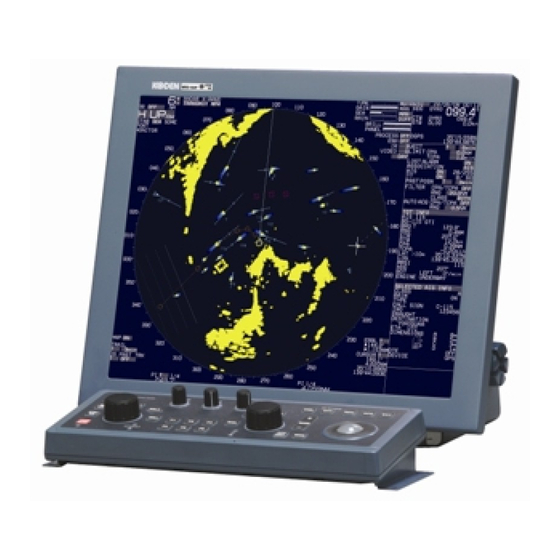

Koden MDC-2900 Series Installation Manual

Hide thumbs

Also See for MDC-2900 Series:

- Operation manual (191 pages) ,

- Installation manual (110 pages) ,

- Operation manual (153 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Koden MDC-2900 Series

- Page 2 Disclaimer The specifications and technical issues described in this manual are subject to change without notice. Koden Electronics Co., Ltd. has no responsibility for any human and physical damage or failure caused by the interpretive error of this manual. 0092629012-00...

-

Page 3: Table Of Contents

MDC-2900 Series A table of content Preface ............................1 Precaution for operation ......................1 Precautions for maintenance ....................2 • Caution against residual high voltage:...................2 • Keep inboard power source “Off”: ..................2 • Caution against the dust:.......................2 • Measures against static electricity:..................2 Chapter 1 Prior to installation...................... 1-1 1.1 Installation precautions .................... - Page 4 A table of content MDC-2900 Series 3.4.6 AIS cable connection....................3-14 3.4.7 Cable connection for NAV, EPFS and SDME or Log ..........3-15 3.4.8 Cable connection for interswitch................3-16 Chapter 4 Setup after installation....................4-1 Display [STARTUP] menu..................4-1 Set up antenna installation height from sea level............4-1 Setup antenna cable length ..................

- Page 5 MDC-2900 Series A table of content 5.2.1 Alarm display and its delete..................5-1 5.2.2 Status indicator lamp ....................5-4 5.3 Malfunction diagnosis ....................5-5 5.3.1 Malfunction detection step..................5-5 5.3.2 Malfunction diagnosis flow chart................. 5-6 5.4 Repair .......................... 5-19 5.4.1 Replacement of fuse ....................5-19 Chapter 6 Maintenance ......................

-

Page 6: Preface

MDC-2900 Series Preface Preface [Precaution for safety issues] Precaution for operation • Caution about rotating antenna: The radar antenna may start rotating without notice. Please keep away from the antenna for your safety. • Caution about health risks caused by radio wave: Powerful electromagnetic waves are emitted from the antenna during operation. -

Page 7: Precautions For Maintenance

Preface MDC-2900 Series • Caution about dangerous internal high voltage in the device: High voltage that may cause risk of life is present in the antenna unit and the display unit of this radar. This high voltage can remain in the circuit after the switch has been turned off. The high-voltage circuit has a protective cover with a label “Caution against high voltage”... -

Page 8: Chapter 1 Prior To Installation

MDC-2900 Series Chapter 1 Prior to installation Chapter 1 Prior to installation 1.1 Installation precautions In order to obtain the maximum performance of radar systems, this radar system should be installed by qualified engineers in charge of installation and maintenance. Installation procedures include the following: (1) Unpacking of components;... -

Page 9: Display Unit And Operation Unit

Chapter 1 Prior to installation MDC-2900 Series (3) The antenna unit should be installed in front of large objects or exhaust stack to prevent a blind sector or the effects on the antenna by engine exhaust soot. (4) Keep sufficient maintenance area. -

