Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Bizerba GSP H

- Page 1 Slicer GSP H, GSP H C, GSP V Instruction manual 6.037.98.5.10.06 en...

- Page 2 All rights reserved Tous droits réservés Reservados todos los derechos Tutti i diritti riservati © 04/2011 Bizerba GmbH & Co. KG, 72336 Balingen P.O. Box 10 01 64 72301 Balingen, Germany Telephone (+49 7433) 12-0, Fax (+49 7433) 12-2696 Email : marketing@bizerba.com...

- Page 3 Chapter index About these instructions About this machine Safety instructions Installation Machine and operating elements Operation Troubleshooting Maintenance Technical data Appendix 6.037.98.5.10.06 en...

- Page 4 6.037.98.5.10.06 en...

-

Page 5: Table Of Contents

0° ............2 - Overview/Naming of components, GSP H, GSP HC ... . . 2 - Overview/Component designation GSP H with carriage inclination 25°... - Page 6 Contents Instruction manual GSP H, GSP H C, GSP V Installation and mounting ........4 - 4.2.1...

- Page 7 Technical data ............9 - Dimensions of GSP H with carriage inclination 0° ....9 - Dimensions of GSP H with carriage inclination 18°...

- Page 8 Contents Instruction manual GSP H, GSP H C, GSP V 0 - 4 6.037.98.5.10.06 en...

-

Page 9: About These Instructions

These operating instructions explain the operation and settings of the machine. It also in- cludes functions that are only required by Bizerba Service. Contact your Bizerba specialist if necessary. Our products are constantly further developed and are subject to various country-specific regulations. -

Page 10: Warning Notices

About these instructions Instruction manual GSP H, GSP H C, GSP V Information This information is provided for greater understanding. Warning notices Warnings are divided into danger levels by the signal word above the warning symbol. DANGER Source of danger with high risk with direct threatening danger for... -

Page 11: About This Machine

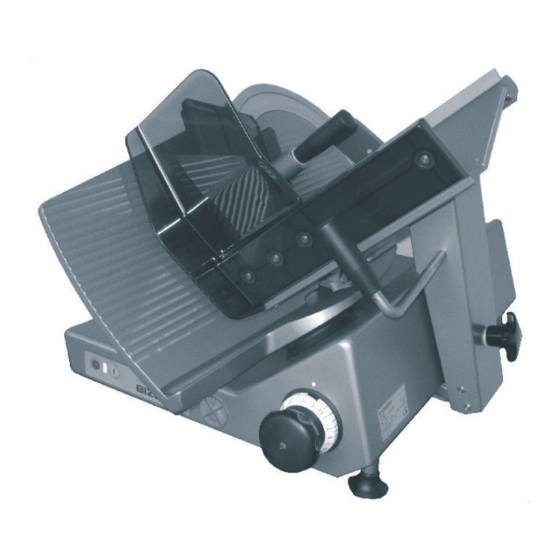

Instruction manual GSP H, GSP H C, GSP V About this machine About this machine Overview/Component designation GSP H with carriage inclina- tion 0° Illustration 1: GSP H, example The device is available in many different versions. Here is an example. -

Page 12: Overview/Naming Of Components, Gsp H, Gsp Hc

About this machine Instruction manual GSP H, GSP H C, GSP V On/Off keys with signal lamp Deflector Handle Gauge plate Back panel Knife Blade guard ring Overview/Naming of components, GSP H, GSP HC Illustration 2: GSP HC, example The device is available in many different versions. Here is an example. -

Page 13: Overview/Component Designation Gsp H With Carriage Inclination

Instruction manual GSP H, GSP H C, GSP V About this machine Handle for carriage Rating plate/CE symbol Slice thickness setting Rubber base On/Off keys with signal lamp Deflector Handle Gauge plate Back panel Knife Blade guard ring Product fixation Overview/Component designation GSP H with carriage inclina- tion 25°... - Page 14 About this machine Instruction manual GSP H, GSP H C, GSP V The device is available in many different versions. Here is an example. Blade cover Handle for product holder Pusher protection Handle for remnant holder plate Remnant holder plate...

