need help?

Do you have a question about the FT1244 and is the answer not in the manual?

Questions and answers