Table of Contents

Advertisement

Quick Links

D-103920 / Rev. 1 / 2020-02-06

Operating Manual

SERIES LIMAX2

Magnetic Absolute Shaft Information System for Elevators

(Translation of the original operating manual)

Robust measuring principle for usage in rough environments

Insensitive against dirt, smoke and humidity

Simple and flexible installation

High accuracy and reproducibility

Absolute position measurement with a length up to 260 m

Resolution up to 1 mm, higher resolution on request

Absolute position is always directly available

no referencing even after long power failure

Compatible with many established controls with absolute encoder interface

Available interfaces:

SSI, CAN, CANopen (DS406, DS417), RS422, RS232, PROFIBUS

Advertisement

Table of Contents

Summary of Contents for ELGO Electronic LIMAX2 Series

- Page 1 D-103920 / Rev. 1 / 2020-02-06 Operating Manual SERIES LIMAX2 Magnetic Absolute Shaft Information System for Elevators (Translation of the original operating manual) Robust measuring principle for usage in rough environments Insensitive against dirt, smoke and humidity Simple and flexible installation ...

- Page 2 Publisher ELGO Batscale AG Föhrenweg 20 FL-9496 Balzers Technical Support +49 (0) 7731 9339 - 0 +49 (0) 7731 2 88 03 support@elgo.de Document- No. D-103920 Document - Name LIMAX2-00-MA-E_06-20 Article Number 799000350 Document- Revision Rev. 1 Issue Date 2020-02-06 Copyright...

-

Page 3: Table Of Contents

Contents 1 Contents Contents ..................... 3 List of Figures ..................5 List of Tables ..................5 General ....................6 Information Operating Manual ................6 Explanation of Symbols ..................6 Statement of Warranties ..................7 Demounting and Disposal ..................7 Safety ....................8 General Causes of Risk .................. - Page 4 Contents Connections and Interfaces ............. 22 10.1 LED’s (Operating status and notices) ..............24 10.2 CAN Interface ....................24 10.3 SSI Interface ..................... 31 10.4 RS232 / RS422 / RS485* ................... 32 10.5 Option Unguided ..................... 35 10.6 Option PROFIBUS Interface ................36 Disturbances, Maintenance, Cleaning ..........

-

Page 5: List Of Figures

Contents 2 List of Figures Figure 1: Sensor Construction ........................11 Figure 2: Dimensions Sensor Standard ..................... 12 Figure 3: Dimensions Sensor Option unguided ..................13 Figure 4: Dimensions Sensor Option PNO ....................13 Figure 5: Dimensions Magnetic Tape ....................... 14 Figure 6: Installation with tension weight .................... -

Page 6: General

General 4 General 4.1 Information Operating Manual This manual contains important information regarding the handling of the device. For your own safety and op- erational safety, please observe all safety warnings and instructions. Precondition for safe operation is the compliance with the specified safety and handling instructions. Moreover, the existing local accident prevention regulations and the general safety rules at the site of operation have to be observed. -

Page 7: Statement Of Warranties

General Statement of Warranties The statement of warranties is enclosed separately in the sales documents. Guarantee The producer guarantees the functional capability of the process engineering and the selected parameters. The period of warranty is one year and begins with the date of delivery. 4.4 Demounting and Disposal Unless acceptance and disposal of returned goods are agreed upon, demount the device considering the safety instructions of this manual and dispose it with respect to the environment. -

Page 8: Safety

Safety 5 Safety CAUTION! Please read the operating manual carefully, before using the device! Observe the installation instructions! Only start up the device if you have understood the operating manual. The operating company is obliged to take appropriate safety measure. The initial operation may only be performed by qualified and trained staff. -

Page 9: Conventional Use

Safety Conventional Use The product described in this manual was developed to execute safety-related functions as a part of an entire assembly or machine. It is the responsibility of the manufacturer of a machine or installation to ensure the prop- er operation of the system. -

Page 10: Transport And Storage

Transport and Storage 6 Transport and Storage Safety Instructions for Transport, Unpacking and Loading CAUTION! Transport the package (box, palette etc.) professionally. Do not throw, hit or fold it. Handling of Packaging Material Notes for proper disposal: 4.4 Inspection of Transport Check the delivery immediately after the receipt for completeness and transport damage. -

