Summary of Contents for Daikin FXMA50A5VEB

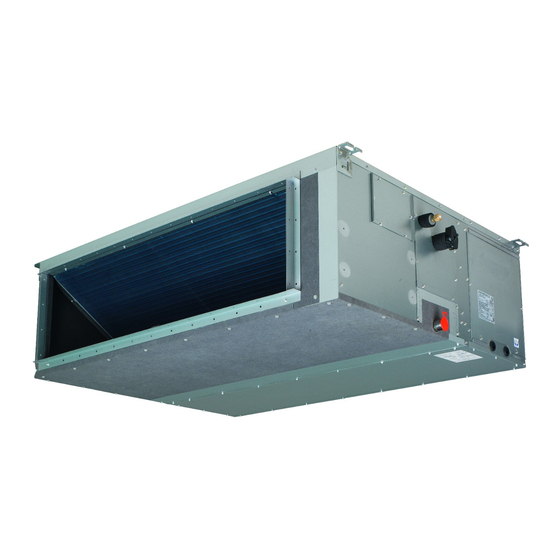

- Page 1 Installer and user reference guide VRV system air conditioner FXMA50A5VEB FXMA63A5VEB FXMA80A5VEB FXMA100A5VEB FXMA125A5VEB...

-

Page 2: Table Of Contents

Table of contents Table of contents 1 About the documentation About this document ..............................2 General safety precautions About the documentation .............................. 2.1.1 Meaning of warnings and symbols ........................ For the installer ................................2.2.1 General ................................2.2.2 Installation site ............................... 2.2.3 Refrigerant —... - Page 3 Table of contents 14 About the box 14.1 Overview: About the box ..............................43 14.2 Indoor unit ..................................43 14.2.1 To unpack and handle the unit ........................43 14.2.2 To remove the accessories from the indoor unit ..................44 15 About the units and options 15.1 Identification ...................................

-

Page 4: About The Documentation

The original documentation is written in English. All other languages are translations. Technical engineering data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). -

Page 5: General Safety Precautions

General safety precautions 2 General safety precautions 2.1 About the documentation ▪ The original documentation is written in English. All other languages are translations. ▪ The precautions described in this document cover very important topics, follow them carefully. ▪ The installation of the system, and all activities described in the installation manual and in the installer reference guide MUST be performed by an authorised installer. -

Page 6: For The Installer

Improper installation or attachment of equipment or accessories could result in electrical shock, short-circuit, leaks, fire or other damage to the equipment. ONLY use accessories, optional equipment and spare parts made or approved by Daikin. WARNING Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions described in the Daikin documentation). -

Page 7: Installation Site

General safety precautions WARNING Provide adequate measures to prevent that the unit can be used as a shelter by small animals. Small animals that make contact with electrical parts can cause malfunctions, smoke or fire. CAUTION Do NOT touch the air inlet or aluminium fins of the unit. CAUTION ▪... - Page 8 General safety precautions NOTICE Make sure the field piping and connections are NOT subjected to stress. WARNING During tests, NEVER pressurise the product with a pressure higher than the maximum allowable pressure (as indicated on the nameplate of the unit). WARNING Take sufficient precautions in case of refrigerant leakage.

-

Page 9: Electrical

General safety precautions ▪ ONLY use tools exclusively for the refrigerant type used in the system, this to ensure pressure resistance and prevent foreign materials from entering into the system. ▪ Charge the liquid refrigerant as follows: Then A siphon tube is present Charge with the cylinder upright. - Page 10 General safety precautions WARNING ▪ ONLY use copper wires. ▪ Make sure the field wiring complies with the applicable legislation. ▪ All field wiring MUST be performed in accordance with the wiring diagram supplied with the product. ▪ NEVER squeeze bundled cables and make sure they do NOT come in contact with the piping and sharp edges.

