Table of Contents

Advertisement

Quick Links

INSTALLATION

and OPERATION

MANUAL

READ THIS INSTRUCTION MANUAL THOROUGHLY

BEFORE INSTALLING, OPERATING, SERVICING OR

MAINTAINING THE LIFT. SAVE THIS MANUAL

.

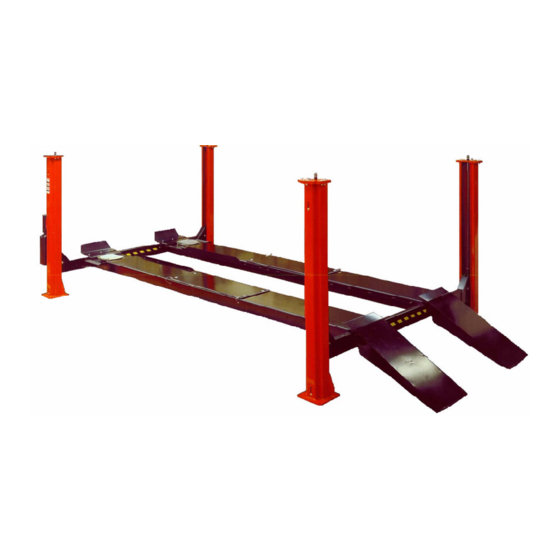

KODIAK QUAD RACK

MODEL: ALIGNMENT 44218Q

SERVICE 44218QF

309 Exchange Avenue, Conway, Arkansas, 72032

TEL: 501-450-1500 FAX: 501-450-1585

REV.‐ 08/17/2021

6‐6197‐W

1 of 76

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for John Bean ALIGNMENT 44218Q

- Page 1 OPERATION MANUAL READ THIS INSTRUCTION MANUAL THOROUGHLY BEFORE INSTALLING, OPERATING, SERVICING OR MAINTAINING THE LIFT. SAVE THIS MANUAL KODIAK QUAD RACK MODEL: ALIGNMENT 44218Q SERVICE 44218QF 309 Exchange Avenue, Conway, Arkansas, 72032 TEL: 501-450-1500 FAX: 501-450-1585 REV.‐ 08/17/2021 6‐6197‐W 1 of 76...

-

Page 2: Table Of Contents

TABLE OF CONTENTS PAGE OWNER / EMPLOYER OBLIGATIONS ............4 IMPORTANT SAFETY INSTRUCTIONS ............ 5 Safety Warning Labels ................. 8 GENERAL SPECIFICATION ..............9 Service & Alignment Wheelbase Specification ........10 ... - Page 3 10.3 Wire Ropes ..................45 10.3.1 Wire Rope Conditions Guide ........45 10.3.2 Wire Rope Replacement Criteria....... 46 10.3.3 Wire Rope Inspection ..........46 10.3.4 Wire Rope Lubrication ..........46 10.3.5 Wire Rope Adjustment ..........

-

Page 4: Owner / Employer Obligations

12.11 Hydraulic And Air Kit ................67 12.12 Parts List – Hydraulic And Air Kit ............68 12.13 Filter / Regulator / Lubricator Assembly ..........69 12.14 Cable Routing ..................70 12.15 Parts List –... -

Page 5: Important Safety Instructions

6. The Owner/Operator shall provide necessary lockout/tagout means for energy sources per ANSI Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of Energy Sources, before beginning any lift repairs and maintenance. 7. The Owner/Employer shall not modify the lift in any manner without the prior written consent of the manufacturer. - Page 6 11. Keep hair, loose clothing, fingers, and all parts of body away from moving parts. 12. To reduce the risk of electric shock, do not use on wet surfaces or expose to rain. 13. Use only as described in this manual. Use only manufacturer’s recommended attachments.

- Page 7 28. Do not remove hydraulic fittings while under pressure. For additional safety instructions regarding lifting, lift types, warning labels, preparing to lift, vehicle spotting, vehicle lifting, maintaining load stability, emergency procedures, vehicle lowering, lift limitations, lift maintenance, good shop practices, installation, operator training and owner/employer responsibilities, please refer to “Lifting It Right”...