Page 10: Chapter 2 System Configurations

MDC-2900 Series Chapter 2 System configurations Chapter 2 System configurations 2.1 Standard configuration list MDC-2960 Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft 6 kg RW701A-06 6 ft 8 kg RW701B-09 9 ft 12 kg Scanner unit RB717A... - Page 11 Chapter 2 System configurations MDC-2900 Series MDC-2920 Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft RW701A-06 6 ft 8 kg RW701B-09 9 ft 12 kg Scanner unit RB719A 25 kW 21 kg Display unit MRD-105 8.2 kg Operation unit MRO-105 1.8 kg...

- Page 12 MDC-2900 Series Chapter 2 System configurations MDC-2910BB No. Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft 6 kg RW701A-06 6 ft 8 kg RW701B-09 9 ft 12 kg Scanner unit RB718A 12 kW 17 kg Processor unit MRM-105 12.4 kg...

-

Page 13: Spare Parts List

Chapter 2 System configurations MDC-2900 Series 2.2 Spare parts list SP-100 Name Specification Comment Type Quantity Usage (Dimension) Fuse F-1065-15A Normal type Tubular Main power (· 6.3 x 32) Fuse MF51NN250V5A Normal type Tubular Motor power (· 5 x 25) Fuse F-7142-0.3A... -

Page 14: Options

MDC-2900 Series Chapter 2 System configurations 2.4 Options (Common) Name Specification Comment Weight /Dimension /Quantity Gyro converter S2N Gyro converter qwerty-electronik Log pulse NMEA L1N 9181 qwerty-electronik converter Rectifier unit PS-010 5A fuse attached 3.5 kg VL-PGS001 VEINLAND GmbH for RW701B-09... -

Page 15: Mdc-2960/2910/2920 Series System Configuration

Chapter 2 System configurations MDC-2900 Series 2.5 MDC-2960/2910/2920 series system configuration Antenna RW701A-04 Scanner unit RW701A-06 RW701B-09 RB717A RB718A RB719A Connecting cable 242J159098B-15M (Standard) 242J159098C-20M 242J159098D-30M Ext Buzzer 242J159098E-**M (65 m Max.) Display unit CW-576-0.5 CW-560-2M CW-387-5M MRD-105 CW-561-10M Remote display... - Page 16 MDC-2900 Series Chapter 2 System configurations 2.6 MDC-2960BB/2910BB/2920BB series system configuration Antenna RW701A-04 RW701A-06 Scanner unit RW701B-09 RB717A RB718A RB719A Connecting cable 242J159098B-15M (Standard) 242J159098C-20M 242J159098D-30M 242J159098E-**M (65m Max.) Alarm out SXGA CW-576-0.5 Monitor Display Processor unit CW-560-2M CW-387-5M MRM-105...

-

Page 17: Chapter 3 Method Of Installation

MDC-2900 Series Chapter 3 Method of installation Chapter 3 Method of installation 3.1 How to install the Antenna-Scanner unit 3.1.1 Installation of the Antenna-Scanner unit The Antenna-Scanner unit is equipped to orient the notch of the attachment to stern as shown in Figure 3.1. -

Page 18: Mounting Antenna

Chapter 3 Method of installation MDC-2900 Series 3.1.2 Mounting antenna (1) Remove the protection cap put on the outlet of the rotating joint on the Scanner. (2) Remove the four bolts temporarily fastened to the antenna base and attach the antenna to the rotating joint. -

Page 19: Connecting The Cable

MDC-2900 Series Chapter 3 Method of installation 3.1.3 Connecting the cable (1) Remove front and back covers of Scanner unit by loosing four mounting bolts. (2) Pull out the Scanner unit by loosing two mounting bolts and disconnect each connector. Be careful not to lose metal parts to the magnetron magnet. -

