Wayne-Dalton 8000 Installation Instructions And Owner's Manual

Hide thumbs

Also See for 8000:

- Installation instructions and owner's manual (38 pages) ,

- Installation instructions and owner's manua (22 pages) ,

- Quick start manual (10 pages)

Table of Contents

Advertisement

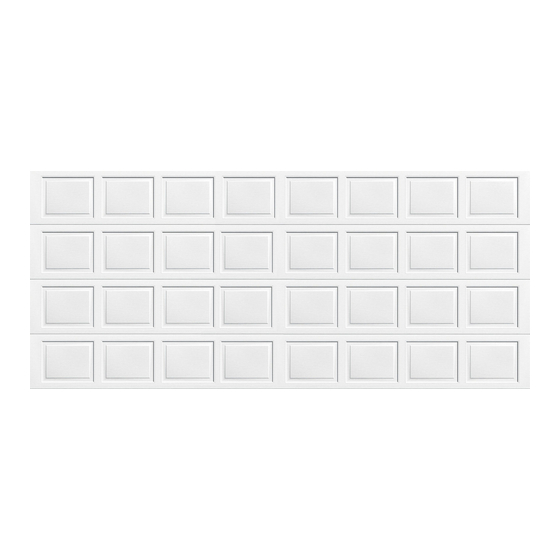

Models 8000 / 8100

/ 8200

T

O R S I O N

R

D

ESIDENTIAL

OORS

F

M

L

RONT

OUNT

OW

I

H

NSIDE

OOKUP

I

I

NSTALLATION

NSTRUCTIONS

M

ANUAL

PLEASE DO NOT RETURN THIS PRODUCT

TO THE STORE

If you need assistance, please call 1-866-

569-3799 (press Option 1) and follow the

prompts to contact a customer service

representative. They will be happy to handle

any questions that you may have.

©Copyright 2021

Wayne Dalton, a division of Overhead Door Corporation

H

EADROOM

A

O

ND

WNER

T a b l e O f C o n t e n t s

'

S

IMPORTANT NOTICES!

To avoid possible injury, read and fully understand the enclosed

instructions carefully before installing and operating the garage door. Pay

close attention to all warnings and notes. After installation is complete,

fasten this manual near garage door for easy reference.

This Installation document is available at no charge from:

- Your local Wayne Dalton Sales Center, or

- Online at www.Wayne-Dalton.com, or

- By mailing to: Wayne Dalton, a division of Overhead Door Corporation, P.O. Box

67, Mt. Hope, OH., 44660

Part Number

361196

2

2

2

3

4

4

6

7

11

16

16

16

17

17

17

17

17

19

REV3_01/12/2021

Advertisement

Table of Contents

Summary of Contents for Wayne-Dalton 8000

-

Page 1: Table Of Contents

Models 8000 / 8100 T a b l e O f C o n t e n t s Pre-Installation / 8200 Important Safety Instructions Removing an Existing Door and Preparing the Opening Package Contents Door Section Identification Tools Required... -

Page 2: Pre-Installation

Existing Door & Prepar- NEVER hang tools, bicycles, hoses, clothing or anything else from horizontal tracks. ing the Opening. These are available for download at www.Wayne-Dalton.com or at your Track systems are not intended or designed to support extra weight. -

Page 3: Package Contents

NOTE: Drill a 3/16” pilot hole in the mounting surface to avoid splitting the lumber. Do not attach the mounting surface with nails. WEATHERSTRIPS (MAY NOT BE INCLUDED): Depending on the size of your door, you may have to cut or trim the weatherstrips (if neces- sary) to properly fit into the header and jambs. -

Page 4: Door Section Identification

Door Section Identification Door Type Of Section Height Bottom Lock Inter- Inter- Inter- Inter- Inter- (sec- medi- medi- medi- medi- medi- ond) ate I ate II ate III ate IV ate V 1/4”-20 x 7/8” Self (third) (fourth) (fifth) (sixth) (sev- 1/4”-20 x 11/16”... - Page 5 Approved winding bars Saw horses Safety glasses Locking pliers...

