Graco 226816 Instructions-Parts List Manual

Viscon high pressure fluid heater

Hide thumbs

Also See for 226816:

- Instructions manual (13 pages) ,

- Instructions and parts list (14 pages)

Table of Contents

Advertisement

Quick Links

Instructions–Parts List

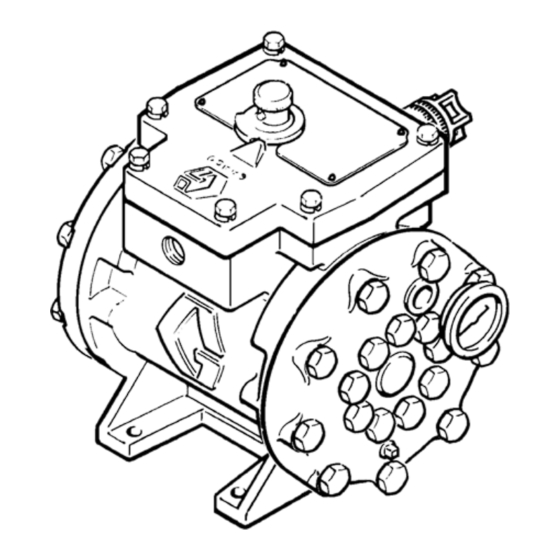

VISCON High Pressure

Fluid Heater

Used for variable heating of fluids.

3000 psi (21 MPa, 210 bar) Maximum Working Pressure

80–190_F (26–88_C) Temperature Range

Model 226816, Series F 120 Volt

Model 226819, Series F 240 Volt

FM Approved as explosion proof for

Class I, Division 1, Group D, Hazardous Locations,

Temp Code (identification number) T3C. See the Technical Data

on page 20 for additional information on this code.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Hazard of Using Fluids Containing Halogenated Hydrocarbons

Never use 1,1, 1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in this equipment. Such use could result in a serious chemical reac-

tion, with the possibility of explosion, which could cause death, serious injury, and/or substantial

property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and

zinc parts.

US

WARNING

307363S

Advertisement

Table of Contents

Summary of Contents for Graco 226816

- Page 1 Used for variable heating of fluids. 3000 psi (21 MPa, 210 bar) Maximum Working Pressure 80–190_F (26–88_C) Temperature Range Model 226816, Series F 120 Volt Model 226819, Series F 240 Volt FM Approved as explosion proof for Class I, Division 1, Group D, Hazardous Locations, Temp Code (identification number) T3C.

-

Page 2: Table Of Contents

D This equipment is for professional use only. D Read all instruction manuals, tags, and labels before operating the equipment. D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco distributor. D Do not alter or modify this equipment. Use only genuine Graco parts and accessories. - Page 3 Permanently coupled hoses cannot be repaired; replace the entire hose. D Use only Graco approved hoses. Do not remove any spring guard that is used to help protect the hose from rupture caused by kinks or bends near the couplings.

- Page 4 WARNING FIRE AND EXPLOSION HAZARD Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury. D Ground the equipment and the object being sprayed. Refer to Grounding on page 5. D If there is any static sparking or you feel an electric shock while using this equipment, stop spray- ing immediately.

-

Page 5: Installation

Installation Grounding 5. Air compressor or hydraulic power supply: follow manufacturer’s recommendations. WARNING 6. Spray gun: grounding is obtained through connec- FIRE AND EXPLOSION HAZARD tion to a properly grounded fluid hose and pump. Before operating the pump, ground the system as explained below. - Page 6 Installation HEATED CIRCULATING SYSTEM Bleed-type Master Air Valve Vis–Con Heater Director Valve Air Regulator and Gauge Fluid Shutoff Valve Siphon tube Ground Wire Fluid Pressure Regulator Drain Back Tube Pump Spray Gun Pressure Relief Valve Fluid Filter with Drain Valve Back Pressure Valve Fig.

- Page 7 To designing a system to suit your needs, contact your reduce the risk of serious injury from a fire or Graco distributor. explosion, do not use the heater near flammable materials or vapors.

-

Page 8: Operation

Operation Pressure Relief Procedure 1. Lock the gun trigger safety. 2. Shut off the main power to the heater. WARNING 3. Circulate the fluid for at least 10 minutes to cool SKIN INJECTION HAZARD the heated fluid and heater. Fluid under high pressure can be in- jected through the skin and cause 4. - Page 9 Operation Flushing the Heater Before First Use Adjusting for Spraying 1. Start the pump and check the fluid flow through The heater was factory tested in lightweight oil. Use the gun. low pressure and a compatible solvent to flush the system.

- Page 10 Notice that most of the MEDIUM LACQUER viscosity reduction occurs by 55_C (130_F). ENAMEL VISCOSITY Under–Boil is the Graco method of hot, airless spray- TIME IN ing in which the fluid is heated to a temperature just SECONDS with No. 2 under the boiling point of its most volatile solvent.

-

Page 11: Maintenance

Maintenance Flushing After Use 1. Drain and clean the fluid filter frequently to be sure it filters the fluid thoroughly. Always relieve system pressure first, and cool the fluid, if possible. If not possible, wear protective eyewear and gloves to protect yourself from possible burns. -

Page 12: Troubleshooting

Troubleshooting Before servicing this equipment always make sure to WARNING relieve the pressure. To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Check all possible problems and solutions before Pressure Relief Procedure on page 8. disassembling the heater. - Page 13 Notes 307363...

-

Page 14: Service

Save the nuts (4). To replace these parts, order 217184 for Heater Model 226816 or 217185 for Model 226819. 8. Reassemble the new parts in the reverse order of 1. Remove the six old screws (3) and lockwasher (1). - Page 15 Service White White 120V Black 240V Apply thermal grease (Graco Part No. 110009) to tip. Fig. 10 307363...

- Page 16 Use only original Graco replacement parts. 1. Unscrew the lens cap (49). Tighten onto socket (50) until seal in lens cap contacts socket and then turn 1/2 to 1 turn more.

- Page 17 Notes 307363...

-

Page 18: Parts

Parts NOTE: See important repair and assembly information on pages 14–16. NOTE: See page 11 for important tightening sequence and torque values for the endcap screws (16). 307363... - Page 19 Keep these spare parts on hand to reduce down 3/16 in. screw size time. 166412* PACKING, o–ring; PTFE 167002 INSULATOR, heat 222217 COVER & CIRCUIT BOARD ASSY 120 V (Model 226816 only) 222218 COVER & CIRCUIT BOARD ASSY 240 V (Model 226819 only) 307363...

-

Page 20: Technical Data

Technical Data Category Data Voltage Model 226816, Series F: 120 volts AC, single phase, 18 amp Model 226819, Series F: 240 volts AC, single phase, 9 amp Explosion proof Class 1 – Division 1 & 2, Group D, Hazardous Location... - Page 21 Circuit Diagrams Model 226816, Series F For 120 Volt Heater RAMP VSYNC CRAMP POSIN NEGIN –VS 222214j Model 226819, Series F For 240 Volt Heater RAMP VSYNC CRAMP POSIN NEGIN –VS 222213j 307363...

-

Page 22: Dimensions

Dimensions Mounting Hole Layout 0.41 in. (10.4 mm) dia. 6.5 in. (165 mm) 4 in. (102 mm) 307363... - Page 23 Notes 307363...

-

Page 24: Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the 226816 and is the answer not in the manual?

Questions and answers