Advertisement

Quick Links

ZKJ-TF2Z005EN-B

ORIGINAL INSTRUCTIONS

Instruction Manual

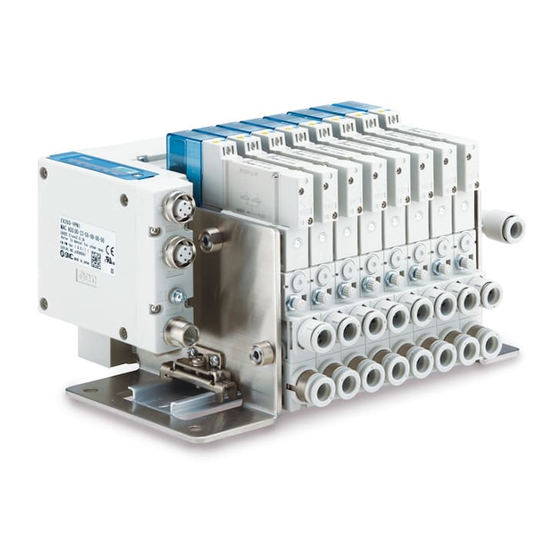

Vacuum Manifold for fieldbus system

Series ZKJ

The intended use of the vacuum manifold is to generate vacuum and

control the operation of suction and release.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of "Caution," "Warning" or "Danger."

They are all important notes for safety and must be followed in addition

*1)

to International Standards (ISO/IEC)

, and other safety regulations.

*1)

ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

• Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

• Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

Caution

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

Warning

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

Danger

not avoided, will result in death or serious injury.

Warning

• Always ensure compliance with relevant safety laws and

standards.

• All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

2 Specifications

Note 1)

2.1 Ejector specifications

Model

ZKJ07

ZKJ10

ZKJ12

Fluid

Air

Nozzle diameter [mm]

0.7

1.0

1.2

Standard supply pressure [MPa]

0.4

Max. vacuum pressure

Note 2)

-89

[kPa]

Without

exhaust

31

53

63

Port

sealing valve

exhaust

With exhaust

30

48

57

sealing valve

Without

High-noise

exhaust

31

51

60

sealing valve

reduction

silencer

Without

exhaust

exhaust

30

45

54

sealing valve

Note 2)

Air consumption

26

48

68

[L/min(ANR)]

2 Specifications - continued

Ejector specifications - continued

Supply pressure range [MPa]

Supply valve: N.C., Release

Type of actuation

Supply valve: N.O., Release

Note 4)

Response time at 0.5 [MPa]

Max. operating frequency [Hz]

Manual override

Power consumption [W]

o

Ambient temperature range [

C]

0 to 50 (No condensation)

Note 5)

2

Vibration resistance

[m/s

]

Impact resistance

Note 6)

[m/s

2

]

500 [VAC] for 1 [min] between

Withstand voltage

FE and all accessible terminals

10 [MΩ] or more (500 [VDC] is

Insulation resistance

Note 7)

Enclosure

Table 1.

Note 1) The supply valve and release valve mounted on this product is the SMC

dual 3-port valve JSY3000 series. Refer to the Web Catalogue for details

on the JSY3000 series.

Note 2) Values are at the standard supply pressure and based on SMC's

measurement standards.

Note 3) If the vacuum port diameter is Φ6 or Φ1/4'', Max. Suction flow rate is

reduced by 15% or less.

Note 4) It shows supply valve/release valve specification. Based on dynamic

performance test, JIS B 8419-2010 (Coil temperature: 20[

voltage).

Note 5) The characteristics are satisfied when tested for 2 hours in each of the X,

Y and Z directions at 10 to 500 Hz without energization (Initial value).

Note 6) The characteristics are satisfied when tested one time in each of the X, Y

and Z directions without energization (Initial value).

Note 7) Cannot be used in an environment where oil, such as cutting oil, splashes

or it is constantly exposed to water. Take appropriate protective measures.

Note 8, 9)

2.2 Noise Level (Reference value)

Model

ZKJ07

Noise level [dB(A)]

52

Table 2.

Note 8) Values at the standard supply pressure.

Note 9) Values are with 1 ejector generating vacuum pressure adequately for

adsorption with high-noise reduction silencer (Not guaranteed values).

2.3 SI Unit specifications

ZKJ15

1.5

Series

Protocol

74

Table 3

For details, refer to SI unit operation manual for 'Specifications'.

-

Note 10)

2.4 Pressure sensor specifications

68

Rated

Without exhaust sealing valve

pressure

With exhaust sealing valve

range [kPa]

-

Proof pressure [kPa]

Accuracy

Current consumption (per piece)

102

Table 4.

Note 10) Cannot be used for actuating the cylinders. Do not apply release pressure

constantly.

