Table of Contents

Advertisement

SETUP, PARTS & MAINTENANCE

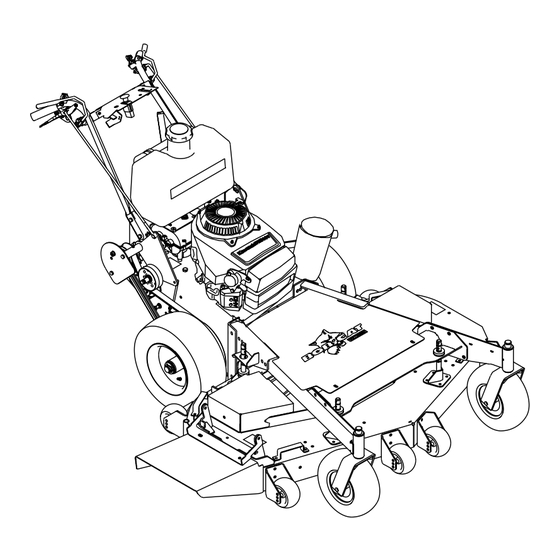

MANUAL GEAR DRIVE MIDSIZE

Power Unit Models:

930022

Power Unit 15HP Kawasaki Gear Drive

930023

Power Unit 17HP Kawasaki Gear Drive

(Operation & Safety Manual: 2721692)

WARNING: If incorrectly used this machine can cause severe injury. Those who use

and maintain this machine should be trained in its proper use, warned of its dangers

and should read the entire manual before attempting to set up, operate, adjust or

service the machine.

2721693 REV D

Advertisement

Table of Contents

Summary of Contents for Textron BOB-CAT 930022

- Page 1 SETUP, PARTS & MAINTENANCE MANUAL GEAR DRIVE MIDSIZE Power Unit Models: 930022 Power Unit 15HP Kawasaki Gear Drive 930023 Power Unit 17HP Kawasaki Gear Drive (Operation & Safety Manual: 2721692) WARNING: If incorrectly used this machine can cause severe injury. Those who use and maintain this machine should be trained in its proper use, warned of its dangers and should read the entire manual before attempting to set up, operate, adjust or service the machine.

- Page 2 © 2002, TEXTRON INC...

-

Page 3: Table Of Contents

You'll always be glad you did. Textron Golf, Turf & Specialty Products One Bob Cat Lane Johnson Creek, WI 53038-0469... -

Page 4: Safety

These words appear in this and approved by Textron Golf, Turf & Specialty manual and on the safety labels attached to Textron Products Engineering Department. Any Textron Golf, Turf & Specialty Products machines. For your Golf, Turf &... -

Page 5: Assembly/Set-Up Instructions

Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize GENERAL NOTE: FRONT, REAR, RIGHT HAND AND LEFT HAND REFERENCES BELOW ARE WITH RESPECT TO AN OPERATOR AT THE CONTROLS. 1. UNCRATE - Place both power unit and cutterdeck crates on a level surface. Remove sides and top from both the power unit and cutterdeck crates. - Page 6 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize 7. Unbolt shipping bracket E from the crate. NOTE: It will be necessary to support the rear of the power unit and level it for attachment to the cutterdeck. 8. Remove the power unit from the crate and support the rear of the power unit using a jackstand.

- Page 7 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize 13. Attach gear shift lever A removed in Step 2 to the lower shift arm with (1) M8-1.25 X 25 Bolt and (1) M8-1.25 whizlock nut. Shift the lever to the neutral position and verify that the lever is centered side to side in the slot.

- Page 8 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize CUTTERDECK ATTACHMENT: Two types of cutterdeck mounting systems are available, fixed and floating. Fixed mounting rigidly attaches the cutterdeck to the power unit. Floating mounting allows the cutterdeck to move independant of the power unit providing a more uniform cut. Follow the appropriate instructions below for the type of cutterdeck being attached to the power unit.

