Summary of Contents for Centurion SDO4 SMART

- Page 1 GARAGE DOOR OPERATORS SDO4 SMART INSTALLATION MANUAL Centurion Systems (Pty) Ltd www.centsys.com...

- Page 2 Saturdays 08h00 to 16h30 GMT+2 Centurion Systems (Pty) Ltd reserves the right to make changes to the product described in this manual without notice and without obligation to notify any persons of any such revisions or changes. Additionally, Centurion Systems (Pty) Ltd makes no representations or warranties with respect to this manual.

-

Page 3: Table Of Contents

Contents INTRODUCTION Page 5 1.1. Important Safety Information Page 6 SPECIFICATIONS Page 9 2.1. Physical Dimensions Page 9 2.2. Technical Specifications Page 10 PRODUCT IDENTIFICATION Page 11 3.1. Fasteners List and Spares Page 12 REQUIRED TOOLS AND EQUIPMENT Page 12 PREPARATION OF SITE Page 13 OPERATOR INSTALLATION... - Page 4 Icons used in this manual This icon indicates tips and other information that could be useful during the installation. This icon denotes variations and other aspects that should be considered during installation. This icon indicates warning, caution or attention! Please take special note of critical aspects that MUST be adhered to in order to prevent injury.

-

Page 5: Introduction

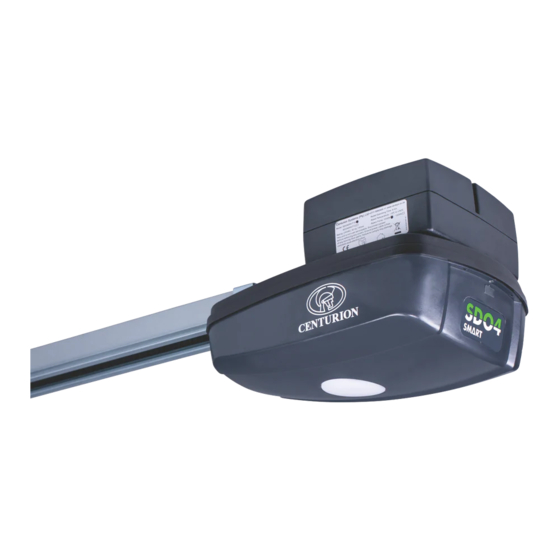

INTRODUCTION 1. Introduction The SDO4 SMART has been designed to automate domestic garage doors safely, quietly and reliably. The product’s belt-driven system allows for whisper-quiet operation, while reliable battery backup ensures that the SDO4 SMART will continue working even during lengthy power outages. -

Page 6: Important Safety Information

• The installation of your new SDO4 SMART must be carried out by a technically qualified or licensed person. Attempting to install or repair the SDO4 SMART without suitable technical qualification may result in severe personal injury, death and / or property damage •... - Page 7 The correct function of the safety obstruction force system should be checked on a monthly basis • Never use the SDO4 SMART unless the garage door is in full view and free from any object which may impede the movement of the garage door such as cars, children and / or adults Never allow children to operate the SDO4 SMART •...

- Page 8 / or property damage • Keep hands and loose clothing clear of the SDO4 SMART and garage door at all times • In order for the safety obstruction force system to function, it must first encounter an obstruction in the form of an object / person onto which some force MUST be exerted.

-

Page 9: Specifications

Please note that images in this installation manual are not to scale. 2. Specifications 2.1. Physical Dimensions 3446mm (Sectional) 2296mm (Tip-up) 3247mm (Sectional) 2097mm (Tip-up) 150mm 3143mm (Sectional) 1993mm (Tip-up) 31mm 303mm 106mm 211mm FIGURE 1. OVERALL DIMENSIONS FOR THE SDO4 SMART page 9 www.centsys.com... -

