Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Winter WSCA Series

- Page 3 – Translation of the original Instruction Manual (Übersetzung der Originalbetriebsanleitung) – Copyright reserved! Technical data are subject to change! Without written agreement of WINTER.pumpen GmbH, contents must not be revised, disseminated, duplicated or passed on to third party. © Winter.pumpen GmbH Document: U99_001 Part-Nr.

-

Page 4: Table Of Contents

Index Glossary ...................................... 3 General .................................... 3 General Information ............................... 3 Fields of application ............................... 4 Subjects for this manual ............................4 Documents applicable with this manual ........................4 Symbolic ................................4 Supplementary information ............................ 5 Safety ....................................5 General Information ............................... 5 Marking of safety- &... -

Page 5: Glossary

Glossary Pressure pipe Pipe, connected to or to be connected to outlet. Hydraulics The so-called hydraulics describes the part of a pump, which converts speed power to pressure power. Product A product identifies a pump or a pump aggregate, according to scope of supply. Pump ... -

Page 6: Fields Of Application

The manufacturer assumes no liability for pumps / aggregates, if instructions of available manual are disobeyed. Assembly works must be done by technical skilled staff only. Warranty for works done at pumps/aggregates is applicable only, if performed by after sales service ... -

Page 7: Supplementary Information

Supplementary information 1.6.1 Manufacturer´s-, agents´-, after-sales service and customer service addresses See Impressum In case of spare part orders or customer service requests, please always indicate pump type and serial number. 4.2 Information to the Product 1.6.2 Accessories (order-related) Frequency regulation, pressure tanks, control systems, drive assemblies, automatic aspirator, other accessories Safety 2.1 General Information Before starting works at the product, this manual must be coned by the responsible personnel / operator prior to assembly... -

Page 8: Safety Instructions Relevant To Operation

Safety instructions relevant to operation If hot or cold machine components involve hazards, they must be guarded against an accidental contact at side. Guards for moving parts (e.g. coupling) must not be removed from the machine while in operation. ... -

Page 9: Preservation

3.2.2 Unpacking Already during unpacking of supplied product make sure that serial number stated on order confirmation is the same as stated on delivery note and name plate of. The shipment must be checked for completeness. The goods should be preferably unpacked on site, sothat unintended and unforeseeable contamination is avoided. -

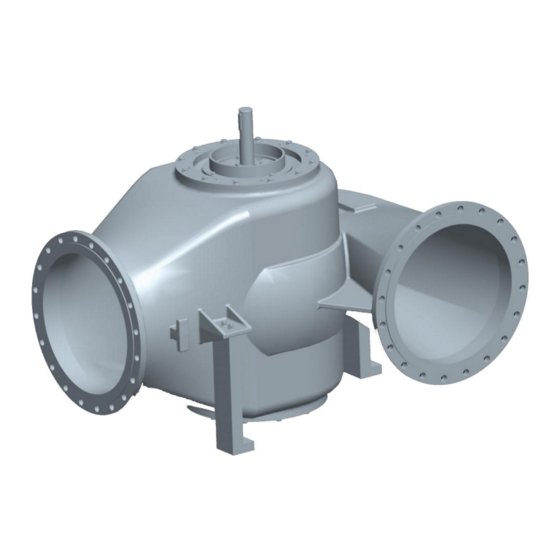

Page 10: Specification Of A Product

Specification of a product 4.1 General description The Norm-Pumps are a single stage, normal priming centrifugal pump with power assignment and main measurements to EN733. The Norm-Pumps are multiple usable and allows/enables to a reliable and cost-efficient pumping of a lot of different liquids. -

Page 11: Details On Installation Site

4.3.1.6 Base frame According to customer request, the aggregate is mounted on base frame. 4.4 Details on installation site 4.4.1 Space requirement for operation and maintenance The pump aggregat must be installed in a way that enables to exchange components or the complete unit. If the aggregate is heavy, facilities adapted to the weight are to be provided in order to safe hang-in support of lifting devices and other auxiliaries. -

Page 12: Installation- And Assembly Instruction

Installation- and assembly instruction Safety Instructions The installation of machines and parts of machines must be done by technical skilled and qualified staff, which obeys the safety instructions, valid and stated in this operation manual. Consider 9.3 Tightening torques Check before assembly and installation Before starting with assembly works, immediately after receipt of goods, check serial number and pump type of name plate with the information in order confirmation and delivery note. - Page 13 5.3.1 Alignment of coupling Hazard by touching/catching at sudden start-up of shaft Put aggregate out of service! Secure against unintended restart! Indications to power supply under 5.7. Connection of energy supply Couplings not supplied by the manufacturer are to be installed and aligned according to the instructions of the respective manufacturer.