Page 20: Interconnection Diagram Of Cable

Chapter 3 Method of installation MDC-2900 Series 3.2 Interconnection diagram of cable Antenna-Scanner unit Display unit Description Cable colour Cable colour Description +250V Purple Purple +250V Blue +24V Yellow Orange (thick) +12V +40V Red (thick) Yellow +40V Yellow (thick) Shield... -

Page 21: Installation Of The Display Unit

MDC-2900 Series Chapter 3 Method of installation 3.3 Installation of the display unit The display unit can be mounted on a table or a panel. The procedure is as follows. 3.3.1 Installation of MRD-105 3.3.1.1 Table mounting of MRD-105 (1) Remove four knob bolts from which the display unit is secured on the mounting bracket. - Page 22 Chapter 3 Method of installation MDC-2900 Series NOTE: In the case of mounting the display unit on the table, some maintenance space is required for cabling, connector access, fuse replacement, fastening of bolts, etc. as shown in the following figure.

- Page 23 MDC-2900 Series Chapter 3 Method of installation 3.3.1.2 Flush Mounting for MRD-105 Preparation: (1) Cut an opening and drill 4.5 mm eight holes with the size shown in Figure 3.8, on the side for attachment of a display unit on a panel.

-

Page 24: Installation Of Operation Unit

Chapter 3 Method of installation MDC-2900 Series 3.3.1.3 Installation of Operation unit Remove the corner guard caps (four places) on the Operation unit. Insert the tip of a small flat-blade screwdriver carefully between a corner guard cap and the front bezel of Operation unit to make a gap, and then pinch and pull up the corner guard cap with fingers. - Page 25 MDC-2900 Series Chapter 3 Method of installation (15 5/32) (1 37/64) (1 37/64) Unit : mm(inch) Figure 3.11 Maintenance space necessary for Operation unit 0092629012-00...

- Page 26 Chapter 3 Method of installation MDC-2900 Series Flush mounting the Operation unit Preparation: (1) Cut an opening with the size as shown in Figure 3.12 on the side for mounting a display unit on the panel. (2) Mark the place of holes for mounting.

-

Page 27: Cable Connection For Mrd-105 Display Unit

MDC-2900 Series Chapter 3 Method of installation 3.4 Cable connection to a display unit 3.4.1 Cable connection for MRD-105 Display unit Attach the connectors of cables from an antenna unit, power source and Operation unit, to corresponding receptacles as shown in Figure 3.14. -

Page 28: Cable Connection For Mrm-105 Processor Unit

Chapter 3 Method of installation MDC-2900 Series 3.4.2 Cable connection for MRM-105 Processor unit Attach the connectors of cables from an antenna unit, power source and Operation unit, to corresponding receptacles as shown in Figure 3.14. The monitor should be able to input analog RGB. -

Page 29: Connecting The 2Nd Monitor With Mrd-105

MDC-2900 Series Chapter 3 Method of installation 3.4.3 Connecting the 2nd monitor with MRD-105 The monitor should be able to input analog RGB. The resolution is SXGA of the VESA standard. mini D-sub15pin connector CW-560-2M or equivalent (VGA cable) Figure 3.16 Cable connection of a display unit to ext. monitor 3.4.4 Connecting a VDR or the 2nd Monitor(MRM-105) and the Alarm output... -

Page 30: Connecting A Gyro Converter Unit Or Thd

Chapter 3 Method of installation MDC-2900 Series 3.4.5 Connecting a Gyro converter unit or THD GYRO SYNCHRO or Step signal S2N Gyro converter or NSK unit CW-406-5M Serial signal IEC 61162-2 Cable connector pin assignment Signal name OUT A OUT-B... -

Page 31: Cable Connection For Nav, Epfs And Sdme Or Log

MDC-2900 Series Chapter 3 Method of installation 3.4.7 Cable connection for NAV, EPFS and SDME or Log Display unit upper view CW-376 CW-376 J4, J5 & J6 L1N Log pulse CW-376 Pin number CW-376 wire Signal NMEA converter color name... -