-

Page 8: Safety Warning Labels

SAVE THESE INSTRUCTIONS SAFETY WARNING LABELS SAVE THESE INSTRUCTIONS 8 of 76... -

Page 9: General Specification

GENERAL SPECIFICATION Maximum Capacity 18,000 lb 8165 kg Maximum Wheelbase – General Service 220” 5588 mm Maximum Wheelbase – 2-Wheel 203” 5156 mm Alignment Maximum Wheelbase – 4-Wheel 144” 3658 mm Alignment Minimum Wheelbase – 4-Wheel Alignment 86” 2184 mm Overall Length 303-3/8”... -

Page 10: Service & Alignment Wheelbase Specification

3.1 SERVICE & ALIGNMENT WHEELBASE SPECIFICATION INSTALLATION REQUIREMENTS & TOOLS AFETY EQUIREMENTS FOR NSTALLATION AND ERVICE Refer to ANSI/ALI ALIS (current edition) MPORTANT Always wear safety glasses while installing lift. 4.1 FOUNDATION It is the user’s responsibility to provide a satisfactory installation area for the lift. Lifts should only be installed on level concrete floors with a minimum thickness of six inches (6") or 152 mm. -

Page 11: Contents

TAPE MEASURE ELECTRICAL TAPE STEP LADDER (adjusting cables and/or safety ladder in posts) SIDE CUTTERS (for cutting shipping straps) (8) JACK STANDS (set up) STANDARD SOCKETS AND WRENCHES ALLAN KEY SET SCREWDRIVER SET ... -

Page 12: Bay Layout

Lift it Right Manual “ALI” Lift it Right Safety Tips “ALI” Standards “ALI” Quick Reference Guide Glide Bearing Lifting cables BAY LAYOUT PLEASE TAKE THE TIME TO READ THESE INSTRUCTIONS COMPLETELY. A QUICK CHECK OF THE CONTENTS OF THE ACCESSORY BOX WOULD ALSO DECREASE THE INSTALLATION TIME. -

Page 13: Typical Bay Layout

6.1 TYPICAL BAY LAYOUT 13 of 76... -

Page 14: Chalk Line Layout

Figure 2 - Typical Bay Layout 6.2 CHALK LINE LAYOUT None of the anchors shall be closer than 4-3/4" to any edge of a concrete slab, expansion joint or crack in the garage floor. Review position of front towers, base plates and anchors, and relocate lines "1", "A", "D" if needed. - Page 15 Figure 3 - Chalk line layout 15 of 76...

-

Page 16: Identification Of Components

6.3 IDENTIFICATION OF COMPONENTS 1. Identify and unpack major lift components (Towers, Crossmembers & Runways) and place them where they belong according Figure 1. Figure 4. Component Identification 16 of 76... -

Page 17: Installation Instructions

2. Locate and identify the coiled cables as follows, place close to the rear of the left side of the chalk outlines. (Table 2): Cable P/N Location Length 2-1360 Front Left 407.5" Table 2: Cable 2-1361 Front Right 473.5" Identification 2-1362 Rear Left 162"... - Page 18 NOTE: THE CYLINDER ROD MUST BE FULLY EXTENDED IN ORDER TO ATTACH THE NON-THREADED ENDS (SLEEVES) OF THE CABLES TO THE CABLE FLANGE ON CYLINDER ROD. USE COMPRESSED AIR IN THE SHOP AND AN AIR NOZZLE AT THE BREATHER END TO EXTEND THE CYLINDER ROD. USE CAUTION AND PROTECTIVE EQUIPMENT WHEN WORKING WITH COMPRESSED AIR.

- Page 19 Assemble lower thrust washer and pulley and reinstall the pulley pin to hold these in place. Assemble four more thrust washers (as shown) and the top pulley with front left cable 2-1360 wrapped around the pulley. Push pulley pin further up to hold these in place.

