Table of Contents

Advertisement

Quick Links

Important information

Serious risk of injury

When working on the engine, e.g. when adjusting the drive belts and clutch, or when changing oil, it is im-

portant not to start the engine. The engine could be damaged, but more importantly there is a serious risk of

injury.

Secure the starting device or disconnect a battery cable before working on the engine. This is especially im-

portant if the engine has a remote starter or automatic starting.

WARNING!

This warning symbol and text can be found next to those maintenance items where it is particularly impor-

tant to bear in mind the risk of injury.

Operator's manual

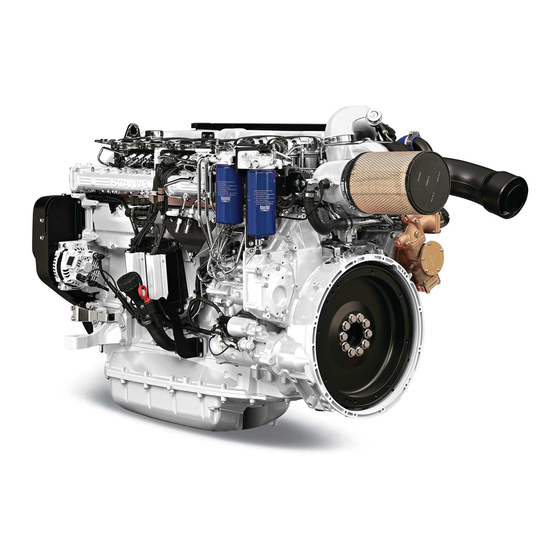

DI13 XPI Marine engine

en-GB 2 975 939

Issue 6.0

Advertisement

Table of Contents

Summary of Contents for Scania DI13 XPI

- Page 1 WARNING! This warning symbol and text can be found next to those maintenance items where it is particularly impor- tant to bear in mind the risk of injury. Operator's manual DI13 XPI Marine engine en-GB 2 975 939 Issue 6.0...

-

Page 2: Table Of Contents

Changing the oil ..... . 31 Scania Assistance ..... . .87 Cleaning the centrifugal oil cleaner . -

Page 3: Start Of Warranty

The more we know about you, your company and your equipment, the more effectively we can adapt our services to you. If you have started to use a new Scania engine, it is very important that you send in the war- ranty start report to us immediately. -

Page 4: Introduction

Modifications may be made by author- The information in this Operator's manual was ised personnel only. correct at the time of going to press. Scania re- serves the right to make alterations without prior • Modifications affecting the exhaust and in- notice. - Page 5 Introduction OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 6: Power Classes

The engine serial numbers and power classes for the engines that are used in this installation should be listed below: You can find the power class of your engine in the engine type data sheet on the Scania website, www.scania.com. -

Page 7: Environment And Safety

Warning! Environmental liability All advisories preceded by Warning! are very important. They warn of serious faults and incor- Scania develops and produces engines that are as rect operation that could lead to personal injury. environmentally-friendly as possible. Scania has Example:... -

Page 8: Warnings And Advisories

This inspection should be done to detect fuel, oil there must be an effective device to extract ex- or coolant leaks, or anything else that may re- haust gases and crankcase gases. quire corrective action. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 9 Parts of the body, clothes or dropped tools can get caught in rotating parts such as the fan and cause injury. For personal safety all ro- tating parts and hot surfaces must be fitted with guards. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 10 There is always a risk of sustaining burns when an engine is hot. Particularly hot parts are branch pipes, turbochargers, oil sumps, and hot coolant and oil in pipes and hoses. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 11 Scania recommends that Scania spare parts are cation system before starting work on it. used for the fuel and electrical systems. Scania spare parts are designed to minimise the risk of Make sure that the oil filler cover is fitted when fire and explosion.