Page 32: Cable Connection For Interswitch

Chapter 3 Method of installation MDC-2900 Series 3.4.8 Cable connection for interswitch 3.4.8.1 Cable connection instructions for cross-over, parallel and independent connection In the case of a dual, crossover, or master/slave connection using two sets of radar system or display unit, the remote cable and data cable are connected as shown in the figure. - Page 33 MDC-2900 Series Chapter 3 Method of installation 3.4.8.2 Cable connection for secondary display unit used as a monitor When the secondary display unit for radar is used as monitor, the remote cable is connected as follows. Primary display unit (MRD-105/MRM-105)

-

Page 34: Chapter 4 Setup After Installation

MDC-2900 Series Chapter 4 Setup after installation Chapter 4 Setup after installation Some setup procedures are required after system installation. Before performing the setup procedures, please check the following items for normal operation: The onboard power supply powering the radar system has the specified voltage. -

Page 35: Adjustment Of Automatic Tune

Chapter 4 Setup after installation MDC-2900 Series 1 Press [MENU] key to display “Menu”. Select [MAINTENANCE] => [STARTUP] => [ANT CABLE] => and press [ENT] key after selection. Selectable value 20m, 40m, and 60m 4.4 Adjustment of automatic tune In order to achieve best performance, adjustment of the automatic tune is required at the time of a new installation or a magnetron exchange. -

Page 36: Setup Of Mbs Value (Main Bang Suppression)

MDC-2900 Series Chapter 4 Setup after installation Press [MENU] key, select MAINTENANCE => STARTUP => HL OFFSET => VALUE will show the current setting of the input value by highlighting it. Roll the trackball up or down to adjust the value to match the bearing value of the target picture to the compass value. -

Page 37: Mon (Performance Monitor)

Chapter 4 Setup after installation MDC-2900 Series About [Reference point] The base point for range, bearing, relative course, and relative speed, CPA or TCPA is named [Reference point]. Either CCRP or ANT position can be used as the reference point. -

Page 38: Setup Interface

MDC-2900 Series Chapter 4 Setup after installation Select [CALIBRATION] and then press [ENT] key. Then, the antenna performance is recorded for later reference. Return to Main menu and select [SYSTEM]. Confirm RX, TX and SYSTEM bars are maximum length. RX: Displays performance degradation of receiver. -

Page 39: Speed Interfaces

Chapter 4 Setup after installation MDC-2900 Series Connecting a Gyro converter unit or THD. Refer to 7.1.1 Details of the data input format for sentence format. Select interface sentence by interface specification of GYRO or THD. In accordance with the bearing sensor, set up interface by following steps. -

Page 40: Select Set/Drift Input

MDC-2900 Series Chapter 4 Setup after installation When EPFS is selected; Select [MAINTENANCE] => [I/O] => [DETAIL] => [FORMAT] => [EPFS] => [61162-1 or 61162-2] and then press [ENT] key. 4.11.2.3 Select SET/DRIFT input Select the sensor of SET/DRIFT when [CURRENT] is selected at COG/SOG. -

Page 41: Setup Of Output

Chapter 4 Setup after installation MDC-2900 Series minute]. Roll the trackball up or down to match it to the coordinated universal time, and then press [ENT] key. 4. Input time difference between local time and UTC. Select [MAINTENANCE] => [I/O] => [TIME ZONE] => to highlight the value of [hour: minute]. Roll the trackball up or down to match it to the time difference, and then press [ENT] key. -

Page 42: Change Of Adjustment Range Of Manual [Sea] Knob

MDC-2900 Series Chapter 4 Setup after installation 1.SET SEA to AUTO (Refer to Operation manual 3.8 Reject sea clutter) 2.Follow the steps below. Select [MAINTENANCE] => [PRESET] => [SEA AUTO SEA] => to highlight the last digit value. Make sea clutter displayed by even dark level in the screen by rolling the trackball up and down while watching the screen. -

