Summary of Contents for Endress+Hauser 51517656 CleanFit H CPA 475

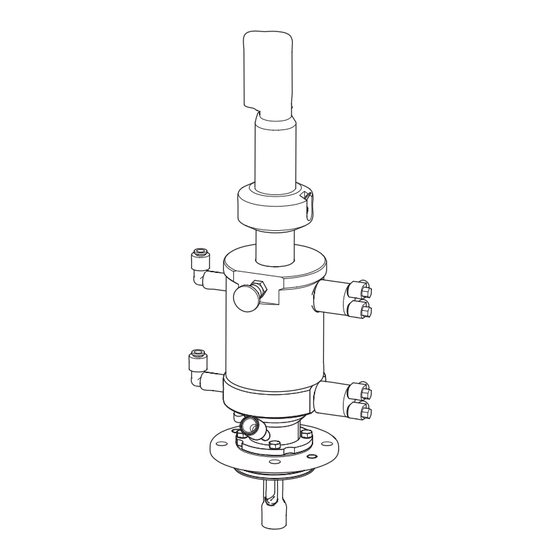

- Page 1 CleanFit H CPA 475 BA 240C/07/en/07.03 51517656 Retractable Process Assembly Operating Instructions Quality made by Endress+Hauser ISO 9001...

-

Page 3: Table Of Contents

Return ......30 Disposal ......30 Endress+Hauser... -

Page 4: Safety Instructions

• Installation instructions • Local prevailing standards and regulations. Return If the assembly has to be repaired, please return it cleaned to the Endress+Hauser sales centre responsible. Please use the original packaging, if possible. Please enclose the completed Dangerous Goods sheet (copy the second last page of these Operating instructions) with the packaging and also the shipping documents. -

Page 5: Notes On Safety Icons And Symbols

This symbol alerts you to hazards. They can cause serious damage to the instrument or to persons if ignored. " Caution! This symbol alerts you to possible faults which could arise from incorrect operation. They could cause damage to the instrument if ignored. Note! This symbol indicates important items of information. Endress+Hauser... -

Page 6: Identification

The scope of delivery comprises: • CleanFit assembly (ordered version) • Operating Instructions (english). If you have any questions, please contact your supplier or your Endress+Hauser sales centre responsible (see back page of these Operating Instructions). Certificates and approvals 2.3.1 Following versions meet the requirements of the rule 3A 74-01: •... -

Page 7: Product Structure

APV DN 50 ... 100 DN 50 flange (acc. to EN 1092-1) 2" ANSI flange Optional equipment With rinse fitting 2 x G ¼ internal thread With rinse fitting 2 x NPT ¼" internal thread CPA 475- complete order code Endress+Hauser... -

Page 8: Installation

The original packaging offers the best protection. Also, keep to the approved ambient conditions (see "Technical data"). • If you have any questions, please contact your supplier or your Endress+Hauser sales centre responsible (see back page of these Operating Instructions). - Page 9 Accessories). • When designing the installation nozzle, please observe the total immersion depth in operation (sensor holder not inserted). Ensure that the sensor is always immersed in the medium during operation (see "Dimensions"). Siphon effect: line emptied by vacuum Endress+Hauser...

- Page 10 Ø 58 / 2.28 Ø80/3.15 Ø 80/3.15 80 / 3.15 84/3.31 G 1¼ Ø 25/0.98 84/3.31 Ø 19/0.75 Ø 19/0.75 ø 19/0.75 C07-CPA475xx-06-07-00-en-002.eps C07-CPA475xx-06-07-00-en-001.eps C07-CPA475xx-06-07-00-en-006.eps Fig. 4: Varivent version Fig. 5: Liquid KCl electrolyte Fig. 6: G1¼ thread nut version version Endress+Hauser...