Page 10: Technical Specifications

Receiver code storage 20x 4-Button NOVA transmitters capacity TABLE 1 1: Can operate off a solar supply, please consult Centurion Systems (Pty) Ltd for assistance 2: Requires infrared safety beams to be fitted 3: Speed varies with load 2.3. Fuse Protection... -

Page 11: Product Identification

SECTION 3 PRODUCT IDENTIFICATION 3. Product Identification END A END B END B FIGURE 2. PRODUCT IDENTIFICATION 1. Control head unit 9. Drive Belt 2. Rail 10. End stop 3. Release handle with warning label 11. Carriage 4. Straight towing arm 12. -

Page 12: Fasteners List And Spares

SECTION 4 REQUIRED TOOLS AND EQUIPMENT 3.1. Fasteners List and Spares Description Description ST5.5 x 50 Self-tapping Coach Screws M8 Wizzlock Nuts ST8 x 60 Self-tapping Screws Ø8 x 71 Clevice Pin ST6.3 x 25 Self-tapping Screws Ø8 x 18 Black Clevice Pin - Hex Flange Head Ø2 Hairpin Clips M6 x 8 Black Cross Pan Head Screws... -

Page 13: Preparation Of Site

• All locks, ropes and / or securing mechanisms have been removed The ceiling structure is adequate enough to support the weight of the SDO4 SMART • • The garage door is in good working order, meaning: •... -

Page 14: Operator Installation

2440mm high. (An optional drive rail extension kit is available for doors over 2440mm high) • The SDO4 SMART is supported by the drive rail hanger which is hung from the ceiling using appropriate hanging material •... - Page 15 SECTION 6 OPERATOR INSTALLATION 6.1.2. General assembly M8 Nut M8 Gutter bolts Open the packing carton and expose the SDO4 SMART components. Orientate the drive rail so that the End ‘A’ terminal bracket faces towards the garage door Drive Rail 1.

- Page 16 SECTION 6 OPERATOR INSTALLATION 4. Place the two U-Brackets into U-Brackets position over the four holes found on the head unit (Figure 9). 5. Secure the U-Brackets into position using 4x black M6x12mm screws supplied (Figure 10). FIGURE 9 M6x12mm Screws FIGURE 10 6.1.3.

-

Page 17: Installation Instructions

SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS 6.2. Installation Instructions 6.2.1. Sectional doors (For Tip-up doors skip to Section 6.2.2) Before commencing the installation, ensure that you have carefully read and understood all safety recommendations. In particular, ensure that the installation of the garage door complies with the requirements specified. - Page 18 The header bracket carries ALL of the opening and closing thrust of the SDO4 SMART and as such must be securely fastened to a rigid, structural member of the garage. It is entirely up to the installer to determine the fixing method and the structural suitability of the fixing points.

- Page 19 SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS Place the header bracket on the Hole A Hole B wall as shown in Figure 15. Ensure that the bottom edge of Hole C the bracket is level, and no more than 50mm above the highest Header bracket arcing point of the garage door.

- Page 20 This will ensure a perfectly tabs level installation (Figure 18). Header bracket FIGURE 18 6.2.1.2. Mounting the SDO4 SMART to the header bracket It is important at this point of the installation to ensure Tensioning bracket that the batteries are connected before continuing Driver head unit with the installation.

- Page 21 SDO4 SMART drive rail FIGURE 21 6.2.1.3. Mounting the SDO4 SMART drive rail to the ceiling Open the garage door, and gently rest the SDO4 SMART on top of the open door. If your ladder is high...

- Page 22 OPERATOR INSTALLATION - SECTIONAL DOORS Spirit level SDO4 SMART Use a long spirit level along the length of the SDO4 SMART drive rail, and level out the SDO4 SMART, so that it is running parallel to the ceiling. FIGURE 24...

- Page 23 SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS 150mm length of punched angle iron Measure and cut a 150mm length of punched angle iron with a pair of tin snips. Snip off the four corners of the punched angle iron to add a degree of safety and neatness to the installation.