2 Specifications - continued

0.3 to 0.5

Special products (-X) might have specifications different from those

valve: N.C. (ZKJ-JSY3A)

shown in this section. Contact SMC for specific drawings.

valve: N.C. (ZKJ-JSY3E)

3 Installation

23 [ms] or less

3.1 Installation

3

Non-locking push type

3.1.1 Mounting

0.4

Mount and tighten the manifold using the holes in the end plate (4xM6)

30

150

given between FE and all

accessible terminals)

IP65

3.1.2 Connecting cables

Refer to SI unit operation manual for 'Wiring'. Select the appropriate

cables to make with the connectors mounted on the SI unit.

o

C], at rated

3.1.3 Ground terminal

The SI unit must be connected to FE (Functional Earth) to divert

electromagnetic interference. For maximum protection, the FE cable

should be as thick and short as reasonably possible.

• Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment

ZKJ10

ZKJ12

ZKJ15

63

67

71

• Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

• Do not use in an explosive atmosphere.

• Do not expose to direct sunlight. Use a suitable protective cover.

• Do not install in a location subject to vibration or impact in excess of

the product's specifications.

• Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product's specifications.

3.3 Piping

• Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

• When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

• Tighten fittings to the specified tightening torque.

EX260

3.4 Lubrication

PROFINET, IO-Link

• SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

• If a lubricant is used in the system, refer to catalogue for details.

-100 to 100

4 Settings

-100 to 200

500

Refer to SI unit operation manual. The setting file can be found on the

± 3%F.S.

SMC website.

15 [mA] or less

5 How to Order

Refer to catalogue for 'How to Order'.

6 Outline Dimensions

Refer to catalogue for outline dimensions.

Warning

7 Maintenance

7.1 General maintenance

• Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

• If handled improperly, compressed air can be dangerous.

• Maintenance of pneumatic systems should be performed only by

qualified personnel.

• Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

• After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

• If any electrical connections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

• Do not make any modification to the product.

• Do not disassemble the product, unless required by installation or

maintenance instructions.

Implement the maintenance and checks shown below in order to use

the ejector safely and in an appropriate way for a long period of time:

• Maintenance should be performed according to the procedure

indicated in the Operation Manual. Improper handling can cause

damage and malfunction of equipment and machinery.

• Maintenance work

Compressed air can be dangerous when handled incorrectly.

Therefore, in addition to observing the product specifications,

replacement of elements and other maintenance activities should be

performed by personnel with sufficient knowledge and experience

Warning

pertaining to pneumatic equipment.

• Draining

Remove condensate from air filters and mist separators regularly. If

the collected drainage is drained to the downstream side, it can stick

inside of the product, causing operation failure and failure to reach the

specified vacuum pressure.

• Replace the filter element built into the ejector and the silencer

Warning

regularly.

It is recommended to replace the filter element and the silencer when

the pressure drop reaches 5kPa as a guideline. The replacement

cycle varies depending on the operating conditions, operating

environment and supply air quality.

However, if there is a vacuum pressure drop and/or delay in the

vacuum (adsorption) response time which causes problem with the

settings during operation, stop the operation of the product and

replace the element regardless of the above mentioned replacement

guideline.

• Operation in an environment where there is a lot of dust in the air

The processing capacity of the filter element built into the product may

Caution

be insufficient. It is recommended to use SMC's air suction filter (ZFA,

ZFB, ZFC series) in order to avoid problems beforehand.

• Check before and after the maintenance work

When the product is to be removed, turn off the power supply, and be

sure to cut off the supply pressure and exhaust the compressed air.

Confirm that the air is released to atmosphere.

When mounting the product after the maintenance work, supply

compressed air, connect to the power, check if it functions properly

and have a leakage inspection.

• Do not disassemble or modify the product, other than the replacement

Caution

of parts specified in the operation manual.

• Tighten to the specified tightening torque.

If the tightening torque is exceeded, the product, the mounting screws

and brackets can be broken. Insufficient torque can cause

displacement of the product from each proper position and loosening

of the mounting screws.

• Before piping, perform air blow (flushing) or cleaning to remove any

cutting chips, cutting oil, dust, etc. from the piping. Otherwise, failure

or malfunction may occur.

• If the fluid contains foreign matter, install and connect a filter or mist

separator to the inlet. Otherwise, failure, malfunction or inaccurate

measurements from the pressure sensor may occur.

Caution

Page 1 of 2

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks ZKJ Series

- Page 1 ZKJ-TF2Z005EN-B 2 Specifications - continued 2 Specifications - continued 6 Outline Dimensions ORIGINAL INSTRUCTIONS Ejector specifications - continued Refer to catalogue for outline dimensions. Supply pressure range [MPa] 0.3 to 0.5 Warning 7 Maintenance Supply valve: N.C., Release Special products (-X) might have specifications different from those Instruction Manual valve: N.C.

- Page 2 ZKJ-TF2Z005EN-B 8 Limitations of Use 8.1 Limited warranty and disclaimer/compliance requirements Refer to Handling Precautions for SMC Products. Caution Exhaust Noise When vacuum ejector generates vacuum, noise can be heard from the exhaust port when the standard supply pressure is close to the pressure that generates peak vacuum pressure making vacuum pressure unstable.

Need help?

Do you have a question about the ZKJ Series and is the answer not in the manual?

Questions and answers