Siemens SIMOTICS DP Operating Instructions Manual

Low-voltage motors

Hide thumbs

Also See for SIMOTICS DP:

- Compact operating instructions (166 pages) ,

- Operating instructions manual (140 pages) ,

- Operating instructions manual (136 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Siemens SIMOTICS DP

- Page 1 Edition 02/2022 OPERATING INSTRUCTIONS SIMOTICS DP, GP, SD Low-voltage motors Synchronous motors 1FZ shaft height 280 www.siemens.com/drives...

- Page 3 Introduction Safety information Description SIMOTICS DP, GP, SD Preparing for use Low-voltage motors 1FZ shaft height 280 Assembly Electrical connection Operating Instructions Commissioning Operation Maintenance Spare parts Disposal Service & support Technical data Quality documents 02/2022 A5E51698698A...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Table Of Contents

Table of contents Introduction ............................9 About these instructions ...................... 9 My support .......................... 9 Safety information..........................11 Information for those responsible for the plant or system ........... 11 The 5 safety rules....................... 11 Qualified personnel......................12 Safe handling ........................12 Working on machines with permanent magnets .............. - Page 6 Table of contents Preparing for use ..........................29 Safety-related aspects to consider when configuring the plant ..........29 Observing the operating mode................... 29 Machines without final paint coating.................. 29 Delivery ..........................29 Transport and storage ......................30 4.5.1 Safety instructions for transport ..................30 4.5.1.1 Electrical voltages are induced when the rotor is rotated.............

- Page 7 Table of contents Aligning and fixing the machine ..................54 5.5.1 Measures for alignment and mounting................55 5.5.2 Flatness of the supporting surfaces for conventional motors..........56 5.5.3 Machine frame mounting feet (special design) ..............56 Installing the machine......................56 5.6.1 Preconditions for smooth, vibration-free operation .............

- Page 8 Table of contents 7.1.3 Converter operation......................79 7.1.4 Insulation resistance and polarization index ............... 80 7.1.5 Testing the cooling of the machine..................80 7.1.6 Commissioning the separately driven fan ................80 7.1.7 Further documents ......................81 7.1.8 Setpoint values for monitoring the bearing temperature ............. 82 Switching on ........................

- Page 9 11.6 Disposing of permanent magnets..................126 11.7 Disposal of components ....................126 Service & support ..........................129 Siemens Industry Online Support ..................129 Further documents ......................130 Technical data............................ 131 Tightening torques......................131 B.1.1 Tightening torques for screw and bolt connections ............131...

- Page 10 Table of contents B.1.2 Terminal board and grounding ..................132 B.1.3 Terminal boxes, end shields, grounding conductors, sheet metal fan covers ...... 132 B.1.4 Tightening torques of additional connecting terminals ............. 132 Quality documents ..........................133 Quality documents SIMOTICS in SIOS ................133 Index ..............................

-

Page 11: Introduction

Extensive assistance and more information can be found under the following link: My Support Links and Tools You can individually compile your personal library, e.g. for your documentation based on Siemens content, and adapt it for your own machine documentation. 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A... - Page 12 Later, you can log on with your login data. You can create your own personal library under "mySupport" using the following procedure. Precondition You have registered for and logged on to "Siemens Industry Online Support", hereinafter referred to as "SIOS". Siemens Industry Online Support (https://support.industry.siemens.com/cs/de/en/) Procedure for creating a personal library 1.

-

Page 13: Safety Information

Safety information Information for those responsible for the plant or system This electric machine has been designed and built in accordance with the specifications contained in Directive 2014/35/EU ("Low-Voltage Directive") and is intended for use in industrial plants. Please observe the country-specific regulations when using the electric machine outside the European Community. -

Page 14: Qualified Personnel

Safety information 2.4 Safe handling Qualified personnel All work at the machine must be carried out by qualified personnel only. For the purpose of this documentation, qualified personnel is taken to mean people who fulfill the following requirements: • Through appropriate training and experience, they are able to recognize and avoid risks and potential dangers in their particular field of activity. - Page 15 Safety information 2.4 Safe handling Risk of burns due to hot surfaces Individual machine parts can become hot in operation. Burns can result when coming into contact with these parts. • Never touch machine parts during operation. • Allow the machine to cool before starting work on the machine. •...

-

Page 16: Working On Machines With Permanent Magnets

Safety information 2.5 Working on machines with permanent magnets Working on machines with permanent magnets On machines with permanent magnets, the magnetic field is guided in an assembled state in the magnetic circuit of the machine. This means that no magnetic fields, which may be to your health, are detectable outside the machine. -

Page 17: Electromagnetic Fields When Operating Electrical Power Engineering Installations

Safety information 2.8 Electrostatic sensitive devices Electromagnetic fields when operating electrical power engineering installations Electrical power equipment generate electromagnetic fields during operation. Potentially lethal malfunctions can occur in medical implants, e.g. pacemakers, in the vicinity of electrical power equipment. Data may be lost on magnetic or electronic data carriers. •... -

Page 18: Electromagnetic Compatibility

Safety information 2.11 Influence on the line power supply through a strongly irregular torque • Always place the modules on conductive and grounded surfaces. • Always pack, store and transport electronic modules or components in conductive packaging, such as: – Metallized plastic or metal containers –... -

