Summary of Contents for Cameron WKM

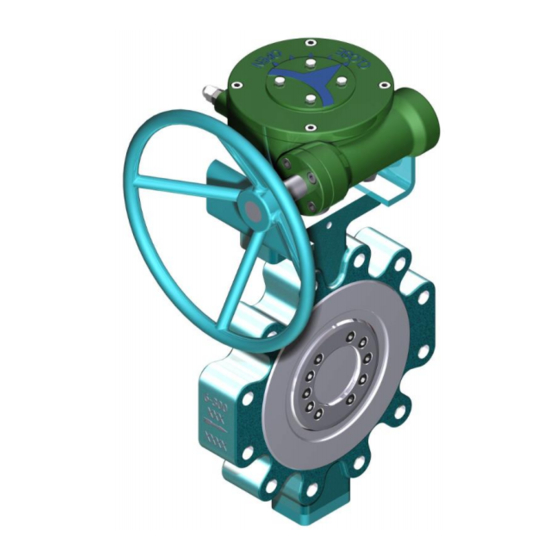

- Page 1 Installation, Operation and Maintenance Manual 3”-24” 150/300/600 CLASS ® TRIPLE OFFSET VALVE ® Installation, Operation and Maintenance Manual WKM-TOV-IOM...

-

Page 2: Table Of Contents

Notes: ® This manual is a general representation of the information required for correct usage of the CAMERON WKM valve. More specific information is available and can be supplied per customer request. CAMERON valve reserves the right to amend this document, with no prior notice. Please reference the applicable drawing and/or parts list when using this IOM manual. -

Page 3: List Of Components

List of components Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 4: Catalog Number Information

Catalog number information Figure number: ® The figure number shown below identifies specific valve configuration details of WKM Triple Offset Valves such as valve type, pressure class, end connections, body/bonnet and trim materials, and special features. Nameplate information 1. Valve size 2. -

Page 5: Scope

Triple Offset Butterfly Valves perform equally well butterfly valves. They are designed and manufactured in with the shaft in the vertical or horizontal position. Cameron a manner that allows the disc to rotate into and out of recommends that the optimum valve installation is with the the seat with absolutely no interference. -

Page 6: Disc/Pipe Clearance

Class 300 valves - Schedule40/XS pipe or equivalent Class 600 valves - Schedule 100 pipe or equivalent Consult Table 1 - Disc clearance for required flange modifications for other pipe schedules (Figure 2). Figure 2: Disc/pipe clearance Pipe Flange Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 7: Disc Protrusion Length Inside Pipe

NO PROTRUSION NO PROTRUSION 11.5 NO PROTRUSION 16" NO PROTRUSION 25.5 15.5 NO PROTRUSION 18" NO PROTRUSION 111.0 88.0 41.0 NO PROTRUSION 20" NO PROTRUSION 119.5 99.0 48.5 38.0 NO PROTRUSION 24" NO PROTRUSION Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 8: Procedure

Open stop "OPEN - CLOSED" position of the disc (Figure 5) adjustment Counter-clockwise rotation of the hand wheel opens Close stop the valve, clockwise rotation closes the valve. adjustment Figure 5: Gearbox Installation, Operation and Maintenance Manual WKM-TOV-IOM... - Page 9 1 1/8-8 UN 12'' 4.27 3.01 6.64 5.27 19.25 1 1/4-8 UN 5.51 4.14 18.75 1-8 UNC 4.22 3.09 5.26 4.00 20.25 1 1/8-8 UN 14" 3.25 3.13 6.97 5.48 20.75 1 3/8-8 UN 4.49 4.37 Installation, Operation and Maintenance Manual WKM-TOV-IOM...

- Page 10 3.59 8.56 6.74 28.50 1 5/8-8 UN 7.19 5.36 5.32 3.87 29.50 1 1/4-8 UN 4.41 2.96 6.92 5.22 24" 32.00 1 1/2-8 UN 5.70 4.00 9.59 7.51 33.00 1 7/8-8 UN 8.02 5.94 Installation, Operation and Maintenance Manual WKM-TOV-IOM...

- Page 11 7/8-9 UNC 3.50 2.50 12'' 17.75 1 1/8-8 UN 4.86 3.60 19.25 1 1/4-8 UN 6.44 5.07 18.75 1-8 UNC 4.22 3.09 14" 20.25 1 1/8-8 UN 5.18 3.92 20.75 1 3/8-8 UN 6.97 5.48 Installation, Operation and Maintenance Manual WKM-TOV-IOM...

-

Page 12: Valve Position Verification

1. Check the operation of the valve by stroking it to "full open" and "full close". To verify the valve orientation, the disc position is accomplished by dimple on shaft. When the dimple is inline with flow axis, disc is open (Figure 6). Figure 6: Position indicator Disc position indicator mark Disc in open position Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 13: Routine Maintenance

® Because of the simple design and operation, WKM Avoid excessive tightening which may result in excessive Triple Offset Valves require virtually no maintenance. valve torque or premature packing wear.(Refer Chart B... -

Page 14: Packing Maintenance

For live loaded packing design, make sure to note down the sequence and pattern of the belleville springs before removing them. Figure 7: Packing maintenance The live load packing nuts shall be tightened in accordance with Torque chart “B”. Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 15: Sealing Elements Maintenance

Then, verify that the seal ring can be moved freely by hand Caution: Seal and seat shall contact uniformly without rotating it. around circumference. No light shall be visible around seal. 14. A thin film of lubricant shall be applied to the body seat Installation, Operation and Maintenance Manual WKM-TOV-IOM... - Page 16 Open valve and visually align disc assembly parallel to valve bore (full Open). Set the open stop adjustment of the gear box and lock the position With jam nut as shown in the figure 5. Installation, Operation and Maintenance Manual WKM-TOV-IOM...

-

Page 17: Bottom Cap Gasket Maintenance

7. A thin film of lubricant by Molykote ® – P74 (Grease) or equivalent shall be applied on the threads of the screws (11), and they shall be fitted and tightened using the appropriate torque value from the torque chart A. Installation, Operation and Maintenance Manual WKM-TOV-IOM... -

Page 18: Mounting Operators

9. 2. WKM TOV’s are torque seated in the closed position and are position seated in the open position, therefore to achieve valve shut off, a few degrees over travel may be required in the operator. Travel stops shall be adjusted accordingly. -

Page 19: Torque Charts

10"-300 M22 x 2.5 10"-600 12"-150 M24 x 3.0 12"-300 M30 x 3.5 12"-600 14"-150 M36 x 4.0 1204 1633 14"-300 14"-600 16"-150 16"-300 16"-600 18"-150 18"-300 18”-600 20"-150 20"-300 20"-600 24"-150 24"-300 24"-600 Installation, Operation and Maintenance Manual WKM-TOV-IOM... - Page 20 For the most current contact and location information go to: www.products.slb.com © Cameron’s Valves & Measurement Segment Released 09/2018 WKM-TOV-IOM Installation, Operation and Maintenance Manual WKM-TOV-IOM...

Need help?

Do you have a question about the WKM and is the answer not in the manual?

Questions and answers