- Page 11 General safety precautions WARNING ▪ After finishing the electrical work, confirm that each electrical component and terminal inside the electrical components box is connected securely. ▪ Make sure all covers are closed before starting up the unit. NOTICE ONLY applicable if the power supply is three‑phase, and the compressor has an ON/ OFF starting method.

-

Page 12: Specific Installer Safety Instructions

WARNING Make sure installation, servicing, maintenance, repair and applied materials follow the instructions from Daikin and, in addition, comply with applicable legislation and are performed by qualified persons only. In Europe and areas where IEC standards apply, EN/IEC 60335-2-40 is the applicable standard. - Page 13 Specific installer safety instructions CAUTION ▪ Make sure the installation of the duct does NOT exceed the setting range of the external static pressure for the unit. Refer to the technical datasheet of your model for the setting range. ▪ Make sure to install the canvas duct so vibrations are NOT transmitted to the duct or ceiling.

-

Page 14: Instructions For Equipment Using R32 Refrigerant

Specific installer safety instructions WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth. Incomplete earthing may cause electrical shock. ▪... - Page 15 WARNING Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable legislation and are executed ONLY by authorised persons. WARNING If one or more rooms are connected to the unit using a duct system, make sure: ▪...

-

Page 16: Installation Space Requirements

Specific installer safety instructions NOTICE ▪ Incomplete flaring may cause refrigerant gas leakage. ▪ Do NOT re-use flares. Use new flares to prevent refrigerant gas leakage. ▪ Use flare nuts that are included with the unit. Using different flare nuts may cause refrigerant gas leakage. -

Page 17: For The User

For the user FXMA-A Installer and user reference guide VRV system air conditioner 4P680920-1 – 2022.01... -

Page 18: User Safety Instructions

User safety instructions 4 User safety instructions Always observe the following safety instructions and regulations. 4.1 General WARNING If you are NOT sure how to operate the unit, contact your installer. WARNING This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning... -

Page 19: Instructions For Safe Operation

User safety instructions ▪ Units are marked with the following symbol: This means that electrical and electronic products may NOT be mixed with unsorted household waste. Do NOT try to dismantle the system yourself: the dismantling of the system, treatment of the refrigerant, of oil and of other parts MUST be done by an authorised installer and MUST comply with applicable legislation. - Page 20 User safety instructions CAUTION ▪ NEVER touch the internal parts of the controller. ▪ Do NOT remove the front panel. Some parts inside are dangerous to touch and appliance problems may happen. For checking and adjusting the internal parts, contact your dealer. WARNING This unit contains electrical and hot parts.

- Page 21 User safety instructions "10 Maintenance and service" [ 31]) Maintenance and service (see CAUTION: Pay attention to the fan! It is dangerous to inspect the unit while the fan is running. Make sure to turn OFF the main switch before executing any maintenance task. CAUTION Do NOT insert fingers, rods or other objects into the air inlet or outlet.

- Page 22 User safety instructions CAUTION Turn off the unit before cleaning the air filter and air outlet. WARNING Do NOT let the indoor unit get wet. Possible consequence: Electrical shock or fire. About the refrigerant (see "10.5 About the refrigerant" [ 34]) WARNING: MILDLY FLAMMABLE MATERIAL The refrigerant inside this unit is mildly flammable.

- Page 23 User safety instructions WARNING The R32 refrigerant leakage sensor must be replaced after every detection or at the end of its lifetime. ONLY authorised persons may replace the sensor. "11 Troubleshooting" [ 37]) Troubleshooting (see WARNING Stop operation and shut OFF the power if anything unusual occurs (burning smells etc.).

