AGS ParkSafe Controller Installation, Operation & Maintenance Manual

Hide thumbs

Also See for ParkSafe Controller:

- Installation & operation manual (16 pages) ,

- Installation & operation manual (16 pages) ,

- Installation operation & maintenance (16 pages)

Table of Contents

Advertisement

Quick Links

Installation, Operation & Maintenance

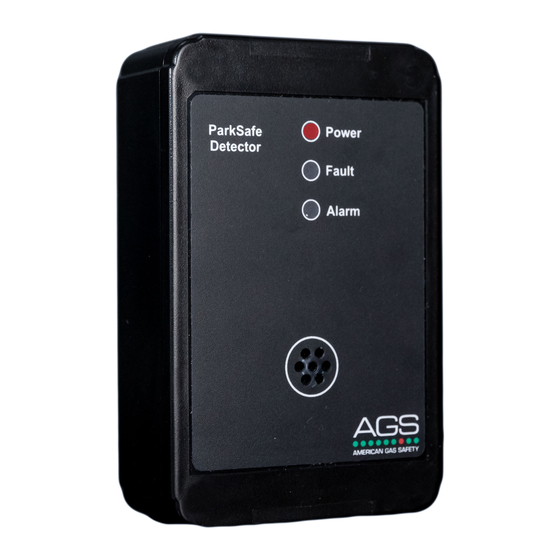

ParkSafe Controller

ParkSafe Controller

Installation, Operation & Maintenance Manual

Please read this manual carefully and retain for future use.

For specific requirements that may deviate from the information in this guide – contact your supplier.

American Gas Safety LLC

www.americangassafety.com

Rev: 20

1

Advertisement

Table of Contents

Summary of Contents for AGS ParkSafe Controller

- Page 1 Installation, Operation & Maintenance ParkSafe Controller ParkSafe Controller Installation, Operation & Maintenance Manual Please read this manual carefully and retain for future use. For specific requirements that may deviate from the information in this guide – contact your supplier.

-

Page 2: Table Of Contents

Typical Application & Location ..................4 ParkSafe Detector Placement Plan ................... 5 Mounting & Cabling ......................5 Electrical Connections ...................... 6 Wiring AGS ParkSafe Detector(s) ..................7 ParkSafe Detector ‘ID’ Switches ..................9 120ohm Termination Resistance..................9 Access Configuration Settings ..................9 Configuration Settings Explained .................. -

Page 3: Important Warning Statements

At the end of their working life, electrochemical sensors should be disposed of in an environmentally safe manner. Alternatively, they can be securely packaged and returned to AGS clearly marked for disposal. Electrochemical sensors should not be incinerated as this may cause the cell to emit toxic fumes. -

Page 4: Installation

RTU protocol back to the controller and monitor the detectors in numbers up to 16 (per controller) and automatically control ventilation systems according to gas levels and an optional temperature level. The ParkSafe controller monitoring system can activate both the exhaust fan(s) and the air intake device(s) such as outside air louvers/dampers and make up air units The ParkSafe will make or break a dry contact internally on relay terminals [Output-1] and a second contact on [Output-2]. -

Page 5: Parksafe Detector Placement Plan

The carbon monoxide monitors must be located as specified by your region’s building code. If not specified contact your local AGS representative. Detection of nitrogen dioxide is done where a significant quantity of diesel engines is typically located such as train stations, bus and truck maintenance garages, rapid transit authorities, car dealerships, ambulance bays, loading docks and diesel- powered vehicle parking structures. -

Page 6: Electrical Connections

POWER/ LINE IN. The ParkSafe controller requires a power supply of 100-120Vac using a 3A switched fused spur. When mains line, power is connected to the controller, a red LED will illuminate on the front of the controller (AGS Logo). OUTPUT-1. -

Page 7: Wiring Ags Parksafe Detector(S)