Page 19: Interference Voltages When Operating The Converter

Safety information 2.13 Special designs and construction versions 2.12 Interference voltages when operating the converter Interference voltages when operating the converter When a converter is in operation, the emitted interference varies in strength depending on the converter (manufacturer, type, interference suppression measures undertaken). On machines with integrated sensors (e.g. - Page 20 Safety information 2.13 Special designs and construction versions 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

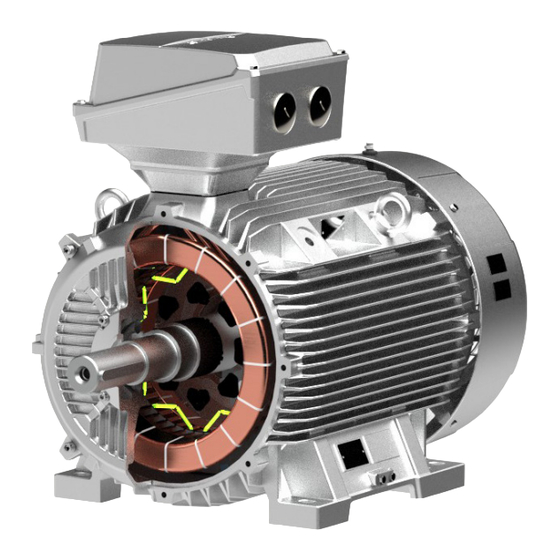

Page 21: Description

Description Area of application WARNING Risk of explosion This machine is not designed for use in hazardous areas. An explosion can occur if the machine is operated in these areas. This can result in death, serious injury or material damage. •... -

Page 22: Converter Operation

Description 3.2 Rating plates Using machines without EAC marking EAC machines are appropriately marked on the rating plate, and are intended for operation within the Eurasian customs union. Within the Eurasian customs union, do not use machines without the appropriate EAC marking. 3.1.1 Converter operation Drive... - Page 23 Description 3.2 Rating plates Item Description Item Description Marine regulation Torque Nm (optional) Machine family type Service factor (optional) Mechanical data Operating mode (optional) Frame size Anti-condensation heating (optional) Type of construction CODE: Motor code number for converter parameterization (op‐ tional) Degree of protection Converter data...

-

Page 24: Installation

Description 3.3 Installation Installation 3.3.1 Regulations of the customs union - Eurasian standard The regulations and standards used as the basis for designing and testing this machine are stamped on the rating plate. The machine design basically complies with the following standards: Table 3-1 Applicable general regulations... -

Page 25: Machines With A Fan

Description 3.3 Installation 3.3.3.2 Machines with a fan Self-ventilation (standard): Cooling method IC 411 according to EN / IEC 60034-6 Located at the ND end of the stator housing is an air intake cowl that guides the external air on its way to the motor. -

Page 26: Bearings

Description 3.3 Installation Surface cooling by relative movement of cooling air: Cooling method IC 418 according to EN / IEC 60034-6 IC418 IC4A1A8 Figure 3-2 IC418 3.3.4 Bearings To support the machine shaft and maintain its position in the non-moving part of the machine, DE and NDE rolling bearings are used. - Page 27 Description 3.3 Installation Table 3-2 Type of construction Basic type of construc‐ Diagram Other methods of in‐ Diagram tion code stallation IM B3 (IM 1001) IM V5 (IM 1011) IM V6 (IM 1031) IM B6 (IM 1051) IM B7 (IM 1061) IM B8 (IM 1071) Basic type of construc‐...

-

Page 28: Degree Of Protection

Description 3.3 Installation Basic type of construc‐ Diagram tion code IM B35 (IM 2001) IM B34 (IM 2101) 3.3.7 Degree of protection The machine has a type of protection as stamped on the rating plate, and can be installed in dusty or humid environments. -

Page 29: Terminal Box

Description 3.3 Installation • Measuring nipple for SPM shock pulse measurement for bearing monitoring • Backstop Note Further documents Observe all of the other documents provided with this machine. Supplementary devices Depending on the order, various supplementary devices can be installed or mounted. These include sensors for bearing temperature monitoring or winding monitoring, for example. - Page 30 Description 3.3 Installation 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 31: Preparing For Use

The drive systems are put together on an individual basis. When you take receipt of the delivery, please check immediately whether the items delivered are in accordance with the accompanying documents. Siemens will not accept any claims relating to items missing from the delivery and which are submitted at a later date. -

Page 32: Transport And Storage

Preparing for use 4.5 Transport and storage Archive the safety and commissioning notes provided in the scope of delivery as well as the optionally available operating instructions so that these documents are always easily accessible. The rating plate optionally enclosed as a loose item with the delivery is provided to enable the motor data to be attached on or near the machine or installation. - Page 33 Preparing for use 4.5 Transport and storage • Use suitable strap guiding or spreading devices. • If not specified otherwise in the transport data, always transport the machine in the position associated with its specific type of construction. Danger due to damaged attachment points •...

-

Page 34: Electrical Voltages Are Induced When The Rotor Is Rotated

Preparing for use 4.5 Transport and storage Danger if the machine falls The attachment points on the machine are designed for the weight of the machine only. If a machine set is lifted and transported at a single machine, this can fracture the attachment point. The machine or machine set may fall. -

Page 35: Storage

Preparing for use 4.5 Transport and storage Comply with the graphic symbols provided on the packaging. Their meaning is as follows: This Fragile Protect Protect Center of Hand hooks Attach way up goods against against gravity forbidden here moisture heat 4.5.3 Storage Storing outdoors... - Page 36 Preparing for use 4.5 Transport and storage Storage temperature Permissible temperature range: -20 °C to +50 °C Maximum permissible air humidity: 60% For machines that have a special design regarding the ambient temperature in the operating state or the installation altitude, other conditions could apply regarding the storage temperature.