-

Page 24: About The System

About the system 5 About the system WARNING ▪ Do NOT modify, disassemble, remove, reinstall or repair the unit yourself as incorrect dismantling or installation may cause an electrical shock or fire. Contact your dealer. ▪ In case of accidental refrigerant leaks, make sure there are no naked flames. The refrigerant itself is entirely safe and non-toxic. -

Page 25: Information Requirements For Fan Coil Units

Total electric power input elec Sound power level (cooling) dB(A) Sound power level (heating) dB(A) Contact details: DAIKIN INDUSTRIES CZECH REPUBLIC s.r.o. U Nové Hospody 1/1155, 301 00 Plzeň Skvrňany, Czech Republic FXMA50 0.125 FXMA63 0.140 FXMA80 0.202 FXMA100 12.5... -

Page 26: User Interface

User interface 6 User interface CAUTION ▪ NEVER touch the internal parts of the controller. ▪ Do NOT remove the front panel. Some parts inside are dangerous to touch and appliance problems may happen. For checking and adjusting the internal parts, contact your dealer. -

Page 27: Before Operation

Before operation 7 Before operation WARNING This unit contains electrical and hot parts. WARNING Before operating the unit, be sure the installation has been carried out correctly by an installer. CAUTION It is unhealthy to expose your body to the air flow for a long time. CAUTION To avoid oxygen deficiency, ventilate the room sufficiently if equipment with burner is used together with the system. -

Page 28: Operation

Operation 8 Operation 8.1 Operation range INFORMATION For the operation limits see the technical data of the connected outdoor unit. 8.2 About operation modes INFORMATION Depending on the installed system, some operation modes will not be available. ▪ The air flow rate may adjust itself depending on the room temperature or the fan may stop immediately. -

Page 29: Special Heating Operation Modes

Operation 8.2.2 Special heating operation modes Operation Description Defrost To prevent a loss of heating capacity due to frost accumulation in the outdoor unit, the system will automatically switch to defrost operation. During defrost operation, the indoor unit fan will stop operation, and the following icon will appear on the home screen: The system will resume normal... -

Page 30: Energy Saving And Optimum Operation

Energy saving and optimum operation 9 Energy saving and optimum operation CAUTION NEVER expose little children, plants or animals directly to the airflow. NOTICE Do NOT place objects below the indoor and/or outdoor unit that may get wet. Otherwise condensation on the unit or refrigerant pipes, air filter dirt or drain blockage may cause dripping, and objects under the unit may get dirty or damaged. -

Page 31: Maintenance And Service

Maintenance and service 10 Maintenance and service 10.1 Precautions for maintenance and service NOTICE Maintenance MUST be done by an authorised installer or service agent. We recommend performing maintenance at least once a year. However, applicable legislation might require shorter maintenance intervals. CAUTION: Pay attention to the fan! It is dangerous to inspect the unit while the fan is running. -

Page 32: Cleaning The Air Filter And Air Outlet

Maintenance and service DANGER: RISK OF ELECTROCUTION Disconnect the power supply for more than 10 minutes, and measure the voltage at the terminals of main circuit capacitors or electrical components before servicing. The voltage MUST be less than 50 V DC before you can touch electrical components. For the location of the terminals, see the warning label for persons performing service and maintenance. -

Page 33: To Clean The Air Outlet

Maintenance and service rear suction bottom suction 1× 1× 3 Clean the air filter. Use a vacuum cleaner or wash with water. If the air filter is very dirty, use a soft brush and neutral detergent. 4 Dry the air filter in the shadow. 5 Re-attach the air filter. -

Page 34: Maintenance After A Long Stop Period

Maintenance and service ▪ Clean air filters and casings of indoor units (see "10.2 Cleaning the air filter and outlet" [ 32]). ▪ Remove the batteries from the user interface (if applicable). 10.4 Maintenance after a long stop period E.g., at the beginning of the season. ▪... -

Page 35: About The Refrigerant Leakage Sensor

Maintenance and service WARNING ▪ The refrigerant inside the unit is mildly flammable, but normally does NOT leak. If the refrigerant leaks in the room and comes in contact with fire from a burner, a heater, or a cooker, this may result in fire, or the formation of a harmful gas. ▪... - Page 36 Maintenance and service In case of detection when the unit is turned on 1 The user interface displays error "A0-11", emits an alarm sound and the status indicator blinks. 2 Contact your dealer immediately. For more information, see the installation manual of the outdoor unit.

