Advertisement

Quick Links

Series

GP8155(-1000)

GP8160(-1000)

GP8165(-1000)

GEARBOX SERIES

Updated 03/22

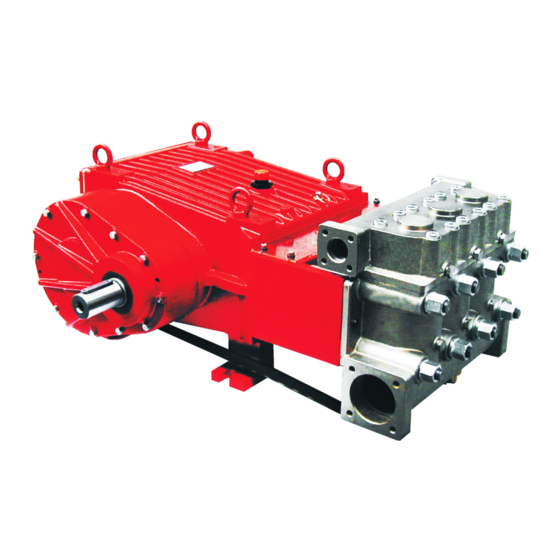

GP8100 - Spheroidal Nickel-Plated Cast Iron Manifold

GP8100-1000 - Bronze Manifold

Contents:

Installation Instructions:

Operating Instructions:

Pump Specifications:

Repair Kits:

Tool List:

Exploded View:

Parts List:

Repair Instructions:

Troubleshooting Chart:

Torque Specifications:

Dimensions:

Warranty Information:

Triplex Ceramic

Plunger Pump

Operating Instructions

Repair and Service Manual

page 2

page 3

page 4

page 5

page 5

page 6

page 7

pages 8-10

page 11

page 11

back page

back page

Advertisement

Summary of Contents for Giant GEARBOX Series

- Page 1 Series Triplex Ceramic Plunger Pump Operating Instructions GP8155(-1000) Repair and Service Manual GP8160(-1000) GP8165(-1000) GEARBOX SERIES GP8100 - Spheroidal Nickel-Plated Cast Iron Manifold GP8100-1000 - Bronze Manifold Contents: Installation Instructions: page 2 Operating Instructions: page 3 Pump Specifications: page 4...

- Page 2 INSTALLATION INSTRUCTIONS The stated figures are for maximum pressure 20 minutes an hour, with the pump running with-out and maximum speed (rpm) and apply for interval pressure or turned off in between. For example, this operation with cold water. can be full load operation for 5 minutes four times an hour with 10 minute breaks in between or continuous Required NPSH refers to water (specific weight 1kg/ full load operation for 20 minutes followed by a 40...

- Page 3 Giant plunger pumps are suitable for pumping ex-ceeded by more than 10%. Pump operation without clean water and other non-aggressive or non-...

- Page 4 Specifications U.S. Measurements Maximum Maximum Maximum Power Plunger NPSHR Flow Pressure Speed Required Diameter Model foot of head GP8155 75.5 3000 2.17 GP8160 2500 2.36 23.6 GP8165 105.6/120* 2000 580/658 142/166 2.55 26.2 Metric Measurements Max. Flow Maximum Maximum Power Plunger NPSHR Pressure...

- Page 5 Pump Repair Kits - GP8155/GP8160/GP8165 Plunger Packing Kit - GP8155 Inlet Valve Kit # 09616 #09587 Item Part # Description Qty. Item Part # Description Qty. 13286 O-Ring 05078 Inlet Valve Seat 05281 Support Ring 05079 Valve Plate 07658 O-Ring 05066 O-Ring 07723...

- Page 6 Exploded View - GP8155/GP8160/GP8165...

- Page 7 Parts List - GP8155/GP8160/GP8165 Item Part Description Item Part Description 05651 Crankcase 05279 Seal Tension Spring, GP8155 06893 Oil Filler Plug Assy. with Vent 05071 Seal Tension Spring, GP8160 05652 Rear Foot for Crankcase 05119 Seal Tension Spring, GP8165 05653 Front Foot for Crankcase 05072 Stud Bolt...

- Page 8 Pump Repair Instructions - GP8155/GP8160/GP8165 Valve Inspection and Repair 2) Lift discharge casing 3) Take out pressure springs Remove socket head cap (50B) up and away. (57A). Pull out assembled screws (58) valves (51 & 52) with valve puller. 4) Remove valve assembly (52) from discharge valve adapter (56) by gently twisting apart. The spring tension cap (51A, 52A) is screwed together with the valve seat (51B or 52B).

- Page 9 Pump Repair Instructions - GP8155/GP8160/GP8165 8) Take out the seal case (38) from the valve Be careful not to damage the seal casing (50) and check o-rings (38A) (if necessary sleeve (39) and pressure ring (41). Check the inner secure two screwdrivers in the front o-ring groove diameter of the pressure ring for wear and if neces- to extract seal casing from valve casing).

- Page 10 Pump Repair Instructions - GP8155/GP8160/GP8165 To Dismantle Gear Take out plungers and seal sleeves as described above. Drain oil by taking off plug (12). After removing the clip ring (33B), remove the seal retainer (33) with a screwdriver. Open hose adaptor (K11). Remove gear cover (K3) and remove the cooling vane plate (K1) by unscrewing the screws (K4).

- Page 11 Troubleshooting GP8155/GP8355/GP8160/GP8360/GP8165/GP8365 TROUBLESHOOTING Problem Cause Solution Pressure Drops, water leaks V-sleeves leak Replace V-sleeves, check surface of plunger Pressure drops, pump gets loud Discharge or suction valve leaks Replace valve(s) Steam formation (Cavitation) Reduce suction height, reduce flow resistance in inlet line, clean inlet filter, lower water temperature.

- Page 12 1. Five (5) years from the date of shipment for all pumps used in portable pressure washers with NON-SALINE, clean water applications. 2. Two (2) years from the date of shipment for Giant pumps used in car wash applications. 3. One (1) year from the date of shipment for all other Giant industrial and consumer pumps.

Need help?

Do you have a question about the GEARBOX Series and is the answer not in the manual?

Questions and answers