- Page 12 Wash with soap and plenty of water. If it gets in your eyes: Rinse immediately with plenty of wa- ter and seek medical attention. Environment Used batteries must be disposed of as specified in national and international laws and regula- tions. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 13: Gines

This section is only applicable to engines used in quent owner, of a new Scania marine diesel the U.S.A, and to engines without exhaust gas af- engine (“You”) that the emission control system tertreatment system (SCR system). -

Page 14: Parts Covered By The Warranty

Specific warranty exclusions below. ment parts be used for maintenance, repair or replacement of emission control systems. If other than Scania parts are used for mainte- nance, repair or replacement, the owner should obtain assurance that such parts are warranted by their manufacturer to be equivalent to genuine Scania parts. -

Page 15: Specific Warranty Exclusions

Replacement items which are not genuine Scania parts or not authorized by Scania as of equal quality to the original parts. Inconvenience, loss of use of the marine ves- sel or commercial loss. -

Page 16: Engine Data Plate

Type approval No: tion code, the normal gross engine output. e5*97/68VC*2012/46*1234*00 Code for application. M means for marine use. Example of an engine data plate. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 17: Component Identification

Centrifugal oil cleaner Nipple for draining and filling coolant Heat exchanger Sea water outlet Note: There is a further water separating prefilter for the fuel located between the fuel tank and engine. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 18: Starting And Running

30 seconds at a time. After that, it must rest for at least 5 minutes before the next attempt to start it. For environmental reasons the Scania engine has Checks before running been developed to be started with a low fuel feed. -

Page 19: Running

2,000 metres. • IFN, Patrol Craft Long and Patrol Craft Short engines must not be used at an altitude of more than 1,000 metres. • Contact Scania if the operating conditions de- viate from these. OPM 260 en-GB ©... - Page 20 If run for extended periods under an extremely light load, the engine may have difficulty in maintaining the coolant temperature. At an in- creased load the coolant temperature rises to the normal value. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 21 • Alarm and torque reduction by 30%. • Alarm and engine shutdown. • Alarm and engine shutdown override control. Note: High oil pressure (above 6 bar/87 psi) is normal if the engine is cold when started. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 22: Engine Shutdown

See the sec- tion Risk of freezing. If the temperature is below 0°C (32°F): Pre- pare for the next start by connecting the en- gine heater (if fitted). OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 23: Maintenance

Particularly hot parts are branch pipes, turbochargers, oil sumps, and hot coolant and oil in pipes and hoses. IMPORTANT! On delivery a Scania engine is optimised for its application. However, regular maintenance is necessary to • prevent unplanned stops •... -

Page 24: Cleaning The Engine

Clean the engine with hot water. Also use a de- greasing agent, if necessary. Do not spray water on the engine control unit, which is marked in the illustration. Clean within the area marked by the line. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 25: Maintenance Interval

Renewing the fuel filters Miscellaneous Checking the drive belt Checking for leakage Checking and adjusting the valve clearance 1. DI13 304M has a shorter oil change interval; see separate table on the next page. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 26 Oil change interval DI13 304M The following oil change intervals apply to DI13 304M: Daily First time at Interval (hours) Minimum first start 1,200 1500 annu- every ally years Lubrication system Changing the oil OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 27: Lubrication System

For operation at extremely low outdoor tempera- tures: Contact a workshop with qualified person- nel in order to avoid starting difficulties. Oil grade Scania LDF stands for the Scania test standard Viscosity Outdoor temperature in °C Long Drain Field. Scania LDF oils have been class carefully selected after extensive testing. - Page 28 The oil filler cap must be clearly marked with a label showing the filled oil grade. However, there are only labels for oils with Scania LDF approval and oil grade ACEA E7. Stick on a new label if the oil type or oil grade is changed in favour of any of the oil types above.

-

Page 29: Oil Analysis

Lubrication system Oil analysis To be able to extend the oil change intervals us- ing an oil analysis, Scania LDF-3 and LDF-2 oils must be used. Certain laboratories offer engine oil analysis. The following requirements must remain satis- fied when the oil is changed: •... -

Page 30: Checking The Oil Level

Maximum angles of inclina- tion during operation 30° Maximum permissible angles of inclination dur- 30° ing operation vary, depending on the type of oil sump. See illustration. 30° 30° 25° 25° 30° 30° OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 31: Changing The Oil

Renew the gasket on the oil plug. Refit the oil plug. Fill with the amount of oil specified for the oil sump. Wait at least 7 minutes. Check the level on the oil dipstick. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 32: Cleaning The Centrifugal Oil Cleaner

