Kärcher Chariot CV 60/1 RS KIRA Autonomous Manual

Hide thumbs

Also See for Chariot CV 60/1 RS KIRA Autonomous:

- Manual (180 pages) ,

- Operator's manual (128 pages)

Summary of Contents for Kärcher Chariot CV 60/1 RS KIRA Autonomous

- Page 1 Chariot CV 60/1 RS KIRA Autonomous English Register 8.644-976.0-B 05/13/22 your product www.kaercher.com/welcome...

-

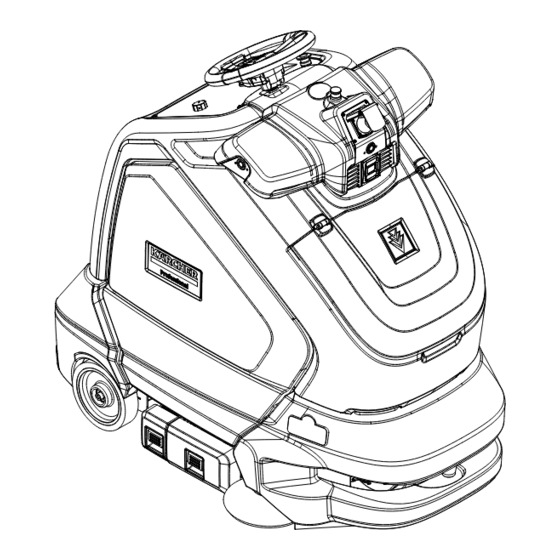

Page 2: Machine Data Label

Machine Data Label Overview The Chariot® KIRA CV60/1 RS Autonomous is a battery powered, stand-on, wide area vacuum intended for commercial use, for example in hotels, schools, hospitals, factories, shops, offices and rental businesses. The Chariot® KIRA CV60/1 RS Autonomous brushes and vacuums debris from the floor and stores it in the debris tray and vacuum bag. -

Page 3: Table Of Contents

Table of Contents Maintenance Machine Data Label ......2 Overview ........2 Battery Location . -

Page 4: Safety

Safety IMPORTANT SAFETY INSTRUCTIONS When using this machine, basic precaution must always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE. To reduce the risk of fire, electric shock, or injury: The operation of this machine is strictly reserved to trained and qualified operators. Operators shall be adequately instructed on the use of these machines. -

Page 5: Hazard Intensity Level

Safety The following symbols are used throughout this guide as indicated in their descriptions: HAZARD INTENSITY LEVEL There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following definitions: WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death. -

Page 6: How To Use This Manual

How To Use This Manual This manual contains the following sections: The SAFETY section contains important information regarding hazardous or unsafe practices of the • How to Use This Manual machine. Levels of hazards are identified that could • Safety result in product damage, personal injury, or severe •... -

Page 7: Safety Label Locations

Safety Safety Label Locations These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible, promptly replace them. 86244300 WARNING LABEL 86244310 CAUTION 86447300 OBC CAUTION 86447260 BATTERY INFORMATION 86444760 QR CODE - READ MANUAL SEE VIEW A 86402490 PINCH HAZARD... -

Page 8: Grounding Instructions

Safety Grounding Instructions 120 Volt Models: THIS PRODUCT IS FOR COMMERCIAL This appliance is for use on a nominal 120-volt circuit, and has a grounded plug that looks like the plug in "Fig. USE ONLY. A". A temporary adapter that looks like the adapter in Electrical: "Fig. -

Page 9: Operations

Operations How This Machine Works bag. The debris tray captures the dirt off the floor as the machine moves forward. The vacuum motor provides The Chariot® CV60/1 RS is a battery powered, self- suction to draw the fine dirt into the vacuum bag, and propelled, vacuum intended for commercial use. -

Page 10: Technical Specifications

Operations Technical Specifications ITEM DIMENSION/CAPACITY Nominal Power 1620W Rated Voltage 36 Volts DC Rated Amperage Battery, Lithium 38.4 Volts Battery Compartment Dimensions 19.25 x 14.5 x 15" (489 x 368 x 381mm) Battery, Lithium - Dimensions 18.5 x 13.7 x 14.7" (470 x 345 x 373mm) Propel Motor 2.0HP (149W) Brush Motor... - Page 11 Operations ITEM MEASURE Height 52 in (1321 mm) Length 51 in (1296 mm) Width 28.3 in (719 mm) WIDTH LENGTH HEIGHT This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

-

Page 12: Controls

Operations Controls 8.644-976.0 Manual Operator CV601 RS KIRA Autonomous... - Page 13 Operations Controls 1. Key Switch 2. Emergency Stop Switch 3. Directional Control / Drive Reset Switch 4. Throttle Pedal 5. Maximum Speed Knob 6. Horn Button 7. Steering Wheel 8. Function Mode Switch 9. Display Screen 10. Operator Presence Pedal 11.

