Advertisement

Quick Links

Models

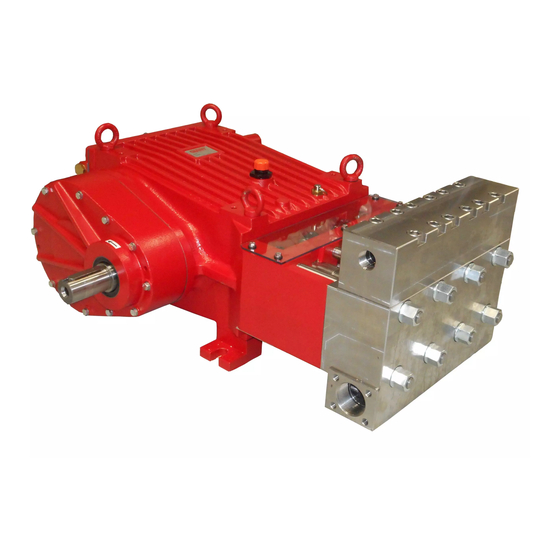

GP8135A & GP8140A

Pumps without oil cooling systems

Contents:

Installation/Operating Instructions:

Pump Specifications:

Exploded View:

Parts List:

Repair Kits:

Tool List/Torque Specifications/

Troubleshooting Chart:

Repair Instructions:

Dimensions:

Warranty Information:

Triplex Ceramic

Plunger Pump

Operating Instructions

Repair and Service Manual

pages 2-3

pages 4-5

page 6

page 7

page 8

page 8

pages 9-10

page 11

back page

Advertisement

Summary of Contents for Giant GP8135A

- Page 1 Models Triplex Ceramic Plunger Pump Operating Instructions GP8135A & GP8140A Repair and Service Manual Pumps without oil cooling systems Contents: Installation/Operating Instructions: pages 2-3 Pump Specifications: pages 4-5 Exploded View: page 6 Parts List: page 7 Repair Kits: page 8...

-

Page 2: Installation Instructions

Gear on left side (from the front of the The following oils may be use: 85-90W pump) = optimal rotation: to the left Industrial Gear Lube oil (Giant’s p/n (counterclockwise) 01154), or ISO VG 220 GL4 (e.g. Aral Degol BG220) or SAE 90 GL4 gear Gear on the right side (from the front of oil. - Page 3 Giant plunger pumps are suitable for read and followed. Giant will not bear pumping clean water and other non- responsiblity for damage to materials aggressive or nonabrasive media with a or persons caused by improper specific weight similar to water.

- Page 4 Specifications Model GP8135A U.S........(Metric) Flow ..............up to 29.1 GPM* ....(110 LPM)* Discharge Pressure ......... up to 7250 PSI* ....(500 bar)* Power Consumption ........94 BHP* ......70 kW* Maximum Crankshaft Speed ..............580 RPM Inlet Pressure ..........Up to 145 PSI ....(10 bar) Plunger Diameter ..........

- Page 5 Specifications Model GP8140A U.S........(Metric) Flow ..............up to 39.6 GPM* ....(150 LPM)* Discharge Pressure ......... up to 5510 PSI* ....(380 bar)* Maximum Crankshaft Speed ................580 RPM* Power Consumption ........94 BHP ........70 kW Inlet Pressure ..........Up to 145 PSI ....(10 bar) Plunger Diameter ..........

- Page 6 EXPLODED VIEW - GP8135 & GP8140...

- Page 7 Parts List - GP8135 and GP8140 Item Part Description Item Part Description 05651 Crankcase 06098 Tension Spring, GP8135 06893 Oil Filler Plug Assy with Vent 05828 Tension Spring, GP8140 05652 Rear Foot for Crankcase 05834 Stud Bolt 05653 Front Foot for Crankcase 05073 Hexagon Nut 05654...

-

Page 8: Troubleshooting

Pump Repair Kits - GP8135 and GP8140 Inlet Valve Kit - #09709 Plunger Packing Kit - GP8135 - # 09707 Item Part # Description Qty. Item Part # Description Qty. 05837 Inlet Valve Assembly 05408 O-Ring 05408 O-Ring 05617 O-Ring 05744 Sleeve Discharge Valve Kit - #09710... - Page 9 GP8135 and GP8140 Pump Repair Instructions To Check Valves Loosen screws (58) and lift discharge casing (50B) up and away. Take out pressure springs (57). Pull out as- sembled valves (51 and 52) with fitting tool (p/n 07662). Dismantling valves: the spring tension cap (51A, 52A) is screwed together with the valve seat (51B/52B). Remove spring tension cap, take out springs (51E/52E) and valve plate (51C/52C).

- Page 10 GP8135 and GP8140 Pump Repair Instructions Mounting Valve Casing: Press seal cases (38) (with the stepped OD diameter 65mm) carefully to its stop in the centering holes of the intermediate casing. Mount flat leakage seal (62D). Important! The flat leakage seal (62D) must be positioned with its 3mm diameter bore onto the notched pin (62C) on the intermediate casing.

- Page 11 GP8135 and GP8140 Pump Dimensions- Inches (MM)

- Page 12 NON-SALINE, clean water applications. 2. One (1) year from the date of shipment for all other Giant industrial and consumer pumps. 3. Six (6) months from the date of shipment for all rebuilt pumps.

Need help?

Do you have a question about the GP8135A and is the answer not in the manual?

Questions and answers