Summary of Contents for tams elektronik B-6

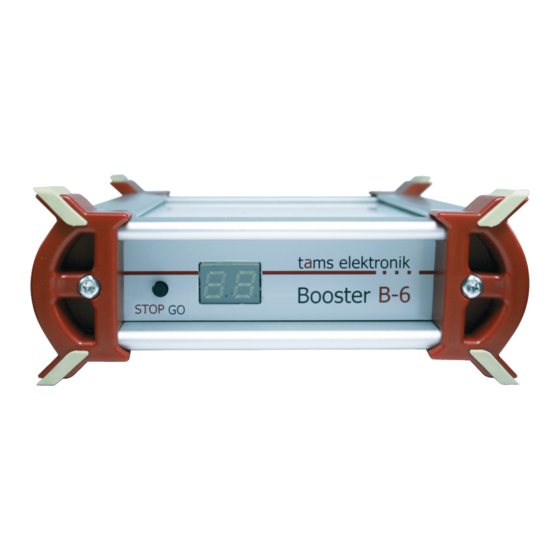

- Page 1 Booster for digital model railway layouts Item no. 40-19607 Manual Front Back tams elektronik n n n...

- Page 2 © Tams Elektronik GmbH All rights reserved, in particular the right of reproduction, distribution and translation. Copies, reproductions and alterations in any form require the written permission of Tams Elektronik GmbH. We reserve the right to make technical changes. Printing the manual The formatting is optimised for double-sided printing.

-

Page 3: Table Of Contents

1.3. Intended use.......................6 1.4. Safety instructions....................6 1.5. Care........................6 2. Your B-6........................7 2.1. Track voltage.......................7 2.2. Displays and operation..................8 2.3. Interfaces of the B-6....................9 Background information: Output signal..............10 2.4. Protocols......................11 2.4.1. Digital formats..................11 2.4.2. RailCom....................11 2.5. Safety devices....................12 2.5.1. Short-circuit switch-off................12 2.5.2. - Page 4 8.3. Problems with control via the BiDi bus..............37 8.4. Problems with the Watchdog Function..............38 8.5. Technical Hotline....................38 8.6. Repairs......................38 9. Technical data......................39 9.1. Booster B-6......................39 9.2. Power supply unit....................41 10. Warranty, EU conformity & WEEE................43 10.1. Guarantee bond....................43 10.2. EU Declaration of Conformity................44 10.3.

-

Page 5: Getting Started

Distribution of the booster current In order to utilise the current of 6 A that the B-6 can provide, even with smaller nominal sizes, a power splitter** can be used. The power splitter distributes the current to 2 to 3 booster sections with 2 to 3 A each. -

Page 6: Intended Use

1.3. Intended use The booster B-6 is intended for use in digital model railway layouts as specified in the instructions. Any other use is not in accordance with the intended use and will result in the loss of the warranty claim. Intended use also includes reading, understanding and following all parts of the instructions. -

Page 7: Your B-6 | 7

Division of the booster current In order to be able to utilise the current of 6 A that the B-6 can provide, even with smaller nominal sizes, a power splitter** can be used. The power splitter distributes the current to 2 to 3 booster sections with 2 to 3 A each. -

Page 8: Displays And Operation

short circuit, overtemperature STOP-GO button The button can be used to manually switch the track voltage on or off at the output of the B-6 independently of the connected digital control unit. The button is also used to ... -

Page 9: Interfaces Of The B-6

2.3. Interfaces of the B-6 Power supply Only the supplied power supply unit may be used as the power supply for your B-6 and the components of your layout that are supplied by the B-6. Conventional model railway transformers are not suitable as power supply for the B-6. -

Page 10: Background Information: Output Signal

The inputs and outputs of the B-6 are galvanically separated from each other by optocouplers. This means that there is no electrical connection between the digital control unit and the booster output. -

Page 11: Protocols

With non-RailCom-capable DCC sound decoders, the sound reproduction can be disturbed. Therefore, the B-6 offers the possibility to switch RailCom on or off (RailCom is switched on in the delivery state). In the case of pure Motorola central units, interference with data transmission through the RailCom cutout is excluded due to the principle. -

Page 12: Safety Devices

Connection to a BiDiB PC interface (separate or integrated in the digital control unit): Based on the status messages and operating values sent by the B-6 via the BiDi bus, the PC control takes over the complete booster management. -

Page 13: Switching Off In Case Of Overtemperature

The B-6 can accept an increased current of 6 A for a short time (adjustable up to max. 500 ms) after switching on, regardless of the set cut-off current, and tolerates the brief collapse of the voltage. -

