Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

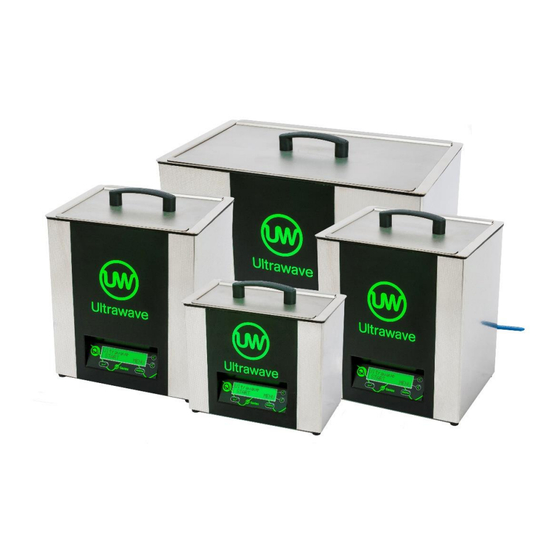

Summary of Contents for Ultrawave Qi Series

- Page 1 Qi Series Operator Instruction Manual C6027205-01 issued October 2021...

-

Page 2: Table Of Contents

Technical information ..................26 Specifications ..................... 27 Maintenance ....................... 28 Troubleshooting ....................29 Returning equipment to Ultrawave ..............31 WEEE Compliance ..................... 31 Warranty ......................32 Compliance with the Control of Noise at Work Regulations ......33 Service record ....................34... -

Page 3: Safety Instructions

Do not place fingers, hands, or other parts of the body in the liquid in the bath when it is sonicating. Fill the Qi series with cold water. This will ensure that the machine runs its automatic de-gas cycle (see page 26 for the importance of degassing). - Page 4 Ultrawave will not be responsible for damage or injury caused by incorrect use of the equipment. The user should apply to Ultrawave or its agent for advice on cleaning techniques or detergents. IMPORTANT: Once the cleaning cycle has finished, remove the cleaned items, and rinse them immediately in clean running water.

- Page 5 Other Symbols Proper shipping Keep dry orientation Catalogue Fragile Number Date of Serial Number Manufacture Indicate the item is Manufacturer medical device Country of Unique Device manufacture Identifier Qi Operating Manual C6027205...

-

Page 6: Installation

Installation The following parts and accessories are included with the Qi-Series ultrasonic bath: 1 x Qi-Series ultrasonic bath 1 x basket 1 x lid 1 x 2m length of drain hose 1 x hose tail 1 x mains lead 1 x Ultraclean detergent sample How to install? Screw the hose connector into the drain valve at the rear of the unit. -

Page 7: Controls

Controls Ensure your Qi-Series ultrasonic bath is plugged into a 230 VAC fully earthed supply. Once plugged in, switch on your Qi-Series bath via the power on/off switch at the rear of the unit. The switch will then illuminate. The Qi-Series is operated through a menu driven control system: KEY 3 KEY 4 KEY 2... -

Page 8: Quick Guide

Quick guide Pour water into the bath so that it submerses the level sensor (Do not overfill). Add the required dose of detergent (see page 25). Switch on the machine via the switch at the rear of the unit, just above the electrical mains lead. -

Page 9: Operating Instructions

Operating instructions When the Qi-Series power is turned on and the bath is full of liquid, the following screens will display alternately. When the water temperature is at or above the temperature set, the message “Temp OK” will display. The actual temperature in the bath may vary and may be different to the value shown in the screen above. - Page 10 When the Qi-Series power is turned on and the liquid level is too low, the following screen will display. The level sensor can be disabled for specialist cleaning applications where deionised (DI) water is used (see page 20). When the bath is filled with liquid to the correct level, you will be given the option to degas.

-

Page 11: Operator Menu

Operator menu A number of the Qi-Series cleaning parameters can be altered. To access the options menu and scroll through the various changeable parameters, press the MENU key, when the following screen is displayed. To scroll through the menu, press the MENU key. To exit the MENU at any time, press the ... - Page 12 Screen 1: Setting the temperature Your Qi-Series is fitted with a thermostat and heaters to ensure the temperature of the cleaning fluid is maintained at the set temperature. Use the UP and DOWN keys to accurately set the desired temperature of the cleaning fluid between ambient and 80°C.

- Page 13 Screen 2: Setting the cycle time Your Qi-Series ultrasonic bath is factory pre-set with a cycle time of 15 minutes. Use this screen to amend the cycle time. Use the UP and DOWN keys to scroll through the numbers in order to increase or decrease the time. When the desired cycle time has been selected, use the MENU key to move to the next screen.

- Page 14 Screen 4: Degas As well as the automatic degas function that you are offered when the machine is first turned on, this menu function allows you to run a degas cycle whenever a cleaning cycle is initiated. Use the ON and OFF keys to select the required option. (See page 26 for the importance of degassing.) If you turn the degas function ON, your Qi-Series ultrasonic bath will run a degas cycle every time the cycle start key is depressed.

- Page 15 Screen 5: Frequency Leap Your Qi-Series ultrasonic bath is equipped with Frequency LEAP technology to provide a more homogeneous ultrasonic cleaning activity throughout the whole tank. Using advanced software and generators, the Qi-Series uses Frequency LEAP to create a pseudo-random leaping action between a wider frequency range, reducing standing waves and improving the cleaning action.

