Table of Contents

Advertisement

Water Specialist

WS2H, WS2HF, and WS3

Control Valve Manual

WARNING: USE ONLY SILICONE-BASED LUBRICANTS ON ALL CLACK CORPORATION COMPONENTS

HYDROCARBONS WILL DAMAGE COMPONENTS THAT CONTAIN O-RINGS AND OR PLASTIC. THIS CAN CAUSE

LEAKS OR BREAKAGE. DO NOT USE LUBRICANTS THAT CONTAIN HYDROCARBONS SUCH AS VASELINE®/

PETROLEUM JELLY, WD-40®, ETC. DO NOT USE CLACK CONTROL VALVE PRODUCTS ON WATER SUPPLIES THAT

CONTAIN HYDROCARBONS, SUCH AS BENZENE, GASOLINE, KEROSENE, ETC.

Advertisement

Table of Contents

Summary of Contents for Water Specialist WS2HF

- Page 1 Water Specialist WS2H, WS2HF, and WS3 Control Valve Manual WARNING: USE ONLY SILICONE-BASED LUBRICANTS ON ALL CLACK CORPORATION COMPONENTS HYDROCARBONS WILL DAMAGE COMPONENTS THAT CONTAIN O-RINGS AND OR PLASTIC. THIS CAN CAUSE LEAKS OR BREAKAGE. DO NOT USE LUBRICANTS THAT CONTAIN HYDROCARBONS SUCH AS VASELINE®/ PETROLEUM JELLY, WD-40®, ETC.

- Page 2 Page 2 WS2H, WS2HF, and WS3 Manual...

-

Page 3: Table Of Contents

Drive Cap Assembly, Downfl ow Piston, Regenerant Piston, Spacer Stack Assembly, Drive Back Plate, Main Body and Meter ......46 Inline Flow Meter Assembly ..................47 WS2H, WS2HF, and WS3 Brine Valve Body and Injector Components ....48 Standard Injector Graphs ..................49 Bases ........................51 Drain Line Flow Controls .................. -

Page 4: General Specifications And Pre-Installation Checklist

WS2H Valve: 125 gpm (473 lpm, 28.4 m /h) @ 15 psig (103 kPa) drop Service fl ow rate WS2HF Valve: 165 gpm (625 lpm, 37.5 m /h) @ 15 psig (103 kPa) drop WS3 Valve: 250 gpm (946 lpm, 56.8 m /h) @ 15 psig (103 kPa) drop WS2H Valve: 125 gpm (473 lpm, 28.4 m... -

Page 5: Wiring For Custom Power Adapter

WS2H, WS2HF, and WS3 Manual Page 5 WIRING FOR CUSTOM POWER ADAPTER Pin 1 1. Cable should be one unshielded pair of 22AWG, UV resistant Black wire UL2464 compliant wire. 2. Connector details: a. Terminate end with one Hirose black housing, P/N DF3-4S-2C and four Hirose pins, P/N DF3-22SC. -

Page 6: Main Pc Board

Page 6 WS2H, WS2HF, and WS3 Manual MAIN PC BOARD POD Display Connection Power Supply Programming Port COMM IN Flow Meter AUX Input COMM OUT Battery USB Port Drive Motor Expansion port 1 Expansion port 2 AUX Drive Motor Bypass Motor... -

Page 7: Typical System Examples

WS2H, WS2HF, and WS3 Manual Page 7 TYPICAL SYSTEM EXAMPLES Twin Tank System, Simple Alternator (Sharing a MAV) System consists of 2 power heads, 1 communication cable and 1 MAV Electrical Connections: • The MAV’s motor wire is connected to the 2-pin connector labeled BYPASS on Unit 2 (Unit B) PC board •... - Page 8 Page 8 WS2H, WS2HF, and WS3 Manual TYPICAL SYSTEM EXAMPLES (CONTINUED) Multi-tank System, 3 Unit shown System consists of 3 power heads, 2 communication cables and 3 No Hard Water Bypass (Isolation) valves Electrical Connections: • Each unit’s isolation valve motor wire is connected to the 2-pin connector labeled BYPASS on each unit’s PC board.