- Page 14 Operations 6. Horn Button The horn is activated by pressing the horn button. 7. Steering Wheel The steering wheel turns the front wheel causing the machine to change direction. 8. Function Mode Switch Transport This mode is used for machine transport. In this mode the machine will propel at the speed that the maximum speed knob is set to.

-

Page 15: What Do Those Lights Mean

Operations 9. Display Screen Displays information about the machine and ability to make adjustments to machine attributes. 10. Operator Presence Pedal Ensures that the operator is on the platform. 11. Start / Pause Robot Button Used to start and pause robot functions. What Do Those Lights Mean? You may occasionally see various lights on this machine. -

Page 16: Pre-Run Machine Inspection

Operations Machine Operation Normal Vacuuming Plan the vacuuming pattern in advance. The longest Pre-Run Machine Inspection track is around the perimeter of the area to be cleaned. For efficient operation, the runs should be the longest Do a pre-run inspection to find possible problems that possible without turning or stopping. -

Page 17: To Begin Vacuuming

Operations To Begin Vacuuming 5. Remove vacuum bag from vacuum box and dispose of properly. 6. Clean vacuum box and remove any debris. 7. Retrieve a new clean vacuum bag. When operating the machine around people, pay close attention for unexpected movement. Use 8. -

Page 18: Service Schedule

Maintenance Service Schedule BEFORE AFTER EACH MAINTENANCE EACH WORK WORK 50 HRS 100 HRS 200 HRS PERIOD PERIOD Check water level of batteries after charging; add distilled water if necessary (Wet cell only) Check that the vacuum box lid seals tightly Check for damaged or worn tires. -

Page 19: Battery Location

Maintenance Battery Location 1. Battery - Lithium shown 2. Charger Wall Plug And Cords 8.644-976.0 Manual Operator CV601 RS KIRA Autonomous... -

Page 20: Changing Batteries - Agm

Maintenance Changing Batteries - AGM On Board Charger Stop the machine in a clean area. Turn off machine. 1. Stop the machine in a clean, well ventilated area next to an AC outlet. FOR SAFETY: Before leaving or servicing the machine;... -

Page 21: Lithium Battery

Maintenance Lithium Battery This product must be recycled and is made of recycled products. Chemical Risk Lithium batteries are chemical risk if mis-operated, mishandled or abused. • Do protect terminals from short circuit before, during, and after installation • Do wear electrically insulated gloves •... -

Page 22: Operating Limits

Maintenance Transportation If the battery is not installed in equipment, it must be transported in the original package or equivalent. Batteries are tested according to UN Handbook of Tests and Criteria, part III, sub section 38.3 (ST/SG/AC. 10/11/ Rev.5). For transport, the batteries belong to category UN3480, Class 9, Packaging Group II. Operating Limits The battery should not be operated outside these operating limits: Operating Limits... -

Page 23: Handling - Lithium Battery

Maintenance Handling - Lithium Battery Copper compression lug M8” bolt (supplied with battery) Lock washer (supplied with battery) Read Safety Section before installing the battery. Shrink-wrap to Flat washer (supplied with battery) color-code the cable • Battery should be off. Battery cable lug Ensure nothing is between •... -

Page 24: Charging

Maintenance Charging CORRECTIVE ACTIONS Before operating the charger make sure to read and Stop discharge or charge understand the instructions that come with the charger. High Temperature Never attempt to charge a battery without first Leave the battery to cool reviewing and understanding the instructions for the Low Temperature Stop discharge or charge... -

Page 25: Service & Maintenance

Maintenance Service & Maintenance Troubleshooting Batteries should be carefully inspected on a regular Battery Won’t Turn On: basis in order to detect and correct potential problems before they can do harm. This routine should be started when the batteries are first received. Does the battery turn on for a short Symptom time, then turn itself off? -

Page 26: Changing Battery - Lithium

Maintenance Changing Battery - Lithium Recycling and Disposal Stop the machine in a clean area. Turn off machine. Batteries must not be mixed with domestic or industrial waste. Discover’s Advanced Energy Systems are FOR SAFETY: Before leaving or servicing the recyclable and must be processed through a machine;... -

Page 27: Brush Deck

Maintenance Brush Deck 1. Brush Deck 2. Release Levers 3. Brush Motor 4. Brush Deck Lift Actuator 5. Side Broom 6. Debris Tray 7. Brush Tray 8.644-976.0 Manual Operator CV601 RS KIRA Autonomous... -

