Wayne-Dalton 8000 Installation Instructions And Owner's Manua

Torque master plus

Hide thumbs

Also See for 8000:

- Installation instructions and owner's manual (38 pages) ,

- Quick start manual (10 pages) ,

- Installation instructions and owner's manual (22 pages)

Table of Contents

Advertisement

Quick Links

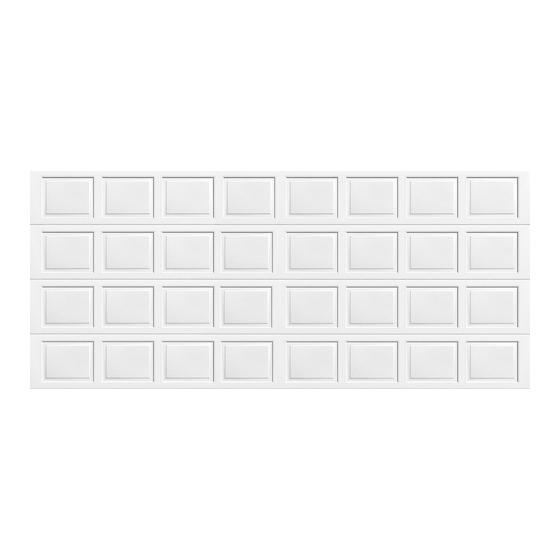

Models 8000 / 8100

/ 8200

T

M

o r q u e

a s T e r

r

esIdenTIal

s

l

Tandard

IfT

I

I

nsTallaTIon

nsTrucTIons

M

anual

PLEASE DO NOT RETURN THIS PRODUCT

TO THE STORE

If you need assistance, please call 1-866-

569-3799 (press Option 1) and follow the

prompts to contact a customer service

representative. They will be happy to handle

any questions that you may have.

©Copyright 2017

Wayne Dalton, a division of Overhead Door Corporation

P

®

l u s

a

o

'

nd

wner

s

T a b l e O f C o n t e n t s

®

IMPORTANT NOTICES!

To avoid possible injury, read and fully understand the enclosed

instructions carefully before installing and operating the garage door. Pay

close attention to all warnings and notes. After installation is complete,

fasten this manual near garage door for easy reference.

This Installation document is available at no charge from:

- Your local Wayne Dalton Sales Center, or

- Online at www.Wayne-Dalton.com, or

- By mailing to: Wayne Dalton, a division of Overhead Door Corporation, P.O. Box

67, Mt. Hope, OH., 44660

Part Number

346450

2

2

2

3

4

4

5

6

10

16

16

16

16

18

18

18

18

18

20

REV12_04/25/2017

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Wayne-Dalton 8000

-

Page 1: Table Of Contents

Models 8000 / 8100 T a b l e O f C o n t e n t s Pre-Installation / 8200 Important Safety Instructions Removing an Existing Door and Preparing the Opening Package Contents Door Section Identification Tools Required ®... -

Page 2: Pre-Installation

Existing Door & Prepar- proper tools and instructions. ing the Opening. These are available for download at www.Wayne-Dalton.com or at your local Wayne Dalton Sales Center. 12. On electrically operated doors, pull down ropes must be removed and locks must be removed or made inoperative in the open (unlocked) position. -

Page 3: Package Contents

12” to 18” apart. FOR FULLY ADJUSTABLE TRACK: For the header, align the weatherstrip 1/8” to 1/4” inside the header edge, and temporarily secure it to the header with equally spaced nails. Starting at either side of the jamb, fit the weatherstrip up tight against the temporarily attached Quick Install flag angles RH/LH (as required) Fully Adjustable flag angles RH/LH (as required) weatherstrip in the header and 1/8”... -

Page 4: Door Section Identification

Ratchet wrench Tape measure Pliers / Wire cutters Flat tip screwdriver (2) 3/8”-16 x 3/4” 1/4”-14 x 5/8” Self tapping (2) 5/16”-18 x 3/4” Truss head bolts screws (as required) Carriage bolts 3” Ratchet Sockets: 7/16”, Wrenches: 3/8”, 7/16”, 1/4” - 20 x 2-1/2” Carriage bolts (lift handles) Phillips head screwdriver extension 1/2”, 9/16”, 5/8”... -

Page 5: Breakdown Of Parts

BREAKDOWN OF PARTS NOTE: The illustrations shown on this page are general representations of the door parts. Each specific door models may have unique variations. Top of vertical Top of vertical track track B2. (Fully Adjustable 3rd hole Feature) B1. (Quick hole set Install Feature) -

Page 6: Door Installation Instructions

DOOR INSTALLATION INSTRUCTIONS Left hand Before installing your door, be certain that you have read and followed all of the instruc- flag angle tions covered in the pre-installation section of this manual. Failure to do so may result in an improperly installed door. - Page 7 BS = Bottom Section Left hand cable drum assembly I2 = Intermediate Section #2 LS = Lock Section ES = Every Section gets a strut. Strutting Schedule For Models 8000 and 8100 Counterbalance Counterbalance lift cable lift cable Door Heights...

