Table of Contents

Advertisement

Quick Links

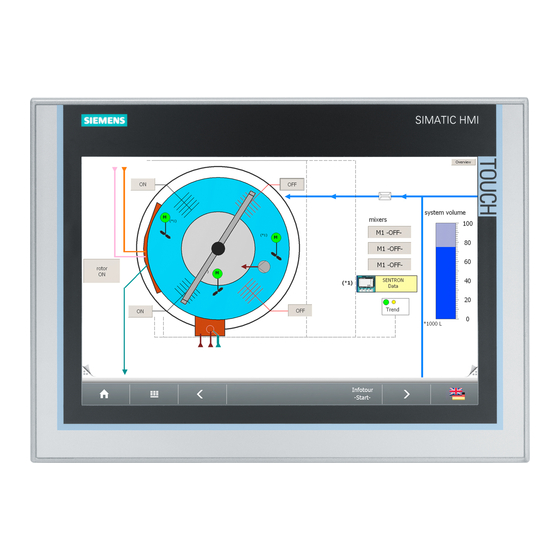

Industrial Thin Client ITC1200, ITC1500,

ITC1900, ITC2200

SIMATIC HMI

HMI device

Industrial Thin Client ITC1200,

ITC1500, ITC1900, ITC2200

Operating Instructions

04/2013

A5E03474888-02

___________________

Preface

___________________

Overview

___________________

Safety instructions

Installing and connecting the

___________________

device

___________________

Commissioning the device

___________________

Assigning device parameters

___________________

Configuring the server

___________________

Operating the device

Device maintenance and

___________________

repair

___________________

Technical specifications

___________________

Technical Support

___________________

Abbreviations

1

2

3

4

5

6

7

8

9

A

B

Advertisement

Table of Contents

Need help?

Do you have a question about the SIMATIC HMI Industrial Thin Client ITC1200 and is the answer not in the manual?

Questions and answers