- Page 20 10. Referring to Figure 7 and Figure 9, assemble the right side of the pulley stack, as shown, with cables 2-1362 & 2-1361. Pass the rear left cable 2-1362 between the two pulleys on the left side (shown above). ...

- Page 21 Figure 10. Front Pulley Stack Assembly 12. Remove the pulley pin and hardware from front of runway. 13. Referring to Figure 10 and Figure 11, assemble the pulley stack with cables as shown. Assemble lower thrust washer and spacer. Insert pulley pin to hold these in place.

-

Page 22: Assembly Of Front & Rear Crossmember

7.2 ASSEMBLY OF FRONT & REAR CROSSMEMBER 1. Move the front crossmember and rear crossmembers into position. Do not assemble yet. Refer to Figure 4 to identify the front and rear crossmembers. 2. Starting at the front pulley stack assembly, route the front cables thru the window in the front crossmember and out past the safety locks on each side of the crossmember. - Page 23 5. Using a floor jack or engine hoist, raise the front crossmember up to the level of the decks and attach it using the ½”DIA x 4½”LG hex bolts, ½” flat washers, ½” lock washers and ½” hex nuts found in the polybag labeled “E” (Decks). The cables running inside the crossmember must pass between the 1/2"x4-1/2"...

-

Page 24: Tower Assembly

Figure 15. Jack Stand setup on Crossmembers 8. Assemble right side deck assembly to front and rear crossmembers. 9. At this point the decks should be completely fastened to the crossmembers and the threaded portion of each cable should be routed through the crossmembers, past the lock safety. -

Page 25: Installation Of Towers

7.4 INSTALLATION OF TOWERS 1. Remove the slider block weldments from both crossmembers by removing the 3/8”-16UNC x 1”LG Hex HD Bolts and 3/8” lock washers attaching them to the crossmember. See Figure 16. 2. Determine which tower is the power post (see Figure 4) and position it in the front left corner. -

Page 26: Cable To Tower Installation

7.5 CABLE TO TOWER INSTALLATION 1. Assemble each cable to the top plate of their respective towers. Secure in place with 7/8" washer and two 7/8" hex nuts. See Figure 17. Note: During leveling of the lift (see Section 6.11), optional 1" and 2" spacers have been included to allow for more adjustment. -

Page 27: Power Pack Installation

7.6 POWER PACK INSTALLATION NOTE: When working with hydraulic lines and valves, it is important to keep all components clean and free of dirt. Figure 18. Powerpack Install 1. Locate Powerpack and Filter/Regulator/Lubricator (FRL) assembly inside the accessory box. Gather the 5/16" hardware located in "Polybag D"... -

Page 28: Hydraulic Installation

7.7 HYDRAULIC INSTALLATION 1. Locate the supply lines: 1/4" and 3/8" polytube (10ft.), 3/8" flexible hydraulic line (16ft.), and install the hose guard to cover all three lines. All four items are found in the accessory box TIP: Tape one end of the hydraulic hose to the two polytubes and feed them through the hose guard. -

Page 29: Air Installations

7.8 AIR INSTALLATIONS NOTE: When cutting polytube, be sure to cut the line at 90 degrees. Failure to do so may result in leaks in the air connections. 1. Locate the 1/4" polytube cross and tee fitting in polybag "C" in hardware kit. 2. -

Page 30: Electrical Connections

Figure 23. Air Connections NOTE: For those units equipped with jacking beams, this is the appropriate time to install them. Consult the jacking beam instruction manual found in each jacking beam box. 6. Hook up an air supply to the inlet of the FRL. (Note: customer to supply this fitting) 7.9 ELECTRICAL CONNECTIONS CAUTION: ALL ELECTRICAL CONNECTIONS SHOULD BE MADE BY A... -

Page 31: Filter/Regulator/Lubricator Commisionning

7.10 FILTER/REGULATOR/LUBRICATOR COMMISIONNING PROCEDURE FOR PREPARING FRL FOR USE WITH LIFT 1. Disconnect shop air from FRL inlet. Adding Oil to the lubricator cannot take place under a pressurized condition. 2. Using a slotted screwdriver or an Allen key, remove the filler cap from the top of the FRL. - Page 32 5. With the output end of the FRL disconnected (remove the quick disconnect fitting), reconnect the air line to the FRL unit. Air will flow freely through the FRL. 6. Perform Drip Check / Adjustment: Drips to be set to 2-3 per minute. SMC Brand - DIAL VERSION Turn the dial on the top end of the oil reservoir to the 2 position.