-

Page 15: Overview/Naming Of Component, Gsp V

Instruction manual GSP H, GSP H C, GSP V About this machine Overview/Naming of component, GSP V Illustration 4: GSP V, example The device is available in different versions. Here is an example. Blade cover Pusher protection Star knob for remnant holder plate... -

Page 16: Accessories

Accessories For the devices we offer comprehensive accessories for different application areas. Only use the original Bizerba spare parts and accessories in order to ensure safe and trouble-free operations. If cheese is the main product being sliced, we recommend using a spe- cial cheese blade. -

Page 17: Intended Use

About this machine Intended use This Bizerba Slicer is a technical work resource which is only suitable for application at work. It may only be operated by instructed personnel over the age of 14. The blade of this gravity feed slicer is operated electrically. The low-noise, low-mainte- nance drive is effected through alternating current or three-phase motor. -

Page 18: Guidelines

Before installation, store and transport the machine in the original packaging. Application area The Bizerba slicer is intended to be installed in a sales area. Installation in wet areas is permissible, making allowances for a cleaning plan and protection type IP 33. -

Page 19: Warranty

To ensure that the machine is recycled environmentally friendly, return the machine to the manufacturer or the dealer after intended use has expired. Naturally, Bizerba and its dealers will take back free of charge old machines no longer in operation. - Page 20 About this machine Instruction manual GSP H, GSP H C, GSP V 2 - 10 6.037.98.5.10.06 en...

-

Page 21: Safety Instructions

Risk of life from electric current. Acute risk of injury of operating personnel. – Damaged supply lines must be replaced immediately by new ca- bles and installed by a certified electrical company or by Bizerba Service. – Protective devices must be checked every day with regards to function before start-up. -

Page 22: Safety Instructions For Transport And Installation

Safety instructions Instruction manual GSP H, GSP H C, GSP V For safety reasons, the machine must be turned off immediately in case of recurring malfunctions, any kind of damage or risks of injury. Always inform the nearest customer service office. -

Page 23: Safety Instructions For Sharpening, Cleaning

Instruction manual GSP H, GSP H C, GSP V Safety instructions Safety instructions for sharpening, cleaning WARNING Unprotected blade! Coming in contact with the sharp blade can lead to serious inju- ries. – Wear cut-proof gloves during cleaning and slicing operations and shoes with steel caps when changing the blade. -

Page 24: Information Plates On Machine

Safety instructions Instruction manual GSP H, GSP H C, GSP V Machines with carriage inclination 0° and 18° – Forcibly guided product holder in cutting range of < 60 mm. Information plates on machine Warning sign on electrical installation: Flash sign... -

Page 25: Installation

Installation and mounting Installation, putting into operation as well as instruction regarding operation, cleaning, maintenance, care and servicing, is initially carried out by the responsible Bizerba Custom- er Service Agent or the Bizerba specialist. Only lift the machine at the lifting straps. The drawing "Packing/unpacking the machine" is included. -

Page 26: Electrical Connection

Installation Instruction manual GSP H, GSP H C, GSP V 4.2.2 Electrical connection Illustration 7: Rating plate GSP H, example Illustration 8: Rating plate GSP HC, example Illustration 9: Rating plate GSP V, example 4 - 2 6.037.98.5.10.06 en... - Page 27 Instruction manual GSP H, GSP H C, GSP V Installation Check before mains connection Before you connect the machine, check the power supply data on the rating plate with the power supply data of the mains connection. WARNING Incorrect mains voltage! Destruction of electrical components, risk of fire.