- Page 24 SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS Ceiling Mounted punched Level the SDO4 SMART again, and angle iron measure the length needed from the ceiling to the underside of the Spirit level drive rail, marked as ‘Value Xmm’ in Figure 29.

- Page 25 Spirit level mounted Use a spirit level to ensure that to ceiling the SDO4 SMART is still level and parallel to the ceiling. Align the holes of the punched angle iron mounted to the ceiling, with the holes on M8 Flange...

- Page 26 SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS 6.2.1.4. Mounting the towing bracket to the garage door. SDO4 SMART Garage door Marked top edge of the top roller Garage door Close the garage door, and find center line Top roller its center line. Make a level mark...

- Page 27 SECTION 6 OPERATOR INSTALLATION - SECTIONAL DOORS 6.2.1.4. Fitting the bent towing arm to the towing bracket and straight towing arm. Towing Garage door bracket Bent towing Slot the bent towing arm between the two protruding tabs of the towing bracket, and align the holes. Note the orientation of the bent towing arm.

- Page 28 Straight towing arm Bent towing FIGURE 42 Please do not forget to affix the safety sticker and tag. The SDO4 SMART is now installed and ready for programming. Warning Sticker FIGURE 43 page 28 www.centsys.com...

-

Page 29: Tip-Up Doors

SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS 6.2.2. Tip-up doors Before commencing the installation, ensure that you have carefully read and understood all safety recommendations. In particular, ensure that the installation of the garage door complies with the requirements specified. Make any necessary adjustments to the garage door BEFORE commencing the installation! Important considerations Pivot... - Page 30 The header bracket carries ALL of the opening and closing thrust of the SDO4 SMART and as such must be securely fastened to a rigid, structural member of the garage. It is entirely up to the installer to determine the fixing method and the structural suitability of the fixing points.

- Page 31 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS Place the header bracket on the Hole A Hole B wall as shown in Figure 48. Ensure that the bottom edge of Hole C the bracket is level, and between 20mm - 50mm, but no more than Header bracket 50mm above the highest arcing 20-50mm...

- Page 32 This will ensure a perfectly tabs level installation. Header bracket FIGURE 51 6.2.2.2. Mounting the SDO4 SMART to the header bracket Tensioning bracket Control unit It is important at this point of the installation to ensure that the batteries are connected before continuing with the installation.

- Page 33 SDO4 SMART drive rail FIGURE 54 6.2.2.3. Mounting the SDO4 SMART drive rail to the ceiling Open the garage door, and gently rest the SDO4 SMART on top of the open door. If your ladder is high...

- Page 34 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS SDO4 SMART Control Head Lift the SDO4 SMART to a point where the control unit (Point B) is in line with the top of the open garage Garage door door (Point A). Point A in line...

- Page 35 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS 150mm length of punched angle iron Measure and cut a 150mm length of punched angle iron with a pair of tin snips. Snip off the four corners of the punched angle iron to add a degree of safety and neatness to the installation.

- Page 36 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS Ceiling Position the SDO4 SMART again, Mounted punched angle iron as shown in Figure 57, and measure the length needed from the ceiling to the underside of the drive rail, marked as ‘Value Xmm’ in Figure 62.

- Page 37 SDO4 SMART FIGURE 65 RECOMMENDED NOT RECOMMENDED Correct and incorrect configurations for mounting the SDO4 SMART to the ceiling. FIGURE 66 page 37 www.centsys.com...

- Page 38 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS 6.2.2.4. Mounting the towing bracket to the garage door. SDO4 SMART Garage door Garage door center line Close the garage door, and find its center line. FIGURE 67 Center the towing bracket on the...

- Page 39 SECTION 6 OPERATOR INSTALLATION - TIP-UP DOORS 6.2.2.5. Fitting the bent towing arm to the towing bracket and straight towing arm. Towing bracket Garage door Slot the bent towing arm between the two protruding tabs of the towing bracket, and align the holes. Note the orientation of the bent towing arm.

