Summary of Contents for Daikin FXMA63A5VEB

- Page 1 Installation and operation manual VRV system air conditioner FXMA50A5VEB FXMA63A5VEB FXMA80A5VEB Installation and operation manual FXMA100A5VEB English VRV system air conditioner FXMA125A5VEB...

- Page 2 4P686450-1...

- Page 3 4P686450-2...

-

Page 4: Table Of Contents

Daikin website (publicly accessible). 13.2 Connecting the refrigerant piping ..........19 ▪ The full set of latest technical data is available on the Daikin 13.2.1 To connect the refrigerant piping to the indoor unit ..19 Business Portal (authentication required). - Page 5 Make sure installation, servicing, maintenance, repair and unit. Refer to the technical datasheet of your model for applied materials follow the instructions from Daikin and, in the setting range. addition, comply with applicable legislation and are ▪...

-

Page 6: Instructions For Equipment Using R32 Refrigerant

A phase advancing capacitor will reduce performance and may Make sure installation, servicing, maintenance and repair cause accidents. comply with instructions from Daikin and with applicable legislation and are executed ONLY by authorised persons. WARNING WARNING Use an all-pole disconnection type breaker with at least 3 ... -

Page 7: Installation Space Requirements

3 User safety instructions NOTICE WARNING ▪ Incomplete flaring may cause refrigerant gas leakage. This appliance contains R32 refrigerant. For the minimum floor area of the room in which the appliance is stored refer ▪ Do NOT re-use flares. Use new flares to prevent to installation and operation manual of the outdoor unit. -

Page 8: Instructions For Safe Operation

3 User safety instructions Instructions for safe operation CAUTION To avoid oxygen deficiency, ventilate WARNING the room sufficiently if equipment with ▪ Do NOT modify, disassemble, burner is used together with the remove, reinstall or repair the unit system. yourself as incorrect dismantling or installation may cause an electrical CAUTION shock or fire. - Page 9 3 User safety instructions CAUTION ▪ Do NOT use cleaning materials or means to accelerate the defrosting After a long use, check the unit stand process other than those and fitting for damage. If damaged, the recommended by the manufacturer. unit may fall and result in injury.

-

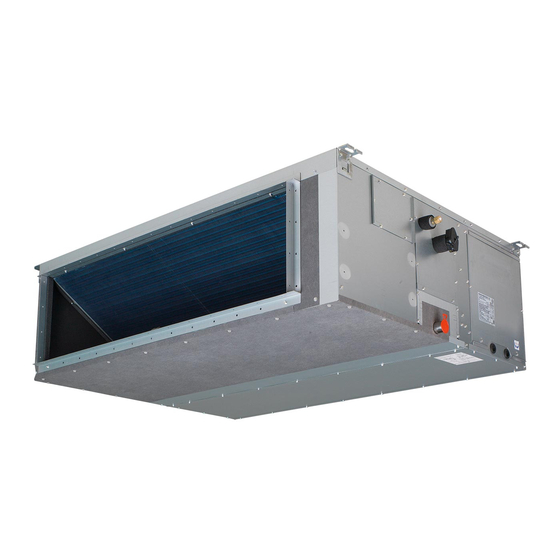

Page 10: About The System

4 About the system Discharge air About the system Refrigerant piping + transmission cable Drain pipe WARNING ▪ Do NOT modify, disassemble, remove, reinstall or User interface repair the unit yourself as incorrect dismantling or installation may cause an electrical shock or fire. Contact your dealer. -

Page 11: Special Heating Operation Modes

7 Maintenance and service Icon Operation mode CAUTION Cooling. In this mode, cooling will be activated as Do NOT insert fingers, rods or other objects into the air required by the setpoint, or by Setback operation. inlet or outlet. When the fan is rotating at high speed, it will cause injury. -

Page 12: Cleaning The Air Filter And Air Outlet

7 Maintenance and service 8 In case of bottom suction with duct, close the protective guard. Cleaning the air filter and air outlet In case of rear suction with duct, close service duct opening. CAUTION 9 Turn ON the power. Turn off the unit before cleaning the air filter and air outlet. -

Page 13: About The Refrigerant Leakage Sensor

8 Troubleshooting 7.3.1 About the refrigerant leakage sensor WARNING Troubleshooting The R32 refrigerant leakage sensor must be replaced after every detection or at the end of its lifetime. ONLY If one of the following malfunctions occur, take the measures shown authorised persons may replace the sensor. -

