Summary of Contents for Parker mSR080

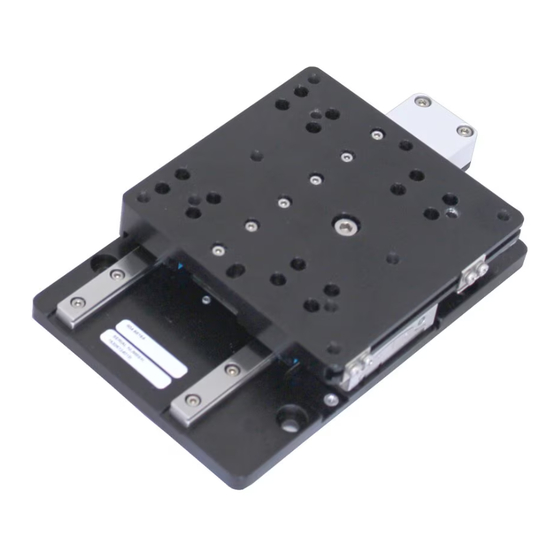

- Page 1 MANUAL NO. 102-6195-01 REV E User Information Guide EFFECTIVE : 11/16/22 SUPERCEDES : 6/1/20 mSR080...

- Page 2 User Information Guide For assistance contact: Parker Hannifin Corporation Electro Mechanical Division 1140 Sandy Hill Road Irwin , PA 15642 Ph 724-861-8200 800-245-6903 E-mail : emn_applications@parker.com www.parkermotion.com WWW.PARKERMOTION.COM PH: (724)-861-8200...

-

Page 3: Table Of Contents

User Information Guide MSR Series Product Manual TABLE OF CONTENTS Introduction………………………………….………………………………………………………….5 General Information…………………………………………………………………….…5 Return….………………………………………………………………………………….5 Repair……………………………………………………………………………………..5 Unpacking and General Installation.………………………………….……………………………..6 Warnings and Precautions………….………………………………………………………………….7 Specification Conditions….………….…………………………………………………………………8 Environmental Specifications.…….…………………………………………………...…8 Mounting Requirements .….…………..……………….…………………………….…..8 Specifications………………. ……….………………………………………………………………….9 Part Number Nomenclature ……….…………………………………………………………………11 Electrical Specifications…………….……………..………………………………………………….12 Standard Cabling and Wiring Diagrams……………………………………………………………..13 Dimensional Drawings…………………………………………………………………………………14 Assembly Diagram……………………………………………………………………………………..15 Optical Encoder Limits………………………………………………………………………………..16... - Page 4 User Information Guide REVISON NOTES REV - INITIAL RELEASE 5/15/15. REV 1 PG 8 - CHANGE TRANSPORT TEMPERATURE TO 0 TO +40 (WAS -20 TO +60) REV 2 Updated mounting information P 14 REV C - p14 - Base Dowel Pin corrected to Slip Fit REV D - updated compliance information REV E–...

-

Page 5: Introduction

(≤ 8 kg). General Information Thank you for your interest in the products and systems offered by Parker Hannifin Electromechanical Automation Division. Our products and systems are recognized around the world for their functionality, performance, and reliability. -

Page 6: Unpacking And General Installation

DO NOT drill holes into the positioner. Drilling holes into the positioner can generate particles and machining forc- es that may effect the operation of the positioner. Parker will drill holes if necessary; contact your local authorized distributor. -

Page 7: Warnings And Precautions

User Information Guide Warnings and Precautions Hot Surfaces DO NOT touch motor coils located in the positioner after high duty operation. Motor temperature may approach 60°C. The unit itself may become warm or hot to the touch. Electrical Shock DO NOT take apart or touch any internal components of the positioner while unit is plugged into an elec- trical outlet. -

Page 8: Specification Conditions

User Information Guide Specification Conditions EnvironmentalÊSpecifica ons Storage and Transport Temperature Range -10 to +60 Degree C. Storage and Transport Humidity Range 10 - 95% Non Condensing Opera on Temperature to Achieve Specifica ons 20 Degrees C +/- 1 degree C Opera on Temperature range for basic mo on ¹... -