- Page 9 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize 6. Remove belt cover and set aside. 7. Block the rear of the cutterdeck with the appropriate height block for the desired height of cut B. See Support Block Chart below. " 5 " 5 "...

- Page 10 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize FLOATING CUTTERDECK ATTACHMENT 1. Unbolt the caster wheels and the shipping brackets from the crate. 2. Remove the shipping bracket from the caster wheel by loosening the caster bolt and sliding the shipping bracket off and retighten caster bolt. 3.

- Page 11 Gear ASSEMBLY/SET-UP INSTRUCTIONS Drive Midsize 5. Position power unit behind the crate and cutterdeck. 6. With the cradle raised above the cutterdeck, roll the front of the cradle and power unit up and over the cutterdeck and crate. 7. Align height of cut pins E on cutterdeck with the bushings on the cradle and lower the cradle so pins pass through bushings.

-

Page 12: Lubrication

Gear LUBRICATION Drive Midsize MACHINE LUBRICATION Every 50 Working Hours - Lubricate the following points with grease: 1) Caster wheel pivots (2 points) 2) Caster wheel bearings on wheel hub (2 points) 3) Drive Wheel Bellcranks (2 points) 4) Brake Levers (2 points) 5) Idler pivot bearings: a) Engine to cutterdeck belt tensioner b) Cutterdeck belt tensioner... - Page 13 Gear LUBRICATION Drive Midsize ENGINE DAILY Remove the dipstick S and check that the oil level reaches the full mark. If necessary, top off with fresh oil. To obtain the correct oil level, the machine must be level. See engine manufacturer’s manual for proper oil viscosity and grade.

-

Page 14: Maintenance

Gear MAINTENANCE Drive Midsize The maintenance schedule detailed is for average operating conditions. Under extreme conditions (dusty, dirty or more than 8 hrs continuous use) maintain more frequently. Engine (daily) Check the engine for oil leaks. Cooling Fins and Air Intake screen (daily) Ensure that the cooling fins and air intake screen I are cleaned daily. - Page 15 Gear MAINTENANCE Drive Midsize Blade Sharpening Blades may be sharpened by filing or grinding, but with either method the balance of the blades must be maintained at 5/8 oz/in or less. Failure to maintain balance causes excess vibration, wear and shortened life of not only the blades, but most all components of the machine.

-

Page 16: Service Chart

Gear SERVICE CHART Drive Midsize NOTE: CHANGE ENGINE OIL AND FILTER AFTER FIRST 5 HOURS OF OPERATION. & & Consult the manufacturer’s manual for your engine for further information and instructions. -

Page 17: Service Record

Gear SERVICE RECORD Drive Midsize NOTES _______________________________________________________________ ____________________________________________________ ________________________________________________________________________ _______________________________________________________________ ____________________________________________________________ ____________________________________________________ ________________________________________________________________________ _______________________________________________________________ ____________________________________________________________ _______________________________________________________________ ____________________________________________________________ _______________________________________________________________ _______________________________________________________________ & & r i f t l i... -

Page 18: Adjustments

Gear ADJUSTMENTS Drive Midsize Make all adjustments with the engine shut off, spark plug wire disconnected and mower drive disengaged. OPERATOR PRESENT CONTROLS The operator present (OP) controls should be adjusted to control the operation of the plunger of the operator present switch (located under the right side of the control panel). - Page 19 Gear ADJUSTMENTS Drive Midsize HANDLE BAR HEIGHT ADJUSTMENT To adjust handle bar height: Remove bolts G and loosen bolts E on each side of handlebars. Raise or lower as required. Reposition upper handle and reinsert bolts G into appropriate hole in lower handle and tighten.

- Page 20 Gear ADJUSTMENTS Drive Midsize DRIVE BELT TENSION ADJUSTMENT Drive belt tension can be adjusted to one of three settings to account for various mowing conditions. 1. Adjust by moving the spring anchor bolt to position 1, 2 or 3. • Position 1 will provide the least amount of hand effort and wheel traction.

