Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser CUM 740

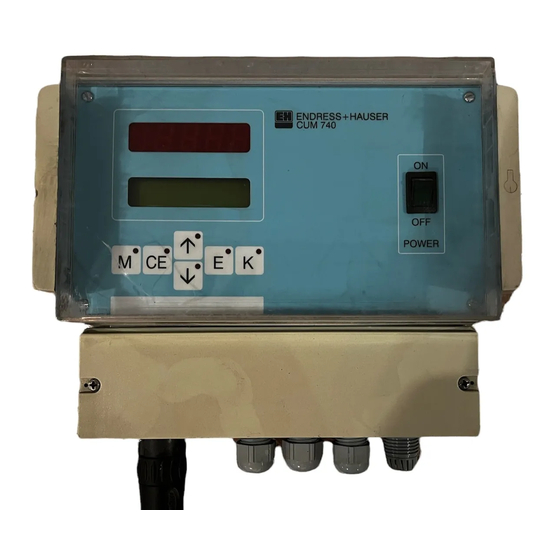

- Page 1 CUM 740 BA 232C/07/en/07.03 No. 51504299 Transmitter for Turbidity and Solids Contents Operating Instructions ENDRESS+HAUSER CUM 740 Quality made by Endress+Hauser Endress Hauser The Power of Know How ISO 9001...

-

Page 2: Table Of Contents

Adjustment ranges of concentration ..................19 Terminal assignments ......................20 Connecting assignments of probe plug, -socket and extension cable ........20 Serial interface CUM 740 (Option) ..................21 Special version “2 sensors” ....................22 Technical data ........................24 Annex .................... -

Page 3: Safety Instructions

CUM 740 1. Safety Information / Sicherheitshinweise / Informations de securité l Only authorized personnel is allowed to carry out installation, putting into operation, handling, maintenance and repairs applying the relevant safety rules for mechanical engineering and electrical engineering especially norm EN 292. -

Page 4: General Information

CUM 740 General information 2.1 Assembly instructions • The measuring location must allow a representative measurement. • We recommend to equip the system with an additional protective roof against direct weather factors (e.g. deposition of snow). • Holding devices must ensure that the weight of the device (approx. 5 kg) can be picked up without vibrations. -

Page 5: Functions

CUM 740 2.2 Functions NOTE: For a correct functioning of the device please proceed according to the operation instructions • In the annex of this manual there is a blank which can be used to fill in by hand all parameters specific to measuring location (important e.g. -

Page 6: Maintenance Instructions

CUM 740 2.3 Maintenance instructions Every four weeks: Cleaning of the probe: Remove rough deposits at the cable with a cloth. Clean the soiled probe with a brush and soap-suds. ATTENTION: Fact is that the measured value may be impaired by heavy scratches or damages at the measuring windows. -

Page 7: General Description

CUM 740 General description The CUM 740 is controlled by a 16-bit-microcontroller and allows the following functions: l Detection and processing of measured values l Special menu-driven routine with an alphanumeric display l Monitoring of the system and probes l Storage and control of user parameters All user parameters such as measuring range, alarms, cleaning intervals and adjustment of output signals are fed in a menu-driven routine and stored in a battery-buffered memory. -

Page 8: Programming Guidelines

CUM 740 Programming The main menu includes the following titles always shown in capital letters: MEASUREMENT PARAMETER ENTRY CALIBRATION SOLIDS INPUT FREQUENCY CONFIGURATION LANGUAGE ERROR DISPLAY After the instrument is powered on, it switches automatically into the measuring state. By pressing the “M“... -

Page 9: Measurement Cycle

CUM 740 5.1 Routine MEASUREMENT / Main Menu MEASURING PARAMETER ENTRY --------------- MEASUREMENT CALIBRATION Measured value (mg/l, g/l, FTU, NTU, %, ppm) SOLIDS INPUT Analog output (mA) FREQUENCY Frequency (Hz) CONFIGURATION LANGUAGE Function: Detection, evaluation and display of the probe signal,... -

Page 10: Calibration Procedure

CUM 740 - Alarm values Alarm A and Alarm B: Concentration-threshold values for alarm relays. The switch hysteresis is ± 2 % each. - Response Time (Damping) (1 - 600 s): The response time sets the time interval period in seconds, by which the probe average signal (corresponding to the concentration value) can be arithmetically determined. -