This output signal sends either zero or 2V under normal operating conditions – selectable in the settings menu. 5V signal when [OUTPUT 1] relay switches. 10V signal when [OUTPUT 2] relay switches. Wiring AGS ParkSafe Detector(s) If you are encountering noise or irregular problems with a Modbus link, the problem is likely related to grounding, incorrect shielding or wiring mains power next to Modbus wiring. - Page 8 Installation, Operation & Maintenance ParkSafe Controller Power and Modbus data are wired between detectors with the first connected to a ParkSafe controller [Detector Chain] terminal. If using a shielded wire (recommended) then connect the shield to [Shield Wire] dedicated terminals.

-

Page 9: Parksafe Detector 'Id' Switches

Before carrying out any work ensure local regulations and site procedures are followed! Turn on the [Settings] switch located on the display circuit board. The screen will display the settings menu. The ParkSafe controller has a touch screen, which allows the engineer/user to configure the system. Adjust the screen brightness... -

Page 10: Configuration Settings Explained

Configuration Settings Explained FUNCTION OPTION Explanation - ON In the event of an unscheduled power loss/outage - the PARKSAFE controller will Auto Start automatically restart when power is restored, or not. - OFF 0-10V Minimum Value - 0 or 2V 0-10V terminal output under normal / safe conditions. -

Page 11: Operation

Operation First Power Up Upon connecting mains power, the ParkSafe controller will ‘warm up’ for approximately one minute. During this time, the screen will display an ‘initialising’ message. After the controller has initialised, the system will begin searching and establishing signals with any connected ParkSafe Detectors. -

Page 12: Gas Detection Status Information

Installation, Operation & Maintenance ParkSafe Controller Gas Detection Status Information To access detector status screens, press the ‘Gas Detection’ section on screen any time. Switch between pages by touching the relevant page button at the bottom of the screen. Each page will display up to four ParkSafe detectors: The ID configured via switches on each detector board. -

Page 13: Maintenance

The annual service message timer will begin after five (5) hours of continuous power irrespective of whether the system is then used intermittently! A service message will appear on the ParkSafe controller home screen after one year of any connected ParkSafe detector operation. The detector will still operate during this time, but you should contact your supplier immediately. -

Page 14: Bump Testing (Gas Response Check)

Bump Testing (Gas Response Check) All certified test gases supplied by AGS are classified as non-flammable and non-toxic, however, they may contain gas under pressure and may explode if heated to extreme temperatures and cause asphyxiation in high concentrations. Always use in accordance with the safety data sheet! Gas response checks are often referred to as a ‘bump test’. - Page 15 Installation, Operation & Maintenance ParkSafe Controller Step 2. Test Detector Access to the interior of the detector, when carrying out any work, must be conducted by a competent person! Apply a gas concentration ~50% higher than the alarm setpoint but do not exceed the upper limit of measurement! Ensure you have the correct calibration gas for the device type.

-

Page 16: Test Record

Installation, Operation & Maintenance ParkSafe Controller Test Record Date Detector ID Gas Details Pass/Fail Sign Rev: 20... - Page 17 Installation, Operation & Maintenance ParkSafe Controller Date Detector ID Gas Details Pass/Fail Sign Rev: 20...

- Page 18 Installation, Operation & Maintenance ParkSafe Controller Page intentionally left blank Rev: 20...

-

Page 19: Specification

Installation, Operation & Maintenance ParkSafe Controller Specification General Model: ParkSafe Controller Capacity: Up to 16 channels per controller unit. Size: (H x W x D) 7.08 x 10.03 x 3” (180 x 255 x 77 mm) ABS Polylac - PA765. - Page 20 Every effort is made to ensure the accuracy of this document; however, AGS can assume no responsibility for any errors or omissions in this document or their consequences. AGS would greatly appreciate being informed of any errors or omissions that may be found in the content of this document.

Need help?

Do you have a question about the ParkSafe Controller and is the answer not in the manual?

Questions and answers