-

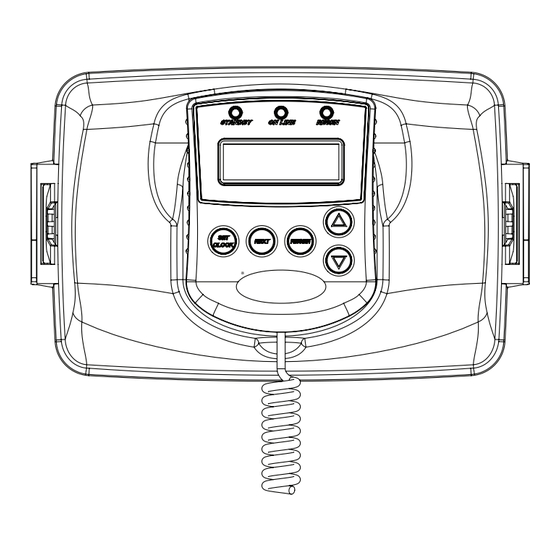

Page 9: Button Function And Programming Key Sequence

WS2H, WS2HF, and WS3 Manual Page 9 BUTTON FUNCTION AND PROGRAMMING KEY SEQUENCE STANDBY ON LINE REGEN Standby LED Online LED Regen LED • Signals that a unit • Signals that a unit is • Signals that a unit is... -

Page 10: Programming Quick Reference

Page 10 WS2H, WS2HF, and WS3 Manual PROGRAMMING QUICK REFERENCE Recommended System Setup Sequence 1. Connect all wiring and communication cables. 2. Apply power. 3. Select System Setup from the Main Setup Menu. 4. Select the correct language to use in System Setup 1. - Page 11 WS2H, WS2HF, and WS3 Manual Page 11 PROGRAMMING QUICK REFERENCE List Of Error Codes Code Description 1001 No Encoder Pulses 1002 Unexpected Stall, Main Drive 1003 Run Time Too Long, Main Drive 14001 Message Queue Full 15003 Run Time Too Long, Bypass Drive...

-

Page 12: Typical User Screens

Page 12 WS2H, WS2HF, and WS3 Manual TYPICAL USER SCREENS USER 1 - Capacity Remaining USER 1 • Displays the units current capacity remaining • This screen does not display on units with volumetric capacity turned off • Can be manually decremented by holding the down arrow... - Page 13 WS2H, WS2HF, and WS3 Manual Page 13 TYPICAL USER SCREENS (CONTINUED) USER 6 – Flow Rate, System USER 6 • Displays the current combined fl ow rate of all the units in the system • This screen does not display on single tank units, or systems with volumetric capacity turned USER 7 –...

-

Page 14: Setting Time Of Day And Date

Page 14 WS2H, WS2HF, and WS3 Manual SETTING TIME OF DAY AND DATE SET TIME AND DATE Accessed by pressing Set Clock while in the User Screens. Use UP or DOWN arrows to scroll through the available settings. RETURN TO... -

Page 15: Main Menu

WS2H, WS2HF, and WS3 Manual Page 15 MAIN MENU SCREEN Accessed the Main Menu is done by pressing NEXT and DOWN simultaneously for >3 seconds while in one of the user screens. INSTALLER SETUP - Setup items under the Installer Setup Screens section... -

Page 16: System Setup Screens

Page 16 WS2H, WS2HF, and WS3 Manual SYSTEM SETUP SCREENS Accessed by pressing NEXT and DOWN simultaneously for >3 seconds and selecting SYSTEM SETUP from the Main Menu. On multi-unit systems only program the main valve number one or the LEAD unit. - Page 17 WS2H, WS2HF, and WS3 Manual Page 17 SYSTEM SETUP SCREENS (CONTINUED) • Delayed systems will fl ag “lead” units based on “lag” capacity, but will not alternate with remaining capacity until the next available delayed time. - Day over ride •...

- Page 18 Page 18 WS2H, WS2HF, and WS3 Manual SYSTEM SETUP SCREENS (CONTINUED) Separate Source • Each unit has isolation to control system operation and will not supply service water during regeneration • Drive timing will keep units isolated through the entire regeneration sequence Simple Alt Sharing MAV •...

