Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

Quality System

ISO 9001 Certified

Environmental Management System

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2022 Warren Rupp, Inc.

All rights reserved

Tel: 866-777-6060

Fax: 866-777-6383

Int'l: +001 267 404 2910

Model S05

Non-Metallic

Design Level 2

Springer Pumps, LLC

Springer Parts®

d

n

u

o

S

&

h

s

e

M

a l

g r

t e

I n

d

e r

f l

u f

M

g

n

n i

s a n d p i p e r p u m p. c o m

e

p

m

a

D

n

i o

p t

O

e r

n

i o

p t

O

4 ]

2

[ 2

1

8

8 .

1 ]

8

[ 1

Websites: www.springerpumps.com

www.springerparts.com

T

R

O

P

E

G

R

A

H

T

P

N

T

E

L

I N

R

A I

T

P

N

F

4

1 /

8

3

1

5

. 4

0

1

a r

d

n

a

S t

f l

u f

M

3

1

7 .

A

Advertisement

Table of Contents

Summary of Contents for Warren rupp SANDPIPER S05

- Page 1 800 N. Main St., Mansfield, Ohio 44902 USA Telephone 419.524.8388 Fax 419.522.7867 SANDPIPERPUMP.COM © Copyright 2022 Warren Rupp, Inc. All rights reserved & s a n d p i p e r p u m p. c o m Springer Pumps, LLC Websites: www.springerpumps.com...

-

Page 2: Safety Information

Safety Information IMPORTANT WARNING When used for toxic or aggressive fluids, the pump should Read the safety warnings and instructions in this manual always be flushed clean prior to disassembly. before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty. - Page 3 Temperature Tables Table 1. Category 1 & Category 2 ATEX Rated Pumps Process Temperature Maximum Surface Tem- Ambient Temperature Temperature Class Range [°C] Range [°C] perature [°C] -20°C to +80°C T100°C -20°C to +108°C T135°C -20°C to +60°C -20°C to + 160°C T200°C -20°C to +177°C (225°C) T2 Per CSA standards ANSI LC6-2018 US & Canadian Technical Letter R14, G-Series Natural Gas Models are restricted to (-20°C to + 80°C) process temperature Table 2. Category 2 ATEX Rated Pumps Equipped with Pulse Output Kit or Integral Solenoid: Options Process Temperature Maximum Sur-...

-

Page 4: Table Of Contents

Table of Contents SECTION 1: PUMP SPECIFICATIONS ....1 • Nomenclature • Performance • Materials • Dimensional Drawings SECTION 2: INSTALLATION & OPERATION ...4 • Principle of Pump Operation • Typical Installation Guide • Troubleshooting SECTION 3: EXPLODED VIEW ......7 • Composite Drawings •... -

Page 5: Explanation Of Pump Nomenclature

Explanation of Pump Nomenclature Your Model #: S __ ____ ____ (fill in from pump S05 M HDF3A nameplate) PB1/4 Wetted Non-Wetted Pump ATEX Details Material Material Options Options ATEX Details Construction Options Pump Pump Check Design Wetted Diaphragm/ Check Valve Non-Wetted Porting Pump Pump... -

Page 6: Performance

Performance S05 NON - METALLIC MODEL S05 Non-Metallic Performance Curve SUCTION/DISCHARGE PORT SIZE Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. •... - Page 7 DISCHARGE PORT 1/2" FNPT (INTERNAL) 1.48 1" MNPT (EXTERNAL) 3.07 78 10.11 257 1.75 44 MANIFOLD CAN ROTATE 90 AIR INLET FROM VERTICAL CENTERLINE 1/4 FNPT S05 Non-Metallic Center Ported Options 11.54 293 MANIFOLD CAN ROTATE 90 Dimensions in inches (metric dimensions in brackets). Dimensional Tolerance .125" (3mm). FROM VERTICAL CENTERLINE 1.48 9.79 249...

