Unigas RG91 Manual Of Installation - Use - Maintenance

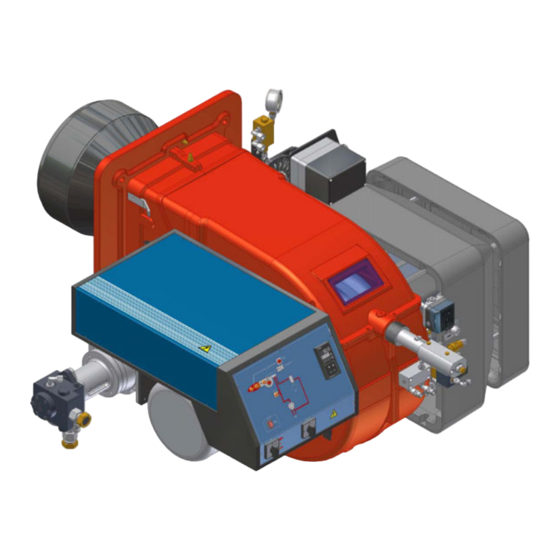

Light oil burners, double stage

Hide thumbs

Also See for RG91:

- Manual of installation - use - maintenance (48 pages) ,

- Manual (108 pages)

Summary of Contents for Unigas RG91

- Page 1 RG91 RG92 Light oil burners Double Stage MANUAL OF INSTALLATION - USE - MAINTENANCE BURNERS - BRUCIATORI - BRULERS - BRENNER - QUEMADORES - ГОРЕЛКИ M039192CB Rev. 4.0 10/2020...

-

Page 2: General Introduction

DANGERS, WARNINGS AND NOTES OF CAUTION THIS MANUAL IS SUPPLIED AS AN INTEGRAL AND ESSENTIAL PART OF THE PRODUCT AND MUST BE DELIVERED TO THE USER. INFORMATION INCLUDED IN THIS SECTION ARE DEDICATED BOTH TO THE USER AND TO PERSONNEL FOLLOWING PRODUCT INSTALLATION AND MAINTENANCE. -

Page 3: Directives And Standards

3b) FIRING WITH GAS, LIGHT OIL OR OTHER FUELS DIRECTIVES AND STANDARDS Gas burners GENERAL European directives The burner shall be installed by qualified personnel and in compliance -Regulation 2016/426/UE (appliances burning gaseous fuels) with regulations and provisions in force; wrong installation can cause -2014/35/UE (Low Tension Directive) injuries to people and animals, or damage to property, for which the -2014/30/UE (Electromagnetic compatibility Directive) -

Page 4: Symbols Used

Burner data plate Type Model Gas - Light oil burners For the following information, please refer to Year European Directives the data plate: S.Number -Regulation 2016/426/UE (appliances burning gaseous fuels) Output burner type and burner model: must be Oil Flow -2014/35/UE (Low Tension Directive) reported in any communication with the Fuel... -

Page 5: Burner Type

Data are referred to standard conditions: atmospheric pressure at 1013mbar, ambient temperature at 15°C. Burner model identification Burners are identified by burner type and model. Burner model identification is described as follows. Type RG92 Model RG91, RG92 (1) BURNER TYPE G - Light oil (2) FUEL AB - Double stage... - Page 6 PART II: INSTALLATION Technical specifications BURNERS RG91 RG92 RG93 Output min. -max. kW 1047 - 2093 1280 - 2558 560 - 4100 Light oil rate min. -max. kg/h 88 - 176 108 - 215 46 - 346 Fuel Light oil Viscosity cSt @ 40 °C...

- Page 7 A (AS*) A (AL*) B (BS*) B (BL*) Omin Omax 1144 1317 RG91 1138 1311 RG92 *AS/BS: measure referred to burner with standard blast tube provided *AL/BL: measure referred to burner with extended blast tube provided...

- Page 8 PART II: INSTALLATION MOUNTINGS AND CONNECTIONS Packing The burners are dispatched in wooden packages whose dimensions are: 1730 mm x 1280 mm x 1020 mm (L x P x H) Packing cases of this kind are affected by humidity and are not suitable for stacking. The following are pla- ced in each packing case.

- Page 9 PART II: INSTALLATION SIDE UP SIDE DOWN Matching the burner to the boiler The burners described in this manual have been tested with combustion chambers that comply with EN676 regulation and whose dimensions are described in the diagram . In case the burner must be coupled with boilers with a combustion chamber smaller in diameter or shorter than those described in the diagram, please contact the supplier, to verify that a correct matching is possible, with respect of the application involved.

-

Page 10: Gravity Circuit

PART II: INSTALLATION OIL TRAIN CONNECTIONS Hydraulic diagrams for light oil supplying circuits GRAVITY CIRCUIT RING CIRCUIT 1 Manual valve 2 Light oil filter 3 Light oil feeding pump 4 One way valve 5 Flexible hoses 6 Relief valve SUCTION CIRCUIT NOTE: in plants where gravity or ring feed systems are provided, install an automatic interception device. - Page 11 PART II: INSTALLATION Installation diagram of light oil pipes PLEASE READ CAREFULLY THE “WARNINGS” CHAPTER AT THE BEGINNING OF THIS MANUAL. From tank To tank Fig. 8 - Double-pipe system The burner is supplied with filter and flexible hoses, all the parts upstream the filter and downstream the return flexible hose, must be installed by the customer.