Page 11: Product Features

Product Features 7 Product Features LIMAX2 is an absolute measuring shaft information system that is used for positioning of elevator cars. It consists of only two components: sensor and magnetic band. A big advantage of the system is the simple and flexible installation. The assembly of the system components is very simple and can be performed by specialists in less than an hour. -

Page 12: Technical Data

Technical Data 8 Technical Data Identification The type label serves for the identification of the unit. It is located on the housing of the sensor and gives the exact type designation (=order reference, see type designation) with the corresponding part number. Furthermore, the type label contains a unique, traceable device number. -

Page 13: Dimensions Sensor Option Unguided

Technical Data Dimensions Sensor Option unguided Figure 3: Dimensions Sensor Option unguided Dimensions Sensor Option PNO 41,5 32,5 13,5 Figure 4: Dimensions Sensor Option PNO - 13 -... -

Page 14: Dimensions Magnetic Tape

Technical Data Dimensions Magnetic Tape Scale 5:1 Figure 5: Dimensions Magnetic Tape Technical Data Sensor LIMAX2 (Standard version) Mechanical Data Measuring principle absolute Repeat accuracy ±1 Increment System accuracy in µm at 20°C ±(1000 + 50 x L) L = measuring length in meter Distance sensor - magnetic tape max. -

Page 15: Technical Data Magnetic Tape

Technical Data Technical Data Magnetic Tape The magnetic tape consists of two components: The actual magnetic tape which carries the position information A mechanical stainless steel back iron TEMPLATE Magnetic Tape AB20-80-10-1-R-D-15-BK80 Coding absolute, single track system Pole pitch 8 mm Operation temperature installed −20 …... -

Page 16: Installation And First Start-Up

Installation and First Start-Up 9 Installation and First Start-Up CAUTION Please read the operating manual carefully before using the device! Strictly observe the Instal- lation instructions! In case of damage caused by failure to observe this operating manual, the warranty expires. ELGO is not liable for any secondary damage and for damage to persons, property or assets. -

Page 17: Description Installation Of The Sensor

Installation and First Start-Up Description installation of the Sensor 9.2.1 Installation Principe Upper tape fixation Upper tape fixation Sensor Sensor Magnetic tape Magnetic tape Guide rail Guide rail Sway guard Spring Tension weight Figure 6: Installation with tension weight Figure 7: Installation with dowel and spring LIMAX2 can be installed at any position in the shaft, depending on spatial conditions and layout of the particular elevator installation. -

Page 18: Description Installation / Mounting Of The Magnetic Tape

Installation and First Start-Up 9.2.2 Installation of the Sensor The sensor is fixated on the cabin or on the car frame. The mounting position is basically determined by the condition. The integrated mounting notches on the housing of the sensor head allow for a very simple and self- explanatory installation from three sides. - Page 19 Installation and First Start-Up 9.3.2 Installation Concept 9.3.2.1 Basic Principle for the Mounting NOTE! The magnetic tape itself is not designed to withstand excessive mechanical wear. It is there- fore important to ensure that the system is installed such that the mechanical contact between tape and sensor head is mainly between the steel tape and the polymer sensor guide.

- Page 20 Installation and First Start-Up 9.3.3 Installation Procedure Attach the top end of the tape in the shaft head. Ideally use an ELGO Mounting Kit. Check for correct orientation of the tape. The arrows on the magnetic side must point in upward direction. Shaft head Shaft pit Figure 10: Correct orientation of the magnetic tape...

- Page 21 Installation and First Start-Up Adjust now the distance between sensor and tape. Up to a travel height of 50 m we recommend an offset of at least 15 mm. This will ensure steady contact between steel side of the band and the polymer guide of the sensor.

- Page 22 Installation and First Start-Up IMPORTANT: Installation check! Values for tape tension and offset between tape and sensor are guidelines based on experience. But in any case, a proper check after installation is mandatory. It must absolutely be avoided that the magnetic side constantly grinds on the sensor body during operation.

- Page 23 Installation and First Start-Up NOTE! Be specifically alert if steel construction work is taking place in the shaft. Steel particles re- leased by grinding, welding or such work will adhere to the magnetic tape. The tape is in- sensitive to fine metal dust. However, coarser metal chips can cause problems. Clean this debris off instantly.

