Table of Contents

Advertisement

Quick Links

3582950/1

IM-P713-04

CTLS Issue 1

AEL7T

EN14597 Compliant

Electric Linear Actuators

Installation and Maintenance Instructions

1. Safety information

2. General product information

3. Electrical connection

4. Installation

5. Actuator Accessories

6. Commissioning

7. Maintenance

8. Declaration of Conformity

AEL7T EN14597 Compliant Electric Linear Actuators

© Copyright 2022

1

IM-P713-04 CTLS Issue 1

Printed in GB

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Spirax Sarco AEL7T

- Page 1 Installation and Maintenance Instructions 1. Safety information 2. General product information 3. Electrical connection 4. Installation 5. Actuator Accessories 6. Commissioning 7. Maintenance 8. Declaration of Conformity AEL7T EN14597 Compliant Electric Linear Actuators © Copyright 2022 IM-P713-04 CTLS Issue 1 Printed in GB...

- Page 2 AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 3: Table Of Contents

1.19 Responsibilities of the operator and operating (including maintenance) personnel 1.20 Qualified Personnel 2. General product information 2.1 Description 2.2 Identification of products in the AEL7T range 2.3 Operating principle 2.4 EN14597 Compliance 3. Installation 3.1 Electrical Connection Safety Information 3.2 Removing the Actuator Cover... - Page 4 7. Maintenance 7.1 Maintenance Safety Information 7.2 General Maintenance of Actuator 7.3 Warranty, Repair and Spare Parts 7.4 Removing the Actuator from the Valve 7.5 Problem Solving 8. Declaration of Conformity AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 5: Safety Information

The requirement s for the disconnec ting device are specif ied in IEC 60947-1 and IEC 60947- 3 or equivalent . viii) The actuator must not be located in such a way that the disconnecting device is made difficult to operate. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 6: Safety Requirements And Electromagnetic Compatibility

For a copy of the declaration of conformity please refer to page 58. 1.3 Intended use The AEL7 Series actuator must only be used to modulate Spirax Sarco and Gestra valves (including Hiter). The actuator must not be used for any other purpose. -

Page 7: Hazardous Liquids Or Gases In The Pipeline

Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high/low temperature, radiation, noise, falling objects, and dangers to eyes and face. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 8: Permits To Work

Should any substances of very high concern be found within a product, details of the location will be identified within the Technical Information Sheet. Further information about product compliance is be available at www.spiraxsarco.com/product- compliance AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 9: Responsibilities Of The Operator And Operating (Including Maintenance) Personnel

Suitably qualified personnel are those who are familiar with the set-up, installation, commissioning and operation of the AEL7T and associated valves. Personnel should be suitably qualified through their activity: Training and authority to switch on and off power circuits... -

Page 10: General Product Information

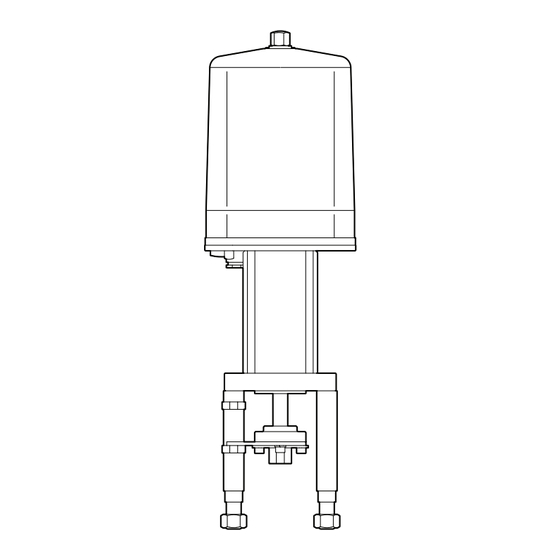

2. General product information 2.1 Description AEL7T series electric linear actuators are only suitable for the use on Spirax Sarco, Gestra and Hiter Valves. Refer to TI-P713-02 for product compatibility and linkage requirements. The AEL7T Series actuators must not be used for any other purpose. Actuators will normally be supplied fitted to the control valve. When supplied separately, ensure the actuator selected is capable of providing the force necessary to close the two-port or three-port control valve against the expected differential pressure. -