-

Page 37: Troubleshooting

Troubleshooting 11 Troubleshooting If one of the following malfunctions occur, take the measures shown below and contact your dealer. WARNING Stop operation and shut OFF the power if anything unusual occurs (burning smells etc.). Leaving the unit running under such circumstances may cause breakage, electrical shock or fire. -

Page 38: Symptoms That Are Not System Malfunctions

Troubleshooting Malfunction Measure The system operates but ▪ Check if air inlet or outlet of outdoor or indoor cooling or heating is unit is not blocked by obstacles. Remove any insufficient. obstacles and make sure the air can flow freely. ▪... -

Page 39: Symptom: White Mist Comes Out Of A Unit (Indoor Unit)

Troubleshooting 11.1.2 Symptom: White mist comes out of a unit (Indoor unit) ▪ When humidity is high during cooling operation. If the interior of an indoor unit is extremely contaminated, the temperature distribution inside a room becomes uneven. It is necessary to clean the interior of the indoor unit. Ask your dealer for details on cleaning the unit. -

Page 40: Relocation

Relocation 12 Relocation Contact your dealer for removing and reinstalling the total unit. Moving units requires technical expertise. FXMA-A Installer and user reference guide VRV system air conditioner 4P680920-1 – 2022.01... -

Page 41: Disposal

Disposal 13 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. FXMA-A Installer and user reference guide VRV system air conditioner... - Page 42 For the installer FXMA-A Installer and user reference guide VRV system air conditioner 4P680920-1 – 2022.01...

-

Page 43: About The Box

About the box 14 About the box 14.1 Overview: About the box This chapter describes what you have to do after the box with the indoor unit is delivered on-site. It contains information about: ▪ Unpacking and handling the unit ▪... -

Page 44: To Remove The Accessories From The Indoor Unit

About the box FXMA100+125 14.2.2 To remove the accessories from the indoor unit 1 Remove the air filter. 2 Remove the accessories from the inside of the unit. 1× 1× 8× 16× 1× 1× 1× 1× 3× a Installation and operation manual b General safety precautions c Washers for hanger brackets d Screws for duct flanges... -

Page 45: About The Units And Options

About the units and options 15 About the units and options In this chapter 15.1 Identification................................... 15.1.1 Identification label: Indoor unit ..........................15.2 About the indoor unit................................15.3 System layout..................................15.4 Combining units and options..............................15.4.1 Possible options for the indoor unit ........................15.1 Identification NOTICE When installing or servicing several units at the same time, make sure NOT to switch... -

Page 46: Combining Units And Options

About the units and options a Indoor unit b Outdoor unit c User interface d Suction air e Discharge air f Refrigerant piping + transmission cable g Drain pipe 15.4 Combining units and options INFORMATION Certain options may NOT be available in your country. 15.4.1 Possible options for the indoor unit Make sure you have the following mandatory options: ▪... - Page 47 About the units and options ▪ Optional output PCB (to provide output for external device): The PCB will trigger the external alarm in case of leak detection, sensor failure or when the sensor is disconnected. For the exact model name, see the option list of the indoor unit. For more information about this option, refer to the installation manual of the optional output PCB.

-

Page 48: Unit Installation

Unit installation 16 Unit installation In this chapter 16.1 Preparing the installation site ..............................16.1.1 Installation site requirements of the indoor unit ....................16.2 Mounting the indoor unit............................... 16.2.1 Guidelines when installing the indoor unit......................16.2.2 Guidelines when installing the ducting........................16.2.3 Guidelines when installing the drain piping ...................... - Page 49 Unit installation CAUTION This equipment is NOT intended for use in residential locations and will NOT guarantee to provide adequate protection to radio reception in such locations. CAUTION Appliance NOT accessible to the general public, install it in a secured area, protected from easy access.