-

Page 24: Connections And Interfaces

Connections and Interfaces 10 Connections and Interfaces 10.1 LED’s (Operating status and notices) The LED’s located on the front serve for monitoring of operating conditions. With startup it has to be ensured that the yellow LED illuminates as this monitors the internal supply voltage. Figure 15: LED signals on the upper side of the sensor YELLOW Supply voltage... - Page 25 Connections and Interfaces ABS-Position Speed Figure 16: Protocol CAN standard 10.2.2 CANopen DS 406 and DS417 For LIMAX2 the CANopen Interfaces DS406 (encoder profile) und DS417 (lift profile) are available. These inter- faces are configured by default as follows: Table 2: Configuration of CANopen DS406 CANopen DS406 Bit rate 250 kbit/s...

- Page 26 Connections and Interfaces 10.2.3 Pin Assignment CAN Table 4: Pin Assignment CAN 9-pin D-SUB connector Open cable exit PIN-No. Function Color Function Pin 6 0 V / GND White 0 V / GND Pin 9 + 24 VDC Brown + 24 VDC Pin 2 CAN L Green...

- Page 27 Connections and Interfaces 3. If the setting should be maintained in the case of a power failure, the changes have to be saved, as described in section ( 10.2.5). 10.2.4.4 Setting the Sending Cycle for the Position Data The position data are sent cyclically by the device, therefore the device has to be in the Operational Mode ( 10.2.6.1).

- Page 28 Connections and Interfaces CANopen Master device Saving all parameters DLC: XXX = 600h + node-ID Example: 604h for the device node-ID 4 Acknowledgment of the CANopen device DLC: XXX = 580h + node-ID Example: 584h for the device with node-ID 4 Figure 21: Saving the parameters 10.2.6 Changing the Operating Modes 10.2.6.1 Changing the device into the Operational Mode...

- Page 29 Connections and Interfaces 10.2.6.3 Changing the device into the Stopped Mode Bus sharing units in the Stopped Mode are passive participants. In this mode all the communication is turned off, except the monitoring activity (e.g. heartbeat). The following CAN-message causes the change of all CANopen participants into the Stopped Mode: CANopen Master device...

- Page 30 Connections and Interfaces ATTENTION! During the saving procedure the device is not accessible over a period of a few milliseconds. 10.2.8 Setting the Baud Rate 1. Change the device into the Stopped mode ( 10.2.6.3) 2. Change the device into the LSS Configuration Mode ( 10.2.7.1) 3.

-

Page 31: Ssi Interface

Connections and Interfaces 10.3 SSI Interface 10.3.1 Function Principle If the clock is not interrupted for the time Tm-T/2 (output of further 25 periods), the shift register clocks once again the same data value (error recognition in the evaluation). Some encoders contain a Power Failure Bit (PFB). -

Page 32: Rs232 / Rs422 / Rs485

Connections and Interfaces 10.4 RS232 / RS422 / RS485* *) Attention: RS485 only unidirectional If the measuring system is equipped with an RS232, RS485 or RS422 interface, the data communication has the following format: 19200 baud (other baud rates on request) 1 Start bit 8 data bits 1 stop bit... - Page 33 Connections and Interfaces 10.4.3 Command Descriptions Important: Before you send a new message to the LIMAX2 wait for the answer first. After allocating a new address the LIMAX2 answers in max. 0.5 seconds. In other cases it even in a few milliseconds. After this time it is not expected to get an answer (transmission error).

- Page 34 Connections and Interfaces 10.4.3.5 Error Messages If one of the described operations failed for some reason LIMAX2 gives an error message with a respective error- code. Answer from LIMAX2 = Error-Code (04h – 0Ah) error – codes are listed at the next page. Table 8: Error-codes of an addressable LIMAX2 Code Meaning...

-

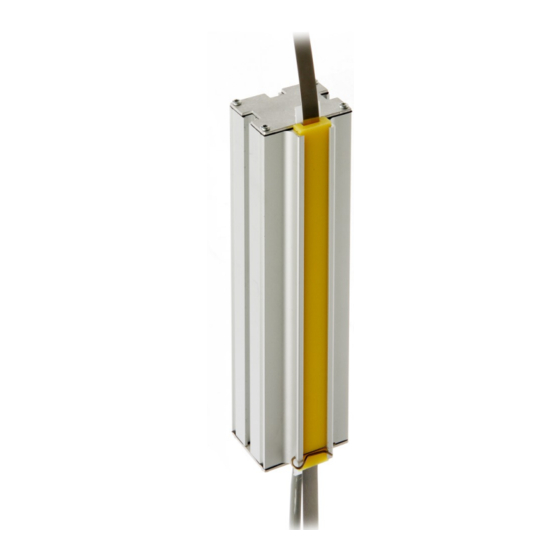

Page 35: Option Unguided

Connections and Interfaces 10.4.3.6 Connection to a RS422 Master LIMAX2 LIMAX2 Figure 32: Connection to a RS422 Master 10.5 Option Unguided LIMAX2 "unguided" is an absolute measuring system, which is used for positioning in the most diverse areas horizontally and vertically. It consists of only two components: magnetic tape and the sensor. Figure 33: LIMAX2 Option unguided - 35 -... -