Let the oil run out from the rotor. x 1.5 Lift out the rotor. Wipe off the outside. Loosen the rotor nut and unscrew it about 1.5 turns. Note: Take care not to damage the rotor shaft. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 33 Remove the strainer from the rotor cover. If the strainer is stuck, insert a screwdriver be- tween the rotor cover and strainer and care- fully prise them apart. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 34 Renew any damaged nozzles. Check that the bearings are undamaged. Renew damaged bearings. Fold and fit a new paper insert on the inside of the rotor cover as illustrated. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 35 Note: Take care not to damage the rotor shaft. Refit the rotor and rotate it by hand to make sure it rotates easily. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 36: Operational Testing Of The Centrifugal Oil Cleaner

Use your hand to feel if the filter housing is vibrating. If the filter housing is not vibrating, disman- tle and check the centrifugal oil cleaner. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 37: Renewing The Oil Filter

Oil the rubber gasket on the new filter. Fit the new filter and tighten it by hand. Nev- er use tools because the filter could sustain damage, obstructing circulation. Start the engine and check for leaks. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 38: Air Cleaner

If the vacuum indicator's red plunger is fully vis- ible, renew the air cleaner filter element in ac- cordance with the following section. Air cleaner without safety cartridge. Filter element Vacuum indicator O-ring Cover OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 39: Renewing The Air Cleaner Filter Element And Safety Cartridge

Renewing an air filter with a non-renewable element IMPORTANT! If the engine has an air filter with a non-renewa- ble Scania element, it should be renewed instead of cleaned. Air filter with a non-renewable element. OPM 260 en-GB ©... -

Page 40: Cooling System

The coolant should be changed when the cooling functioning antifreeze and corrosion protection system is cleaned: every 6,000 hours or at least may be used in Scania engines. Products not ful- every 5 years. See Changing the coolant and filling the demands in this section may lead to cleaning the cooling system. - Page 41 There is no risk of damage by freezing if the content of Scania antifreeze and corrosion protection, or an equivalent mixture of a similar product, is at least 35% by volume.

- Page 42 In order to retain the corrosion protection and the Scania Ready Mix 50/50 higher boiling point, it is essential to use coolant Scania Ready Mix 50/50 is a ready-mixed cool- consisting of water mixed with antifreeze and ant containing 50% antifreeze (ethylene glycol) corrosion protection (ethylene glycol).

- Page 43 Cooling system Antifreeze and corrosion protection concentration table, litres 35% by volume of Scania antifreeze provides sufficient corrosion protection. Example: • The total volume of the cooling system is 40 litres. • The measured concentration of ethylene gly- col is 35% by volume (freezing point -21°C).

- Page 44 15.9 19.8 23.8 39.6 14.8 16.9 21.1 25.4 42.3 15.9 20.3 22.5 26.9 44.9 16.6 21.4 23.8 28.5 47.6 17.7 20.1 22.7 25.1 30.1 50.2 18.5 21.1 23.8 26.4 31.7 52.8 OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 45: Checking The Coolant Level

Filling coolant. Only pour pre-mixed coolant into the cooling system. The following instructions apply to Scania ex- pansion tanks. For other types of expansion tanks, follow the manufacturer’s instructions. Check the coolant level through the sight glass on the expansion tank. -

Page 46: Checking The Coolant's Antifreeze And Corrosion Protection

• If ice forms in the coolant, there are disrup- tions initially, but there is no immediate risk of damage. The engine should not be subject- ed to heavy loads when ice starts to form. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 47: Checking The Sacrificial Anodes

If the sacrificial anodes are very corroded, they often come loose entirely. Renew the gasket when fitting. New sacrificial anode Approx. 3/4 remains Approx. 1/4 remains OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 48: Checking The Sea Water Pump Impeller

Fit a new impeller and cap. Check that the cap seal is not hard or damaged. IMPORTANT! When fitting the new impeller, bend the vanes in the same direction as on the old one. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 49: Changing The Coolant And Cleaning The Cooling