- Page 50 Unit installation c ≥500 (mm) A Minimum distance to the floor 2.5 m to avoid accidental touching a Ceiling b Floor surface c Maintenance space ▪ Discharge grille. Minimum requirement installation height of discharge grille ≥1.8 m. Service space and ceiling opening size Make sure ceiling opening is big enough to ensure a sufficient clearance for maintenance and service.

-

Page 51: Mounting The Indoor Unit

Unit installation Installation options <45 ≥1000 ≥255 (≥950/≥1295) ≥700 (mm) A Installation with rear canvas duct and duct service opening B Installation with bottom canvas duct and air inlet grill a Ceiling surface b Ceiling opening c Air filter d Air inlet duct e Duct service opening f Interchangeable plate g Canvas connection for air inlet side (field supply) - Page 52 Unit installation a Thread cutting screw M4×20 (field supply) in case of installation without duct on air inlet side b Air filter holding plate with air filters c Interchangeable plate ▪ Ceiling strength. Check whether the ceiling is strong enough to support the weight of the unit.

-

Page 53: Guidelines When Installing The Ducting

Unit installation e2 Suspension bolt pitch Class 50~80: 1038 mm Class 100~125: 1438 mm ▪ Level. Make sure the unit is level at all four corners using a level or a water-filled vinyl tube. a Water level b Vinyl tube NOTICE Do NOT install the unit tilted. - Page 54 Unit installation CAUTION ▪ Make sure the installation of the duct does NOT exceed the setting range of the external static pressure for the unit. Refer to the technical datasheet of your model for the setting range. ▪ Make sure to install the canvas duct so vibrations are NOT transmitted to the duct or ceiling.

-

Page 55: Guidelines When Installing The Drain Piping

Unit installation 16.2.3 Guidelines when installing the drain piping Make sure condensation water can be evacuated properly. This involves: ▪ General guidelines ▪ Connecting the drain piping to the indoor unit ▪ Checking for water leaks General guidelines ▪ Pipe length. Keep drain piping as short as possible. ▪... - Page 56 Unit installation a T-joint To connect the drain piping to the indoor unit NOTICE Incorrect connection of the drain hose might cause leaks, and damage the installation space and surroundings. a Drain pipe connection b Water inlet cover c Drain outlet for maintenance d Refrigerant pipes Drain piping connection 1 Push the drain hose as far as possible over the drain pipe connection.

- Page 57 Unit installation Drain outlet for maintenance Pull out the plug. ▪ Do NOT wiggle the plug up and down. Push in the plug. ▪ Set the plug and push it in using a Phillips screwdriver. a Drain plug b Philips screwdriver To check for water leaks The procedure differs depending on whether installation of the system is already completed.

- Page 58 Unit installation a Drain connection b Water inlet c Refrigerant pipes d Drain outlet for maintenance e Water inlet cover f Bucket (adding water through water inlet) g Portable pump 6 Turn OFF the power. 7 Disconnect the electrical wiring. ▪...

-

Page 59: Piping Installation

Piping installation 17 Piping installation In this chapter 17.1 Preparing refrigerant piping ..............................17.1.1 Refrigerant piping requirements ........................... 17.1.2 Refrigerant piping insulation..........................17.2 Connecting the refrigerant piping............................17.2.1 About connecting the refrigerant piping....................... 17.2.2 Precautions when connecting the refrigerant piping.................... 17.2.3 Guidelines when connecting the refrigerant piping.................... -

Page 60: Refrigerant Piping Insulation

Piping installation Outer diameter (Ø) Temper grade Thickness (t) Ø 6.4 mm (1/4") Annealed (O) ≥0.8 mm 9.5 mm (3/8") 12.7 mm (1/2") 15.9 mm (5/8") Depending on the applicable legislation and the maximum working pressure of the unit (see "PS High" on the unit name plate), larger piping thickness might be required. 17.1.2 Refrigerant piping insulation ▪... -