-

Page 33: Deck Leveling Procedure

7.11 DECK LEVELING PROCEDURE 7.11.1 Leveling Lift to Floor Note: Read the Operation Label on the powerpack for instructions. 1. Now that all the hydraulic and pneumatic connections are completed, push the up button on the powerpack to raise the lift off the jack stands. 2. -

Page 34: Leveling On Safety Ladders

7.12 LEVELING ON SAFETY LADDERS 1. Repeat the preceding steps until the lift is completely level when supported by the cables. 2. Raise the lift so that the deck is supported by the cables and is not resting on the safety ladders. -

Page 35: Anchor Installation

7.13 ANCHOR INSTALLATION Check all layout dimensions in the General Specifications in Figure 2 before continuing with anchor installation. 1. Refer to Figure 28 while reading through these instructions. Figure 28. Anchor installation 2. Ensure that the lift is fully supported by the cables and is at a level just above ground. - Page 36 NOTE: If anchors do not tighten to required torque, OR project more that 2-1/4" above the concrete surface due to floor slope, contact a foundation engineer to determine the best course of action. Figure 29: Embedment Figure 30: Leveling NOTE: The 3/4” 5 ½” lg. wedge anchor bolts supplied must have a minimum embedment of 3¼”...

-

Page 37: Accessory Installation

7.14 ACCESSORY INSTALLATION 1. Install the front wheel stops using the 1/2"-13 UNC × 1"LG hex bolts, 1/2" lock washers and flat washers found in polybag “F” (Wheelstops/Ramps). Figure 31: Front Wheelstops 2. Install the (4) sheave covers over the sheaves in the crossmember assembly. These are found in the accessory box. -

Page 38: Final Check Of Assembled Lift

6. Notice there are two Pinch Warning decals on the outside side of each runway, one towards the rear and one towards the front. Place the Large John Bean Decals 2 inches from the rear Pinch Warning Decal on each side of the runway being careful to center the decal vertically. -

Page 39: Operating Instructions

ANSI / ALI Safety Tip Card ANSI / ALI ALIS Safety Requirements for Installation and Service of Automotive Lifts ANSI / ALI Quick Reference Guide Train end user on operation of the lift Check level of hydraulic oil when the lift is fully lowered ... - Page 40 Stop vehicle well before it contacts the front wheel stops. At all times, be sure the rear wheels are forward of the approach ramps/chocks and the approach ramps/chocks will clear the tires when the lift is raised. Driver must exit the vehicle before rising.

-

Page 41: Operation Test With Vehicle

Do not operate lift with pulley covers removed from cross-member ends. Keep hands clear of the cross-member ends when lift is being raised or lowered. Do not raise or lower the lift while the jack beams are loaded. 8.1 OPERATION TEST WITH VEHICLE 1. -

Page 42: Recommended Inspection And Maintenance

8. Always keep the lift area free from debris. Grease and oil spills should always be cleaned up immediately. Never leave any tools or parts laying on the decks. 9. Never operate lift with passengers in vehicle. 10. Always raise the lift off safety locks before lowering. NOTE: DO NOT ATTEMPT TO OPERATE THIS LIFT IF ANY PART IS NOT WORKING PROPERLY OR YOU HAVE NOT READ THE COMPLETE OPERATING INSTRUCTION MANUAL. - Page 43 INSPECTION FREQUENCY COMPONENT SEMI- DAILY WEEKLY MONTHLY QUARTERLY ANNUALY ANNUALY Entire Lift and surrounding 8.15 area Entire Lift 8.15 Operation Fasteners Wire Ropes 8.2.3 8.2.4 8.2.5 Sheaves 8.4.1 8.4.2 Sheave Pins 8.4.3 8.4.2 Safety Dogs Slack Cable Devices Latch Plates (Ladders) Air Filter, Regulator,...