-

Page 11: Installation Instructions

Varivent DN 50 ... 125 Triclamp 2" APV DN 50 ... 100 DN 50 dairy fitting DN 50 flange (DIN 1092-1) resp. ANSI 2" flange Installation instructions 3.3.1 Measuring system ENDRESS+HAUSER ENDRESS+HAUSER MYCOM S CPM 153 MYCOM S CPM 153 Hold MEAS DIAG PARAM... - Page 12 8 bar (116 psi) (including any short pressure surges). We recommend you also use a pneumatic throttle for lower pressures. This results in a smoother assembly operation. E+H offers such a throttle as an accessory (see chapter "Accessories"). pneumatically operated assembly only Endress+Hauser...

- Page 13 "Assembly measuring". When the "Measuring" position is reached, the air applied to the inlet (1) is switched through and can be tapped at the outlet (2) (TopCal/ TopClean: connect hose ➄ to the limit position switch outlet). Endress+Hauser...

- Page 14 Operate the rinse water connection of the assembly with a water pressure of 2 to max. 6 bar (29 to 87 psi). In addition, install a non-return valve and a dirt trap (100 µm) in the water supply line (at the inlet to the assembly). Endress+Hauser...

- Page 15 These can cause the sensor holder to get stuck, producing a counterforce when unscrewing the sensor holder. Remove the splash protection cap (Fig. 16, position 5) from the assembly. Then loosen the retractable pipe (position 2) by turning it anticlockwise. Endress+Hauser...

- Page 16 Remove the splash protection cap (Fig. 17, position 6) and the KCl hood (position 7) from the assembly. Then slacken the retractable pipe by turning it anticlockwise. Unscrew the tension sleeve (position 10). Remove the sensor holder (position 9) from the retractable pipe. Endress+Hauser...

-

Page 17: Post-Installation Check

Sensor with liquid KCl connection Sensor holder sequence of operations. Tension sleeve Post-installation check • After installation, check that all connections are firmly in position and leak-tight. • Ensure that the hoses cannot be removed without force. • Check all hoses for damage. Endress+Hauser... -

Page 18: Operation

Turn the bolt by 90° so that the plastic grooves rest on the metal edge. Locking the stop lock bolt: Turn the stop lock bolt through 90° so that the plastic grooves are located above the recesses. When the retractable pipe is turned clockwise, the bolt engages. Endress+Hauser... -

Page 19: Manual Operation

• If a maintenance switch is fitted on the transmitter, set it to "Maintenance" or "Service". Note! It is not possible to lock the assembly in the "Measuring" position. The pneumatic system maintains the back pressure to the process pressure. Endress+Hauser... -

Page 20: Maintenance

• After cleaning the sensor, rinse the rinse chamber of the assembly with copious amounts of water (possibly distilled or de-ionised). Otherwise, remaining residues of cleaning agent can corrupt measurement. • If required, re-calibrate after cleaning. in reverse sequence of operations to the installation procedure with the corresponding assembly equipment only Endress+Hauser... -

Page 21: Cleaning Agents

(PML) and the buffer solution. • Do not allow a glass electrode to stand dry or pH sensors (including ISFET) to stand in distilled water. • Do not use compressed air to blow clear automatic calibration systems with ISFET sensors. Endress+Hauser... -

Page 22: Accessories

/ inch C07-CPA471xx-00-07-00-en-001.eps Fig. 21: Flow vessel ❑Hose nozzles for rinse connections G¼, DN 12, SS 1.4404 (AISI 316L), 2 pieces; order no. 51502808 ❑Hose nozzles for rinse connections G¼, DN 12, PVDF, 2 pieces; order no. 50090491 Endress+Hauser... -

Page 23: Limit Position Switches

Sterilisable ISFET sensor for media with low conductivity, with liquid KCl electrolyte; Ordering acc. to product structure, see Technical Information (TI 352/C07/en) ❑TopHit CPS 491 ISFET sensor with open aperture for media with high dirt load; Ordering acc. to product structure, see Technical Information (TI 377/C07/en) Endress+Hauser... -

Page 24: Calibration Solutions

Ordering by product structure, see Technical Information (TI 194C/07/en) ❑Mycom S CPM 153 Transmitter for pH and ORP, one or two channel version, Ex or Non-Ex, ® Hart or PROFIBUS available, Ordering by product structure, see Technical Information (TI 233C/07/en) Endress+Hauser... -