Page 9: Specifications

User Information Guide Specifications Specifica ons Units Travel Size (WxH) 80 x 25 80 x 25 80 x 25 80 x 25 80 x 25 Normal Load Con nuous Thrust Peak Thrust (Max) Duty Cycle Accelera on (Max– no load) Rated Bus Voltage Volts DC Standard grade... - Page 10 User Information Guide mSR080 Specifica ons (Travel & Encoder Dependent) TravelÊ(mm) Specifica on Units Magne cÊEncoderÊ-1ÊMicronÊResolu on Max.ÊSpeed mm/s 1100 1500 2000 2000 2000 Bi-direc onalÊ μm ±5.0 Repeatability Posi onalÊAccuracy μm Op calÊEncoder-Ê1ÊMicronÊResolu on Max.ÊSpeed mm/s 1100 1500 2000...

-

Page 11: Part Number Nomenclature

User Information Guide Part Number Nomenclature mSR 080 Part Number Example: WWW.PARKERMOTION.COM PH: (724)-861-8200... -

Page 12: Electrical Specifications

User Information Guide Electrical Specifications 4ÊPole 8ÊPole MotorÊSpecifica ons Units (CSÊOp on) (CDÊOp on) Magne c Pitch Con nuous Force¹ Peak Force Con nuous Current¹ A(rms) Peak Current²˒³ A(rms) Voltage Constant²˒³ Volts/m/s Force Constant² N/A(rms) 5.51 5.51 Resistance² Ohms Inductance⁴ Max Bus Voltage Thermal Resistance C/Wa... -

Page 13: Standard Cabling And Wiring Diagrams

User Information Guide Op cal Encoder Func on Signal PinÊ# 5 Volts DC Power Ground Incremental Signals Reference Mark Posi ve Limit Limits Nega ve Limit Setup (Used in installa on) Magne c Encoder Error Output Func on Signal PinÊ# 5 Volts DC Power Ground... -

Page 14: Dimensional Drawings

User Information Guide Dimensional Drawings- mSR080 - mm Configuration Bolt size mSR80—mSR80 M4 x 0.7 x 8 mSR80—mSR100 M4 x 0.7 x 8 Moun ngÊRequirements Hardware SCH M4x8 4 mm Slip Fit of Dowel Pin (2X Hole) TorqueÊ 30 in-lbs WrenchÊSize... -

Page 15: Assembly Diagram

User Information Guide Assembly Diagram - mSR080 WWW.PARKERMOTION.COM PH: (724)-861-8200... -

Page 16: Optical Encoder Limits

Setting the Optical Encoder Limits The mSR080 with the op cal encoder op on comes equipped with adjustable end of travel limit sensors. The sensors are ac vated by two magne c targets on the side of the stage as shown in image #1 below. -

Page 17: Magnetic Encoder Limits

Setting the Magnetic Encoder Limits The mSR080 with the magne c encoder op on comes equipped with adjustable end of travel limit sensors and a home sensor. The sensors are ac vated by magne c targets on the side of the stage as shown in image #2 below. -

Page 18: Part And Serial Number Location

User Information Guide Part and Serial Number Location The mSR 80 part number and serial number can be located at the nega ve end of travel, be- tween the square rail bearings. Caution and Warning Label The mSR Cau on and Warning label is located on the motor phase an hall cable (9 pin D-Sub), as pictured below. -

Page 19: Maintenance And Life Expectancy

Maintenance and Life Expectancy Maintenance: The mSR080 is designed to be a maintenance free device. The drive train is a non-contact linear motor and does not need maintenance of any kind. The linear bearings are designed with internal lubricators which provide lubrication of the bearings for the life of the stage. -

Page 20: Compliance Documents

User Information Guide Compliance Documents WWW.PARKERMOTION.COM PH: (724)-861-8200... -

Page 21: Ce Declaration Of Conformity

User Information Guide WWW.PARKERMOTION.COM PH: (724)-861-8200... -

Page 22: Notes

User Information Guide Notes WWW.PARKERMOTION.COM PH: (724)-861-8200... - Page 23 User Information Guide WWW.PARKERMOTION.COM PH: (724)-861-8200...

Need help?

Do you have a question about the mSR080 and is the answer not in the manual?

Questions and answers