-

Page 37: Securing The Rotor

Preparing for use 4.5 Transport and storage 4.5.4 Securing the rotor Depending on the version, the machine is fitted with a rotor shipping brace. This protects the bearings against damage due to shock and vibration during transport or storage. NOTICE Motor damage due to vibrations Not using the rotor shipping brace can cause damage to the machine if it is jolted during transport or storage. - Page 38 Preparing for use 4.5 Transport and storage Alternative rotor bracing • If you transport the machine after the output element has been pulled on, then you must axially fix the rotor in another way. ① ② Sleeve Shaft screw and washer Figure 4-1 Axial fastening of the rotor Thread in the shaft extension...

-

Page 39: Commissioning After Storage

Preparing for use 4.5 Transport and storage 4.5.5 Commissioning after storage 4.5.5.1 Insulation resistance and polarization index Measuring the insulation resistance and polarization index (PI) provides information on the condition of the machine. It is therefore important to check the insulation resistance and the polarization index at the following times: •... -

Page 40: Ensure Adequate Cooling

Preparing for use 4.6 Ensure adequate cooling Ensure adequate cooling WARNING Overheating and failure of the motor Death, severe injury or material damage can occur if you do not carefully observe the following points. • Do not obstruct ventilation. • Prevent the air expelled by neighboring equipment from being immediately sucked in again. •... - Page 41 Preparing for use 4.6 Ensure adequate cooling Incorrect Correct Minimum dimension "x" for the distance between neighboring modules and the air intake of the machine Table 4-2 Minimum dimension "x" for the distance between adjacent modules and the air intake of the machine Shaft height 63 ...

-

Page 42: Interlock Circuit For Anti-Condensation Heating

Preparing for use 4.10 Rotational speed limit values Interlock circuit for anti-condensation heating If the anti-condensation heating is operated while the machine is running, this can increase the temperatures inside the machine. • Install an interlock circuit that switches off the anti-condensation heating once the main machine is switched on. -

Page 43: System-Inherent Frequencies

Preparing for use 4.12 Electromagnetic compatibility Machine damage due to excessively high speeds Excessive rotational speed can lead to serious damage to the machine. This can result in death, serious injury or material damage. • Avoid operation above the permissible speed by using the appropriate control function. •... -

Page 44: Converter Operation

Preparing for use 4.13 Converter operation Immunity to interference The machines fulfill the requirements of interference immunity in conformity with EN / IEC 61000-6-2. For machines with integrated sensors, e.g. PTC thermistors, the operating company must ensure sufficient interference immunity by selecting a suitable sensor signal cable (possibly with shielding, connected in the same way as the machine feeder cable) and a suitable evaluation unit. -

Page 45: Reducing Bearing Currents

Preparing for use 4.13 Converter operation NOTICE Material damage caused by an excessively high supply voltage The insulation system will be damaged if the supply voltage is too high for the insulation system. This can completely destroy the machine. • Comply with the peak voltages as laid down in the guidelines above. 4.13.3 Reducing bearing currents To prevent damage due to bearing currents, you must carefully assess the complete system, i.e. -

Page 46: Insulated Bearings For Converter Operation

Preparing for use 4.13 Converter operation • Use the common-mode filter (damping cores) at the converter output. The Siemens sales representative is responsible for selection and dimensioning. • Limit the rise in voltage by using output filters. Output filters dampen the harmonic content in the output voltage. -

Page 47: Speed Limits For Converter Operation

Preparing for use 4.13 Converter operation ① ④ Driven machine Insulated bearings ② ⑤ Motor Insulated tachometer fitting ③ ⑥ Coupling Insulated coupling Figure 4-3 Schematic representation of a tandem drive NOTICE Bearing damage Bearing currents can flow if the coupling between the motors of the tandem drive is not insulated. - Page 48 Preparing for use 4.13 Converter operation 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 49: Assembly

Assembly Observe the following when carrying out any work on the machine: • Comply with the general safety instructions (Page 11). • Comply with the applicable national and sector-specific regulations. • When using the machine within the European Union, comply with the specifications laid down in EN 50110‑1 regarding safe operation of electrical equipment. -

Page 50: Electrical Voltages Are Induced When The Rotor Is Rotated

Assembly 5.3 Preparing for installation Electrical voltages are induced when the rotor is rotated Danger due to induced voltages Electrical voltages are induced in the stator when rotating the rotor. Touching the stator connections can result in death or severe injury. •... -

Page 51: Insulation Resistance

Assembly 5.3 Preparing for installation Damage to mounted parts and components as a result of high temperatures The motor components get very hot during operation. High temperatures can damage parts mounted by customers, such as cables manufactured out of materials that are not heat resistant. •... -

Page 52: Checking The Insulation Resistance And Polarization Index Of The Winding

Assembly 5.3 Preparing for installation 5.3.2.2 Checking the insulation resistance and polarization index of the winding Measure the insulation resistance 1. Follow the instructions in the Operating Manual of the insulation measuring instrument used. 2. Ground other windings, integrated winding temperature sensors and, if applicable, other mounted and installed components. - Page 53 Assembly 5.3 Preparing for installation Limit values for the winding insulation resistance The following table lists the measuring voltage and limit values for the insulation resistance R These values correspond to recommendations provided in IEC 60034-27-4. Table 5-1 Insulation resistance of the winding at 40 °C / MΩ...