Page 25: Measuring, Cleaning And Calibration Systems

❑Technical Information TopHit CPS 471, TI 283C/07; order no. 51506685 ❑Technical Information TopHit CPS 441, TI 352C/07; order no. 51506565 ❑Technical Information TopHit CPS 491, TI 377C/07; order no. 51513174 ❑Technical Information Rinse adapter CPR 40, TI 342C/07; order no. 51510059 Endress+Hauser... -

Page 26: Trouble-Shooting

O-rings. 7. Re-install the sensor and screw-in the retractable pipe clockwise. C07-CPA471xx-09-07-06-xx-006.eps 8. Unlock the stop bolt. Fig. 22: Seal replacing without process interrupt 9. Move the assembly to the "Measuring" position and check it for tightness. Endress+Hauser... - Page 27 8. Re-assemble the assembly. 9. Install the assembly into the process via the process connection. 10.Restart the process and move the assembly to the "Measuring" position. 11.Check the leak-tightness. 14-3, 14-4 C07-CPA475xx-09-07-06-xx-007.eps Fig. 23: Seal replacing with process interrupt Endress+Hauser...

-

Page 28: Spare Part Kits

14-2 10-1 14-5 10-2+10-3+10-4 14-1, 14-2 14-3, 14-4 10-4 14-1 C07-CPA475xx-09-07-06-xx-001.eps Fig. 24: Spare parts (all assembly versions) Note! Please, refer to the following table for the spare part kits ordering numbers acc. to the positions in Fig. 24. Endress+Hauser... - Page 29 Set of electric limit switches, Ex and Non-Ex 51502873 For assembly version: – pneumatic 2 pieces Set of gaskets, in contact with medium 51506408 14-1, EPDM 14-2. 14-3, Set of gaskets, in contact with medium 51506407 14-4, 14-5 VITON Endress+Hauser...

-

Page 30: Return

For assembly version: – for G1¼ internal thread process connection only Return If the assembly has to be repaired, please return it cleaned to the Endress+Hauser sales centre responsible. Please use the original packaging, if possible. Please enclose the completed Dangerous Goods sheet (copy the second last page of these Operating instructions) with the packaging and also the shipping documents. -

Page 31: Technical Data

[psi] 43.5 T[°C] C07-CPA471xx-05-07-00-en-001.eps Fig. 25: Pressure-temperature diagram acc. to the assembly material (overpressure) SS 1.4404 (AISI 316L) cylinder PA cylinder " Caution! The process pressure for a manually driven assembly must not exceed 4 bar (58 psi)! Endress+Hauser... -

Page 32: Mechanical Construction

Material Cylinder PA / SS 1.4404 (AISI 316L) / SS 1.4571 (AISI 316 Ti) (not in contact with Electric limit position switch fore-part PBT, cable PVC medium) Rinse fittings 2 x G¼ (internal) or 2 x NPT ¼" (internal) Endress+Hauser... -

Page 33: Index

Gel sensors ....... . 15 Glass electrode......23 Endress+Hauser... - Page 34 Wall spacing....... . 9 Water filter ....... . 22 Endress+Hauser...

- Page 35 'HFODUDWLRQ RI FRQWDPLQDWLRQ Dear customer, Because of legal determinations and for the safety of our employees and operating equipment we need this “Declaration of contamination” with your signature before your order can be handled. Please put the completely filled in declaration to the instrument and to the shipping documents in any case. Add also safety sheets and/or specific handling instructions if necessary.

- Page 36 ❑ Endress+Hauser Ges.m.b.H. Poland – Wroclaw Japan – Tokyo Costa Rica – San Jose ❑ Endress+Hauser Polska Sp. z o.o. ❑ Sakura Endress Co. Ltd. Tel. (01) 88 05 60, Fax (01) 88 05 63 35 Euro-Tec S.A. Tel. (0422) 54 06 11, Fax (0422) 55 02 75 Tel.

Need help?

Do you have a question about the 51517656 CleanFit H CPA 475 and is the answer not in the manual?

Questions and answers