Page 11: Solids Input

CUM 740 5.4 Routine SOLIDS INPUT MEASURING -------------- SOLIDS INPUT PARAMETER ENTRY Input of code number (91) CALIBRATION Measuring point 1...n (mg/l, g/l, FTU, NTU, %, ppm) SOLIDS INPUT FREQUENCY Function: In this submenu concentration values of the media CONFIGURATION (known or subsequently detected in the lab) corresponding to the detected probe signals from routine 5.3 “calibration“... -

Page 12: Select Configuration

CUM 740 5.6 Routine CONFIGURATION -------------- CONFIGURATION MEASURING Input of code number (91) PARAMETER ENTRY Probe type CALIBRATION SOLIDS INPUT Factory adjustment FREQUENCY Unit of measure (ppm, mg/l, g/l, FTU, NTU, %) CONFIGURATION Calibration Factor (± 25 %) LANGUAGE Analog output... -

Page 13: Selection Of Foreign Language

CUM 740 - Analog output: Select if the defined concentration measuring range (refer to 5.2 “parameter entry“) is to be displayed in a linear manner on a current range of 0-20 mA or 4-20 mA. (Corresponding to the range start is either 0 mA or 4 mA but the end is always 20 mA.) -

Page 14: Reading Error Messages

CUM 740 5.8 Routine ERROR DISPLAY MEASURING -------------- ERROR DISPLAY PARAMETER ENTRY Error report CALIBRATION SOLIDS INPUT Function: FREQUENCY Error messages MTF software Rev. 4.6: CONFIGURATION 0 = too high concentration 2 = wrong type of probe LANGUAGE 3 = no probe signal... -

Page 15: Putting Into Operation

In most cases it is enough to work with a two point calibration, alltough the measurement converter CUM 740 allows to save up to 8 calibration points. The two point calibration happens with tap water (1.measurement point) and with the sludge of the respective application (2.measurement point). -

Page 16: Multipoint Calibration

CUM 740 6.1.2 Multipoint calibration Example putting into operation TS-measurement with CUS 65-A: For a 4-point calibration you will need about 5 liters of activated sludge and 4 Setup procedure: black buckets. The minimum bucket volume for calibration is 2 liters. The first bucket contains clear water for the zero point. - Page 17 CUM 740 MEASUREMENT 1. Press Ö 3x, display shows CONFIGURATION press key E. Code No.: Ö/× 91, press key E. Type of probe Ö/× CUS 65-A, press key E. Unit of measure Ö/× g/l, press key E. Alarm A Ö/× operating- or rest current, (make or break), then E.

- Page 18 CUM 740 -> M press key M. MEASUREMENT 3. Press ×3x, display shows SOLIDS INPUT press key E. Ö/× 91, press key E. Code No.: Ö/× 0.00 zero-value, press E 1. Value x.xx g/l 0.00 g/l 2. Value Ö/× 1. lab-value, press E x.xx g/l...

- Page 19 CUM 740 Ö/× Value, then press E. Alarm A x.xx g/l switch value e.g. 5.6 g/l Ö/× Value, then press E. Alarm B x.xx g/l switch value e.g. 8.5 g/l Damping Ö/× 1 - 600 s, press key E. e.g. 5 Cleaning interval Ö/×...

-

Page 20: Inputs And Outputs

CUM 740 Inputs and Outputs Control inputs (+24V) l 24 V DC „IN“ (terminals 24/25): Freezing of the measurement (The measurement is interrupted and the currently displayed value is “frozen“.) For control of 24 V DC „IN“ you can use U (+24V, terminal 26). -

Page 21: Terminal Assignments

CUM 740 9. Terminal assignments: Connection of 1 sensor: Connection of 2 sensors: 10. Pin connection of probe plug, -socket and extension cable: Control cable, flexible ≤ 50 m: 5 x 0.25 ≤ 100 m : 5 x 0.5 cable plug, 7-poles, IP 67 cable socket, 7-poles, IP 67 >100 m : 5 x 1... -

Page 22: Serial Interface Cum 740 (Option)

9600, N, 8, 1 Output format: ASCII The output of the results (measured value + measuring unit + CR) is effected continuously during the automatic measurement in second intervals. A configuration of the interface on CUM 740-side is not necessary. Endress+Hauser... -

Page 23: Special Version "2 Sensors

CUM 740 Special version „2 sensors“ 12.1 Menu (special version „2 sensors“) Function and construction of the menu points are – disregarding unimportant exceptions – identical with the 1-sensor version. All memory values (configuration of probe as type, measuring unit etc. , calibration curve, measuring range, cleaning interval, calibration factor) however, are created twice. - Page 24 CUM 740 12.5 Calibration factor (special version „2 sensors“) Each probe has an own calibration factor. It can either be put in via the menu “CONFIGURATION“ , or it can be called up or changed during the running measurement by pressing the key “K“ (press once: sensor 1, twice: sensor 2).