-

Page 44: Maintenance Records

10.2 MAINTENANCE RECORDS Maintenance and Training Performed Date Notes 44 of 76... -

Page 45: Wire Ropes

10.3 WIRE ROPES Wire ropes are critical to safe and reliable performance of your lift. Cables are expendable items and should be replaced as a set. 10.3.1 Wire Rope Conditions Guide Typical good cable Cable with necking Broken wires Excessive wear of wires Rust on sheave stack and Corrugated sheave... -

Page 46: Wire Rope Replacement Criteria

10.3.2 Wire Rope Replacement Criteria If any cable is found to be in need of replacement, the entire cable set, pulleys and safety rollers must be replaced immediately. See 8.2.1, cable conditions guide. In the following table, "lay" means the distance measured along a line parallel to the axis of the rope in which the strand makes one complete turn about the axis of the rope, or the wires make a complete... -

Page 47: Inspect Cable Flange

replaced. Do not add washers or other spacers to re-use previously used adjustment threads. Wire rope tension adjustment should be performed when installing the lift and every three months. 10.3.6 Inspect Cable Flange Make sure the edges of the counter-bores in the cable flange are not damaged or worn, indicating that cable sleeves may not be properly seated at all times. -

Page 48: Sheave Pins

Fully raise the lift, to inspect sheaves in runways. Hold lowering handle down to lower lift onto safety latches Pull on cables in runway to create slack in cables. Check all sheaves for excessive wobble, or movement. Grasp rim of sheave and attempt to wobble (tilt) side to side. -

Page 49: Air Lubricator Oil Level

Drain water bowl on lift supplied water separator. Press valve at the bottom of the bowl to clear. Check operation of air release valve for air leaks. Check air cylinders for visible damage. Check air lines for leaks, wear or kinks. 10.8.2 Air Lubricator Oil Level NOTE: Failure to maintain oil level in lubricator will void warranty of all pneumatic... -

Page 50: Runways

10.11 RUNWAYS 10.11.1 Check Runways Check level of runways on the floor, on the locks and on the cables: Refer to Section 6.10. Adjust as required. Check runways for damage or abnormal deformation. If such conditions exist, contact Snap-on Equipment Technical Support. 10.11.2 Inspect Jackbeam Tracks ... -

Page 51: Front And Rear Turn/Slip Plates

10.14 FRONT AND REAR TURN/SLIP PLATES 10.14.1 Visual Inspection Check front turn tables and rear slip plates for unusual deflection, damage, fluid spills. Clean or further inspect if needed. 10.14.2 Clean Rear Slip Plates and Front Turn Tables ... -

Page 52: Rolling Air Jacks

10.15 ROLLING AIR JACKS Lubricate roller bearings and roller guide springs. Dismantle and clean lift arms. Clean and lubricate rollers/sliders and hinge points. Clean and lubricate safety mechanism. Change hydraulic oil every two years 10.16 ENTIRE LIFT ... - Page 53 or release of stored energy could occur and cause injury, as well as while working on or near exposed de-energized electrical conductors and parts of electrical equipment. Hazards being guard against include being caught in, being crushed by, being struck by, being thrown from, or contacting live electrical circuits/parts.