Page 14: Use With Bidib

Booster B-6 tams elektronik 2.6. Use with BiDiB The Booster B-6 is in the sense of the BiDiB specification a device of the class "Booster" with the additional specification "BiDi-(RailCom-)Detector". 2.6.1. Features According to the BiDiB specification, data can be sent to and from the B-6 via the BiDi bus. -

Page 15: Possible Applications

BiDiB PC interfaces (e.g. ZEUS**) In both variants, all settings for the B-6 can be made on the PC with the help of software that supports BiDiB. The B-6 sends its status messages and operating values as well as the RailCom messages to the PC via the BiDi bus. -

Page 16: Wiring

In accordance with the BiDiBus specification, patch cables with RJ 45 connectors (Cat5 cables) are provided as bus cables for the B-6 booster. These cables are easy and quick to handle and ensure secure connections to the interface and to other nodes. Connecting and disconnecting the cables during operation is permitted (hot plug). -

Page 17: Conception Of The Digital Layout

Booster B-6 3. Conception of the digital layout 3.1. Dividing the layout Divide your layout into individual, electrically separate sections (booster circuits), each supplied with its own booster. A maximum of three to five locomotives should run in each booster circuit at the same time. -

Page 18: Supply With Several Boosters

Booster B-6 tams elektronik Cut the transitions between the booster circuits as follows: For 2-conductor layouts: one rail. Make sure that you cut the same rail ("left" or "right") in all booster circuits. In larger, unclear systems, it is recommended to cut both rails. - Page 19 Booster B-6 Equalising currents and double track voltage When crossing the separation points, equalising currents occur between the (briefly differently polarised) booster circuits, even when using identical boosters from the same manufacturer. These currents are harmless for rails and vehicles and do not affect the operation.

-

Page 20: Tip: Detecting Equalising Currents

Booster B-6 tams elektronik Tip: Detecting equalising currents The question of whether or not dangerous equalising currents occur at a booster separation point can be detected relatively easily with the help of a model railway incandescent lamp connected to the rails or the centre conductors across the separation point. -

Page 21: Connections

4. Connections 4.1. Connection to the power supply Note: Only use the supplied power supply unit as power supply for your B-6 and the components of your layout that are supplied by the B-6. Insert the 4-pin appliance plug of the power supply connection cable into the "Power"... - Page 22 Booster B-6 tams elektronik Cable cross-sections For the connection to the rails, use a cable with a cross-section sufficient for the load (recommended cross-section: > 0.75 to 1.5 mm²). Please note: If the cross-section is too small, the overcurrent/short-circuit cut-off will not function reliably and the cable may become very warm.

-

Page 23: Connection To The Digital Central Unit

Evaluation of short-circuit feedback signals The B-6 sends a corresponding message via the BiDi bus in case of an overload at the track output (e.g. in case of a short circuit). The digital control can react to this and e.g. switch off the track voltage for the entire installation. -

Page 24: Connection Variant 2: Dcc-Compliant Interface ("Cde")

Installing the B-6 at the end of the BiDi bus line If you only connect one B-6 to the central unit via a patch cable with a length of up to 5 m via BiDiB, you do not need a terminating resistor. -

Page 25: Connection To A Bidib-Pc Interface Without Track Output Function

Connection to the digital control unit If the B-6 is only connected to a BiDiB PC interface without track output function via the BiDi bus, no track signal is present at the BiDiB interface of the B-6. In this constellation, you must therefore additionally connect the B-6 to a digital control unit via the DCC-compliant booster interface (→... -

Page 26: Settings / Configuration

Switching to programming mode To be able to program the B-6, it must be connected to a BiDiB connection or the DCC booster connection of the digital control unit and the control unit must be set to "GO". To start the programming mode of the B-6, enter the value "62"... - Page 27 Booster B-6 Function Input Setting / Comment Display value for CV 7 Start programming To change settings, you must enter a mode value for CV 7 again within 30 seconds. Otherwise, the programming mode is automatically terminated. Reset To reset all settings to the default values (= values at delivery).

- Page 28 Booster B-6 tams elektronik Function Input Setting / Comment Display value for CV 7 Switching the → The RGB LEDs flash white. watchdog on and off Switch to switch turnouts on your digital with DCC turnout control. Set the desired turnout address...

-

Page 29: Recommendations For The Settings

Maximum track current (cut-off current in case of short circuit) The idea of using the current of 6 A, which the Booster B-6 can provide, to supply large sections or even the complete layout is obvious. This solution, which at first glance appears to be cost-effective, promises minimised installation effort and avoids problems that can arise when crossing separation points between booster circuits. -

Page 30: Operation

Booster B-6 tams elektronik 6. Operation 6.1. Operating and display elements The Booster B-6 has a button with which you can trigger the following functions: switch the track voltage on and off independently of the control unit trigger a reset ... -

Page 31: Display And Rgb-Leds

Booster B-6 6.1.2. Display and RGB-LEDs Display Colour Meaning of the RGB LEDs | present current consumption [A] Booster Track voltage at booster output is switched on. 0.0 to 6.0 A valid input signal is present at Central the booster input. - Page 32 As soon as the booster has cooled down, you can put it back into operation. blue flashing: BiDiB-Identify The B-6 reports to the PC control software via BiDiB (BiDiB-Identify). To stop sending the signal, press the button again until the RGB LEDs light up green or red again.