Page 14: For The Installer

11 About the box For the installer NOTICE About the box The professional installer shall evaluate the EMC situation before installation, if the equipment is installed closer than 11.1 Indoor unit 30 m to a residential location. CAUTION 11.1.1 To remove the accessories from the This equipment is NOT intended for use in residential indoor unit locations and will NOT guarantee to provide adequate... -

Page 15: Mounting The Indoor Unit

12 Unit installation 12.2 Mounting the indoor unit 12.2.1 Guidelines when installing the indoor unit Installation options CAUTION In case of installation WITHOUT duct on the air inlet side, fix the air filter on the service cover side by screw (field supply). -

Page 16: Guidelines When Installing The Ducting

12 Unit installation 12.2.2 Guidelines when installing the ducting WARNING Do NOT install operating ignition sources (example: open flames, an operating gas appliance or an operating electric heater) in the duct work. CAUTION ▪ Make sure the installation of the duct does NOT exceed the setting range of the external static pressure for the unit. -

Page 17: Guidelines When Installing The Drain Piping

12 Unit installation ▪ Filter. Be sure to attach an air filter inside the air passage on the intake side. Use an air filter with dust collecting efficiency ≥50% (gravimetric method). 12.2.3 Guidelines when installing the drain piping Make sure condensation water can be evacuated properly. This involves: ▪... -

Page 18: Piping Installation

13 Piping installation NOTICE ▪ Do NOT remove the drain pipe plug. Water might leak out. ▪ Use the drain outlet only to discharge the water if the drain pump is not used or before maintenance. ▪ Insert and remove the drain plug gently. Excessive force may deform the drain socket of the drain pan. -

Page 19: Refrigerant Piping Insulation

14 Electrical installation ▪ Flare connections: Only use annealed material. ▪ Piping temper grade and thickness: Outer diameter Temper grade Thickness (t) (Ø) Ø 6.4 mm (1/4") Annealed (O) ≥0.8 mm 9.5 mm (3/8") 12.7 mm (1/2") 15.9 mm (5/8") Depending on the applicable legislation and the maximum Liquid piping working pressure of the unit (see "PS High"... -

Page 20: To Connect The Electrical Wiring To The Indoor Unit

Next commissioning instructions in this chapter, a general commissioning checklist is also available on the Daikin Business Portal (authentication required). The general commissioning checklist is complementary to the instructions in this chapter and can be used as a guideline and reporting template during the commissioning and hand-over to the user. -

Page 21: Checklist Before Commissioning

16 Configuration 15.1 Checklist before commissioning Configuration 1 After the installation of the unit, check the items listed below. 16.1 Field setting 2 Close the unit. 3 Power up the unit. Make the following field settings so that they correspond with the You read the complete installation and operation actual installation setup and with the needs of the user: instructions, as described in the installer and user... - Page 22 16 Configuration 1 Operate the unit in fan only mode prior to using the airflow If you want… Then automatic adjustment function. — 2 Stop the air conditioning unit. During thermostat 12 (22) OFF at cooling 3 Set the value number “—“ to 03 for M 11(21) and SW 7. Setup volume operation 4 Start the air conditioning unit.

-

Page 23: Technical Data

▪ A subset of the latest technical data is available on the regional 6°C cooling 24°C/heating Daikin website (publicly accessible). 18°C ▪ The full set of latest technical data is available on the Daikin 7°C cooling 24°C/heating Business Portal (authentication required). 17°C Setting: Auto-restart after power failure 17.1... - Page 24 17 Technical data Symbol Meaning Symbol Meaning BZ, H*O Buzzer S*W, SW* Operation switch Capacitor SA*, F1S Surge arrester AC*, CN*, E*, HA*, HE*, HL*, Connection, connector SR*, WLU Signal receiver HN*, HR*, MR*_A, MR*_B, S*, U, Selector switch V, W, X*A, K*R_*, NE SHEET METAL Terminal strip fixed plate D*, V*D...

- Page 28 3P680922-1A 2022.01 Verantwortung für Energie und Umwelt...

Need help?

Do you have a question about the FXMA63A5VEB and is the answer not in the manual?

Questions and answers