- Page 54 Assembly 5.3 Preparing for installation Note Comment to IEEE 43 According to IEEE 43, also for winding temperatures < 40 °C, R must be converted over to the reference temperature of 40 °C. As the minimum values for R apply at 40 °C, the required R values are somewhat higher for winding temperatures below 40 °C.

-

Page 55: Installing The Machine

Assembly 5.4 Installing the machine Installing the machine 5.4.1 Preparing the assembly area 1. Prepare a suitable assembly area (e.g. assembly stands). Make sure that the assembly area has sufficient clearance from the floor for the DE shaft end. The necessary data is provided in the machine dimension drawing. -

Page 56: Foot Mounting

Assembly 5.5 Aligning and fixing the machine NOTICE Damage to the motor Material damage can occur if the following notes are not carefully observed: • The IM B3 bearing shield with integrated distance ring mounted at the drive end (DE) is only used transport lock. -

Page 57: Measures For Alignment And Mounting

Assembly 5.5 Aligning and fixing the machine • Avoid rigid couplings. • Repair any damage to the paint, this must be done immediately and correctly. 5.5.1 Measures for alignment and mounting The following measures are required in order to compensate any radial offset at the coupling and to horizontally adjust the electrical machine with respect to the driven load: •... -

Page 58: Flatness Of The Supporting Surfaces For Conventional Motors

Assembly 5.6 Installing the machine 5.5.2 Flatness of the supporting surfaces for conventional motors Shaft height Flatness [mm] ≤ 132 0.10 0.15 ≥ 180 0.20 5.5.3 Machine frame mounting feet (special design) Please note that when the terminal box is mounted at the NDE (option H08), dimension C can deviate from EN 50347. -

Page 59: Horizontal Types Of Construction With Mounting Feet

Assembly 5.6 Installing the machine 5.6.2.2 Horizontal types of construction with mounting feet 1. Refer to any instructions for aligning the driven machine and those of the coupling manufacturer. 2. Align the machines with coupling output to the driven machine in such a manner that the center lines of the shafts are parallel with no offset. -

Page 60: Vertical Types Of Construction With Flange

Assembly 5.6 Installing the machine 5.6.2.4 Vertical types of construction with flange The standard flange is provided with a centering. The choice of fit for the mating flange on the driven machine is the system manufacturer's or the plant operator's responsibility. If the machine is not fitted with a standard flange, align the machine to suit the driven machine. -

Page 61: Mounting The Drive Output Elements

Assembly 5.6 Installing the machine 5.6.5 Mounting the drive output elements The rotor is dynamically balanced. For shaft extensions with feather keys, the type of balancing is specified using the following coding on the face of the drive end of the shaft extension and on the rating plate: •... - Page 62 Assembly 5.6 Installing the machine Pulling on drive output elements • Requirements: – The coupling and/or the drive output element must be appropriately dimensioned for the operating case at hand. – Observe the coupling manufacturer's instructions. – Make sure that the balancing type of the drive output element correctly matches the type of balance of the rotor.

- Page 63 Assembly 5.6 Installing the machine You can obtain the permissible values for axial and radial forces by contacting the Service Center (Page 129) or by referring to the machine catalog. Shaft extensions with feather key The feather key data for the shaft and drive output element must match and indicate the correct type of balancing.

- Page 64 Assembly 5.6 Installing the machine 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 65: Electrical Connection

Electrical connection Safety instructions for the electrical connection Observe the following when carrying out any work on the machine: • Comply with the general safety instructions (Page 11). • Comply with the applicable national and sector-specific regulations. • When using the machine within the European Union, comply with the specifications laid down in EN 50110‑1 regarding safe operation of electrical equipment. -

Page 66: Connecting The Machine

Electrical connection 6.2 Connecting the machine See also Tightening torques (Page 131) Note Service Center If you require support when electrically connecting up the machine, please contact the Service Center (Page 129). Connecting the machine Take the following criteria into account when selecting the connecting cables: •... -

Page 67: Terminal Box

Electrical connection 6.2 Connecting the machine 6.2.1 Terminal box DANGER Hazardous voltage Electric motors have high voltages. When incorrectly handled, this can result in death or severe injury. Switch off the machine so that it is in a no-voltage condition before you open the terminal box. NOTICE Damage to the terminal box If you incorrectly carry out work on or in the terminal box, this can result in material damage. -

Page 68: Terminal Marking

Electrical connection 6.2 Connecting the machine 6.2.1.3 Terminal marking According to IEC / EN 60034‑8, the following basic definitions apply to the terminal markings for 3-phase machines: Table 6-1 Terminal markings using the 1U1-1 as an example 1 Marking Code for split winding, where applicable. Special case for pole assignment for pole- changing machines. -

Page 69: Protruding Connection Cables

Electrical connection 6.2 Connecting the machine 6.2.1.6 Protruding connection cables WARNING Risk of short-circuit and voltage hazard A short circuit can occur if connecting cables are clamped and crushed between parts of the enclosure and the cover plate. This can result in death, severe injury and material damage. •... -

Page 70: Minimum Air Clearances

Electrical connection 6.2 Connecting the machine Remove insulation from the ends of the conductors so that the remaining insulation almost reaches the cable lug. Note The direct contact between the cable lug surfaces and the contact nuts or contact screws ensure that the connection can conduct current. -