-

Page 28: Attaching Product Feed For Tomatoes

Installation Instruction manual GSP H, GSP H C, GSP V 4.2.3 Attaching product feed for tomatoes These machines allow the product fence and product feed for tomatoes to be easily at- tached. Set slice thickness below "0". Switch off machine. -

Page 29: Carry Out A Trial Operation

Pole reversal of phase turner at the 3-phase current socket of the machine Putting into operation Putting into operation, as well as briefing in the operation, cleaning, maintenance and serv- icing is carried out by the relevant Bizerba customer services office or the Bizerba trade consultant. 4.3.1... -

Page 30: Switching Off Machine

Installation Instruction manual GSP H, GSP H C, GSP V 4.3.2 Switching off machine Press<O> (red). (reduced operating force) With some options: set the slice thickness at the rotary knob smaller/equal "0" while the blade motor runs. The machine is switched off. -

Page 31: Machine And Operating Elements

Instruction manual GSP H, GSP H C, GSP V Machine and operating elements Machine and operating elements Foil keypad Illustration 14: Foil keypad <I> (green) blade motor on LAMP (white) display for blade motor on / off <O> (red) blade motor off (lower activation force) -

Page 32: Product Holder

Machine and operating elements Instruction manual GSP H, GSP H C, GSP V Product holder Machines with carriage inclination 0° and 18° When placing the product holder on the car- riage, the product holder can be lifted up to its unstable equilibrium. - Page 33 Instruction manual GSP H, GSP H C, GSP V Machine and operating elements Machines with carriage inclination 25° For slicing purposes, the product holder is set on top or behind the product. The prod- uct is moved towards the blade by means of its own weight.

-

Page 34: Product Fixation / Product Guide

Machine and operating elements Instruction manual GSP H, GSP H C, GSP V Product fixation / product guide The product fixation or product guide prevent the product from deflecting or tilting during slicing. The product guide is irreversibly self-locking on its shaft and is moveable across the full width of the carriage. -

Page 35: Product Feed For Tomatoes

Instruction manual GSP H, GSP H C, GSP V Machine and operating elements Product feed for tomatoes The product feed for tomatoes allows double slicing of tomatoes or similar vegetable to be sliced. The applied product fixation device holds the product in position during slicing pre- venting the product from tipping over. - Page 36 Machine and operating elements Instruction manual GSP H, GSP H C, GSP V CAUTION When lowering! Risk of crushing. – Effort and strength required. Move carriage away from operator side until it comes to a stop. Slightly lift machine up from the front via...

-

Page 37: Operation

Instruction manual GSP H, GSP H C, GSP V Operation Operation Slice permissible products only as described in these operating instruc- tions chapter 2.6. Slicing long product DANGER Rotary blade! Cut-injuries. – Do not allow yourself to become distracted. Concentrate on the task in hand and avoid time pressure. - Page 38 Operation Instruction manual GSP H, GSP H C, GSP V Place product on carriage rear wall and move to gauge plate. Position the product fixation or product guide against the product. Turn in product holder and position on the product.

-

Page 39: Slicing Product Ends

Instruction manual GSP H, GSP H C, GSP V Operation Slicing product ends DANGER Rotary blade! Cut-injuries. – Do not allow yourself to become distracted. Concentrate on the task in hand and avoid time pressure. – When slicing, the carriage may only be moved by the handle. -

Page 40: Slicing With Product Feed For Tomatoes

Operation Instruction manual GSP H, GSP H C, GSP V For tied product ends to be cut by hand. Place product end against the back wall of the carriage, making sure that the original cut surface faces the remnant holder plate. -

Page 41: Slicing With Vegetable Hopper

Instruction manual GSP H, GSP H C, GSP V Operation Position product on gauge plate of car- riage between both product fences. Fasten both slides with fence on prod- uct. Using handle, turn in product holder and position behind product. -

Page 42: Options

Options The options need to be selected when ordering a machine. Only the Bizerba customer service can set them at a later point of time. Option setting zero The machine can only be switched on if the slice thickness setting at the knob is smaller/ equal"0". -

Page 43: Troubleshooting

Switch off machine immediately if untypical noises are heard or if there is a suspected risk of injury. Call the responsible Customer Service if you are unable to rectify the fault yourself. Please provide your Bizerba customer service point with the following details: – Machine type (see rating plate), –... - Page 44 Troubleshooting Instruction manual GSP H, GSP H C, GSP V 7 - 2 6.037.98.5.10.06 en...