Repeat the procedure at the cooling system's Drain nipple in the cylinder block. lowest drainage point. The location of the lowest drainage point on the engine may dif- fer depending on engine application. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 50 The lowest point in the sea water circuit may be at different points, but it is usually in the sea wa- ter pump intake (3). IMPORTANT! Plug the connections to prevent dirt ingress into the engine. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 51 Remove the water pipe (4) of the charge air cooler. Release the hose clamp and remove the sea water hose (5) between the charge air cooler and the heat exchanger. Remove the charge air cooler (6). OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 52 Renew damaged or hard O-rings (2). Assemble the charge air cooler. Tighten the M8 screws on the covers to 15 Nm (11 lb-ft). Cover O-rings Cooler core Charge air cooler housing Spacer OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 53 (4) in the 2 brackets. Slacken the screws holding the heat ex- changer bracket (5) in the cylinder block suf- ficiently to allow the heat exchanger to be removed. Remove the heat exchanger. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 54 Renew damaged or hard O-rings (2). Assemble the heat exchanger. Tighten the M8 screws on the covers to 15 Nm (11 lb-ft). Cover O-rings Spacer Heat exchanger housing Cooler core OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 55 Fit the inlet and outlet coolant pipes and the sea water pipe from the heat exchanger (2). Fit the hose (1) between the heat exchanger and the water-cooled exhaust pipe bend and tighten the V-clamp. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 56 Check that the charge air pipe is properly fitted. Fit the protective plate (1) to the charge air cooler. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 57 Run the engine until it has reached operating cleaning of the expansion tank will suffice. temperature if possible and then drain the cooling system following the previous de- scription. Remove the thermostat. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 58 20-30 minutes. Drain the water from the cooling system. Reinstall the thermostat. Fill the cooling system with new coolant as described in the next section. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 59 Do not start the engine until the correct coolant level has been obtained. If the engine is started with an insufficient coolant level, it can damage the coolant pump shaft seal, which leads to cool- ant leakage. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 60 Open the sea cock on the sea water inlet. Start the engine and check that there are no leaks. Check the coolant level and top up if neces- sary via the expansion tank. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 61: Fuel System

Be extra careful and always use clean, lint-free and dust-free clothes and disposable gloves when working on the fuel system. Scania recom- mends using Tegera 848 gloves. Clean tools before they are used and do not use any worn or chrome-plated tools. Material and flakes of chrome may come off. -

Page 62: Renewing The Fuel Filter

Screw the filter into place by hand until it makes contact. Screw a further half turn by hand. Bleed the fuel system according to the in- structions in the Bleeding the fuel systemsec- tion. Fuel filter location. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 63: Draining And Renewing An Engine-Mounted Water Separating Prefilter

Connect the sensor cable to the contact hous- ings on the filters. Bleed the fuel system according to the in- structions in the Bleeding the fuel systemsec- tion. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 64: Draining And Renewing The Single Water Separat- Ing Prefilter (Option)

Screw the sensor cable in the contact housing onto the filter bracket. Bleed the fuel system according to the in- structions in the Bleeding the fuel systemsec- tion. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 65 Be careful that the valve does not pass the closed position when the engine is in operation. A closed position can result in the engine stopping. Remove the cover from the filter housing. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 66 Fuel system Undo the drain plug. Tighten the drain plug when all the water has emptied. Fill the filter housing with clean fuel. Fit the cover. Tighten the cover screw by hand. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 67 A closed position can result in the engine stopping. Clean the filter housing externally with a cleaning cloth. Remove the cover from the filter housing. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 68 Remove the filter and fit the new filter. Renew the O-rings in the cover. Lubricate the O-rings with engine oil. Fill the filter housing with clean fuel. Fit the cover. Tighten the cover screw by hand. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 69: Bleeding The Fuel System

Tool Designation Illustration Suction tool for fuel sys- Note: Scania recommends venting the fuel system us- ing suction tools rather than with a hand pump. This is a quicker and simpler method, which en- sures a complete venting. Environment Use a suitable container. The fuel collected must be disposed of as specified in national and inter- national laws and regulations. - Page 70 Connect the plastic hose to the ventilating valve on the main filter. Open the ventilating valve. Pump with the hand pump until fuel without air bubbles comes out. Close the ventilating valve. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 71 It will take around 150 pump strokes. Close the ventilating valve and screw the hand pump handle downwards. Start the engine. The engine should be easy to start. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 72: Miscellaneous