Page 71: Mounting Position Of Sheet Metal Nuts In Screw-Type Connections

Electrical connection 6.3 Tightening torques Cable glands with reductions and (sheet metal) nuts (EN 50262) ① ② O ring 6.2.2.1 Mounting position of sheet metal nuts in screw-type connections ② O ring ③ Mounting position of metal-sheet nuts Cable glands with connecting thread in the terminal box (EN 50262) ②... -

Page 72: Cable Entries, Sealing Plugs And Thread Adapters

Electrical connection 6.4 Connecting the grounding conductor 6.3.1 Cable entries, sealing plugs and thread adapters Note the following when mounting: • Avoid damaging the cable jacket. • Adapt the tightening torques to the cable jacket materials. Observe the documentation for tightening torques of the cable entries and sealing plugs for direct mounting at the machine as well as additional glands (e.g. -

Page 73: Grounding Connection Type

Electrical connection 6.4 Connecting the grounding conductor 6.4.2 Grounding connection type Type of enclosure grounding Conductor cross-sec‐ tion mm² … 10 Connection of an individual conductor under the external grounding bracket. … 25 Connection is made using a DIN cable lug under the external grounding bracket. -

Page 74: Connection, Temperature Sensor/Anti-Condensation Heating

Electrical connection 6.6 Conductor connection Connection, temperature sensor/anti-condensation heating WARNING Hazard due to electric shock The installation of the temperature sensors for the winding monitoring with respect to the winding is implemented according to the requirements for basic insulation. The temperature sensor connections are located in terminal boxes, safe to touch, and have no protective separation. -

Page 75: Type Of Conductor Connection

Electrical connection 6.6 Conductor connection Table 6-4 Max. conductor connection Shaft height Max. connectable conductor cross-section [mm²] 63 ... 90 2.5 with cable lug 100 ... 112 160 ... 180 16.0 25.0 35.0 with cable lug 250 ... 280 120.0 240.0 6.6.1 Type of conductor connection... -

Page 76: Connecting Aluminum Conductors

Electrical connection 6.7 Connecting converters 6.6.2 Connecting aluminum conductors If you are using aluminum conductors, then comply with the following: • Use only cable lugs that are suitable for connecting aluminum conductors. • Immediately before inserting the aluminum conductor, remove the oxide layer from the contact areas on the conductor and/or the mating piece. -

Page 77: Final Checks

Electrical connection 6.8 Final checks Table 6-6 Maximum voltage peaks at the motor terminals for motors specifically designed for converter operation Rated motor voltage Maximum peak voltage at the motor terminals Û Û DC link U phase-to-phase phase-to-ground ≤ 500 V 1600 1400 >... - Page 78 Electrical connection 6.8 Final checks 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 79: Commissioning

Commissioning Observe the following when carrying out any work on the machine: • Comply with the general safety instructions (Page 11). • Comply with the applicable national and sector-specific regulations. • When using the machine within the European Union, comply with the specifications laid down in EN 50110‑1 regarding safe operation of electrical equipment. -

Page 80: Mechanical And Electrical Check

Commissioning 7.1 Measures before commissioning Once the system has been correctly installed, you should check the following prior to commissioning: • The machine is undamaged. • The machine has been properly installed and aligned. • The output transmission elements are set correctly for their type, e.g. -

Page 81: Check The Electrical Connections

Commissioning 7.1 Measures before commissioning • Rotate the rotor to ensure that it does not touch the stator. • Ensure that the bearing insulation is not bridged/jumpered. • Using the appropriately designed and adjusted control and speed monitoring functions, ensure that the permissible speeds specified on the rating plate cannot be exceeded. •... -

Page 82: Insulation Resistance And Polarization Index

Commissioning 7.1 Measures before commissioning 7.1.4 Insulation resistance and polarization index Measuring the insulation resistance and polarization index (PI) provides information on the condition of the machine. It is therefore important to check the insulation resistance and the polarization index at the following times: •... -

Page 83: Further Documents

Commissioning 7.1 Measures before commissioning • The grounding and equipotential bonding connections to the mains have been correctly made. • The air flow is not impeded or shut off by flaps, covers or similar. • If the cooling air is in open circulation, it has only weak, chemically abrasive properties and a low dust content. -

Page 84: Setpoint Values For Monitoring The Bearing Temperature

Commissioning 7.2 Switching on 7.1.8 Setpoint values for monitoring the bearing temperature Prior to commissioning If the machine is equipped with bearing thermometers, set the temperature value for disconnection on the monitoring equipment before the first machine run. Table 7-1 Set values for monitoring the bearing temperatures before commissioning Set value Temperature... -

Page 85: Test Run

Commissioning 7.2 Switching on • If mechanical operation improves immediately after the machine is switched off, then the cause is magnetic or electrical, e.g. voltage imbalance, magnetic imbalance. If mechanical operation does not improve immediately after switching the machine off, then the cause is mechanical, e.g. - Page 86 Commissioning 7.2 Switching on 3. If it runs perfectly, connect a load. NOTICE Thermal overload of motors connected directly to the line supply In addition to the load torque, the ramp-up (accelerating) time is essentially influenced by the moment of inertia to be accelerated. While ramping up when connected to the line supply, the inrush (starting) current is a multiple of the rated current.

-

Page 87: Operation

Operation Observe the following when carrying out any work on the machine: • Comply with the general safety instructions (Page 11). • Comply with the applicable national and sector-specific regulations. • When using the machine within the European Union, comply with the specifications laid down in EN 50110‑1 regarding safe operation of electrical equipment. - Page 88 Operation 8.1 Safety instructions for operation Danger as a result of stationary parts under voltage (live parts) Live parts represent a hazard. Touch protection against active (live) parts is no longer guaranteed if covers are removed. The minimum air and creepage distances may be fallen below (violated) when coming close to active parts.