Page 61: Precautions When Connecting The Refrigerant Piping

Piping installation 17.2.2 Precautions when connecting the refrigerant piping INFORMATION Also read the precautions and requirements in the following chapters: ▪ "2 General safety precautions" [ 5] ▪ "17.1 Preparing refrigerant piping" [ 59] DANGER: RISK OF BURNING/SCALDING NOTICE ▪ Use the flare nut fixed to the main unit. ▪... -

Page 62: Guidelines When Connecting The Refrigerant Piping

Piping installation INFORMATION Do NOT open the refrigerant stop valve before checking the refrigerant piping. When you need to charge additional refrigerant it is recommended to open the refrigerant stop valve after charging. 17.2.3 Guidelines when connecting the refrigerant piping Take the following guidelines into account when connecting pipes: ▪... -

Page 63: To Connect The Refrigerant Piping To The Indoor Unit

Piping installation a Cut exactly at right angles. b Remove burrs. 3 Remove the flare nut from the stop valve and put the flare nut on the pipe. 4 Flare the pipe. Set exactly at the position as shown in the following figure. Flare tool for R410A or Conventional flare tool R32 (clutch type) - Page 64 Piping installation b Tie wrap (field supply) c Insulation pieces: Large (gas pipe), small (liquid pipe) (accessories) d Flare nut (attached to the unit) e Refrigerant pipe connection (attached to the unit) f Unit g Sealing pads: Medium 1 (gas pipe), medium 2 (liquid pipe) (accessories) 1 Turn up the seams of the insulation pieces.

-

Page 65: Electrical Installation

Electrical installation 18 Electrical installation In this chapter 18.1 About connecting the electrical wiring ..........................18.1.1 Precautions when connecting the electrical wiring ....................18.1.2 Guidelines when connecting the electrical wiring ....................18.1.3 Specifications of standard wiring components ..................... 18.2 To connect the electrical wiring to the indoor unit ....................... 18.1 About connecting the electrical wiring Typical workflow Connecting the electrical wiring typically consists of the following stages:... -

Page 66: Guidelines When Connecting The Electrical Wiring

Electrical installation WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪ Establish proper earthing. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth. Incomplete earthing may cause electrical shock. ▪... -

Page 67: Specifications Of Standard Wiring Components

Electrical installation Wire type Installation method Stranded conductor wire with round crimp-style terminal a Terminal b Screw c Flat washer Allowed NOT allowed Tightening torques Wiring Screw size Tightening torque (N•m) Power supply cable 1.2~1.4 Transmission cable M3.5 0.79~0.97 (indoor↔outdoor) User interface cable ▪... -

Page 68: To Connect The Electrical Wiring To The Indoor Unit

Electrical installation 18‒1 Minimum circuit ampacity Class 1.8 A 2 A 2.4 A 3 A 3.2 A 18.2 To connect the electrical wiring to the indoor unit NOTICE ▪ Follow the wiring diagram (delivered with the unit, located at the inside of the service cover). ▪ For instructions on how to connect the optional equipment, see the installation manual delivered with the optional equipment. - Page 69 Electrical installation 5 Plastic clamp for tie wrap: Pass tie wraps through the plastic clamps and fasten to fix the cables. 6 Reattach the service cover. Complete system example 1 user interface controls 1 indoor unit. TO IN/D TO OUT/D a Outdoor unit b Indoor unit c User interface...

-

Page 70: Commissioning

19 Commissioning NOTICE General commissioning checklist. Next to the commissioning instructions in this chapter, a general commissioning checklist is also available on the Daikin Business Portal (authentication required). The general commissioning checklist is complementary to the instructions in this chapter and can be used as a guideline and reporting template during the commissioning and hand-over to the user. -

Page 71: Checklist Before Commissioning

Commissioning 19.3 Checklist before commissioning 1 After the installation of the unit, check the items listed below. 2 Close the unit. 3 Power up the unit. You read the complete installation and operation instructions, as described in the installer and user reference guide. The indoor unit is properly mounted. -

Page 72: Configuration

Configuration 20 Configuration 20.1 Field setting Make the following field settings so that they correspond with the actual installation setup and with the needs of the user: ▪ Bottom suction or rear suction installation ▪ External static pressure setting using: Airflow automatic adjustment setting User interface ▪... - Page 73 Configuration NOTICE ▪ Do NOT adjust the dampers during the fan only operation for airflow automatic adjustment. ▪ For the external static pressure higher than 100 Pa, do NOT use airflow automatic adjustment function. ▪ If the ventilation paths have been changed, perform the airflow automatic adjustment again.