-

Page 21: Belt Replacement

Gear BELT REPLACEMENT Drive Midsize PTO BELT 1. Rotate idler arm using a 3/8" ratchet or breaker bar and remove belt. CUTTERDECK BELT 1. Remove PTO belt. 2. Rotate idler arm using a 3/8" ratchet or breaker bar and remove belt. 3. - Page 22 Gear BELT REPLACEMENT Drive Midsize WHEEL DRIVE BELT - Remove brake rod C and tracton control rod D from bellcrank. Remove bottom bolt and spacer from fender A and loosen the other bolt that holds bellcrank. Rotate bellcrank and idler up and out of the way.

-

Page 23: Parts Section

Gear Drive Midsize PARTS SECTION... -

Page 24: Upper Engine Deck Assy

Gear UPPER ENGINE DECK ASSY Drive Midsize FIGURE 1... - Page 25 Gear UPPER ENGINE DECK ASSY Drive Midsize FIGURE 1 2721693-01 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 2721520 CAP-FUEL GASOLINE 3.5 2721525 TANK-FUEL MID (INCLUDES ITEMS 3 & 4) 48310 S BUSHING,FUEL TANK 38540 S FUEL SHUT-OFF VALV 88042N HOSE CLAMP 48016-10A HOSE-25ID X .50OD X 13"...

-

Page 26: Lower Engine Deck Assy/Clutch

Gear LOWER ENGINE DECK ASSY/CLUTCH Drive Midsize FIGURE 2... - Page 27 Gear LOWER ENGINE DECK ASSY/CLUTCH Drive Midsize FIGURE 2 2721693-02 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 38460 PULLEY-ENGINE 64163-07 1-1/32X1-3/4X1/4 WASH 2721110 CLUTCH-ELECTRIC (INCLUDES ITEM 30) 2721331.7 WLDMT-CLUTCH STOP MID 1 2721410 BELT-HA 41.00 128175 PULLEY-SNGL GRV 7 ED 64144-01 SNAP RING 5/8 64164-19...

-

Page 28: Drive Wheels & Brakes

Gear DRIVE WHEELS & BRAKES Drive Midsize FIGURE 3... - Page 29 Gear DRIVE WHEELS & BRAKES Drive Midsize FIGURE 3 2721693-03 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 2722622 S-ENGINE DECK W/LABELS 1 2722491.7 WLDMT-AXLE GD 64163-07 WASHER 64197-005 BLT-TDFM 3/8-16X1-1/4 4122115 BRAKE-DRUM 64246-03 NUT-WHIZ M10-1.50 64163-64 WASHER 64163-25 WASHER 2721432 WHL ASSY-4PLY 16 X 6.5-8 2 (INCLUDES ITEMS 10, 12 &...

-

Page 30: Transmission Drive

Gear TRANSMISSION DRIVE Drive Midsize FIGURE 4... - Page 31 Gear TRANSMISSION DRIVE Drive Midsize FIGURE 4 2721693-04 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 2721382.7 LEVER-SHIFT 4-42 64163-29 21/64X1X11GA.WASHER 2722621 S-GEAR SELECTOR PLATE 1 4-43 64251-003 WASHER-M8 64044-2 SCREW-SET 5/16-18X3/8 4-44 33135-01 ROD-BRAKE 2722622 S-ENGINE DECK W/LABELS 1 4-45 64229-02 LOCKNUT-NYLON 5/16-18 2721394.2...

-

Page 32: Upper Handle/Roller Latch

Gear UPPER HANDLE/ROLLER LATCH Drive Midsize FIGURE 5... - Page 33 Gear UPPER HANDLE/ROLLER LATCH Drive Midsize FIGURE 5 2721693-05 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 64175-01 PUSHNUT-3/16 ROD 2721495.2 WLDMT-UPPER HANDLE 64141-4 NUT-WLF 3/8-16 64168-2 HAIRPIN COTTER 33103 SWIVEL 2721364.2 WLDMT-BELLCRANK RH * 2721365.2 WLDMT-BELLCRANK LH 64123-50 BLT-HEX 3/8-16 X 1 2721650 ROD-TRACTION CNTRL GD 2 38009N...