Page 43: Change Of Signal Detection Level Of Tt

Chapter 4 Setup after installation MDC-2900 Series 4.18 Change of signal detection level of TT It is possible to change detection level of targets for TT. Select [MAINTENANCE] => [PRESET] => [TT TGT LEVEL] => to highlight the last digit value, roll the trackball up or down to change the value, and then press [ENT] key. -

Page 44: F (Function Key) Usage

MDC-2900 Series Chapter 4 Setup after installation 4.20 F (Function key) usage For quick function access, this radar is provided with six dedicated function keys (“F1”, “F2”, ”F3” , ”F4” , ”F5” , ”F6”). You can switch to a prespecified function by pushing each key. -

Page 45: Chapter 5 Troubleshooting And On-Board Repair

MDC-2900 Series Chapter 5 Troubleshooting and on-board repair Chapter 5 Troubleshooting and on-board repair In this chapter we provide troubleshooting procedures to find malfunction parts on a ship. 5.1 Necessary information at the time requesting repairs Please note the following items:... - Page 46 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.2.1.1 Alarm display list Table 5.1 Alarm display list of radar Cause Tracked target is lost. Ref tracked target is lost. Tracked target exceeded the CPA/TCPA limit. Tracked target entered into the guard zone.

- Page 47 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair Change to reference antenna. AIS interface not connected. AIS alarm signal. AIS no OS COG/SOG data. AIS no data. 5.2.1.2 Warning display list Warning is displayed when the function is not available because of lack of information required for its operation.

- Page 48 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.2.2 Status indicator lamp Three LED (Light Emitting Diodes) lamps are provided on the logic PCB in the display unit. The operational conditions are indicated by these LED's. Refer to the following table for details.

-

Page 49: Malfunction Diagnosis

MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.3 Malfunction diagnosis This chapter specifies necessary information required troubleshooting and repair of the radar system. 5.3.1 Malfunction detection step As a first step of on-board repair, refer to the following tables describing outlines of malfunction diagnosis procedure. -

Page 50: Malfunction Diagnosis Flow Chart

Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.3.2 Malfunction diagnosis flow chart The following malfunction analysis chart can be used by service personnel for malfunction diagnosis and location of defect module. This chart shows flow chart of analysis procedure of basic malfunction analysis to details. - Page 51 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.3.2.2 Initial malfunction diagnosis 2 Is main power fuse (F1) Exchange fuse Is rating fuse proper? normal? (not blowout) Is inboard power polarity Reconnect correctly correct? Power supply failure Is power supply voltage...

- Page 52 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.3.2.3 No display Press [Brilliance] key, turn EBL (EBL/VRM) Is brilliance control of knob to clockwise with display to the maximum observing brilliance position? control window to maximize bar graph. Is backlighting of the LCD...

- Page 53 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.3.2.4 No response from the antenna unit Is alarm message “Error, Antenna disconnection” Main logic PCB failure displayed on the screen? Is the voltage between Is the voltage between Pin J7-3 and ground...

- Page 54 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.3.2.5 Radar picture error Is noise observed in Is the warning “Error, No Refer to [5.3.2.9 Antenna unit background of radar echo and Video signal” picture at maximum failure or radar picture error].

- Page 55 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.3.2.6 Data such as heading, speed, latitude/longitude cannot be received Is navigation data (IEC 61162-1) normally obtained via connector (J4, J5, J6) and displayed? Turn on power and carry on MENU=> SYSTEM=>...

- Page 56 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series 5.3.2.7 Operation unit error Is main logic PCB connection normal? Can radar power turn on? Connect normally (1) J710 to power supply PCB (2) J722 to Operation unit Operation unit failure Select [MENU] =>...

- Page 57 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.3.2.8 Other errors Unstable or out of sync. of display Is following signal observed by connector J1-7 and J1-8 of display unit back panel? Main logic PCB [J1-7] [J1-8] failure 12 V 12 V 48.4 us...