-

Page 33: Activating The Watchdog

If the autostart function is set to inactive, the automatic switching on of the track voltage at the output of the B-6 is prevented (e.g. after manually setting the control unit to "GO" or after eliminating a short circuit on the layout). In this case, the RGB LEDs light up yellow (→ section... -

Page 34: Automatic Switching Off Of The Track Voltage

When the watchdog is activated, the central unit (usually controlled by PC software) sends a DCC turnout setting command to a turnout address assigned to the B-6 at intervals of approx. 5 seconds. As soon as the booster no longer receives these commands, it automatically switches off the track voltage. -

Page 35: Reset

There is no risk that devices connected to the bus line will be damaged by a missing or incorrectly set terminating resistor. If possible, the B-6 booster should not be installed at the end of a BiDi bus line in a BiDiB- controlled system, as setting a terminating resistor for the B-6 is comparatively complex compared to other BiDiB devices (stationary decoders, feedback devices). -

Page 36: Update

BiDiB. Update without BiDiB If you cannot carry out the update yourself, send us your B-6 for an update (free of charge for you). You only have to bear the costs of sending it back and forth. -

Page 37: Checklist For Troubleshooting And Error Correction

Warning: If you notice a strong heat development or if the booster has switched off the track voltage due to overtemperature, disconnect the B-6 from the supply voltage immediately. Fire hazard! If the overheating is not caused by external influences (obstruction of air exchange, sunlight), send the B-6 in for inspection. -

Page 38: Problems With The Watchdog Function

(telephone number and e-mail address on the last page). 8.6. Repairs You can send us a defective B-6 or a defective power supply unit for inspection / repair (address on the last page). Please do not send us your return freight collect. In the event of a warranty or guarantee claim, we will reimburse you for the regular shipping costs. -

Page 39: Technical Data

Booster B-6 9. Technical data 9.1. Booster B-6 Digital protocols Data formats Motorola-I and -II DCC (according to NMRA and RCN standard) m3 and mfx (limited to the control of mfx decoders) Formats for the automatic DCC-A registration of vehicle This function is not yet available (Status: 04/2023). - Page 40 Booster B-6 tams elektronik Protection class IP 20 Meaning: Protected against solid foreign bodies with a diameter ≥ 12.5 mm and access with a finger. No protection against water. Overload 100 ~ 110% of the rated output power Protection: Switching off the voltage at the track output...

-

Page 41: Power Supply Unit

Booster B-6 9.2. Power supply unit Manufacturer MEAN WELL ENTERPRISE Co. Ltd. Type designation GSM160B24-R7B Output Output voltage 24 VDC Rated current 6.67 A Output current 0 – 6.67 A Rated powerNennleistung max. 160 watts Input Input voltage... - Page 42 Booster B-6 tams elektronik Environment For use in closed rooms Note: To allow unhindered air exchange and to predect the unit from overheating, a distance of at least 20 cm must be maintained between the side surfaces, the top surfaces and the rear surfaces to ambient surfaces.

-

Page 43: Warranty, Eu Conformity & Weee

Booster B-6 10. Warranty, EU conformity & WEEE 10.1. Guarantee bond For this product we issue voluntarily a guarantee of 2 years from the date of purchase by the first customer, but in maximum 3 years after the end of series production. The first customer is the consumer first purchasing the product from us, a dealer or another natural or juristic person reselling or mounting the product on the basis of self-employment. -

Page 44: Eu Declaration Of Conformity

Booster B-6 tams elektronik 10.2. EU Declaration of Conformity This product fulfils the requirements of the following EU directives and therefore bears the CE marking. 2001/95/EU Product Safety Directive 2015/863/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS) 2014/30/EU on electromagnetic compatibility (EMC Directive). - Page 45 Booster B-6...

- Page 46 Booster B-6 tams elektronik...

- Page 47 Booster B-6...

- Page 48 Further Information and Tips: http://www.tams-online.de Warranty and Service: Tams Elektronik GmbH Fuhrberger Straße 4 DE-30625 Hannover fon: +49 (0)511 / 55 60 60 fax: +49 (0)511 / 55 61 61 e-mail: modellbahn@tams-online.de...

Need help?

Do you have a question about the B-6 and is the answer not in the manual?

Questions and answers