-

Page 25: Technical Data

CUM 740 13. Technical Data 13.1 General information Measuring principle: Multi-beam pulsed-light, infra-red light with 880 nm wave length Measuring range: dependent on the measuring probe connected Power supply: 115 - 230 V /, 50 / 60 Hz 24 V / AC-DC (optional) Power consumption: max. - Page 26 CUM 740 13.3 Dimensions 13.3.1 Field enclosure Sensor connection socket(s) Back view: Endress+Hauser...

-

Page 27: Annex

CUM 740 Annex Contents: Connection of solenoid valves for cleaning Measuring procedure - applications CUM 740 - factory adjustments ( standard parameters) Troubleshooting guide Error messages Error diagnosis CUM 740 factory settings Accessories Endress+Hauser... - Page 28 CUM 740 Drive system for solenoid valves for cleaning CUM 740 max. 250 V ~ 2 A max. 30 V = 1 A Terminal Cleaning Solenoid valve 230 V ~ 230 V ~ 7900 SP 7900 SPÜ 7900 EGG Endress+Hauser...

- Page 29 CUM 740 Measuring procedure - Applications Measuring Physical Type of Ranges Typical application procedure Unit probe mg/l 2 ... 1000 FTU, NTU Treatment plant outlet, Scattering light 2 ... 1000 mg/l River water (depends on media) Process water, filtrate 0 ... 40 g/l NS* Primary sludge 0 ...

- Page 30 CUM 740 Troubleshooting guide Before exchanging the fuses disconnect the device from the mains! Attention Start the device only with inserted and screwed probe plug! Plug in or out the probe plug only when the device is off! Causes of error : Causes for errors in the system may be found at the measuring probe, the measuring transformer, the cable section between both units and in the field of mains supply.

- Page 31 CUM 740 Error messages The signal output “error” is only set when a cause of error exists for at least 10 seconds without interruption. Over-concentration is displayed when the predetermined range end is exceeded more than twice Wrong type of probe is shown when the connected probe does not correspond to the selected type.

- Page 32 CUM 740 CUM 740 - parameters Serial-Number: Sensor - 2, see next page Sensor - 1, No.: PO - Software-Version: 1. Configuration Type of probe Factory settings Measurement unit Calibration factor Analog output Alarm A Alarm B Error contact 2. Frequency [Hz] 1.

- Page 33 CUM 740 CUM 740 - parameters Serial-Number: Sensor - 1, see previous page Sensor - 2, No.: PO - Software-Version: 1. Configuration Type of probe Factory settings Measurement unit Calibration factor Analog output Alarm A Alarm B Error contact 2. Frequency [Hz] 1.

- Page 34 CUM 740 Accessories Sensors TurbiMax W CUS 61 Turbidity and solids content sensor for medium concentrations Technical Information TI 228C/07/en, Order No.: 51504289 TurbiMax W CUS 62 Turbidity and solids content sensor for high concentrations Technical Information TI 229C/07/en, Order No.: 51504291...

- Page 35 CUM 740 Connection accessories Extension cable Extension cable, length 10 m, shielded, with SXP plug and SXK coupling. Ingress protection IP 67. Order No.: 51503633 Plugs SXP plug, 7-pole Order No.: 51504027 SXK coupling, 7-pole Order No.: 51504025 Junction box Junction box for extension of cable connection between sensor and instrument.

- Page 36 Tel. ++6 75 (3) 25 11 88, Fax (3) 25 95 56 Austria Fax (11) 5 0 31 30 67 Endress+Hauser Ges.m.b.H. Poland Philippines Wien Endress+Hauser Polska Sp. z o.o. Canada Brenton Industries Inc. Tel. ++43 (1) 8 80 56-0, Fax (1) 8 80 56-35 Warszawy Endress+Hauser Ltd. Makati Metro Manila Tel.

Need help?

Do you have a question about the CUM 740 and is the answer not in the manual?

Questions and answers