Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Maktek 25 MKK-S

-

Page 2: Table Of Contents

CONTENT 1. GENERAL WARNINGS BEFORE OPERATING THE UNIT......4 2. FEATURES OF THE BOILER...............5 3. SECTIONS OF THE BOILER...............6 4. INSTALLATION..................7 4.1 INSTALLATION AND WATER FLOOD............9 BOILER INSTALLATION SCHEMA..............10 4.2 AIR CONNECTION................11 4.3 CHIMNEY...................11 CHIMNEY CONNECTION SCHEMA............12 5. TECHICAL FEATURES................…13 6. CONTROL PANEL..................14 7. FIRST OPEATION AND USE...............15 7.1 FIRST BURNING..................15 7.2 WARNINGS FOR USE...............….16 8. CLEANING AND MAINTAINANCE............…..17 9. ELECTRICAL SCHEME ............……………..18 10. TROUBLE SHOOTING................19 11. CARRIAGE AND TRANSPORT..............20 ... - Page 3 PREFACE MAKTEK is one the leading institutions in Turkey in heating industry since its foundation in 1976 . Inconsideration of monitoring technological developments closely, MAKTEK takes the pride of presenting MAKTEK Solid Fuel Boilers in Turkey and World market. Our company, which has acquired advanced technology and superior quality, stands on in accordance with these principles. This handbook is a helpful guide during operation and maintenance of the user boiler assembly. For malfunctions and maintenance, please contact our authorized service. Our after sales service network is always at your service with abundant spare parts and widespread service organization. MAKTEK GROUP COMPANIES...

-

Page 4: General Warnings Before Operating The Unit

1.GENERAL WARNING BEFORE OPERATING THE UNIT • Please check the conformity of waste gas , water and electric infrastucture of the area • to the necessary technical parameters where the boiler will be installed. • For safe use of electricity , make sure that the grounding of the installation is isolated and there is no phase. -

Page 5: Features Of The Boiler

2. FEATURES OF THE BOILER - Capacity between 25.000 kcal-250.000 kcal/h - Burns the fuel which is up to 20mm diameter with high energy thanks to automatic fuel feeding. - Heating with high efiiciency for coal and all solid fuels - Monitoring of heating water on digital screen - Electronic control panel - Safe use with safety thermostat against overheating - Energy saving thanks to special body design... -

Page 6: Sections Of The Boiler

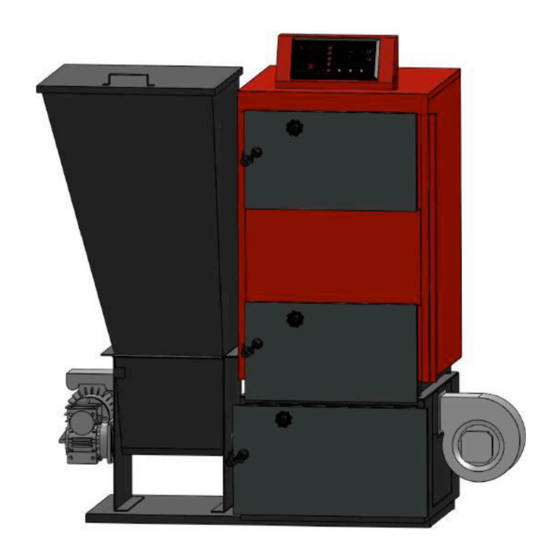

3. SECTIONS OF THE BOILER *See techic table for dimensions stated with letters ... -

Page 7: Installation

*Boiler must be placed at a location with enough air intake for an efificient burning. It is required to use open expansion tank for the installation of MAKTEK Automatic Coal Boilers. * Boiler- expansion tank return pipes must be absolutely isolated in extreme cold regions. - Page 8 MODEL CAPACITY EXPANSION TANK 25 MKK-S 25.000 kcal/h 50 lt 40 MKK-S 40.000 kcal/h 75 lt 60 MKK-S 60.000 kcal/h 100 lt 80 MKK-S 80.000 kcal/h 200 lt 100 MKK-S 100.000 kcal/h 250 lt 125 MKK-S 125.000 kcal/h 275 lt 150 MKK-S 150.000 kcal/h...