-

Page 45: Maintenance

Instruction manual GSP H, GSP H C, GSP V Maintenance Maintenance Preparation for cleaning Clean thoroughly: – Before putting into operation, – Depending on use and application frequency, – If extremely soiled, several times a day, – After sharpening, –... - Page 46 Maintenance Instruction manual GSP H, GSP H C, GSP V Remove components as follows: GSP H, GSP HC Turn out handle on carriage foot. Tilt carriage in the direction of the arrow. Illustration 34: Tilting carriage GSP V: Pull carriage to stop plate to operator.

- Page 47 Instruction manual GSP H, GSP H C, GSP V Maintenance Using the handle, move product holder away from blade and lift up. Loosen handle or star knob. Remove the remnant holder plate from the pusher guard. Illustration 36: Remnant holder plate, exam-...

- Page 48 Maintenance Instruction manual GSP H, GSP H C, GSP V Pull the product fences one after the other towards the operator as far as they will go and then remove from the guide shaft, moving them towards the right. Illustration 39: Product fences for tomatoes...

-

Page 49: Cleaning

Instruction manual GSP H, GSP H C, GSP V Maintenance Cleaning Do not clean the machine using a high-pressure cleaner. Do not use any abrasive cleaning devices since they can damage the Teflon-coated parts of the machine! Clean removed parts in warm water us- ing a soft cleaning agent. - Page 50 Maintenance Instruction manual GSP H, GSP H C, GSP V Thread a moist disposable cleaning cloth into the front between blade and guard ring. Illustration 44: Blade guard ring Use your hands to turn the blade and the disposable cleaning cloth; while you are doing so, press the cloth lightly against the inside of the guard ring.

- Page 51 Instruction manual GSP H, GSP H C, GSP V Maintenance Wipe off rear wall in the direction away from blade. Never wipe towards the blade. Illustration 47: Back panel Wipe off the carriage. Leave surfaces dry in the air. Illustration 48: Carriage 6.037.98.5.10.06 en...

-

Page 52: Cleaning Plan For Slicing Machines

Maintenance Instruction manual GSP H, GSP H C, GSP V Cleaning plan for slicing machines Work steps Cleaning Procedures Cleaning devi- Instructions agents 1 Preparatory Close slice measures thickness, switch off ma- chine, pull out power plug 2 Disassem- in accordance... - Page 53 Instruction manual GSP H, GSP H C, GSP V Maintenance Work steps Cleaning Procedures Cleaning devi- Instructions agents 4.2 Acid max. 3% P3- manually, me- Brush to re- only if required for cleaning riksan chanically move lime resi- lime residue...

-

Page 54: Preparing The Machine For Operation

All warranty claims lapse if the cleaning agents approved by the manu- facturer are not used. The safety sheets and product sheets supplied with the cleaning and disinfection agents must be read. The cleaning agent can be acquired from the BIZERBA customer services: Designation Order no. Packaging unit... - Page 55 Instruction manual GSP H, GSP H C, GSP V Maintenance Hold the blade cover by the handle with your right hand, tilt towards the blade and fix into position with the stud. Fasten the catch behind the blade guard ring with the left hand.

-

Page 56: Blade Sharpening

For safety reasons, the blade may only be ground to an annular gap of max. 6 mm. For safety reasons, the blade may only be changed by the Bizerba cus- tomer services. 8 - 12... -

Page 57: Sharpener

Instruction manual GSP H, GSP H C, GSP V Maintenance 8.6.1 Sharpener The sharpener identified by the machine number has been adjusted for this machine. The device is fitted with a coarse sharpening stone and a finely grained honing stone. Dirty or greasy sharpening stones do not sharpen well. -

Page 58: Attaching Sharpener

Maintenance Instruction manual GSP H, GSP H C, GSP V 8.6.3 Attaching sharpener WARNING Unprotected blade! Coming in contact with the sharp blade can lead to serious inju- ries. – Always wear cut-proof gloves when cleaning and sharpening. – Do not clean the blades when operating the machine. -

Page 59: Sharpening

Instruction manual GSP H, GSP H C, GSP V Maintenance 8.6.4 Sharpening Wear eye protection! Hearing protection is recommended. Switch on machine. Set handwheel marking to "1". The sharpening stone is engaged. Sharpen until right blade edge shows a burr. -