- Page 89 Operation 8.1 Safety instructions for operation Risk of burn injuries as a result of hot surfaces Individual machine parts can become hot in operation. Burns can result when coming into contact with these parts. • Never touch machine parts during operation. •...

-

Page 90: Safety Instructions Relating To Ventilation And Cooling

Operation 8.1 Safety instructions for operation Danger to life as a result of the converter voltage As long as the feeding converter is switched on, or the DC link of the converter is not discharged, there can be a voltage at the motor terminals even when the rotor is not moving. Depending on the converter type, the voltage is up to 1000 V. -

Page 91: Switching On The Machine

Operation 8.5 Stoppages Switching on the machine 1. If at all possible, run the machine without load and check that it is running smoothly. 2. If it runs perfectly, connect a load. NOTICE Thermal overload of motors connected directly to the line supply In addition to the load torque, the ramp-up (accelerating) time is essentially influenced by the moment of inertia to be accelerated. - Page 92 Operation 8.5 Stoppages Longer non-operational periods • For longer non-operational periods (> 1 month), either operate the machine or at least turn the rotor regularly, approximately once per month. • If attached, remove the rotor shipping brace before you turn the rotor. •...

-

Page 93: Avoidance Of Damage To Rolling Bearings During Stoppages

Operation 8.6 faults 8.5.1 Avoidance of damage to rolling bearings during stoppages Extended stoppages at the identical or almost identical resting position of the rotor in the rolling bearings can result in damage, such as brinelling or corrosion. • During stoppages, regularly start up the machine for a brief period once a month. As a minimum, turn the rotor several times. -

Page 94: Electrical Faults Air-Cooled Machines

Operation 8.6 faults 8.6.2 Electrical faults air-cooled machines Note When operating the machine with a converter, also refer to the operating instructions of the frequency converter if electrical faults occur. Table 8-1 Electrical faults ↓ Motor fails to start ↓ Motor accelerates sluggishly ↓... -

Page 95: Rolling Bearing Faults

Operation 8.6 faults ↓ Grinding noise ↓ Radial vibrations ↓ Axial vibrations Possible causes of faults Remedial measures Rotor out of round, shaft bent Consult the manufacturing plant. Poor alignment Align the machine set; check the coupling. Coupled machine not balanced Rebalance the coupled machine. -

Page 96: Faults At The External Fan

Operation 8.6 faults 8.6.5 Faults at the external fan The following table shows the possible causes of and remedial measures for faults on forced- ventilated machines. Table 8-4 Cooling system faults ↓ High temperature rise with load Possible causes of faults Remedial measures Wrong direction of rotation of the separately Check the electrical connections to the separately driven fan. -

Page 97: Maintenance

Maintenance Through careful and regular maintenance, inspections, and overhauls you can detect faults at an early stage and resolve them. This means that you can avoid consequential damage. Operating conditions and characteristics can vary widely. For this reason, only general maintenance intervals can be specified here. -

Page 98: Touch Up Any Damaged Paintwork

Maintenance 9.2 Inspection and maintenance 9.1.2 Touch up any damaged paintwork If the paint is damaged, it must be repaired in order to protect the unit against corrosion. Note Paint system Contact the Service Center before you repair any damage to paint. They will provide you with more information about the correct paint system and methods of repairing paint damage. -

Page 99: Electrical Voltages Are Induced When The Rotor Is Rotated

Maintenance 9.2 Inspection and maintenance Danger when cleaning using compressed air When cleaning parts of the machine using compressed air, loose parts or particles of dirt can be flung around and cause injury. • Installed suitable extraction measures. • Wear personal protective equipment, such as protective glasses, gloves, overall. •... -

Page 100: First Inspection After Installation Or Repair

Maintenance 9.2 Inspection and maintenance Note Inspection specifications • Carefully comply with the relubrication intervals for rolling bearings that deviate from the inspection intervals. • When servicing a three-phase machine, it is generally not necessary to dismantle it. The machine only has to be dismantled if the bearings are to be replaced. 9.2.3 First inspection after installation or repair Perform the following checks after approximately 500 operating hours or at the latest six... -

Page 101: General Inspection

Maintenance 9.2 Inspection and maintenance 9.2.4 General inspection Check that the installation conditions are observed. We recommend that the following checks are performed after approx. 16 000 operating hours or at the latest after two years: Table 9-2 Checks that have to be performed during the general inspection Checking When the At stand‐... -

Page 102: Maintenance Intervals

Maintenance 9.2 Inspection and maintenance 9.2.6 Maintenance intervals Please note the following in order to identify faults at an early stage, rectify them and avoid follow-on damage: • Maintain the machine regularly and carefully. • Inspect the machine. • Motors must be allocated a revision/inspection number after inspection. NOTICE Motor failure Material damage can occur if the machine develops faults or is overloaded. -

Page 103: Re-Greasing

Maintenance 9.2 Inspection and maintenance 9.2.7 Re-greasing For machines with regreasing system, relubrication intervals, grease quantity and grease grade are provided on the lubricant plate. Additional data can be taken from the main machine rating plate. Grade of grease for standard motors (IP55) UNIREX N3 - ESSO. Note It is not permissible to mix different types of grease. -