- Page 8 NOTE: Depending on your door some sections may or may not require a strut to be installed Outside lift onto the section. handle 1/4”-20 x 7/8” Self drilling Outside of screws lock section 20” Minimum to Outside of Center 30” Maximum bottom stile(s) section...

- Page 9 Vertical Vertical track track Intermediate section Flag angle Lock Vertical 5/16” x 1-5/8” section track Lag screws assembly Jamb 12R FA 15R FA 12R QI 15R QI bracket Flag angle lag screw locations 3/8” to 5/8” Spacing Track Bottom rollers Bottom section section Vertical track...

-

Page 10: Counterbalance Installation Instructions

Horizontal Door width track angle + 3-3/8” to 3-1/2” Level Horizontal Top of flag track angle Nail Top section Horizontal Level track angle 1-11/16” Horizontal to 1-3/4” track Adjusting Top Fixtures Flag angle Flag angle assembly section With horizontal tracks installed, you can now adjust the top fixtures. Vertically align the top section of the door with the lower sections. - Page 11 FOR SINGLE SPRING APPLICATIONS: Insert the idler bracket into the left hand cable drum. Shake the TorqueMaster ® spring tube assembly gently to extend the winding shafts out about 5” on each side. For single spring applications, there will be no left hand spring in the Lightly press the idler bracket into the cable drum until two distinct clicks are heard, or the TorqueMaster ®...

- Page 12 Right hand 5/16” x 1-5/8” Right cable drum Lag screw Intermediate section hand end bracket 5/16” Washer Locking pliers attached 5/16” Vertical Vertical to inner and outer rail Hex nut Lock TorqueMaster ® track of vertical track track section spring tube assembly 5/16”...

- Page 13 Counterbalance WARNING Left hand lift cable end bracket IT IS RECOMMENDED THAT LEATHER GLOVES BE WORN WHILE WINDING Marks SPRINGS. FAILURE TO WEAR GLOVES MAY CAUSE INJURY TO HANDS. NOTE: A 3” ratchet extension is recommended for added clearance from the horizontal track angle.

- Page 14 were temporarily attached in Preparing the Opening, in the pre-installation section of this WARNING manual. NOTE: When permanently attaching the weatherstrips to the jambs, avoid pushing the weath- MAKE SURE BACK HANGS ARE BRACED SUFFICIENTLY TO RESIST ANY erstrips too tightly against the face of door. MOTION DURING SPRING APPLICATION AND DOOR TRAVEL.

- Page 15 Ratchet wrench Pawl knob in lower position 3” Ratchet Pawl Winding extension shaft Pawl Pawl knob in End bracket upper position 5/8” Socket Ratchet wheel...

-

Page 16: Optional Installation

Optional Installation TorqueMaster Plus Reset Instructions ® IMPORTANT: TO AVOID POSSIBLE INJURY, HAVE A TRAINED DOOR SYSTEMS TECHNICIAN MAKE ADJUSTMENTS/ REPAIRS TO COUNTERBALANCE LIFT CABLES, SPRING ASSEMBLIES AND OTHER HARDWARE. Ratchet Cable Cable pawl drum drum IMPORTANT: THE DRAWBAR OPERATOR FORCE SETTINGS MUST BE ADJUSTED AC- Side CORDING TO THE MANUFACTURER’S INSTRUCTIONS. - Page 17 No. 6 Screw eye Typical bottom corner bracket 48” to 50” From floor Pull down rope Pull down rope...

-

Page 18: Maintenance

Wayne Dalton, a division of Overhead Door Corporation, P.O. Box Cleaning Your Garage Door 67, Mt. Hope, OH., 44660, or at www.Wayne-Dalton.com. For additional information on garage door/operator maintenance go to www.dasma.com and reference TDS 151, 167 and 179. - Page 19 Wayne Dalton 2501 S. State Hwy 121 Bus., Suite 200 Lewisville, TX 75067 For service, call (800) 827-3667 www.Wayne-Dalton.com SAFETY INSTRUCTIONS 1. Operate door ONLY when it is properly adjusted and free of obstructions. 2. If a door becomes hard to operate,...

-

Page 20: Warranty

Models 8000, 8100, 8200 Wayne Dalton, a division of Overhead Door Corporation ("Seller") warrants to the original purchaser of the Models 8000, 8100, 8200 (“Product”), subject to all of the terms and conditions hereof, that the Product and all components thereof will be free from defects in materials and workmanship for the following period(s) of time,... - Page 22 Thank you for your purchase. PLEASE DO NOT RETURN THIS PRODUCT TO THE STORE If you need assistance, please call 1-866-569-3799 (press Option 1) and follow the prompts to contact a customer service representative. They will be happy to handle any questions that you may have.

Need help?

Do you have a question about the 8000 and is the answer not in the manual?

Questions and answers