UEi C161C Instruction Manual

Residential combustion analyzer

Hide thumbs

Also See for C161C:

- Quick start manual (9 pages) ,

- Quick start manual (9 pages) ,

- Instruction manual (24 pages)

Summary of Contents for UEi C161C

- Page 1 C161 Residential Combustion Analyzer INSTRUCTION MANUAL BACKED BY ENGLISH CO/CO2 O2/Eff Temp Exch Test Status C161 1-800-547-5740 • Fax: (503) 643-6322 www.ueitest.com • Email: info@ueitest.com...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Temperature Testing . -

Page 3: General Specifications

GENERAL SPECIFICATIONS • Operating Temperature: 32˚ to 113˚F (0˚ to 45˚C) • Calibration: Recommended Annually • Storage Temperature: 0˚ to 113˚F (-18˚ to 45˚C) • Certification: UK CA, CE Conformity, RoHS, REACH Compliant, AHRI 1260 standard • Operating Humidity: 15% to 90% R.H. NiMH (AA) 3 •... -

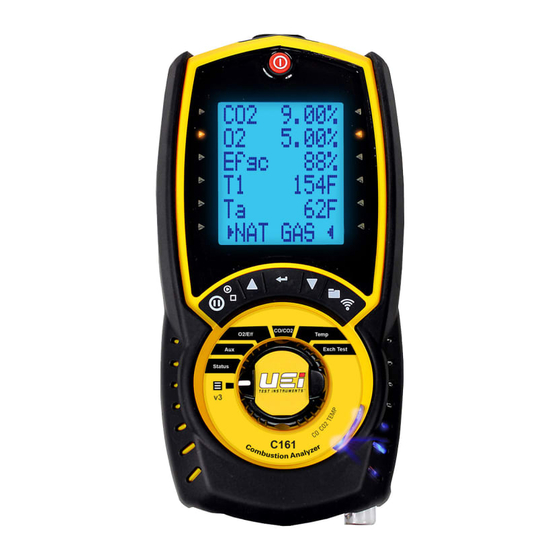

Page 4: Analyzer Overview

ANALYZER OVERVIEW A. Infrared Printer Port B. On/ Off (Power) Button C. 6 Line Backlit Display • Press any button to turn Back light on (will turn off after 10 seconds) D. Protective Rubber Boot With Magnets E. Status Bar Line F. - Page 5 ANALYZER OVERVIEW (CONT.) Serial No. Sensors Fitted: CO/CO2 Temp O2/Eff Exch Test Status C161 Black Connector (plugs into Flue Gas Inlet) Flue Probe Temperature Plug (Plugs into T1) Narrow Pin MUST be on the Flue Probe Right hand side. Gas Inlet Plug...

-

Page 6: Overview

OVERVIEW The direct measurement of CO is achieved using UEi’s own EOS technology sensor. CO is set to zero in fresh air automatically after the initial 60 second countdown. If “ZERO CO ” is indicated, ensure the unit is in outside fresh air before selecting the “Purge” option. -

Page 7: Emptying & Cleaning The In-Line Water Trap

EMPTYING & CLEANING THE IN-LINE WATER TRAP • Remove the rubber plug • Allow the water to drain out • Re-insert the rubber plug CHANGING THE PARTICLE FILTER • Remove the protective rubber boot • Slide the water trap unit from the analyzer •... -

Page 8: Display Parameters

DISPLAY PARAMETERS The large display is backlit with 6 lines, the last line is the Status Bar line. Menu Screen Time (settable parameter; HH:MM:SS, displayed in 24 hour clock format) Date (settable parameter; MM:DD:YY) Header (16 character, 2 line settable parameter; 10 characters can be added to Line 1 of the header, 6 characters to Line 2) IR Print (KMIRP or IRP-2) ˚C/˚F (Selectable parameter) Gas Unit (Selectable parameter;... -

Page 9: Status Screen

T1 (displayed in ˚F or ˚C, depending on selection in Menu Screen) T2 (displayed in ˚F or ˚C, depending on selection in Menu Screen) CO/CO2 Screen CO (displayed in ppm) COa (O2++ displayed in ppm) CO2 (displayed in %) Loss (displayed in %) XAIr (Excess Air, O2++ displayed in ppm) Temp Screen T1 (displayed in ˚F or ˚C, depending on selection in Menu Screen) -

Page 10: Status Bar

STATUS BAR Status Bar Icons The icons are designed to provide quick and simple instrument status information without having to navigate complicated menu systems or detract from the job at hand. Status Bar Icon Layout Pump Pump on Pump Pump paused Sending Data Indicates data is being transmitted to either the App or the Printer Battery... -