- Page 19 WS2H, WS2HF, and WS3 Manual Page 19 SYSTEM SETUP SCREENS (CONTINUED) SYSTEM SETUP 9 - Regeneration control SYSTEM SETUP 9 Delayed 1 – 4 • Delays regeneration of units upon reaching 0 gallons capacity • Allows setting of up to 4 regeneration windows per day •...

- Page 20 Page 20 WS2H, WS2HF, and WS3 Manual SYSTEM SETUP SCREENS (CONTINUED) SYSTEM SETUP 11A SYSTEM SETUP 11A - Level Input option selected SET METER PULSES Set a time duration of switch closure when Level option is selected PULSES PER GALLON...

-

Page 21: Cycle Setup Screens

WS2H, WS2HF, and WS3 Manual Page 21 CYCLE SETUP SCREENS Accessed by pressing NEXT and DOWN simultaneously for >3 seconds and selecting CYCLE SETUP from the Main Menu. CYCLE SETUP 1A CYCLE SETUP 1A Select fi rst step of the primary regeneration cycle. - Page 22 Page 22 WS2H, WS2HF, and WS3 Manual CYCLE SETUP SCREENS (CONTINUED) CYCLE SETUP 3C CYCLE SETUP 3C Select the second step of the secondary regeneration cycle. SECONDARY CYCLE STEP 6 FILL HOLD Continue selecting the step type and entering the duration until the secondary regeneration SLOW RINSE cycle has been defi ned.

-

Page 23: Expansion Setup Screens

WS2H, WS2HF, and WS3 Manual Page 23 EXPANSION SETUP SCREENS Accessed by pressing NEXT and DOWN simultaneously for >3 seconds and selecting EXPANSION SETUP from the Main Menu. EXPANSION SETUP 1 EXPANSION SETUP 1 Select the expanison port, 1 or 2, that you will modify. - Page 24 Page 24 WS2H, WS2HF, and WS3 Manual EXPANSION SETUP SCREENS (CONTINUED) EXPANSION SETUP 2B-1A SERVICE VOLUME EXPANSION SETUP 2B-1A • Enter the volume to energize the relay at EXPANSION SETUP 2B-1B SERVICE VOLUME EXPANSION SETUP 2B-1B • Enter the total time to keep the relay energized for...

- Page 25 WS2H, WS2HF, and WS3 Manual Page 25 EXPANSION SETUP SCREENS (CONTINUED) EXPANSION SETUP 2B-5A REGEN VOLUME EXPANSION SETUP 2B-5A • Enter the volume to energize the relay at EXPANSION SETUP 2B-5B REGEN VOLUME EXPANSION SETUP 2B-5B • Enter the total time to keep the relay energized for...

-

Page 26: Installer Setup Screens

Page 26 WS2H, WS2HF, and WS3 Manual INSTALLER SETUP SCREENS Accessed by pressing NEXT and DOWN simultaneously for >3 seconds then select INSTALLER SETUP from the Main Menu. INSTALLER 1 – Set hardness INSTALLER 1 Set the inlet water hardness, in grains. - Page 27 WS2H, WS2HF, and WS3 Manual Page 27 INSTALLER SETUP SCREENS (CONTINUED) INSTALLER 6 – Set Delayed Regeneration Close Time Minute INSTALLER 6 • Set delayed time of regeneration, minute • When confi gured for multiple delayed regeneration windows, repeat Installer steps 3 through 6 for each additional window INSTALLER 7 –...

-

Page 28: Diagnostic Screens

Page 28 WS2H, WS2HF, and WS3 Manual DIAGNOSTIC SCREENS Accessed by pressing UP and DOWN simultaneously for >3 seconds. DIAGNOSTIC 1 DIAGNOSTIC 1 Days since the last regeneration. All Diagnostic History screens are resettable with the History Reset sequence while in the Diagnostics 1 screen. - Page 29 WS2H, WS2HF, and WS3 Manual Page 29 DIAGNOSTIC SCREENS (CONTINUED) DIAGNOSTIC 4A DIAGNOSTIC 4A Hourly history of volume use. Use the UP and DOWN arrow to select the hours of the day. Returns user back to USE Day 0 in Diagnostic 4 screen.

- Page 30 Page 30 WS2H, WS2HF, and WS3 Manual DIAGNOSTIC SCREENS (CONTINUED) DIAGNOSTICS 7A DIAGNOSTIC 7A Total system hourly history of volume use UP and DOWN arrow to select the hours of the day from Screen 7. Returns user back to USE Day 0 in Diagnostic 7 screen.