Page 28: Brush Removal & Bearing Cleaning

Maintenance Brush Removal & Bearing Cleaning Side Broom Removal NOTE: The brushes should wear evenly side to side. 1. Rotate the side broom to align pin with Brushes should be replaced as a set when bristle vertical slot. length wears. 2. -

Page 29: Vacuum Filters

Maintenance Vacuum Filters Changing the Bag, Pre Filter or Post Filter 1. Vacuum Pre Filter 1. Lift lid to replace bag or pre filter. 2. Vacuum Post Filter 2. Release bag from debris snout. 3. Knob 3. Place new bag over debris snout and ensure card board flange is engaging bag presence switch. -

Page 30: Circuit Protection

Maintenance Circuit Protection Circuit Breakers 1. MAIN CIRCUIT BREAKER Interrupts the flow of power from batteries in the event of an electrical overload. When the circuit breaker is tripped, it can be reset by pressing the toggle switch. If the circuit breaker continues to trip, the cause of the electrical overload must be corrected. -

Page 31: Drive Motor

Maintenance B R A K E O V E R - R I D E L E V E R Drive Motor 1. Drive Motor 2. Brake 8.644-976.0 Manual Operator CV601 RS KIRA Autonomous... -

Page 32: Electric Brake Engagement

Maintenance Electric Brake Engagement FOR SAFETY: Before leaving or servicing machine, stop on a level surface, turn off machine and remove key. Electric Brake Engagement This machine is equipped with an electric brake. The brake automatically engages and keeps the machine from moving whenever the operator steps off the platform or when emergency stop is engaged. -

Page 33: Transporting

Maintenance Transporting Trailer Loading/Unloading Brush deck must be in the up position before loading. Pushing Machine Park machine in a corner of the trailer with padding The machine may be pushed for short distances at between machine and the walls, Once loaded, lower speeds not to exceed 5 mph. -

Page 34: Troubleshooting

Maintenance Troubleshooting PROBLEM CAUSE SOLUTION Check all battery cable connections; No power to machine Battery disconnected replace or tighten as necessary. Emergency shut-off activated Reset Faulty key switch Replace switch Battery cables corroded Clean connections On board charger plugged in Unplug and stow cord Main circuit breaker tripped Reset circuit breaker... -

Page 35: Error Codes Table

Maintenance Error Codes Table Corrective actions – Code Description of code If the problem persists, call for service Disconnect power with the main breaker, remove the brush tray and clean the brushes. Brush Motor Overheat Allow the motor to cool down for 1 hour before continuing operation. - Page 36 Maintenance Error Codes Table, cont. Corrective actions – Code Description of code If the problem persists, call for service Disconnect power with the main breaker, remove the brush tray and clean the brushes. Drive Motor Internal Motor Controller Error Allow the motor to cool down for 1 hour before continuing operation.

- Page 37 Maintenance Corrective actions – Code Description of code If the problem persists, call for service Disconnect power with the main breaker. Remove the side broom and clean. Vacuum Motor DMC Over Temperature Remove the brush tray and clean the brushes. Allow the controllers to cool down for 1 hour before continuing operation.

- Page 38 Maintenance Error Codes Table, cont. Corrective actions – If the problem persists, call for Code Description of code service Brush Motor High Voltage Protect Error Locate the brush motor circuit breaker and reset. Side Broom Motor High Voltage Protect Turn the main breaker off and wait 10 seconds before Error turning it back on.

- Page 39 Maintenance Corrective actions – If the problem persists, call for Code Description of code service Side Broom Motor ANIN Limit. Motor temperature is above software limit. Disconnect power with the main breaker, remove the Throttle input range is being affected. side broom and clean.

- Page 40 Maintenance Error Codes Table, cont. Corrective actions – Code Description of code If the problem persists, call for service Vacuum Motor PWM is being limited by unspecified source. Service soon. All modes are still allowed. Vacuum Motor Limited. The controller is driving but a power-limiting condition Service soon.

-

Page 41: Suggested Spare Parts

Suggested Spare Parts 8.644-976.0 Manual Operator CV601 RS KIRA Autonomous... - Page 42 THANK YOU! DANKE! MERCI! GRACIAS! Register your product and benefit from many advantages. Enregistrez votre produit et bénéficiez de nombreux avantages. Registre su producto y aproveche de muchas ventajas. Registrieren Sie Ihr Prudukt und Sie von vielen Vorteilen. www.kaercher.com/welcome Rate your product and tell us your opinion. Évaluez votre produit et donnez-nous votre opinion.

Need help?

Do you have a question about the Chariot CV 60/1 RS KIRA Autonomous and is the answer not in the manual?

Questions and answers