-

Page 8: Principle Of Pump Operation

Principle of Pump Operation Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen. The main directional (air) control valve distributes ① compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm . -

Page 9: Model S05 Non-Metallic

Recommended Installation Guide Available Accessories: 1. Surge Suppressor Unregulated Air Supply to Surge 2. Filter/Regulator Suppressor 1 Surge Suppressor 3. Air Dryer 4. Lubricator Pressure Gauge Note: Surge Suppressor and Shut-Off Valve Piping, including air line, must be supported after the flexible connections. Pipe Connection (Style Optional) Discharge... -

Page 10: Troubleshooting Guide

Troubleshooting Guide Symptom: Potential Cause(s): Recommendation(s): Pump Cycles Once Deadhead (system pressure meets or exceeds air Increase the inlet air pressure to the pump. Pump is designed for 1:1 pressure ratio at zero flow. supply pressure). (Does not apply to high pressure 2:1 units). Air valve or intermediate gaskets installed incorrectly. -

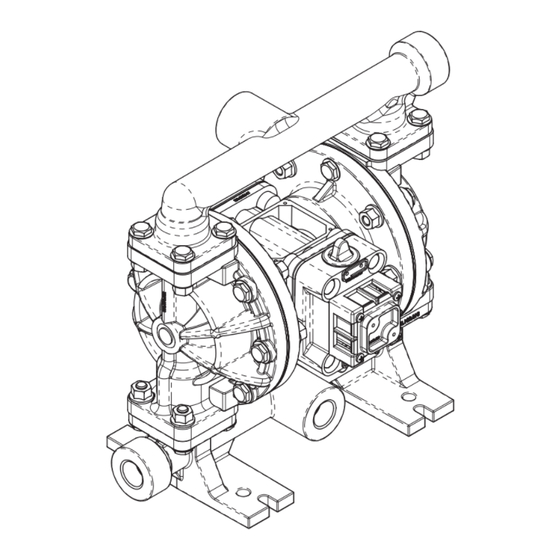

Page 11: Composite Repair Parts Drawing

Composite Repair Parts Drawing ILLUSTRATION SHOWS DIRECTION OF DIAPHRAGMS DIAPHRAGM CONFIGURATION DETAIL NOTE TO ASSEMBLY THE DIAPHRAGMS FOR BOTH CONFIGURATIONS SHOWN ABOVE ARE TO BE INSTALLED WITH CONVOLUTIONS FACING TOWARDS CENTER OF PUMP INLINE DISCHARGE MANIFOLD OPTION DETAIL A OVERLAY OPTION THREADED MUFFLER OPTION TORQUE SETTING TABLE in-lbs... -

Page 12: Composite Repair Parts List

Composite Repair Parts List 286.116.000 Diaphragm, One-Piece, PTFE .......... 2 Item Part Number Description ..............Qty 286.096.600 Diaphragm, Overlay, PTFE ..........2 031.166.000 Air Valve Assembly ............1 312.106.520 Elbow, Suction, PVDF ............2 031.166.002 Air Valve Assembly (with PTFE Coated Hardware) ..1 312.106.552 Elbow, Suction (not used with Inline option), Poly .... -

Page 13: Material Codes

Check Balls/EPDM Seats Nitrile Rubber Color coded: RED end up in a landfill. The recyclability of SANDPIPER EPDM/Santoprene ® products is a vital part of Warren Rupp’s commitment FKM (Fluorocarbon) FDA Nitrile Diaphragm, to environmental stewardship. Color coded: YELLOW sandpiperpump Model S05 Non-Metallic •... -

Page 14: Air Distribution Valve Assembly Drawing

Air Distribution Valve Assembly Drawing MAIN AIR VALVE ASSEMBLY PARTS LIST Item Part Number Description 031.166.000 Air Valve Assembly 095.106.551 Body, Air Valve 031.132.000 Sleeve and Spool Set 560.101.360 O-Ring 165.122.551 End Cap 560.026.360 O-Ring 675.062.115 End Cap Retainer 530.031.550 Muffler 165.109.551 Muffler Cap... - Page 15 Air Valve with Stroke Indicator Assembly Drawing, Parts List MAIN AIR VALVE ASSEMBLY PARTS LIST Item Part Number Description 031.167.000 Air Valve Assembly 095.106.559 Body, Air Valve 031.134.000 Sleeve and Spool Set Air Distribution Valve Servicing 560.101.360 O-Ring See repair parts drawing, remove screws. 132.030.552 Bumper 165.123.147...