- Page 12 PART II: INSTALLATION Bleed Bleeding in two-pipe operation is automatic : it is assured by a bleed flat on the piston. In one-pipe operation, the plug of a pressure gauge port must be loosened until the air is evacuated from the system. About the use of fuel pumps Make sure that the by-pass plug is not used in a single pipe installation, because the fuel unit will not function properly and damage ...

-

Page 13: Electrical Connections

PART II: INSTALLATION WARNING: (only for double stage and progressive burners) The burner is provided with an electrical bridge between terminals 6 and 7; when connecting the high/low flame thermostat, remove this bridge before connec- ting the thermostat. ELECTRICAL CONNECTIONS WARNING! Respect the basic safety rules. - Page 14 PART II: INSTALLATION ADJUSTMENTS ATTENTION: before starting the burner up, be sure that the manual cutoff valves are open. Be sure that the mains switch is closed. Before starting up the burner, make sure that the return pipe to the tank is not obstructed. Any obstruction would cause the pump seal to break.

- Page 15 PART II: INSTALLATION Choosing the light oil nozzles OUTPUT YECTOR kg/h kcal/h 10 bar 12 bar 14 bar 918.900 1068 14.00+9.50 13.00+8.00 12.00+8.00 969.950 1128 15.00+10.00 14.00+8.00 13.00+8.00 1.021.000 1187 16.00+10.00 15.00+9.00 13.00+9.00 1.072.050 1247 16.00+11.00 16.00+9.00 14.00+9.00 1.123.100 1306 17.00+12.00 16.00+10.00 14.00+10.00 1.174.150 1365...

- Page 16 PART II: INSTALLATION Priming the pump and adjustments remove the electric panel cover; prime the oil pump, by means of the related contactor: check the motor rotation and keep pressed for some seconds until the oil cir- cuit is charged bleed the air from the M pressure gauge port of the pump (see picture below), loosening the cap without removing it;...

- Page 17 PART II: INSTALLATION 13 the 3rd cam drives the opening of the 2nd stage solenoid valve (EVG2) and must be set between the other two cams, however near to ST1; The cycle goes on and il the thermostat TAB is connected, the control box drives the burner to high flame. If there is not theTAB thermostat, place a bridge between terminals 6 and 7 on the MA terminal block (see picture above).

- Page 18 PART II: OPERATION PART II: OPERATION LIMITATIONS OF USE THE BURNER IS AN APPLIANCE DESIGNED AND CONSTRUCTED TO OPERATE ONLY AFTER BEING CORRECTLY CONNEC- TED TO A HEAT GENERATOR (E.G. BOILER, HOT AIR GENERATOR, FURNACE, ETC.), ANY OTHER USE IS TO BE CONSIDE- RED IMPROPER AND THEREFORE DANGEROUS.

-

Page 19: Operation

PART II: OPERATION OPERATION ATTENTION: before starting the burner up, be sure that the manual cutoff valves are open. Be sure themains switch is closed. Read carefully th “Warnings” chapter. Turn the switch A on the burner control panel to the ON position. ... -

Page 20: Routine Maintenance

PART III: MAINTENANCE PART III: MAINTENANCE At least once a year carry out the maintenance operations listed below. In the case of seasonal servicing, it is recommended to carry out the maintenance at the end of each heating season; in the case of continuous operation the maintenance is carried out every 6 months. - Page 21 PART III: MAINTENANCE Correct position of electrodes and combustion head Fig. 11 ATTENTION: avoid the electrodes to get in touch with metallic parts (blast tube, head, etc.), otherwise the boiler operation would be compromised. Check the electrodes position after any intervention on the combustion head. To guarantee a good ignition the measures showed on the next picture Fig.

- Page 22 PART III: MAINTENANCE Replacing the ignition electrodes ATTENTION: avoid the electrodes to get in touch with metallic parts (blast tube, head, etc.), otherwise the boiler operation would be compromised. Check the electrodes position after any intervention on the combustion head. To replace the ignition electrodes, proceed as follows: remove the burner cover;...

-

Page 23: Troubleshooting

PART III: MAINTENANCE TROUBLESHOOTING MAIN SWITCH OPEN LINE FUSE INTERVENTION MAX. PRESSURE SWITCH FAULT FAN THERMAL CUTOUT INTERVENTION AUXILIARY RELAIS FUSES INTERVENTION CONTROL BOX FAULT SERVOCONTROL FAULT ... -

Page 24: Burner Exploded View

BURNER EXPLODED VIEW 1.1.1 1.8.1 1.8.2 10.1 10.2 10.7 10.3 10.6 10.5 10.4... - Page 25 PART III: MAINTENANCE...

- Page 28 C.I.B. UNIGAS S.p.A. Via L.Galvani, 9 - 35011 Campodarsego (PD) - ITALY Tel. +39 049 9200944 - Fax +39 049 9200945/9201269 web site: www.cibunigas.it - e-mail: cibunigas@cibunigas.it Note: specifications and data subject to change. Errors and omissions excepted.

Need help?

Do you have a question about the RG91 and is the answer not in the manual?

Questions and answers