-

Page 54: Isolation And Verification Procedure

11.1 ISOLATION AND VERIFICATION PROCEDURE: Table 1: ISOLATION AND VERIFICATION PROCEDURES: LOCKOUT LOCATION ENERGY PROCEDURE FOR LOCING (TO BE TYPE AND OUT AND OR RELEASING VERIFY PROCEDURES COMPLETED SOURCE ENERGIES BY END USER) VERIFY THAT THE LIFT IS CONTACTING THE SUPPLEMENTARY JACK STANDS, THE BLOCKS ARE SECURLY PLACED AND THE... -

Page 55: Emergency Operation

VERIFY THE VALVE IS CLOSED AND LOCKOUT SLOWLY CLOSE LOCKOUT DEVICE IS PROPERLY VALVE TO RELEASE AIR ATTACHED. OPERATE THE PRESSURE GRADUALLY. PNEUMATIC SYSTEM TO ATTACH MULTIPLE LOCKOUT ENSURE THE SYSTEM IS DE- PNEUMATIC DEVICE, LOCK AND TAG. ENERGIZED. IT MAY BE UPTO 160PSI NECESSARY TO BLEED THE SYSTEM OF REMAINING... - Page 56 4) Use a second person standing at a safe distance away from the lift to keep watch on the area, lift, vehicle and other personnel throughout the process. This person should signal the person performing the procedure to stop if necessary. 5) Use a caution tape or similar to barrier the area around the lift to avoid personnel from accidently entering the area while this process is being performed.

-

Page 57: Parts List

12.0 PARTS LIST 12.1 LIFT ASSEMBLY 57 of 76... -

Page 58: Parts List - Lift Assembly

12.2 PARTS LIST – LIFT ASSEMBLY REPLACE WORN, DAMAGED OR BROKEN PARTS WITH PARTS APPROVED BY THE ORIGINAL EQUIPMENT MANUFACTURER ONLY Item# Part # Description Qty. 4-1457 POWER TOWER (FL) ASSY 4-0657-3 FRONT CROSSMEMBER ASS'Y 4-0656-3 DECK ASSEMBLY, LS 4-0659-3 DECK ASSEMBLY, RS 4-0658-3 REAR CROSSMEMBER ASS'Y... -

Page 59: Tower Assembly

12.3 TOWER ASSEMBLY 59 of 76... -

Page 60: Parts List - Power Tower Assembly

6-0047 HEX HD BOLT, 1/2-13 X 1-3/4 LG, GR.5, PL 6-4322 JOHN BEAN RUNWAY DECAL * NOTE: These part numbers are only applied to the front left (power) tower. **NOTE: Items 9-11 come as a set, part # 6-0988. 60 of 76... -

Page 61: Deck Assembly (Left Side)

12.5 DECK ASSEMBLY (LEFT SIDE) 61 of 76... -

Page 62: Parts List - Deck Assembly (Left Side)

12.6 PARTS LIST – DECK ASSEMBLY (LEFT SIDE) Item# Part # Description Qty. 4-0629 ALIGNMENT DECK WELDMENT LS 2-1355 DECK SHEAVE PIN 3-0681 HYDRAULIC CYLINDER ASSEMBLY 6-0248 Flat Washer, ½ ID SAE 6-0044 Hex HD Bolt, 1/2" x 1/2" 1-1747 CYLINDER SLING 6-0058 LOCK WASHER, 3/8"... -

Page 63: Crossmember Assembly

12.7 CROSSMEMBER ASSEMBLY 63 of 76... -

Page 64: Parts List - Crossmember Assembly

12.8 PARTS LIST – CROSSMEMBER ASSEMBLY Item# Part # Description Qty. 4-0627 FRONT CROSSMEMBER WELDMENT 1-1744 LOCK SAFETY PIN WELDMENT 2-1424 SAFETY LOCK WELDMENT 6-0801 SHOULDER BOLT , 3/8 x 1 ½ LG. 6-0069 Shoulder Bolt, 3/8 DIA. X 5/8 LG. 1-0786 SHEAVE SPACER 1-1712... -

Page 65: Cylinder Assembly

12.9 CYLINDER ASSEMBLY 65 of 76... -

Page 66: Parts List - Cylinder Assembly

12.10 PARTS LIST – CYLINDER ASSEMBLY ITEM QTY. DESCRIPTION PART # CYLINDER TUBE WELDMENT 4” BORE 2-1345 PISTON ROD - MACHINED 2-1340 ORING, 4”OD x 1/8”C/S 6-1633 BACKUP RING 6-1634 GLAND 3-0673 ROD SEAL, 1½”ID x 1 7/8”OD x 1/4” 6-1892 ROD WIPER, 1½”ID x 1 7/8”OD x 3/16”... -