Page 11: Identification Of Products In The Ael7T Range

2.2 Identification of products in the AEL7T range Actuator Type Electric Action Linear Series 1.2 kN 0.9 kN for AEL71T Thrust 2.0 kN 2.1 kN for AEL72T Nominal Stroke 30 mm 230 Vac Supply Voltage 115 Vac 24 Vac Speed 0-0.7mm/s... -

Page 12: Operating Principle

2.3 Operating principle The AEL7T Series is a range of linear electric actuators of various voltages and thrusts suitable for the modulation of Spirax Sarco Group valves either by means of VMD or modulating signal. Independent of the control method, the actuators typically uses stroke dependent (travel) switches to determine the end position of the actuator stroke in both directions and stop the actuator motor. -

Page 13: En14597 Compliance

The AEL7T Series actuator complies with EN14597 (2012) temperature control devices and temperature limiters for heat generating systems. To comply with EN14597 (2012), as an electromagnetic device, the AEL7T actuator shall be suitable for continuous operation at VR +10% and the highest permissible ambient temperature. The actuator shall automatically close at a voltage level of VR -70% (i.e. -

Page 14: Electrical Connection Safety Information

3. Electrical Connections Warning The AEL7T Series actuator requires electrical connection to be made before it is possible to couple the actuator to a valve. Therefore the electrical connection must be made and the actuator cover replaced to make the unit safe to handle for the coupling stage. -

Page 15: Removing The Actuator Cover

(or in the cover of the actuator) taking care to ensure that the routing of the cores protects them from damage of moving parts or from damage when replacing or removing the actuator cover AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 16: Electrical Connection

3.4 Electrical Connection See below for all AEL7T actuator electrical connections unless otherwise stated Power Supply (Vac) Modulating Signal Setpoint Position Feedback ▲ ▼ ▲ ▲ ▼ ▼ Fig.5 AEL7T actuator electrical connections AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... - Page 17 Options Heater Potentiometer Position Switches ▲ ▼ (NC) (NO) (NC) (NO) AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 18: Installation

For internal installations where there is a risk of condensation a condensate heater should also be installed. Refer to Technical Information Sheets for details (TI-P713-02). AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 19: Operational Considerations - End Position And Stroke Settings

4.2 Operational Considerations – End Position and Stroke Settings The AEL7T actuators require a stroke dependent (travel) switch to be set prior to commissioning the actuator. This is an important difference to the standard AEL7 Series without integrated spring shut down. -

Page 20: Coupling The Actuator To A Valve

The operator is responsible for ensuring that safe systems of operation and practice are implemented and maintained. Only competent persons must be allowed to be couple the AEL7T Series actuator to a valve, and these persons must be familiar with, and comply with the applicable health and safety standards or guidelines. - Page 21 Lift the actuator over the valve stem and place onto the mounting flange and loosely refit the actuator pillar nuts raise the valve plug to the actuator until the threaded bush meets the actuator coupling AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 22 Couple the adapter locking plate Tighten the pillar nuts to 30 Nm Tighten the (4) valve adaptor screws to 8 Nm Tighten the thread lock nut to 15 Nm AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 23: Setting The End Position

4.5 Setting the end position Warning Operation of the AEL7T actuator without the protection of the cover must only be used for the short term commissioning or replacement of parts (positioner, potentiometer, auxiliary switches of heater). During this activity there exists access to live electrical connections and moving parts. - Page 24 S1 and finish with the adjustment of S2. Do not loosen the lock nuts under any circumstances (Fig. 9). AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 25 Flat blade screwdriver Switch Cam Cam Shaft Cam Lock Nuts Switch Switch Retaining Nuts Switch Retaining Plate Fig. 9 Switch Adjustment Fig. 10 Switch Overview AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 26 Output Wheel Driving Rod Pin Driving Rod Fig. 11 Gearbox Overview 1 – 1.5 mm Fig. 12 Drive Rod Pin at End Position AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 27: Actuator Accessories