Page 60: Removing Sharpener

Maintenance Instruction manual GSP H, GSP H C, GSP V 8.6.6 Removing sharpener Pull sharpener back after loosening the star grip screw and remove to the top. Set slice thickness immediately to "0". Illustration 58: Removing sharpener 8 - 16... -

Page 61: Removing Sharpening Dust

Instruction manual GSP H, GSP H C, GSP V Maintenance 8.6.7 Removing sharpening dust Requirement: – Slice thickness to "0", – Power plug is pulled. Press dry disposable cleaning towel to blade surface and slowly clean from center to outside. -

Page 62: Care Of Machine, Servicing, Maintenance

Maintenance Instruction manual GSP H, GSP H C, GSP V Use your hands to turn the blade and the disposable cleaning cloth; while you are doing so, press the cloth lightly against the inside of the guard ring. Illustration 61: Blade guard ring... - Page 63 Instruction manual GSP H, GSP H C, GSP V Maintenance Lubricate the product holder guide shaft lightly 1 x week with BIZERBA lubricating oil from the accessories bag. At an annular gap of 6 mm between the blade and the guard ring, the sharpener no longer has a sharpening effect and the blade has to be re- placed.

- Page 64 Maintenance Instruction manual GSP H, GSP H C, GSP V 8 - 20 6.037.98.5.10.06 en...

-

Page 65: Technical Data

Instruction manual GSP H, GSP H C, GSP V Technical data Technical data Dimensions of GSP H with carriage inclination 0° Illustration 62: GSP H, example The device is available in many different versions. Here is an example. Outer dimensions: = 725 mm = 28.5"... -

Page 66: Dimensions Of Gsp H With Carriage Inclination 25

Technical data Instruction manual GSP H, GSP H C, GSP V max. product size, diam- = 260 mm = 10.5" eter max. product height = 290 x 246 mm = 11.5 x 10" Slice thickness setting = 0 to 24 mm = 0 to 0.94" stepless... - Page 67 Instruction manual GSP H, GSP H C, GSP V Technical data Work area: = 800 mm = 31.5" Length = 791 mm = 31.5" Width Weight = ca. 43 kg = 95 lb Blade diameter = 330 mm = 13"...

-

Page 68: Dimensions Of Gsp V

Technical data Instruction manual GSP H, GSP H C, GSP V Installation surface: = 530 mm = 20.87" Length = 480 mm = 18.90" Width Work area: = 806 mm = 31.74" Length = 899 mm = 35.4" Width Weight = ca. -

Page 69: Power Supply

Instruction manual GSP H, GSP H C, GSP V Technical data The device is available in different versions. Here is an example. Outer dimensions: = 725 mm = 28.5" Length = 570 mm = 22.5" Width = 516 mm = 20"... -

Page 70: Ambient Conditions

Technical data Instruction manual GSP H, GSP H C, GSP V Ambient conditions – Humidity Protection type IP 33. High air humidity and condensation can result in damage to the machine. – Relative humidity for operation and storage: 90 % (condensation of the unit is not permissible) –... - Page 71 Instruction manual GSP H, GSP H C, GSP V Appendix Appendix Declaration of conformity Declaration of conformity for plastic materials with direct food contact 6.037.98.5.10.06 en...

- Page 72 Appendix Instruction manual GSP H, GSP H C, GSP V 6.037.98.5.10.06 en...

-

Page 73: Declaration Of Conformity

The basis for the declaration of conformity are the contract documents (Bizerba pur- chase order documents). In the event of a modification to a machine of the above description that is not coor- dinated with Bizerba or not carried out by Bizerba, this declaration looses its validi- Date: 03.11.2010 Signature of manufacturer: ppa. -

Page 74: Declaration Of Conformity For Plastic Materials With Direct Food Con

Functional barriers made of plastic are not used in the specified machine. Information on suppliers or preliminary suppliers can be provided on request. Date: 29.06.2011 Signature of manufacturer: ppa. Title of signatory: Martin Arndt Chief Executive Officer Technology (CEO-T) Bizerba GmbH & Co. KG 6.037.98.5.10.06 en...

Need help?

Do you have a question about the GSP H and is the answer not in the manual?

Questions and answers