Page 67: Hydraulic And Air Kit

12.11 HYDRAULIC AND AIR KIT 67 of 76... -

Page 68: Parts List - Hydraulic And Air Kit

12.12 PARTS LIST – HYDRAULIC AND AIR KIT ITEM QTY. DESCRIPTION PART # 90° ELBOW, 1/8" NPT x 1/4" POLYTUBE 6-0709 AIR CYLINDER 6-0651 10FT 1/4" DIA. POLY TUBE 6-1396 ADAPTER, 3/8" POLY TUBE x 1/4" NPT 6-0710 TERMINAL BOLT, 3/4" 6-0713 1/4"... -

Page 69: Filter / Regulator / Lubricator Assembly

12.13 FILTER / REGULATOR / LUBRICATOR ASSEMBLY Complete Assembly: 2-3005 ITEM QTY DESCRIPTION PART # MOUNTING BRACKET, FRL 2-3022 DECAL, SAFETY RELEASE 6-3558 DECAL, OIL LEVER 6-3696 FRL ASSEMBLY W/ RELEASE BUTTON, contains: 2-3021 FILTER/REGULATOR/LUBRICATOR ASS'Y 6-4142_FM 90 DEG. ELBOW, 1/4"NPT M - 3/8" POLY 6-3010 AIR VALVE &... -

Page 70: Cable Routing

12.14 CABLE ROUTING 70 of 76... -

Page 71: Parts List - Cable Routing

12.15 PARTS LIST – CABLE ROUTING ITEM QTY. DESCRIPTION PART # CABLE ASSY. 407.5” - FRONT LEFT 2-1360 CABLE ASSY. 473.5” - FRONT RIGHT 2-1361 CABLE ASSY. 162” - REAR LEFT 2-1362 CABLE ASSY. 228” - REAR RIGHT 2-1363 HEX NUT, 7/8”-14UNF GR5 6-0724 CABLE SPACER, 2”LG 1-0800... -

Page 72: Power Pack Assembly

12.16 POWER PACK ASSEMBLY 72 of 76... -

Page 73: Parts List - Power Pack

12.17 PARTS LIST – POWER PACK ITEM QTY. DESCRIPTION PART # MICROSWITCH AND WIRING ASSEMBLY, 1PH 6-0881 MICROSWITCH BOOT 6-1084 MOTOR, 230V AC, 1 PHASE, 60 HERTZ 3HP 6-1959 MOTOR ADAPTER KIT 0-0197 SOCKET HD.CAP SCW. 1/4"-20UNC X 1 5/8"LG. 6-1085 LOCK WASHER, 1/4"I.D. - Page 74 CAUTION ALL SAFETY LADDERS USED ON 4-POST LIFTS ARE PRELOADED. REMOVING THE BOLT HOLDING THE BOTTOM PORTION OF THE SAFETY LADDER WITHOUT PROPER PRECAUTIONS CAN RESULT IN INJURY. PLEASE CONTACT CUSTOMER SERVICE FOR PROPER REMOVAL INSTRUCTIONS. 74 of 76...

-

Page 75: Available Accessories

13.0 AVAILABLE ACCESSORIES Hydraulic Jack Beams Premium Air / Standard Air / Hydraulic Jack Hydraulic Jack Beam Beam 4500 lb, 6000 lb, 7000 lb 6000 lb, 7000 lb Other Accessories Drive-On Ramp Air Outlet Kit Extension for (Factory Low Profile Installed) Vehicle (set of 2) - Page 76 REVISIONS 08/17/2021-Safety Requirements for Installation, added Outdoor Installs are Prohibited 76 of 76...

Need help?

Do you have a question about the ALIGNMENT 44218Q and is the answer not in the manual?

Questions and answers