-

Page 16: Pilot Valve Servicing, Assembly Drawing & Parts List

Pilot Valve Servicing, Assembly Drawing & Parts List PILOT VALVE ASSEMBLY PARTS LIST Pilot Valve Servicing Item Part Number Description With Pilot Valve removed from pump. 095.091.000 Pilot Valve Assembly Step 1: Remove snap ring (3-F). 095.087.551 Valve Body Step 2: Remove sleeve (3-B), inspect O-Rings (3-C), 755.051.000 Sleeve (With O-Rings) 560.033.360... -

Page 17: Intermediate Assembly

Intermediate Assembly Drawing Intermediate Assembly Drawing INTERMEDIATE REPAIR PARTS LIST Step 1: Remove plunger, actuator (29) from center of Item Part Number Description 114.023.551 Bracket, Intermediate intermediate pilot valve cavity. 114.023.559 Bracket, Intermediate Step 2: Remove Ring, Retaining (30), discard. 135.036.506 Bushing, Plunger Step 3: Remove bushing, plunger (7), inspect for wear... -

Page 18: Diaphragm Service Drawing - With One-Piece Bonded

Diaphragm Service Drawing Diaphragm Orientation Install diaphragm and spacer Torque: as shown above. 100 in/lbs Diaphragm Service Drawing - with Overlay Diaphragm Orientation Install diaphragm and spacer Torque: as shown above. 100 in/lbs Diaphragm Service Drawing - with One-Piece Bonded Diaphragm Orientation Install diaphragm as shown above. -

Page 19: Diaphragm Servicing

DIAPHRAGM SERVICING Step 1: With manifolds and outer chambers Step 8: On opposite side of pump thread the removed, remove diaphragm assemblies from remaining assembly onto the diaphragm rod. Using a diaphragm rod. DO NOT use a pipe wrench or similar torque wrench tighten the assembly to the diaphragm tool to remove assembly from rod. -

Page 20: Solenoid Shifted Air Valve Drawing

Solenoid Shifted Air Valve Drawing Wiring Diagram 3rd Terminal for ground. #2 Terminal #1 Terminal Neutral Power (Negative) (Positive) SOLENOID SHIFTED AIR VALVE PARTS LIST (Includes all items used on Composite Repair Parts List except as shown) Item Part Number Description 114.023.551 Bracket, Intermediate... -

Page 21: Dual Port Option Drawing

Dual Port Option Drawing 1" NPT or 1" BSP Tapered External ½" NPT or ½" BSP Tapered Internal Connection ½" NPT or ½" BSP Tapered Connection ½" NPT or ½" BSP Tapered Connection Illustration for Dual Port Suction and Single or Dual Port Discharge *Dual suction/dual discharge = no manifold. -