-

Page 14: Pipe Works

5.4 Pipe works 5.4.1 General The pipe work must be absorbed directly in front of the pump, must be assembled stress less to the pump and possible charges on connections must be absorbed by suitable measures (e. g. with compensators,…) Pay attention to heavy forces, which may arise at thermal expansion and at filling up big tubes. -

Page 15: Installation- And Assembly Instructions For Emission-Decrease

Pressure pipe The pressure pipe must be fitted with a gate valve and a non-return- valve.The gate valve renders possible to set a special flow rate while water hammers in pipes at the occasion of switching off the pump are avoided by means of the nonreturn valve. -

Page 16: Connection To Power Supply

5.6.2 Electrical If the pump aggregate works outdoors (hazard by lightning) or in case of hazards by electricity charge during operation, an additional earth lug can be installed upon request of customer. Please, contact manufacturer. connection to power supply Connection of machine to electrical grid must be done by technical qualified staff, under consideration of the valid DIN- / VDE- rules and, if necessary, of national valid rules as well as of safety-norms of the European Community. - Page 17 6.2.2 Filling / Venting Pump and conduits are to be filled-up with the pumping medium and are to be vented at the highest point. Check that there is no pressure in pump before venting of pump, to avoid injuries. Mind protection for persons and environment, when using liquids, which are hazardous for environment and health.

-

Page 18: Starting-Up

devices is not permissible! Protecting devices must not be dismantled during operation. If a dismantling of protecting devices is necessary, pay attention, that they are reinstalled before next start of machine... 6.2.6.2 Acoustic-emission protection In the proximity of the aggregate must be ear protection is generally necessary. For combustion engines use a silencer with high damping to avoid noise pollution beyond site. -

Page 19: Shut-Down

6.5 Shut-down 6.5.1 Safety instructions The VdE rules, the corresponding EU-rules as well as all national valid rules must be observed. Pay attention to Safety. 6.5.2 Switch-off Disconnect aggregate from power supply! Secure against unintentional restarting! If combustion engines are used, stop fuel supply and disconnect batteries, respectively remove spark plugs. -

Page 20: Preventive Measures

7.2.1 Motor with regreasing The quality and quantity of stuff lubricants for motors with regreasing devices has to be taken from label on motor. 7.2.2 Oil lubrication bearing At normal operation conditions the oil must be changed after abt. 2000 working hours. For oil change also consider 6.2.1 bearing applications. -

Page 21: Change Of Sealing

Change of sealing Assembly works must be done by technical qualified staff. To obtain warranty, works at the product must be done by the service-staff of the manufacturer or by persons, authorized by the manufacturer. Consider 6.5 Shut-down Exemplar procedures are valid for all executions of Normpumps Consider 9.3 Tightening torques Disconnect aggregate from power supply! - Page 22 7.4.2 Change of lip seal Depending on installation circumstances, pump- and motor size must be decided whether the pump aggregate has to be partly or totally dismantled from basement. On principle, complete mechanical seal has to be changed. Auxiliaries: 0,5 % soapsuds , soft fuzz-free cloth Comply with following procedure: Switch-off pump aggregate as per 6.5.2 Switch-off...

-

Page 23: Disassembly And Assembly

7.5 Disassembly and Assembly Assembly works must be done by technical qualified staff. To obtain warranty, works at the product must be done by the service-staff of the manufacturer or by persons, authorized by the manufacturer. Procedures are valid for all executions of Normpumps Consider 6.5 shut-down 9.3 Tightening torques... -

Page 24: Interruptions

Interruptions Example to use Interruption matrix: Fault: Pump runs not properly/noisy From the list of mechanic interruptions take code letter „E“ According to the following chart; Interruption matrix: The following causes are possible: 4; 8; 13; 14; 15; 16; 17; 18 In the following chart;... -

Page 25: Corresponding Documents

Corresponding documents Specification of pump parts Please, find the specification of pump parts in order-related technical documentation. Drawings Please, find drawings corresponding to supplied product in order-related technical documentation. Tightening Torques Tightening torques shown in the following Ill. correspond to stated strength classes! For other strength classes contact screw manufacturer for information to tightening torques. - Page 26 This declaration is no longer valid if the machine is modified without our consent. Manufacturer and name of the authorised representative of the technical file: Winter.pumpen GmbH An der Autobahn L2 D – 91161 Hilpoltstein Description of the machine: ...

- Page 28 Winter.pumpen GmbH An der Autobahn L 2 . D-91161 Hilpoltstein Tel.: (0 91 74) 9 72 - 0 . Fax: (0 91 74) 9 72 49 info@winter-pumpen.de . www.winter-pumpen.de Ein Unternehmen der www.winter-group.de...

Need help?

Do you have a question about the WSCA Series and is the answer not in the manual?

Questions and answers