- Page 58 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series +250 V and frame is shorted Does status recover by Antenna unit wiring failure disconnecting J2 connector or display unit failure from modulator PCB? Modulator PCB failure Pulse length control failure Is transmitter unit drive signal...

- Page 59 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair Failure of motor power or wiring in Is motor drive power (12V for J4-5 antenna unit, or failure of display to J4-4) normal? unit power Is motor brush length within Change motor brush to a new one.

- Page 60 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series No transmission Is transmitter high voltage fuse Modulator PCB failure (F3) blowout? Check connecting cable Is +250 V (J2-1) on modulator between display unit and PCB normal? antenna unit. TP2 shape Is trigger signal (TP2) on...

- Page 61 MDC-2900 Series Chapter 5 Troubleshooting and on-board repair Tuning meter failure Is tuning meter voltage of IF IF Amp. PCB failure Amp. J1-13 around 2 V? Confirm connection between IF Amp. PCB J1 and modulator PCB. Auto tuning inoperable Re-initialize auto tuning function.

- Page 62 Chapter 5 Troubleshooting and on-board repair MDC-2900 Series Low gain Is error message “Error Antenna, Magnetron failure Magnetron current” displayed on the screen? Is MIC monitor output terminal MIC module failure voltage within 30-70 mV range? IF Amp. PCB failure...

-

Page 63: Repair

MDC-2900 Series Chapter 5 Troubleshooting and on-board repair 5.4 Repair 5.4.1 Replacement of fuse The location of the fuses is on the back panel of display unit. Fuse type and rating Application Type, dimension (mm) Fuse characteristic Rating Main power Tubular (φ6.3 x 32) -

Page 64: Chapter 6 Maintenance

MDC-2900 Series Chapter 6 Maintenance Chapter 6 Maintenance To prevent electric shock, be sure to turn off the radar system power Warning: before opening the cover of the antenna unit. For health safety reason, transmission is basically inhibited when antenna is not rotating. -

Page 65: Annual Inspection

Chapter 6 Maintenance MDC-2900 Series with soft cloth soaked in water or soap detergent. Also make sure no cracks or coating material is on the front radiation part of antenna unit. Never turn on the power of radar system under inspection. - Page 66 MDC-2900 Series Chapter 6 Maintenance Internal structure of the antenna housing Motor Motor brush Turn the screw slowly to counter clockwise using Motor a screwdriver to remove old motor brush. Motor brush Figure 6.2 Changing the motor brushes 0092629012-00...

-

Page 67: Method Of Exchanging The Magnetron

Chapter 6 Maintenance MDC-2900 Series 6.3 Method of exchanging the magnetron shield case 6.3.1 remove Magnetron 1. Remove the 4 screw (1,2,and 3) and remove a shield case. 2. Remove the Cable ties in 3 places (4,5,and 6). 3. Remove the yellow wire from A and B terminals. -

Page 68: Chapter 7 Input/Output Data

MDC-2900 Series Chapter 7 Input/output data Chapter 7 Input/output data Input data 7.1.1 Details of the data input format. Check sum: All the data from $ to the check sum position * is calculated by exclusive operation and used as checksum. - Page 69 Chapter 7 Input/output data MDC-2900 Series Datum reference $ - - DTM, ccc, a, x.x, a, x.x, a, x.x, ccc*hh <CR><LF> Check sum Reference datum Formatter Altitude offset, m Talker W84 : WGS84 Lon offset, min, E/W device W72 : WGS72...

- Page 70 MDC-2900 Series Chapter 7 Input/output data Water temperature $ - - MTW, x.x, C*hh <CR><LF> Check sum Formatter Temperature, degrees C Talker device Start of sentence Recommended minimum navigation information $ - - RMB, A, , , , c-c, xxxx.xxx, N/S , xxxxx.xxx, E/W , xxx.x, xxx.x, , , a*hh <CR><LF>...