- Page 40 Straight towing arm Bent towing FIGURE 74 Please do not forget to affix the safety sticker and tag. The SDO4 SMART is now installed and ready for programming. Warning Sticker FIGURE 75 page 40 www.centsys.com...

-

Page 41: Engaging And Disengaging The Operator

6.4. Emergency Lock Functionality In the event of a system malfunction with the door in any position other than fully closed, the SDO4 SMART offers an emergency lock system that can be used to secure the door in the fully closed position. -

Page 42: Positioning The Opening And Closing Limit Stoppers

SECTION 6 OPERATOR INSTALLATION 5. Open the door slightly by hand and re-engage the operator by pulling the manual release handle back towards the control head until you hear a ‘click’. 6. Raise the door slowly to the fully open position until it engages with the bullet. A click will be heard as it engages. -

Page 43: The Wireless Wall Switch

• Insert the battery, and replace the front cover • The wireless wall switch may be learned into the SDO4 SMART’s memory via the MyCentsys Pro mobile application under “Remotes” at the bottom of the screen. page 43... -

Page 44: Safety Beams

SECTION 6 OPERATOR INSTALLATION 6.7. Safety Beams The Photon or other four-wire safety beams may be connected to the SDO4 SMART • • The installation of safety beams greatly enhances safety by constantly monitoring for persons or objects which may pass within the path of the moving garage... -

Page 45: Electrical Setup Of Accessories

Refer back to Section 3 - “Product Identification“ • The SDO4 SMART supports the Photon SMART infrared gate safety beams, which are completely wireless safety ancillaries. Photon SMART beams can also be added to another set of safety beams (wired or wireless) to add further functionality, safety and peace of mind to the automated setup. -

Page 46: Wiring External Radio Receivers

WiZo 2 Inside House +24V +12-24V DC 12V DC Lead Acid Battery WiZo 1 Inside SDO4 SMART Siren +12-24V DC WiZo 1’s INPUT is linked to WiZo 2’S OUTPUT. FIGURE 84. ANTI-TAMPER ALARM WIRING WITH TWO WIZOS page 46 www.centsys.com... -

Page 47: Commissioning The System

1. Once installed, open the application. 2. From the list of operators, select the operator that is applicable to this installation. 3. Connect to the relevant operator. 4. Use the app by following the prompts to configure the SDO4 SMART. page 47 www.centsys.com... -

Page 48: Installation Handover

Centurion Systems (Pty) Ltd does not accept any liability caused by improper use of the product, or for use other than that for which the automated system was designed. -

Page 49: Month Product Warranty

4. Has been repaired by any workshop and / or person NOT previously authorised by the manufacturer. 5. Has been repaired with components not previously tested, passed or authorised by Centurion Systems (Pty) Ltd, South Africa or one of its subsidiary companies. page 49 www.centsys.com... - Page 50 Notes page 50 www.centsys.com...

- Page 51 Notes page 51 www.centsys.com...

- Page 52 South Africa and/or other countries, in favour of Centurion Systems (Pty) Ltd, South Africa. The CENTURION and CENTSYS logos, all product and brand names in this document that are accompanied by the TM symbol are trademarks of Centurion Systems (Pty) Ltd, in South Africa and other territories; all rights are reserved.

Need help?

Do you have a question about the SDO4 SMART and is the answer not in the manual?

Questions and answers

i have a centurion garage door opener and when the door starts to lift the light flicker after the door is =-300mm off the floor and stos. What could eb the cause

The Centurion SDO4 SMART garage door opener light could flicker and the door could stop about 300mm off the floor if the drive is incorrectly adjusted and fails to reverse properly when the door contacts an object. This can happen if the drive does not reverse when the door hits a 40 mm high object placed on the floor, indicating a possible safety sensor or force setting issue. Also, improper lubrication of the counterbalance springs can increase friction and cause malfunction.

This answer is automatically generated