-

Page 31: Valve History

WS2H, WS2HF, and WS3 Manual Page 31 VALVE HISTORY Accessed by pressing UP and DOWN simultaneously for >3 seconds, then by pressing UP and DOWN simultaneously again for >3 seconds. Non-Resettable HISTORY 1 HISTORY 1 Total days since startup. Time only accumulates while the unit is plugged in. -

Page 32: Custom Motorized Drive Timing

Page 32 WS2H, WS2HF, and WS3 Manual CUSTOM MOTORIZED DRIVE TIMING • Used to alter the standard timing sequence of the motorized isolation valve for SET BYPASS CONTROL HARD WATER BYPASS complete custom timing of the drive circuits NO HARD WATER BYPASS SEPARATE SOURCE INLET - Setup procedure applies to both the “Bypass”... -

Page 33: Modbus Information

Page 33 MODBUS INFORMATION The WS2H, WS2HF, and WS3 can use Modbus through a half-duplex RS485 connection using the COMM IN connector on the fi rst control in a system. The baud rate is adjustable from 9600 to 115200 (default). - Page 34 Page 34 WS2H, WS2HF, and WS3 Manual MODBUS INFORMATION (CONTINUED) Modbus Valid Description Properties Register Values 40001 Year 0-99 40002 Month 1-12 R./W 40003 1-31 40004 Day of Week 40005 Hour (24 Hour Format) 0-23 40006 Minute 0-59 40007 Seconds...

- Page 35 WS2H, WS2HF, and WS3 Manual Page 35 MODBUS INFORMATION (CONTINUED) Next Regen Unit (upper byte) and Days Remaining (lower byte) A decimal value of 270 in hexadecimal is 0x010E. Broken down, 0x01 is valve 1 and 0x0E is 14 days. For valve 6, 14 days (0x060E) a decimal value of 1550 will be read.

-

Page 36: Installation

Page 36 WS2H, WS2HF, and WS3 Manual INSTALLATION WS2H... - Page 37 WS2H, WS2HF, and WS3 Manual Page 37 INSTALLATION (CONTINUED) WS2HF...

- Page 38 Page 38 WS2H, WS2HF, and WS3 Manual INSTALLATION (CONTINUED)

- Page 39 Clean up water spills. Allow two feet of clearance to service WS2H, WS2HF, and WS3 valves. The valve will withstand transportation and storage temperatures of -13 ˚F (-25 ˚C) to 131 ˚F (55 ˚C) and for short periods up to 158 ˚F (70 ˚C).

- Page 40 7. Drain: Verify that the drain can handle the backwash rate of the water conditioner. Correctly size the drain line and install an appropriately sized drain line fl ow control. For WS2H, WS2HF, and WS3 valves a drain line fl ow control are NOT supplied with a valve.

-

Page 41: Installation Summary

WS2H, WS2HF, and WS3 Manual Page 41 INSTALLATION SUMMARY Installation Date: ___________________________________________ Installation Location: _______________________________________ Installer(s): ________________________________________________ Phone Number: Application Type: (Softener) __________Other: _____________ Water Source: ____________________________________________ Water Test Results: Hardness: ______________Iron: _______________pH: ___________ Other: ____________________________________________________ __________________________________________________________ Misc: Service Flow Rates: min. ______________ max. -

Page 42: Cycle Positions / Flow Diagrams

Page 42 WS2H, WS2HF, and WS3 Manual CYCLE POSITIONS / FLOW DIAGRAMS SERVICE Raw Water Inlet Treated Water Outlet BACKWASH Backwash Water to Drain Raw Water Raw/Hard Water is bypassed Inlet during regeneration... - Page 43 WS2H, WS2HF, and WS3 Manual Page 43 CYCLE POSITIONS / FLOW DIAGRAMS (CONTINUED) DRAW Backwash Water to Drain Raw Water Raw/Hard Water is bypassed Inlet during regeneration Regenerant solution being drawn in Injector feed water from Raw Water Inlet supply...