Page 22: Ec Declaration Of Conformity

Warren Rupp, Inc. (“Warren Rupp”) warrants to the original end-use purchaser that no product sold by Warren Rupp that bears a Warren Rupp brand shall fail under normal use and service due to a defect in material or workmanship within five years from the date of shipment from Warren Rupp’s factory. - Page 23 EC Declaration of Conformity Manufacturer: Warren Rupp, Inc. 800 N. Main Street Mansfi eld, Ohio, 44902 USA Certifi es that Air-Operated Double Diaphragm Pump Models: DSB Series, DMF Series, G Series, HDB Series, HDF Series, HP Series, F Series, MS Series, S Series, SL Series, SP Series, SSB Series, T Series, U1F Series, WR Series; High Pressure Pump Models: EH Series, GH Series, SH Series; Submersible Pump Models: SMA3 Series, SPA Series; and Surge Dampener/ Suppressor Models: DA Series, TA Series comply with the United Kingdom Statutory Instruments 2008 No. 1597, The Supply of Machinery (Safety) Regulations 2008, according to Annex VIII. This product has used Designated Standard EN809:2012, Pumps and Pump Units for Liquids - Common Safety Requirements, to verify conformance. October 17, 2022 Signature of authorized person DATE/APPROVAL/TITLE: Dennis Hall Technical File on record with: Printed name of authorized person DEKRA Certifi cation UK Limited Stokenchurch House Engineering Manager Oxford Road Title Stokenchurch...

-

Page 24: Eu Declaration Of Conformity

ATEX EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc. declares that Air Oper- ated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of Directive 2014/34/EU and applicable harmonized standards. Harmonized Standards: • EN ISO 80079-36: 2016 • EN ISO 80079-37: 2016 • EN 60079-25: 2010 DEKRA Certifi cation B.V. 1. AODD Pumps and Surge Suppressors - Technical File on record with: Meander 1051 6825 MJ Arnhem The Netherlands Hazardous Location Applied: II 2 G Ex h IIC T5...225°C (T2) Gb II 2 D Ex h IIIC T100°C...T200°C Db • Metallic pump models with external aluminum components (DMF Series, EH Series, F Series, G & GH Series, HDB Series, HDF Series, MS Series, S Series, SH Series, SL Series, SPB Series, ST Series, T Series, and U1F Series) • Conductive plastic pump models with integral muffl er (PB1/4 Series, S Series, SL Series, SPE Series) • Tranquilizer® surge suppressors (TA Series) II 2 G Ex h IIB T5...225°C (T2) Gb II 2 D Ex h IIIB T100°C...T200°C Db • ST Series with sight tubes (VL) and HP Series because of the projected area of non-conductive external components 2. AODD Pumps - EU Type Examination Certifi cate No.: DEKRA 18ATEX0094X - DEKRA Certifi cation B.V. (0344) Meander 1051 6825 MJ Arnhem Hazardous Location Applied:... - Page 25 UKEx EU Declaration of Conformity Manufacturer: Warren Rupp, Inc. A Unit of IDEX Corporation 800 North Main Street Mansfi eld, OH 44902 USA This declaration of conformity is issued under the sole responsibility of the manufacturer. Warren Rupp, Inc declares that Air Operated Double Diaphragm Pumps (AODD) and Surge Suppressors listed below comply with the requirements of United Kingdom Statutory Instruments 2016 No. 1107 and all the applicable standards. Designated Standards: • EN ISO 80079-36: 2016 • EN ISO 80079-37: 2016 • EN 60079-25: 2010 DEKRA Certifi cation UK Limited 1. AODD Pumps and Surge Suppressors - Technical File on record with: Stokenchurch House Oxford Road Stokenchurch Hazardous Location Applied: HP14 3SX II 2 G Ex h IIC T5...225°C (T2) Gb II 2 D Ex h IIIC T100°C...T200°C Db • Metallic pump models with external aluminum components (DMF Series, EH Series, F Series, G & GH Series, HDB Series, HDF Series, MS Series, S Series, SH Series, SL Series, SPB Series, ST Series, T Series, and U1F Series) • Conductive plastic pump models with integral muffl er (PB1/4 Series, S Series, SL Series, SPE Series) • Tranquilizer® surge suppressors (TA Series) II 2 G Ex h IIB T5...225°C (T2) Gb II 2 D Ex h IIIB T100°C...T200°C Db • ST Series with sight tubes (VL) and HP Series because of the projected area of non-conductive external components See “ATEX Details” page in user’s manual for more information See “Safety Information” page for conditions of safe use DATE/APPROVAL/TITLE:...

Need help?

Do you have a question about the SANDPIPER S05 and is the answer not in the manual?

Questions and answers