-

Page 16: Starting The Cycle

Starting the cycle Once all the Operator Menu options have been selected, the following screen will display. Qi-Series is now ready for use. Press the key to begin the cleaning cycle. When the Qi-Series is in operation, the following screen will display. (The actual time and temperature may show different values.) ... -

Page 17: Advanced Menu

Advanced menu The Advanced Menu allows different settings to be specified which may not require regular changes and also allows the usage history of the individual Qi-Series ultrasonic bath to be seen. To access the advanced menu, press and hold Keys 3 and 4 together. The following screen will then appear: KEY 3 KEY 4... - Page 18 Screen 2: Time used This screen shows the total time your Qi-Series ultrasonic bath has been in use in days, hours and minutes; i.e. the sum of all the cleaning cycle times since new. For example, the screen above shows that the bath has been in use for a total of 2 days, 5 hours and 27 minutes.

- Page 19 Screen 4: Cycle Count The second screen shows the number of cycles which the Qi-Series ultrasonic bath has run since new. The cycle count shows all cycles which the bath has begun and includes those cycles which are not completed; i.e. those cycles aborted by the operator or because the fluid level was low.

- Page 20 Screen 6: Fluid level sensor Qi-Series ultrasonic bath is fitted with a fluid level sensor to ensure it is not under-filled prior to or during the cycle. This ensures that the optimum cleaning process can occur and potential damage to the tank is minimised. The level sensor is a resistive device, so will not detect fluids with very low conductivity such as pure deionised (DI) water.

- Page 21 WARNING Setting the liquid level sensor to OFF means that the Qi-Series ultrasonic bath will operate as if the bath were full of liquid. This means that without water, the heaters will continue to operate and the surface inside the bath will become extremely hot. It is therefore the operator’s responsibility to ensure that the tank is filled with sufficient water when the liquid level sensor is disabled.

- Page 22 Screen 7: Portable appliance testing Qi-Series ultrasonic bath is provided with this screen to make portable appliance testing easier. When the ON button is pressed, both the heater and the ultrasonic generator will turn on, irrespective of any other programmed settings. You will then be sure that the Qi-Series ultrasonic bath is operating in the mode required for accurate portable appliance testing.

-

Page 23: Cycle Abort Modes

Cycle abort modes If the cycle is aborted, the reason for the failure will be displayed. If the operator aborts the cycle, the following screen will be displayed. If the Level sensor is set to ON, and the fluid drops below the required level during operation, the cleaning cycle will stop and the following screen will be displayed. -

Page 24: Cycle Abort Modes

Cycle abort modes If the liquid temperature exceeds the allowed maximum of 80°C, the following screen will be displayed If the internal heater exceeds its allowed maximum temperature, the following screen will be displayed If the unit overheats due to prolonged use, the following message will be displayed In each instance of a cycle abort, the cycle count in the Advanced Menu will still log the cycle as complete. -

Page 25: Ultrasonic Cleaning Detergents

Each of these detergents is available from Ultrawave. The required detergent dose may vary depending on the component being cleaned and the level of contamination. Ultrawave recommend a dosage of between 2 and 5% for all detergents other than Sonozyme, which is recommended at 0.5% by volume. -

Page 26: Technical Information

The time needed to degas the liquid varies depending on the amount of gas present in the liquid and the quantity of water in the tank. Ultrawave recommends a degas period of at least 10 minutes. -

Page 27: Specifications

Specifications Ambient Temperature 5 to 40°C 80% R.H. in room temperatures up to Maximum relative 31°C humidity decreasing linearly to 50 % R.H. at 40°C Altitude above sea level Up to 2,000 m (6,500 ft) Operating Environment Indoor use only Mains supply: 230V ±... -

Page 28: Maintenance

Ultrawave recommend that your Qi-Series ultrasonic bath is serviced and tested by an Ultrawave approved engineer on an annual basis. More regular periodic testing can be done by the operator to ensure that your ultrasonic bath is operating at optimum efficiency. -

Page 29: Troubleshooting

Troubleshooting Ultrawave have a dedicated service team who are able to resolve any problems that occur with your Qi-Series . However, on many occasions it is possible that the problem can be rectified by the operator. The unit fails to turn on... - Page 30 If we are unable to solve your problem over the phone, we may suggest returning your product to the distributor where purchased or directly to Ultrawave. Where appropriate, we operate a Return To Base (RTB) warranty and repairs policy. Qi Operating Manual...

-

Page 31: Returning Equipment To Ultrawave

It remains the user’s liability to ensure Ultrawave (and/or its distributors) are made aware of any potential contamination issues relating to medical chemical, biological or radioactive contamination. -

Page 32: Warranty

36 months of the date of sale, or 6000 hours usage (whichever comes first) because of faulty material or manufacture. Genuine defective items returned to Ultrawave or its agent’s premises will be replaced or repaired free of charge at their discretion. -

Page 33: Compliance With The Control Of Noise At Work Regulations

To help you calculate your workers’ exposure, Ultrawave publish the noise generated by your ultrasonic bath on the Certificate of Test. The figure is that experienced by a worker standing in the operating position. -

Page 34: Service Record

12 months. This record must be maintained by the engineer conducting the service. There are no user serviceable parts inside your machine. All service and repair should be referred to qualified Ultrawave engineers only. Date Cycle count... - Page 35 Date Cycle count Engineer Details Next service due Date Cycle count Engineer Details Next service due Date Cycle count Engineer Details Next service due Date Cycle count Engineer Details Next service due Date Cycle count Engineer Details Next service due Qi Operating Manual C6027205...

- Page 36 Ultrawave Ltd Eastgate Business Park Wentloog Avenue Cardiff CF3 2EY www.ultrawave.co.uk Tel +44 (0) 29 2083 7337 C6027205-01 issued October 2021...

Need help?

Do you have a question about the Qi Series and is the answer not in the manual?

Questions and answers