- Page 44 Page 44 WS2H, WS2HF, and WS3 Manual CYCLE POSITIONS / FLOW DIAGRAMS (CONTINUED) RINSE Rinse Water to Drain Raw Water Raw/Hard Water is bypassed Inlet during regeneration SOFT WATER REFILL Raw Water Inlet Treated Water Supply Treated Water to Regenerant Tank...

-

Page 45: Front Cover And Drive Assembly

WS2H, WS2HF, and WS3 Manual Page 45 FRONT COVER AND DRIVE ASSEMBLY Drawing No. Order No. Description Quantity V3068-01 WS2H/3 POD FRONT/BACK COVERS V3082-01 WS2H/3 GRAPHICS POD ASY W/BRD* Optional V3241-02BOARD WS2H/3 DISPLAY GRPH POD PCB REPL V3248-01 WS2H/3 GRAPHICS POD CABLE... -

Page 46: Drive Cap Assembly, Downfl Ow Piston, Regenerant Piston, Spacer Stack Assembly, Drive Back Plate, Main Body And Meter

Page 46 WS2H, WS2HF, and WS3 Manual DRIVE CAP ASSEMBLY, DOWNFLOW PISTON, REGENERANT PISTON, SPACER STACK ASSEMBLY, DRIVE BACK PLATE AND MAIN BODY Order No. Drawing No. Description Quantity 3” V3275 3/8-16 x 2 1/4 SS Screw V3291 3/8 Washer SS... -

Page 47: Inline Flow Meter Assembly

WS2H, WS2HF, and WS3 Manual Page 47 INLINE FLOW METER ASSEMBLY Order No. Drawing No. 2H 2HF 3” Description Quantity V3003-02 See Meter Instructions V3118-03 WS1.5/2H Meter Commercial Asy V3632 Commercial Meter Retaining Clip V3118-03 Turbine Asy V3501 Commercial Meter Turbine Clip... -

Page 48: Ws2H, Ws2Hf, And Ws3 Brine Valve Body And Injector Components

Page 48 WS2H, WS2HF, and WS3 Manual WS2H, WS2HF, AND WS3 BRINE VALVE BODY AND INJECTOR COMPONENTS Quantity Drawing No. Order No. Description WS2H V3237-01 WS2H/3 SOFTFILL TUBE ASY V3236-04* WS2H INJECTOR TUBE ASY FOR A THRU H V3289 O-RING 344... -

Page 49: Standard Injector Graphs

WS2H, WS2HF, and WS3 Manual Page 49 STANDARD INJECTOR GRAPHS Order No. V3010-2B Order No. V3010-2A US Units US Units Total Total Slow Rinse Slow Rinse Draw Draw Pressure (psi) Pressure (psi) Order No. V3010-2D Order No. V3010-2C US Units... - Page 50 Page 50 WS2H, WS2HF, and WS3 Manual STANDARD INJECTOR GRAPHS (CONTINUED) Order No. V3010-2A Order No. V3010-2B Metric Units Metric Units Total Total Slow Rinse Slow Rinse Draw Draw Pressure (kPa) Pressure (kPa) Order No. V3010-2C Order No. V3010-2D Metric Units...

-

Page 51: Bases

WS2H, WS2HF, and WS3 Manual Page 51 BASES V3064 WS2H/2QC 4 INCH BASE ASY (FOR USE ON WS2H OR WS2QC ONLY) Drawing No. Order No. Description Quantity V3202-01 WS2H BASE V3419 O-RING 347 V3055 WS2H/2QC 6 INCH FLANGE BASE ASY or V3090 WS3 6 INCH FLANGE BASE ASY... -

Page 52: Drain Line Flow Controls

Page 52 WS2H, WS2HF, and WS3 Manual DRAIN LINE FLOW CONTROLS All drain line fl ow control housings are shipped without fl ow control washers. See drain line fl ow control washer section for available fl ow selections. PVC Elbow, 0.7 - 10 GPM... - Page 53 WS2H, WS2HF, and WS3 Manual Page 53 M X F STAINLESS STEEL, 0.7 – 150 GPM Quantity Drawing Order Description V3051 V3051BSPT V3052 WS2 DLFC Retainer Asy V3245 WS2 DLFC Flange Inlet NPT V3245BSPT WS2 DLFC Flange Inlet BSPT V3246...

