Wayne-Dalton 8000 Installation Instructions And Owner's Manual

Torsion cut-down

residential and light commercial

Hide thumbs

Also See for 8000:

- Installation instructions and owner's manual (38 pages) ,

- Installation instructions and owner's manua (22 pages) ,

- Quick start manual (10 pages)

Table of Contents

Advertisement

Quick Links

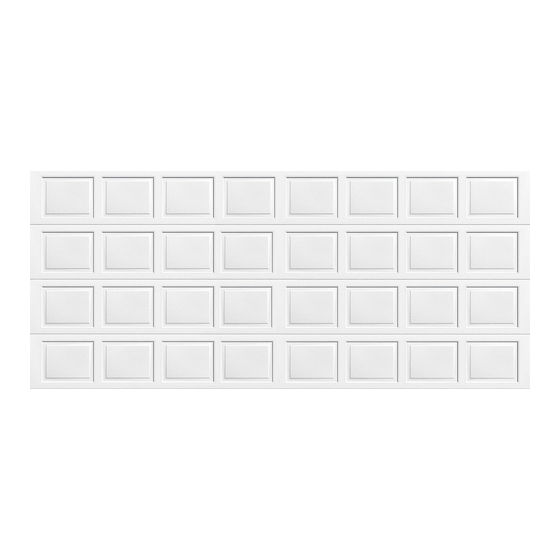

Models 8000 / 8100

/ 8200

T

, C

o r s i o n

u T

r

l

esiDenTial anD

ighT

i

i

nsTallaTion

nsTruCTions

M

anual

DEFINITION OF LIGHT COMMERCIAL:

1. Door heights less than or equal to 8'0" (< = 8'0") are considered

Residential applications.

2. Door heights greater than 8'0" (> 8'0") are considered Light

Commercial applications.

PLEASE DO NOT RETURN THIS PRODUCT

TO THE STORE

If you need assistance, please call 1-866-

569-3799 (press Option 1) and follow the

prompts to contact a customer service

representative. They will be happy to handle

any questions that you may have.

©Copyright 2016

Wayne Dalton, a division of Overhead Door Corporation

D

o w n

C

oMMerCial

a

o

'

nD

wner

s

T a b l e O f C o n t e n t s

IMPORTANT NOTICES!

To avoid possible injury, read and fully understand the enclosed

instructions carefully before installing and operating the garage door. Pay

close attention to all warnings and notes. After installation is complete,

fasten this manual near garage door for easy reference.

This Installation document is available at no charge from:

Wayne Dalton, a division of Overhead Door Corporation,

P.O. Box 67, Mt. Hope, OH., 44660, Or Online At www.Wayne-Dalton.com.

Part Number

350140

2

2

2

2

3

3

4

5

6

17

17

17

18

18

18

18

18

19

REV7_09/15/2016

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Wayne-Dalton 8000

-

Page 1: Table Of Contents

They will be happy to handle any questions that you may have. This Installation document is available at no charge from: Wayne Dalton, a division of Overhead Door Corporation, P.O. Box 67, Mt. Hope, OH., 44660, Or Online At www.Wayne-Dalton.com. Part Number 350140 REV7_09/15/2016 ©Copyright 2016... -

Page 2: Pre-Installation

Pre-Installation WARNING Important Safety Instructions PRIOR TO WINDING OR MAKING ADJUSTMENTS TO THE SPRINGS, ENSURE YOU'RE WINDING IN THE PROPER DIRECTION AS STATED IN DEFINITION OF KEY WORDS USED IN THIS MANUAL: THE INSTALLATION INSTRUCTIONS. OTHERWISE, THE SPRING FITTINGS WARNING MAY RELEASE FROM SPRING IF NOT WOUND IN THE PROPER DIRECTION AND COULD RESULT IN SEVERE OR FATAL INJURY. -

Page 3: Door Section Identification

5/16” x 1-5/8” Hex head lag screws Graduated hinges Top fixture slides (RED HEAD) (as required) Bottom corner brackets RH/LH (as required) (as required) (as required) Top fixture bases Track rollers Top fixture 5/16” x 1-5/8” Hex head (as required) (as required) assemblies (as required) Top fixtures (as required) lag screws (as required) -

Page 4: Preparing The Opening

Opening”. These instructions are not supplied with the door, but are available at no charge from Wayne Dalton, a division of Overhead Door Corporation, P.O. Box 67, Mt. Hope, Min. Side OH., 44660, or at www.Wayne-Dalton.com. room Suitable mounting surface... -

Page 5: Parts Breakdown

PARTS BREAKDOWN NOTE: The illustrations shown on this page are general representations of the door parts. Each specific door models may have unique variations. A. FLAG ANGLES (AS REQUIRED): H. TRACKS (AS REQUIRED): A1. Fully Adjustable (F.A.) Flag Angles H1. Left Hand and Right Hand Horizontal Track Assemblies A2. -

Page 6: Installation

NOTE: If you have riveted tracks, skip this step. NOTE: Flag angles are right and left handed. INSTALLATION Hand tighten the left hand flag angle to the left hand vertical track using (2) 1/4” - 20 x 9/16” track bolts and (2) 1/4” - 20 flange hex nuts. Repeat for other side. Flange nuts will be secured after flag angle spacing is completed in step, Top Section. - Page 7 two holes on the side of the left hand bottom corner bracket. Slide a clevis pin through the the end caps with (2) 1/4” - 14 x 5/8” self tapping screws. Repeat for other side. Next, align innermost hole, cable loop, and outermost hole, of the bottom corner bracket. Slide a washer the lower hinge leaf of the #1 center hinges with the pre-punched holes at each center stile onto the clevis pin and secure in place by inserting a cotter pin into the hole of the clevis location(s), located at the top of the bottom section.