Section 3.1 “Electrical Connection Safety Information”. In order to select the correct accessories for each actuator, refer to Table 4. Because the AEL7T Series actuators are a safety device, it is recommended that the actuator is purchased with all of the required accessories direct from the factory. -

Page 28: Auxiliary Travel Switches

Fig. 13 Auxiliary Travel Switch Terminal Diagram Position Switches (NC) (NO) (NC) (NO) Potential Free Position Switch S3 Potential Free Position Switch S4 Fig. 13 Auxiliary Travel Switch Terminal Diagram AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 29: Potentiometer

Tighten the lock nut and replace the potentiometer assembly plate Connect the potentiometer wiring harness plug to the positioner board Refer to Section 6.3 for commissioning Potentiometer plug Potentiometer plate Potentiometer Fig. 14 AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 30: Positioner Card

Connect the DE wiring harness as indicated in Fig. 15 Refer to Section 6.4 for commissioning information Main Terminal Positioner Fig. 15 Positioner Installation Terminal Diagram AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 31: Commissioning

Do not attempt to restrict actuator stroke or movement, or increase seat load through the placing of objects within the actuator yoke. This practice could also result in the loss of sight. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 32: Adjustment Of Auxiliary Travel Switch

Connection Safety Information” and Section 6.1 “Commissioning Safety Information” The AEL7T Series actuator is supplied with two auxiliary switches (S3 and S4). The S3 and S4 auxiliary travel switches can be used to notify the user of a user defined valve and actuator position by means of a volt free contact (VFC). -

Page 33: Commissioning Of Potentiometer

The actuator may respond to manual interaction resulting in muscular- skeletal damage to fingers. Caution It is possible to damage the force dependent switches by applying excessive load by use of the hand wheel or hand crank. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... - Page 34 Positioner Support (Green LED) DOWN (Red LED) HAND (Blue LED) Fig. 16 The setting of DIP switches will be updated after power on or reset by simultaneous pressing HAND+UP+DOWN+PROG buttons. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 35 Off* Off* WE/WE 1.0% DE/WE 0.5% WE/DE 0.3% DE/DE Table 7 Failure Mode Configuration S2.5 S2.6 Failure mode Off* Off* Extend Fail in place X=100% X=0% * Indicates default setting AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

-

Page 36: Autotune - Quick Set-Up

When commissioning is complete, the red and green LEDs will switch off; "PROG" LED which will flash. Set S1.2 to OFF and apply a modulating signal. The actuator movement will now correspond to the input signal AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 37: Maintenance

For small actuators that do not require mechanical lifting aids, always ensure that manual lifting best practice is observed. Always use two personnel where possible and ensure that proper access is available in order to ensure a secure foothold. AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 38: General Maintenance Of Actuator

In the rare event that an actuator should fail in operation, please contact your local Spirax Sarco Sales Company for product return instructions. -

Page 39: Removing The Actuator From The Valve

Sometimes it may be necessary to remove the actuator from the valve for general valve maintenance or to replace the actuator itself. In order to remove the AEL7T, a power supply must be maintained to the actuator in order to relive the spring pressure from the valve: Use the UP travel button to drive the actuator to approx. -

Page 40: Problem Solving

Stroke arm incorrectly commissioned Control signal out of range (check voltage/ current) Actuator does not respond to signal Positioner incorrectly commissioned (positioner) Potentiometer failure Poor PID set-up Actuator moving continuously Motor capacitor failure AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... -

Page 41: Declaration Of Conformity

8. Declaration of Conformity AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1... - Page 42 Spirax Sarco Ltd, (signature): (name, function): N Morris Compliance Manager Steam Business Development Engineering (place and date of issue): Cheltenham 26 September 2022 GNP217-UK-C issue 1 Page 1 of 1 AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 43 AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

- Page 44 AEL7T EN14597 Compliant Electric Linear Actuators IM-P713-04 CTLS Issue 1...

Need help?

Do you have a question about the AEL7T and is the answer not in the manual?

Questions and answers