-

Page 34: Operator Present

Gear OPERATOR PRESENT Drive Midsize FIGURE 6... - Page 35 Gear OPERATOR PRESENT Drive Midsize FIGURE 6 2721693-06 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 38148 SWITCH-ENGINE STOP 64152-10 10-24X3/4 MACH SCREW 2722705 S-CONTROL PNL W/LAB 64152-23 1/4-20X3/8 LG SCREW 48412 CLIP-CABLE 2721505 SWITCH-PTO 2188178 SWITCH-RETAINER 38357-04 CONTROL-THROTTLE 64025-15 NUT-HEX #10-24 KEPS 6-10 2308152 LEVER OP LH...

-

Page 36: Decals

Gear DECALS Drive Midsize FIGURE 7... - Page 37 LABEL-CNTRL PNL GD 2000569 LABEL-PARK/NEUTRAL 2000570 LABEL-WARN FUEL PICT 340830 DECAL-CAUTION SPANISH 1 2000571 LABEL-IMPORTANT 2721882 LABEL-BOBCAT TEXTRON 1 2000572 LABEL-WARNING BLADES 1 2000677 LABEL-DANGER/WARNING 1 2000678 LABEL-ROT PARTS/WSHR 1 7-10 2000704 LABEL-MIDSIZE PATENT 7-11 2000673 DECAL - OP MAN/TIRES...

-

Page 38: Peerless Transmission

Gear PEERLESS TRANSMISSION Drive Midsize FIGURE 8... - Page 39 2721693-08 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 2308136 PEERLESS TRANS MODEL 700-078 8-81 786081 CHAIN,ROLLER #41 (COMPLETE UNIT AVAILABLE THRU TEXTRON) 8-82 786082 SPROCKET (9 TEETH) 8-83 786083 SPROCKET (18 TEETH) (INDIVIDUAL COMPONENTS AVAILABLE 8-89 780092 BALL BEARING...

-

Page 40: Electrical Diagram

Gear ELECTRICAL DIAGRAM Drive Midsize FIGURE 9... - Page 41 Gear ELECTRICAL DIAGRAM Drive Midsize FIGURE 9 2721693-09 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 2721110 CLUTCH-ELECTRIC (INCLUDES ITEM 2) 2720949 ASSY-CLUTCH WIRE 2722033 SWITCH-NEUTRAL 38148 SWITCH-ENGINE STOP 38383 SWITCH-N.C. 148082-10 FUSE 10 AMP 2721505 SWITCH-PTO 4118008 HARNESS-GEAR DRIVE (INCLUDES ITEM 6)

-

Page 42: Cutterdeck Mounting

Gear CUTTERDECK MOUNTING Drive Midsize FIGURE 10... - Page 43 Gear CUTTERDECK MOUNTING Drive Midsize FIGURE 10 2721693-10 ITEM PART NO. DESCRIPTION ITEM PART NO. DESCRIPTION 10-1 2721991.7 PLATE-NUT 10-2 64246-04 NUT-WHIZ M12-1.75 10-3 64246-03 NUT-WHIZ M10-1.50 10-4 64163-82 WASHER-.406 X 1.44 X 9GA 2 10-5 A1104057 BOLT-M10-1.50 X 25 10-6 64263-018 BLT-FLG HD M12-1.75 X 30 4...

-

Page 44: Kawasaki Electrical Schematic

Gear KAWASAKI ELECTRICAL SCHEMATIC Drive Midsize FIGURE 11 2721693-11...

Need help?

Do you have a question about the BOB-CAT 930022 and is the answer not in the manual?

Questions and answers