Page 11: Menu

MENU Using the Menu The Menu position on the Rotary Dial allows for the customization of the default settings for the analyzer as per the user’s requirements. Navigation through the Menu system is via the dedicated user’s interface buttons (Up, Down, Enter). Menu Option to edit As you navigate up or down through the Menu, the items will scroll accordingly, eventually back to the beginning. -

Page 12: Stored Logs Memory

STORED LOGS MEMORY The C161 utilizes a shared memory system much like a computer hard drive. The different Log types are stored sequentially until the shared memory area is full. This means the log types are not restricted to a smaller number of memory locations as the full memory capacity is available as required for Logs of any type. -

Page 13: Viewing Stored Logs

Viewing Stored Logs Once the view has been selected from the Logs Menu the following screen will be displayed: List of available Logs (Navigation and selection via the buttons). Log View Menu Options View stored Combustion Logs (Option will appear if Logs are available). View stored Auxiliary Logs (Option will appear if Logs are available). -

Page 14: Log Navigation Menu Options

Log Navigation Menu Options Print the currently selected Log Navigate to the next available Log of the selected type (Option will only appear if there is more than one Log). Navigate to the previously selected Log of the selected type (Option will only appear if there is more than one Log). -

Page 15: Heat Exchanger Test

HEAT EXCHANGER TEST NOTE: Test results; O2, CO and Excess Air will show on the printout. There are many methods to test heat exchanger integrity. One of these is to observe the Excess Air, O2 and CO readings both before and after the blower turns on. -

Page 16: Printouts

To print, simply press and release the PRINT BUTTON. Printing can be aborted by pressing the PRINT BUTTON again. UEi Infrared Printer Make sure the printer is switched on, ready to accept data and its infrared receiver is in line with the analyzer’s infrared emitter (on top... -

Page 17: Specifications

The following harmonized standards and technical specifications have been applied: CERTIFICATION The UEi C161 is TUV-tested and certified to EN 50379, Parts 1, 2 & 3 in accordance to 1st German Federal Emission Control Ordinance (BlmSchV). Manufactured to meet AHRI 1260 standard. -

Page 18: Where To Test

WHERE TO TEST Air Conditioning / Heat Pump Suction Line: • Temperature Verify proper: • Static Duct Pressures • Temperature Differential • Static Pressure Drop Across Coils to condensing unit Boiler & Water Heaters & High Efficiency Modulating Hot Water Systems Boiler HE Boiler Instant Water Heater... -

Page 19: What Results Are Generally Acceptable

WHERE TO TEST (CONT.) Furnaces (continued): Atmospheric, Gas & Oil Natural Gas & Propane Verify proper combustion: • O • CO Atmospheric Furnace • CO Draft • Stack Temp • Vent Pressure Verify proper • Efficiency • Temperature Rise • AC side Static Pressure Test Drop across coils •... -

Page 20: Powering Off

POWERING OFF When you power off the C161, there is a 10 second purge. Make sure you do not exceed the analyzer’s operating specifications. In particular: • Do not exceed the flue probes maximum temperature (1112˚F) • Do not exceed the analyzer’s internal temperature range •... -

Page 21: Replacing The Batteries

REPLACING THE BATTERIES This meter has been designed for use with both alkaline and rechargeable Nickel Metal Hydride (NiMH) batteries. No other types are recommended and will void warranty. The analyzer is supplied with 3 (AA) size NiMH rechargeable batteries. These should be installed into the instrument. -

Page 22: Usa Annual Recertification Services

Same Day Service: All qualifying analyzers received for recertification through UEi Service+ are returned on the same business day .* Free Shipping: UEi Service+ offers free shipping both to and from our service center . When customers book their recertification, they receive a prepaid UPS Ground shipping label . -

Page 23: Other Important Factors Relating To Combustion

UEi’s electronic combustion analyzers perform the measurements on a continuous basis, and can calculate the efficiency as adjustments are being made. Combine this with a printout and you are able to provide a before and after comparison of the combustion equipment in relatively little time as part of normal servicing. -

Page 24: Disposal

Any implied warranties, including but not limited to implied warranties of merchantability and fitness for a particular purpose, are limited to the express warranty. UEi shall not be liable for loss of use of the instrument or other incidental or consequential damages, expenses, or economic loss, or for any claim or claims for such damage, expenses or economic loss.

Need help?

Do you have a question about the C161C and is the answer not in the manual?

Questions and answers