Page 104: Cleaning The Fan Cover Of Machines For The Textile Industry

Maintenance 9.2 Inspection and maintenance Cleaning the cooling air ducts Regularly clean the cooling air ducts through which the ambient air flows. The frequency of the cleaning intervals depends on the local degree of fouling. Damage to the machine when cleaning with compressed air or water jets •... -

Page 105: Insulation Resistance And Polarization Index

Maintenance 9.2 Inspection and maintenance 9.2.11 Insulation resistance and polarization index Measuring the insulation resistance and polarization index (PI) provides information on the condition of the machine. It is therefore important to check the insulation resistance and the polarization index at the following times: •... -

Page 106: Corrective Maintenance

Maintenance 9.3 Corrective maintenance Servicing the separately driven fan motor • Occasionally inspect the separately driven fan motor, and check it electrically and mechanically every time the rolling bearings are replaced. • Replace the permanently lubricated rolling bearing of the separately driven fan motor after 40 000 operating hours or five years at the latest. - Page 107 Maintenance 9.3 Corrective maintenance Bearing lifetime Prolonged storage periods reduce the useful lifetime of the bearing grease. For permanently lubricated bearings, this reduces the bearing service life. We recommend that the grease is replaced after a storage time of 12 months. Replace greased bearings also in the case of closed bearings (suffix 2Z or 2 RS).

-

Page 108: Bearing Bushes

Maintenance 9.3 Corrective maintenance ① Heat up 80 ... 100 °C 9.3.1.1 Bearing bushes Protect the bearings against the ingress of dirt and moisture. When fitting the bearing cartridges, observe the specified screw tightening torques (Page 132). 9.3.1.2 Installing bearings Sealing the bearings Note the following details: •... - Page 109 Maintenance 9.3 Corrective maintenance Danger as a result of rotor falling out If the motor is in a vertical position, the rotor can fall out while work is being performed on the locating bearing. This can result in death, serious injury or damage. •...

-

Page 110: Mounting Dimension "X

Maintenance 9.3 Corrective maintenance 8. Warm up the grease slinger (if one is available), and push it onto the shaft. 9. Depending on the particular version, fix the bearing with a locking ring or shaft nut. 10.Support the rotor when installing the bearing housing or bearing end shield. 11.Use a suitable sealant when assembling. - Page 111 Maintenance 9.3 Corrective maintenance Plastic fan • Correctly expose the breakout openings provided in the fan plate. • Heat up the fans to a temperature of approximately 50° C around the area of the hub. • Use a suitable tool to pull off the fan (puller). •...

-

Page 112: Mounting Fans

Maintenance 9.3 Corrective maintenance Shaft height 180 ... 200 1. Carefully release the first snap opening of the cover. 2. For machines with type construction B3, select the snap opening in the area of the machine mounting feet. ① 3. Insert the lever at the edge of the cover close to the lug. ②... -

Page 113: Canopy; Mounting A Rotary Pulse Encoder Under The Canopy

Maintenance 9.3 Corrective maintenance Plastic fan cover shaft heights 80 ... 200 • Align the cover with the line marked on the edge of the cover with the middle enclosure rib as extension to the terminal box base. • Center the cover by axially moving on the snap-in lugs of the enclosure or the bearing shield cams. -

Page 114: Reassembly: Miscellaneous Information

Maintenance 9.3 Corrective maintenance 9.3.8 Reassembly: Miscellaneous information • Position all rating and supplementary plates as in the original state. • Where relevant, fix electric cables. • Check the tightening torques of all screws, as well as those of screws that have not been released. -

Page 115: O-Ring Seal

Maintenance 9.3 Corrective maintenance 9.3.10 O-ring seal If O-ring seals are present, you should check that they are in perfect condition and that the O-ring seals are properly seated in the grooves between the components. Replace damaged O-ring seals. O-ring seals can be present on the following components, for instance: •... - Page 116 Maintenance 9.3 Corrective maintenance 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 117: Spare Parts

• Order number and serial number of the machine The machine type and serial number can be found on the rating plate. See also Spares On Web (https://www.sow.siemens.com/) Note The graphical representations in this chapter show schematic diagrams of the basic versions. -

Page 118: Replacing Rolling Bearings

Spare parts 10.4 Groups of parts See also Guide for Spares on Web (https://www.weblogx.siemens.de/SoWHilfe_HS/motors/en/) 10.3 Replacing rolling bearings Rolling bearings When ordering rolling bearings, in addition to the bearing identification code, the supplementary specifying code is also necessary for the bearing version. Both of these codes are stamped on the lubricant plate and specified in the motor documentation, or can also be taken from the installed bearings. -

Page 119: Ordering Example

• For up to 3 years after the delivery of the original machine, in the event of total machine failure, Siemens will supply a comparable replacement machine with regard to the mounting dimensions and functions; it is possible that this will involve a new series. -

Page 120: Machine Parts

Spare parts 10.6 Machine parts 10.6 Machine parts 10.6.1 Part lists Part Description Part Description 1.00 DE bearings Terminal box, complete 1.30 Bolt 5.43 Entry plate 1.31 Spring lock washer 5.44 Terminal box top side 1.32 Bolt 5.45 Enclosure 1.33 5.46 Bolt 1.40... - Page 121 Spare parts 10.6 Machine parts Part Description Part Description 4.12 5.92 Terminal box cover 4.18 Rating plate 5.93 Seal 4.19 Self tapping screw or slotted pin 5.94 Bolt 4.20 Cover 5.95 Terminal box top side 4.30 Contact bracket 5.96 Screw plugs 4.31 Grounding bracket 5.97...