-

Page 6: Breakdown Of Parts

BREAKDOWN OF PARTS NOTE: The illustrations shown on this page are general representations of the door parts. Each specific door models may have unique variations. Top of vertical Top of vertical track track B2. (Fully Adjustable 3rd hole Feature) B1. (Quick hole set Install Feature) -

Page 7: Door Installation Instructions

DOOR INSTALLATION INSTRUCTIONS 12” Or 15” Horizontal Radius track Before installing your door, be certain that you have read and followed all of the instruc- tions covered in the pre-installation section of this manual. Failure to do so may result in an 15”... - Page 8 Counterbalance Strutting Schedule For Models 8000 and 8100 Counterbalance lift cable lift cable Door Heights Section Qty Section Type Door Widths Bottom 14’0” - 16’0” 17’0” - 18’0” 20’0” section 6’0” - 7’0” Solid (1) TS (3) TS, LS, BS...

- Page 9 each end and at each center stile locations. Center (2) 9/32” Outside Inside lift (2) Spacers stile Diameter holes lift handle NOTE: Depending on your door some sections may or may not require a strut to be installed handle onto the section. Inside 1/4”-20 x 7/8”...

- Page 10 1/4”-14 x 5/8” 1/4”-14 x 5/8” Self tapping Self tapping screw locations screw locations Right graduated end hinge Left graduated end hinge Center with short stem track roller Flag with short stem track roller hinge(s) angle 1/4”-14 x 5/8” 1/4”-14 x 5/8” Self tapping Self tapping Vertical...

-

Page 11: Counterbalance Installation Instructions

Short stem Upper rail Horizontal Quick fixture track roller Quick track Install Flag Install tab in angle section place slot section Install and tighten Level 1/4”-20 x 11/16” 1/4”-20 1/4”-20 x Self drilling screws Intermediate Flange hex 9/16” Flag angle Lower section Track bolt... - Page 12 which intersects the vertical pencil line. Mark a vertical pencil line on the mounting surface above the door, at the center. Align the edge of the center bracket with the vertical pencil line and the center of the center bracket NOTE: Layout with the horizontal pencil line;...

- Page 13 Center Chalking Torsion Spring(s) Center bracket Center bracket bracket Stationary 3/8”-16 bearing spring Hex nuts NOTE: If your springs have stenciling, then skip this step. cone Center Draw a chalk line horizontally along the center of the torsion spring coil(s). As the torsion bracket bearing spring is wound, the chalk line will create a spiral.

- Page 14 WARNING Perforated Angle Gauge Weight Limitations: Perforated Angle Gauge Door Balance Weight USE ONLY SPECIFIED WINDING BARS, AS STATED IN STEP 1-1/4” x 1-1/4” x 15 Gauge 220 lbs. to 440 lbs. SECURING DOOR FOR SPRING WINDING. DO NOT SUBSTITUTE WITH SCREWDRIVERS, PIPE, ETC.

- Page 15 Attaching Weather Seal Permanently attach the weatherstrips on both door jambs and header. The weatherstrips were temporarily attached in Preparing the Opening, in the pre-installation section of this manual. NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath- erstrips too tightly against the face of door.

-

Page 16: Optional Installation

Optional Installation Inside Lock Install the inside lock on the second section of the door. Secure the lock to the section with (4) 1/4” - 20 x 11/16” self drilling screws. Square the lock assembly with the door section, and align with the square hole in the vertical track. The inside lock should be spaced ap- proximately 1/8”... -

Page 17: Maintenance

Cleaning Your Garage Door available at no charge from Wayne Dalton, a division of Overhead Door Corporation, P.O. Box 67, Mt. Hope, OH., 44660, or at www.Wayne-Dalton.com. For additional information on garage door/operator maintenance go to www.dasma.com and reference TDS 151, 167 and 179. - Page 18 Wayne Dalton 2501 S. State Hwy 121 Bus., Suite 200 Lewisville, TX 75067 For service, call (800) 827-3667 www.Wayne-Dalton.com SAFETY INSTRUCTIONS 1. Operate door ONLY when it is properly adjusted and free of obstructions. 2. If a door becomes hard to operate,...

-

Page 19: Warranty

Wayne Dalton, a division of Overhead Door Corporation ("Seller") warrants to the original purchaser of the Models 8000, 8100, 8200, 8024 PO, 8124 PO, 8224 PO (“Product”), subject to all of the terms and conditions hereof, that the Product and all components thereof will be free from defects in materials and workmanship for the following period(s) - Page 20 Thank you for your purchase. PLEASE DO NOT RETURN THIS PRODUCT TO THE STORE If you need assistance, please call 1-866-569-3799 (press Option 1) and follow the prompts to contact a customer service representative. They will be happy to handle any questions that you may have.

Need help?

Do you have a question about the 8000 and is the answer not in the manual?

Questions and answers