- Page 54 Page 54 WS2H, WS2HF, and WS3 Manual MXF STAINLESS STEEL, 9-225 GPM Quantity Drawing Order No. Description V3764 V3764BSPT V3765-01 WS3 DLFC HOUSING NPT V3765BSPT-01 WS3 DLFC HOUSING BSPT V3766 WS3 DLFC RETAINER V3767 WS3 DLFC RETAINER COVER V3768 WS3 DLFC RETAINER RING...

- Page 55 WS2H, WS2HF, and WS3 Manual Page 55 DRAIN LINE FLOW CONTROL WASHERS V3162-XXX Order No. Description V3162-xx Flow Rate V3162-007 .7 GPM Drain line fl ow control Identification V3162-010 1.0 GPM Drain line fl ow control 5/8" V3162-013 1.3 GPM Drain line fl ow control V3162-017 1.7 GPM Drain line fl ow control...

-

Page 56: Ws2H, Ws2Hf, And Ws3 Troubleshooting Guide

Page 56 WS2H, WS2HF, and WS3 Manual WS2H, WS2HF, AND WS3 TROUBLESHOOTING GUIDE WS2H, WS2HF, and WS3 Error Codes Possible Errors Code Description 1001 No Encoder Pulses 1002 Unexpected Stall, Main Drive 1003 Run Time To Long, Main Drive 14001... - Page 57 WS2H, WS2HF, and WS3 Manual Page 57 Problem Possible Cause Solution 1. No Display on POD a. No power at electric outlet a. Repair outlet or use working outlet b. Control valve Power Adapter b. Plug Power Adapter into outlet or...

- Page 58 Page 58 WS2H, WS2HF, and WS3 Manual Problem Possible Cause Solution 7. Control valve does not a. Bypass/isolation valves in a. Turn bypass/isolation valves handles regenerate automatically bypass position to place in service position but does when the REGEN b. Meter is not connected to meter b.

- Page 59 WS2H, WS2HF, and WS3 Manual Page 59 Problem Possible Cause Solution 10. Residual regenerant being a. Low water pressure a. Check incoming water pressure delivered to service – water pressure must remain at minimum of 25 psi b. Plugged, fouled, or incorrect b.

- Page 60 Page 60 WS2H, WS2HF, and WS3 Manual Problem Possible Cause Solution 14. Err – 1001 = Control a. Motor not inserted fully to a. Disconnect power, make sure motor unable to sense motor engage pinion, motor wires is fully engaged, check for broken...

- Page 61 WS2H, WS2HF, and WS3 Manual Page 61 Problem Possible Cause Solution 16. Err – 1003 = Control valve a. Motor failure during a a. Check motor connections then motor ran too long and regeneration Press NEXT and REGEN buttons for...

- Page 62 Page 62 WS2H, WS2HF, and WS3 Manual Problem Possible Cause Solution 19. Err – 15010 = Motorized a. Foreign material is lodged in a. Open up Motorized Bypass or MAV Bypass or MAV for NHBP Motorized Bypass or MAV for...

- Page 63 WS2H, WS2HF, and WS3 Manual Page 63 Problem Possible Cause Solution # of units error: 1) Correct all errors on satellite units Communications has before attempting to reset error on been broken with the master unit specifi ed in the error a.

- Page 64 Page 64 WS2H, WS2HF, and WS3 Manual Problem Possible Cause Solution 25. Err – 20001 = AUX motor a. Control valve programmed a. Press NEXT and REGEN buttons for ran too long while trying for NHBP or Separate Source about 3 seconds to resynchronize...

- Page 65 WS2H, WS2HF, and WS3 Manual Page 65 NOTES:...

- Page 66 Page 66 WS2H, WS2HF, and WS3 Manual NOTES:...

- Page 67 WS2H, WS2HF, and WS3 Manual Page 67...

- Page 68 Page 68 WS2H, WS2HF, and WS3 Manual Revision History: 11/23/2021 Page 52-60 - Updated Troubleshooting 5/20/2022 Page 26: Accessed by pressing NEXT and DOWN simultaneously for >3 seconds then select INSTALLER SETUP from the Main Menu. 10/19/2022 Table of Contents:...

Need help?

Do you have a question about the WS2HF and is the answer not in the manual?

Questions and answers