Page 36: Option Profibus Interface

Connections and Interfaces 10.6 Option PROFIBUS Interface 10.6.1 LED’s (Operation Status and Messages) The LED’s located on the top side, a green LED (Bus Run) and a red LED (Bus Fail), serve for monitoring of op- erating status. For setting the address are two rotary coding switches located on the top next to the LED’s BUS RUN GREEN ... - Page 37 Connections and Interfaces 10.6.2.3 PROFIBUS Interface The sensor option profibus is fitted as standard with a profibus interface according to IEC61158 / IEC61784. The following parameters are specified. Table 10: Parameter PROFIBUS Interface PROFIBUS Interface Transmission RS485 two-wire line Wire length 1200 m at 9,6 kBaud 200 m at 1,5 MBaud 100 m at 12 MBaud...

-

Page 38: Disturbances, Maintenance, Cleaning

Disturbances, Maintenance, Cleaning 11 Disturbances, Maintenance, Cleaning This chapter describes possible causes for disturbances and measures for their removal. In case of increased disturbances, please follow the measures for fault clearance in chapter 11.1. In case of disturbances that cannot be eliminated by following the advice and the fault clearance measures given here, please contact the manufacturer (see second page). -

Page 39: Maintenance

Disturbances, Maintenance, Cleaning 11.3 Maintenance The LIMAX2 shaft information system requires little maintenance. On the occasion of regular elevator inspection and maintenance do the following: Optical inspection of proper alignment between sensor and band. Worn off material indicates possible alignment flaws. Check ... -

Page 40: Type Designation

Type Designation 12 Type Designation LIMAX2 1000 CO0T Series / Type: LIMAX2 = LIMAX02 (1-Kanal) SN-number: = standard version = special version Signal cable length: = 3,0 m (Standard) = 5,0 m Other on request Resolution: 62N5 = 62,5 µm = 0,0625 mm 0125 = 125 µm = 0,125 mm 0250... -

Page 41: Control Specific Sensors

Type Designation 12.1 Control specific Sensors Table 14: Control specific Sensors Product key Control type LIMAX2-00-030-0500-CO1TG-D9M Böhnke bp306/bp308 (CANopen CiA 417) - terminated LIMAX2-00-030-0500-CO1G-D9M Böhnke bp306/bp308 (CANopen CiA 417) - not terminated LIMAX2-00-030-62N5-SSG0-D9M1 NEWLift FST2 LIMAX2-00-030-1000-SSB0 KW Aufzugstechnik David 606 LIMAX2-00-030-1000-CO0 LIMAX2 with CANopen encoder profile DS406 LIMAX2-14-030-1000-SSBX... -

Page 42: Accessories

12.2 Accessories Table 15: Accessories Order Designation Description Image AB20-80-10-1-R-D-15-BK80 Magnetic Tape Guidance LIMAX2 complete Polymer guide rail with underlay and safety splint Installation kit LIMAX MKF Mounting set for suspended installation with dowel. Installation kit LIMAX MKB Mounting set for suspended installation with guiding rails and rail holder. -

Page 43: Index

Index 13 Index Accessories ............. 42 Maintenance ..........38, 39 Accident prevention regulations......6 Operating area ..........16 CAN Interface and Protocols ......24 Operational safety ..........6 Causes of risk ............ 8 Option Profibus Interface ......... 36 Cleaning ........... 38, 39 Order reference .......... - Page 44 F ö h r e n w e g 2 0 , F L - 9 4 9 6 B a l z e r s Subject to change - © 2020 Tel.:+423 (0) 380 02 22, Fax.:+423 (0) 380 02 24 Internet: www.elgo.li, Mail: info@elgo.li ELGO Electronic GmbH & Co. KG - 44 -...

Need help?

Do you have a question about the LIMAX2 Series and is the answer not in the manual?

Questions and answers