-

Page 9: Installation And Water Flood

4.1 INSTALLATION AND WATER FLOOD Please use open expansion tank for MAKTEK Solid Fuel Boilers. Closed expansion tank systems may trigger steaming of the boiler when there is an electric cut out or when the pump is not functioning. Please connect open expansion tanks according to standarts. -

Page 10: Boiler Installation Schema

BOILER INSTALLATION SCHEMA... -

Page 11: Air Connection

4.2 AIR CONNECTION The area where the boiler is installed must always be suppplied with fresh air by using a window or a duct. In order for a boiler to burn safely and efficiently, fresh air is required. Otherwise once the burning starts, the oxygen level will drop causing the burning to be inefficient. In turn, this will result in formation of soot in the boiler and chimney and will require frequent cleaning. 4.3 CHIMNEY • The chimney that will be connected to the boiler must be independent. The chimney must be connected to provide minimum draught. A boiler without chimney connection should not be operated. • Chimney connection pipe and pipe systematic should be installed and checked by authorized people only. -

Page 12: Chimney Connection Schema

• There should be no sectional narrow down in any place of the chimney. • Main walls of the building should never be used as chimney wall element. The chimney must be inside the building, if the chimney must pass from outside, the isolation must be done properly. -

Page 13: Techical Features

5. TECHNICAL SPECIFICATION... -

Page 14: Control Panel

6. BOILER WITH STOCKER CONTROL PANEL ( Fuel Waiting Period Setting Button ) Fuel Feeding Period Setting Button) Fan Button ) Termostat Setting Button) Fan Led ) (Pump Led) Fuel Finshed Led) Fuel Squeezed Led) Burron) ( Up Down Button) 7 part Led Indicator ) Reductor Button ) Fan Button) (Fuel Feeding Button) -

Page 15: First Opeation And Use

7. FIRST OPERATION AND USE 7.1 INITIAL BURNING Before initial burning, system water must be full and system air must be purged. Fuel loading must be done over the sifter. The sifter prevents the entrance of foreign objects, large size coal pieces inside the reductor and damage reductor and helezon. Also it enables the passing of the proper size of coal which will burn easily and efficiently At initial burning, fan and reductor must be on and boiler water temprature must be previously set. -

Page 16: Warnings For Use

7.2 WARNINGS FOR USE Circulation pump will start running when the burning continues and boiler water temperature comes to 35°C. This prevents extra electric cunsumption and heats boiler immediately so prevents damages from sweat of steam. Prevents water that is not properly heated to the raditaors. Boiler water temperature decreases when the fuel is finished and when it is 30°C, circulation pump stops running. -

Page 17: Cleaning And Maintainance

8. CLEANING AND MAINTAINENCE Following instructions should be followed in order to keep boiler working safe and efficient for long time. Quality of the fuel used, would effect the boiler cleaning time, consumption amount of fuel and efficiency of boiler. Small coal is burned in boiler. Do not burn dust and coke coal. Ash drawers should be cleansed up every day. -

Page 18: Electrical Scheme

10. ELECTRICITY SCHEMA ... -

Page 19: Trouble Shooting

11. TROUBLE SHOOTING Problem Reason Solution Offer Check the connection Electricity connection might be loose Tighten the klemens cables. Reductor doesn't work Shaft from the reductors can be Clean up the shaft bearing There is H4 warning on congested helezon entrance hole control panel digital screen If it doens't work call service. -

Page 20: Carriage And Transport

12. CARRYING AND TRANSPORT A) PLACING THE BOILER ON VEHICLE *When the boiler is placed placed on vehicle, loading should be with crane. * Gates of the vehicle should be opened previously. * Make use of the supporting ring while loading boiler with crane. * Pass the crane boom hook from the supporting ring. *Make sure that hook pim is in safety mode.

Need help?

Do you have a question about the 25 MKK-S and is the answer not in the manual?

Questions and answers