-

Page 122: Standardized Parts

Spare parts 10.7 Standardized parts 10.7 Standardized parts 10.7.1 Standardized parts Table 10-1 Purchase standard parts according to dimensions, material and surface properties through normal commercial channels. Standard Picture Standard Picture 3.02 DIN 471 1.32 DIN 939 6.02 7.12 1.49 EN ISO 4017 4.11 6.12... -

Page 123: Exploded Drawings

Spare parts 10.8 Exploded drawings 10.8 Exploded drawings 10.8.1 1FZ shaft height 280 Exploded drawing as PDF required with specification of the spare parts and standard parts, see the example here 1LE7: 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A... - Page 124 Spare parts 10.8 Exploded drawings 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 125: Disposal

Disposal Protecting the environment and preserving its resources are corporate goals of the highest priority for us. Our worldwide environmental management system to ISO 14001 ensures compliance with legislation and sets high standards in this regard. Environmentally friendly design, technical safety and health protection are always firm goals even at the product development stage. -

Page 126: Preparing For Disassembly

Disposal 11.4 Dismantling the machine 11.3 Preparing for disassembly Disassembly of the machine must be carried out and/or supervised by qualified personnel with appropriate expert knowledge. 1. Contact a certified waste disposal organization in your vicinity. Clarify what is expected in terms of the quality of dismantling the machine and provision of the components. -

Page 127: Working On Machines With Permanent Magnets

Disposal 11.5 Working on machines with permanent magnets 11.5 Working on machines with permanent magnets On machines with permanent magnets, the magnetic field is guided in an assembled state in the magnetic circuit of the machine. This means that no magnetic fields, which may be to your health, are detectable outside the machine. -

Page 128: Disposing Of Permanent Magnets

Disposal 11.7 Disposal of components 11.6 Disposing of permanent magnets If the entire motor is melted down, no special action is required for the permanent magnets. Remove all cables before the melting process. Demagnetizing the motor If the motor is disassembled and dismantled, the permanent magnets must be demagnetized. To do this, the motor is heated up to 350 °C so that during and after disposal, the rotors do not represent any danger. - Page 129 Disposal 11.7 Disposal of components Sort the components for recycling according to whether they are: • Iron and steel • Aluminum • Non-ferrous metal, e.g. windings The winding insulation is incinerated during copper recycling. • Insulating materials • Cables and wires •...

- Page 130 Disposal 11.7 Disposal of components 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 131: Service & Support

(www.siemens.com/yourcontact) Siemens Support for on the move With the "Siemens Industry Online Support" App, you can access more than 300,000 documents for Siemens Industry products – any time and any‐ where. The App supports you in the following areas: •... -

Page 132: Further Documents

Service & support A.2 Further documents Further documents These operating instructions can also be obtained at the following Internet site: http://support.industry.siemens.com (Page 129) 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A... -

Page 133: Technical Data

You can find product information on your motor according to ErP Directive 2019/1781 in the configurator for drive technology. If you enter the motor order number (MLFB), you will find technical documentation such as data sheets, characteristic curves and CAD drawings for your motor: www.siemens.com/dt-configurator Tightening torques B.1.1... -

Page 134: Terminal Board And Grounding

Technical data B.1 Tightening torques Non-standard tightening torques Different tightening torques for electrical connections and bolted connections for parts with flat seals or insulating parts are specified in the relevant sections and drawings. B.1.2 Terminal board and grounding Table B-2 Tightening torques for electrical connections on the terminal board and grounding Thread ∅... -

Page 135: Quality Documents

Quality documents Quality documents SIMOTICS in SIOS You can find the quality documents here: https://support.industry.siemens.com/cs/ww/de/ps/13310/cert (https:// support.industry.siemens.com/cs/ww/en/ps/13310/cert) 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A... - Page 136 Quality documents C.1 Quality documents SIMOTICS in SIOS 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

-

Page 137: Index

Index " "Siemens Industry Online Support" App, 129 Damping cores, 44 Data matrix code, 115 Demagnetization Rotor, 126 Disassembly 5 safety rules, 11 Disposal, 124 Disposal Chemicals, 127 Components, 126 Aligning, 57, 58 Drive, 20 Aluminum conductors, 74 Drive output element, 60... - Page 138 Index High-frequency grounding, 43 Overspeed, 29 Hot surfaces, 13 Paint finish, 27 IEC 60034-27-4, 51 Paint system, 96 IEEE 43, 52 Paintwork damage, 96 Inspection Permanent magnet, 14, 125, 126 Faults, 91, 97 Polarization index, 37, 49, 80, 103 Installation Measuring, 52 Initial inspection, 98 Positioning, 57...

- Page 139 Rotating parts, 12 Selection of bolts, 56 Separately driven fan, 38 Commissioning, 80 Maintenance, 103 Test run, 81 Siemens Industry Online Support App, 129 SIMOTICS Digital Data, 115 Spare parts, 116, 129 Spares on Web, 115 Standard flange, 57, 58...

- Page 140 Index 1FZ shaft height 280 Operating Instructions, 02/2022, A5E51698698A...

- Page 142 More information Siemens: Industry Online Support (service and support): www.siemens.com/online-support IndustryMall: www.siemens.com/industrymall Germany...

Need help?

Do you have a question about the SIMOTICS DP and is the answer not in the manual?

Questions and answers