Summary of Contents for Cameron WKM MA

- Page 1 D I S T R I B U T E D V A L V E S Installation, Operation and Maintenance Manual ® WKM MODEL MA ® DYNACENTRIC HIGH PERFORMANCE BUTTERFLY VALVE ® Installation, Operation and Maintenance Manual WKM-MA-HPBV-IOM...

-

Page 2: Table Of Contents

Disc/Pipe Clearance ........5 Gaskets ............6 Flange Bolt and Stud Size ......6 Procedure ............7 Operation ..............8 Routine Maintenance ..........9 Trouble Shooting ............9 © Cameron’s Valves & Measurement Group Revised 11/07 WKM-MA-HPBV-IOM Installation, Operation and Maintenance Manual WKM-MA-HPBV-IOM... -

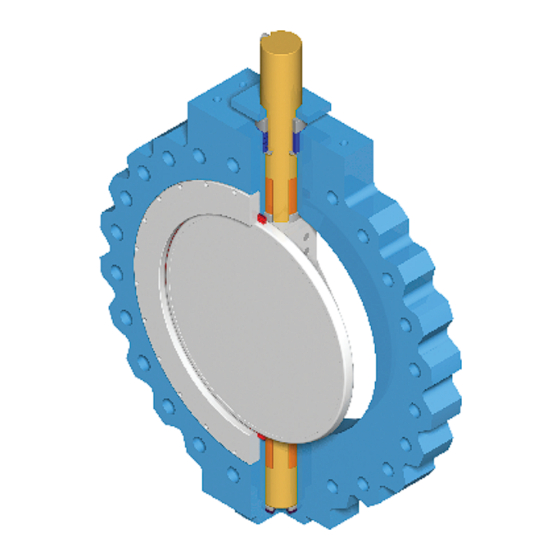

Page 3: Bill Of Materials

D I S T R I B U T E D V A L V E S Bill of Materials (Wafer body shown, lug body available) Figure 1 - Cameron Valves' WKM 3" - 12" Class 150, 3" - 10" Class 300, 3" - 8" Class 600 DynaCentric Butterfly Valve Components. ITEM DESCRIPTION ITEM... - Page 4 Bill of Materials (Lug body shown, wafer body available) Figure 2 - Cameron Valves' WKM 14" - 30" Class 150, 12" - 24" Class 300, 10" - 12" Class 600 DynaCentric Butterfly Valve Components. Installation, Operation and Maintenance Manual WKM-MA-HPBV-IOM...

-

Page 5: Catalog Number Information

D I S T R I B U T E D V A L V E S Catalog Number Information A5XXX Body Trim Seal Packing Packing Size Inches Group Group Group Group Group 3" Class Material Style CS Disc* TFE VEE Bare Stem 4"... -

Page 6: Scope

When such action is desired, the protected from the elements. For long term valve should be installed seat upstream (flow from storage, contact your Cameron representative. the seat side of the valve) with the integral stop pin in the vertical up position. (Figure 6). -

Page 7: End-Of-Line Service

D I S T R I B U T E D V A L V E S End-of-Line Service Threaded style lug valves are recommended for end-of-line or equipment isolation service. The WKM DynaCentric MA High Performance Butterfly Valve can handle flow from either direction in end-of-line service. -

Page 8: Gaskets

D I S T R I B U T E D V A L V E S Gaskets Non-asbestos gaskets made in accordance with ASME B16.5, Group 1a and 1b are standard for the WKM DynaCentric High Performance Butterfly Valve. API 601 standard spiral wound gaskets may also be used. -

Page 9: Procedure

D I S T R I B U T E D V A L V E S Raised Face Procedure Area The following procedure applies to new installation between standard ASME B16.5 pipe flanges. When replacing a valve from an existing installation, clean the flange faces of any residual gasket material before starting. -

Page 10: Operation

D I S T R I B U T E D V A L V E S Operation Manually Operated The WKM DynaCentric MA High Performance Butterfly Valve operates from fully open to fully closed by a 90° turn of the handle. Visual "OPEN - CLOSED"... -

Page 11: Routine Maintenance

Restrain handle or actuator when in and closes with proper restraint. static position. line flow. * Contact your Cameron representative for technical information or repair manual. Additional information is also available on-line at www.c-a-m.com Installation, Operation and Maintenance Manual WKM-MA-HPBV-IOM... - Page 12 D I S T R I B U T E D V A L V E S Contact your Cameron’s Valves & Measurement group representative for a Repair Manual ® 3250 Briarpark Drive, Suite 300 Houston, Texas 77042 USA Toll Free 800 323 9160 For the most current contact and location information go to: www.c-a-m.com...