- Page 71 Chapter 7 Input/output data MDC-2900 Series Water speed and heading $ - - VHW, , , , , xx.x, N, , *hh <CR><LF> Note 1 : Check sum In case the speed data in knots is not available, Formatter then the metric speed data fields will be recovered used for alternative metric data.

- Page 72 MDC-2900 Series Chapter 7 Input/output data AIS other ship data ! AI VDM, x, x, x, x, xxxxx・・・・・・・・・・・・・・・・・・・xxxx, N*hh <CR><LF> Check sum Message part Formatter (6bit field) Channel number Fill bit Talker device Message number Start of Sentence number sentence...

-

Page 73: Details Of Tt Tracking Data Output

Chapter 7 Input/output data MDC-2900 Series 7.2 Details of TT tracking data output Data standard name: IEC61162-2 Target data of the automatic tracking unit is provided via data connectors (J4/J5) on the back panel. Target label $ RA TLB, x.x, c - - c, x.x, c - - c, . . . x.x, c - - c * hh<CR><LF>... -

Page 74: Radar System Data

MDC-2900 Series Chapter 7 Input/output data Acknowledge alarm $ - - ACK, xxx * hh<CR><LF> Check sum Unique alarm number (identifier) at alarm source Formatter Talker device Start of sentence Set alarm state $ - - ALR, xxxxxx.xx, xxx, A, A, c- -c*hh <CR><LF>... -

Page 75: Interface Specification

Chapter 7 Input/output data MDC-2900 Series 7.4 Interface specification 7.4.1 NAV, EPFS and SDME serial data input/output specification Input connector: J4, J5 and J6 Connector used: LTWD-06PMMP-LC Connector acceptable: LTWD-06BFFA-L180 Data connector pin assignment J4-J6 Data connector pin location J4, J5 & J6... -

Page 76: Vdr (External Monitor) And Alarm Output Signal Specification

MDC-2900 Series Chapter 7 Input/output data 7.4.2 VDR (external monitor) and Alarm output signal specification Output connector name: RGB & Alarm Connector used: LTWBU-10PMMP-LC Pin number Signal name Connector acceptable: LTWBU-10BFFA-L180 R-GND Pin location is shown below. G-GND J1 External monitor and alarm output... -

Page 77: Serial Data Input/Output Specification (Ais)

Chapter 7 Input/output data MDC-2900 Series Alarm Output specification Inside of Radar DC +24V or +32V BZ(+) For external Buzzer Ship's power supply Filter BZ(-) DC 24 or 32 I=1A max 7.4.3 Serial data input/output specification (AIS) I/O connector J2 (AIS) -

Page 78: Radar Input/Output Signal Specification

MDC-2900 Series Chapter 7 Input/output data 7.4.4 Radar input/output signal specification I/O connector: J3 Remote Data connector pin assignment Connector used: LTWU-12PMMP-LC Connector acceptable: LTWBU-12BFFA-L180 Pin number Signal name VIDEO OUT TRIG OUT J3 Remote connector pin location (Display unit upper view) -

Page 79: Gyro Input Signal Specification

Chapter 7 Input/output data MDC-2900 Series 7.4.5 Gyro input signal specification +Vcc Gyro data connector Connector used: LTWD-08PMMP-LC Data input A Connector acceptable: LTWBD-08BFFA-L180 TLP115A IN-A Data input B Serial data input (Listener): IN-B Standard signals conforming to IEC61162-2 is acceptable. -

Page 80: Talker Device Code Of The Data Output Devices

MDC-2900 Series Chapter 7 Input/output data 7.4.6 Talker device code of the data output devices The device code displayed as talker is shown in the table below. Data output device Talker device code Displayed code Decca navigator device Global positioning system (GPS)

Need help?

Do you have a question about the MDC-2900 Series and is the answer not in the manual?

Questions and answers