- Page 74 Configuration — External static pressure (Pa) 13(23) — Setting: Air volume when thermostat control is OFF This setting must correspond with the needs of the user. It determines the fan speed of the indoor unit during thermostat OFF condition. 1 If you have set the fan to operate, set the air volume speed: If you want…...

- Page 75 Configuration Only use in combination with optional remote sensor or when setting M 10 (20), SW 2, — 03 is used. Setting: Time to clean air filter This setting must correspond with the air contamination in the room. It determines the interval at which "Time to clean filter"...

- Page 76 Configuration If you want to set… Then Example — 0°C 12 (22) cooling 24°C/heating 24°C 1°C cooling 24°C/heating 23°C 2°C cooling 24°C/heating 22°C 3°C cooling 24°C/heating 21°C 4°C cooling 24°C/heating 20°C 5°C cooling 24°C/heating 19°C 6°C cooling 24°C/heating 18°C 7°C cooling 24°C/heating 17°C Setting: Auto-restart after power failure Depending on the needs of the user, you may disable/enable the automatic restart...

- Page 77 Configuration This setting must correspond with the needs of the user. If you want to set… Then — Forced OFF 12 (22) ON/OFF Operation Emergency (recommended for alarm operation) Forced OFF - multi tenant Interlocking setting A Interlocking setting B Field settings are defined as follows: •...

-

Page 78: Hand-Over To The User

Hand-over to the user 21 Hand-over to the user Once the test run is finished and the unit operates properly, please make sure the following is clear for the user: ▪ Make sure that the user has the printed documentation and ask him/her to keep it for future reference. -

Page 79: Troubleshooting

Troubleshooting 22 Troubleshooting 22.1 Solving problems based on error codes If the unit runs into a problem, the user interface displays an error code. It is important to understand the problem and to take measures before resetting an error code. This should be done by a licensed installer or by your local dealer. This chapter gives you an overview of most possible error codes and their descriptions as they appear on the user interface. - Page 80 Troubleshooting Code Description Room temperature thermistor in remote controller abnormality FXMA-A Installer and user reference guide VRV system air conditioner 4P680920-1 – 2022.01...

-

Page 81: Disposal

Disposal 23 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. FXMA-A Installer and user reference guide VRV system air conditioner... -

Page 82: Technical Data

Technical data 24 Technical data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). 24.1 Wiring diagram 24.1.1 Unified wiring diagram legend... - Page 83 Technical data Symbol Meaning AC*, CN*, E*, HA*, HE*, HL*, HN*, HR*, Connection, connector MR*_A, MR*_B, S*, U, V, W, X*A, K*R_*, NE D*, V*D Diode Diode bridge DIP switch Heater FU*, F*U, (for characteristics, refer to Fuse PCB inside your unit) Connector (frame ground) Harness H*P, LED*, V*L...

- Page 84 Technical data Symbol Meaning Thermo switch Residual current device Resistor Thermistor Receiver Limit switch Float switch S*NG Refrigerant leak detector S*NPH Pressure sensor (high) S*NPL Pressure sensor (low) S*PH, HPS* Pressure switch (high) S*PL Pressure switch (low) Thermostat S*RH Humidity sensor S*W, SW* Operation switch SA*, F1S...

-

Page 85: Glossary

Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with the product according to the instructions in the accompanying documentation. - Page 88 4P680920-1 2022.01 Verantwortung für Energie und Umwelt...

Need help?

Do you have a question about the FXMA50A5VEB and is the answer not in the manual?

Questions and answers