- Page 8 Top section Strutting Schedule End cap Door Height Configuration Door Width Upper center Hole slotted hole 14’0” - 16’11” 17’0” - 19’11” 20’0” Top fixture slide Top fixture 6’0” - 7’0” Solid (1) 2” Strut, Top (3) 2” Struts, (1) 3” Strut, Per base (4) 1/4”-20 x 7/8”...

- Page 9 Bottom Section Bottom Bottom section section Tools Required: Tape measure, Level, Wooden shims (if necessary), Safety inside outside glasses, Leather gloves (2) 5/16” Dia. Center the bottom section in the door opening. Level the section using wooden shims (if drilled holes necessary) under the bottom section.

- Page 10 manual. Door width NOTE: The sections can be identified by the graduation of the factory installed graduated end + 3-3/8” to 3-1/2” hinges. The smallest graduated end hinge on section should be stacked on top of the bottom Flag angle section, with each graduated end hinge increasing as the sections are stacked, see Parts Breakdown.

- Page 11 (1) 1/4”-20 Flange hex nut 1” x 4” x 23” Left end bracket Angle (if Supplied) (1) 5/16” x 1-5/8” (2) 3/8”-16 Lag screw (2) 3/8”-16 x 3/4” Hex nuts Truss head bolts Bottom rail of Washer Top rail of Flag angle horizontal track horizontal track...

- Page 12 Torsion Spring Assembly Left hand end bearing bracket Tools Required: 3/8” Wrench, 9/16” Wrench, Step ladder, Tape measure, Safety glasses, Leather gloves (2) 5/16” x 1-5/8” Lag screws IMPORTANT: RIGHT AND LEFT HAND IS ALWAYS DETERMINED FROM INSIDE THE BUILDING LOOKING OUT.

- Page 13 (2) 3/8”-16 Nuts Center bracket Jamb Jamb bushing assembly Locking pliers Left hand end bearing bracket Torsion spring Set screws Torsion spring Counterbalance lift cable Left hand cable drum Torsion shaft (2) 3/8”-16 x 1-1/2” Stationary spring cone Hex head bolts Counterbalance Lift Cables Tools Required: Step ladder, Locking pliers, 3/8”...

- Page 14 Adjustments to the number of turns stated may be necessary. If door rises off floor under Winding Bars Size Of Winding Bar Spring Diameter spring tension alone, reduce spring tension until door rests on the floor. If the door is hard to (Steel Rods) (Inches) Used On...

- Page 15 Now, permanently attach the weatherstrips on both door jambs and header. The weather- strips were temporarily attached in Preparing the Opening, in the pre-installation section of Sound framing this manual. members NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath- erstrips too tightly against the face of door.

- Page 16 Sound framing members (3) 5/16” Bolts and nuts Horizontal Perforated angle bolted track using (2) 5/16” x 1-5/8” hex head lag screws to Perforated angle ceiling member and parallel to door 5/16”-18 x 1-1/4” Hex bolts must extend into the track to serve as a roller stop Sound framing members...

-

Page 17: Optional Installation

Optional Installation Inside Lock Install the inside lock on the second section of the door. Secure the lock to the section with (4) 1/4” - 20 x 11/16” self drilling screws. Square the lock assembly with the door section, and align with the square hole in the vertical track. The inside lock should be spaced ap- proximately 1/8”... -

Page 18: Maintenance

To avoid possible damage to your door, Cleaning Your Garage Door Wayne Dalton recommends reinforcing the top section on models 8000, 8100, 8200 and 9100 doors with a strut (may or may not be supplied). The installation of the drawbar opera- tor must be according to manufacturer’s instructions and force settings must be adjusted... -

Page 19: Warranty

Models 8000, 8100 and 8200 Wayne Dalton, a division of Overhead Door Corporation (“Seller”) warrants to the original purchaser of the Models 8000, 8100, 8200 (“Product”), subject to all of the terms and conditions hereof, that the Product and all components thereof will be free from defects in materials and workmanship for the following period(s) of time,... - Page 20 Thank you for your purchase. PLEASE DO NOT RETURN THIS PRODUCT TO THE STORE If you need assistance, please call 1-866-569-3799 (press Option 1) and follow the prompts to contact a customer service representative. They will be happy to handle any questions that you may have..

Need help?

Do you have a question about the 8000 and is the answer not in the manual?

Questions and answers