5. Coolant pump Example of a minor crack in the drive belt. The drive The drive belt has deep cracks and must be renewed. belt can be refitted. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 73: Checking For Leakage

O-rings between the cylinder liners and crankcase are leaking. Check whether the drain hole on the coolant pump is blocked. If there is a leak, renew the pump seal or the entire coolant pump. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 74: Checking And Adjusting The Valve Clearance

Carry out a check and adjustment of the valve clearances one more time after the first 500 hours of operation. After this, adjustment according to the regular interval takes place, which is every 2,000 operational hours. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 75 Valve transition on cyl- Adjust valves on cylin- Reading in the upper window inder window DOWN TDC UP TDC 120/480 300/660 240/600 60/420 DOWN TDC UP TDC 120/480 300/600 240/600 60/420 Order of cylinders. OPM 260 en-GB © Scania CV AB 2021, Sweden...

- Page 76 Mark the rocker arm with the felt-tip pen and then continue with the next cylinder accord- ing to the table. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 77: Quality Requirements For Fuel

The operator is responsible for using the correct type of diesel to ensure that local laws are com- of fuel are described in the Workshop Manual. This can be ordered from Scania dealers or di- plied with. rectly from Scania. -

Page 78: Biodiesel (Fame)

Biodiesel (FAME) Maintenance interval Use of biodiesel IMPORTANT! Scania uses the term biodiesel to refer to a re- Make sure that maintenance intervals are differ- newable diesel made from greases or oils and ent when operating on diesel or biodiesel. -

Page 79: Hvo

To the user, HVO is reminiscent of diesel in accordance with EN590, apart from HVO having a somewhat lower density. Scania approves the use of up to 100% HVO for all engines in accordance with the European standard EN 15940. -

Page 80: Preparing The Engine For Storage

• Otherwise prepare the engine for storage (fil- ter renewal, lubrication, etc.). Preservative products Preservative oil Use a normal engine oil that meets the require- ments in the gradesection. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 81 Preservative fuel should comply with the follow- ing requirements: • 0% biodiesel. • Max. sulphur content 50 ppm. • Max. water content 200 ppm. • The fuel must contain additives to stop the growth of micro-organisms. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 82: Preparations For Storage

Dinitrol 25B and then with Dinitrol 112 or connect a hose from the can. the equivalent. Clearly mark the engine with the storage preparation date, and state that the engine must not be started or cranked. OPM 260 en-GB © Scania CV AB 2021, Sweden... - Page 83 Wash off any preservative oil on the outside ature. The engine must be packed in packaging using white spirit. made of VCI plastic to protect against dust, dirt and moisture. OPM 260 en-GB © Scania CV AB 2021, Sweden...

-

Page 84: Technical Data

Total Base Number (TBN) > 12 (ASTM D2896) Oil pressure (bar/psi) Normal with hot engine and nominal engine speed 3-6/43.5-87 Minimum permitted at idling speed 0.7/10.2 Crankcase pressure (mbar/psi) -5.4 to 2.0/-0.08 to 0.03 OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 85: Intake System

Fuel filter with water separator Scania polymer filter Electrical system Type 2-pin, 24 V, DC Starter motor, standard equipment 2-pin, 24 V, 7.0 kW Alternator, standard equipment 2-pin, 28 V, 100 A OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 86: Material Content

Re-use if possible; otherwise hand in to an authorised waste disposal contrac- tor. Fuel filter and oil filter Hand in to an authorised waste disposal contractor. Colour No known recycling methods. Electronics Hand in to an authorised waste disposal contractor. OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 87: Scania Assistance

Scania Assistance Scania Assistance Wherever you are, you can always get assistance from the Scania service organisation, Scania As- sistance, all day, every day of the year. Always call the contact for your country. 0800 999 722 642 +32 226 400 000... -

Page 88: Hexagon Screws, Hexagon Socket Screws, Torx Screws, Hexagon Nuts

Metric thread. Strength class 8.8/8. Tightening torque Thread Lb-ft Flange screws with hexago- nal head and hexagonal flange nuts Metric thread. Strength class 8.8/8. Tightening torque Thread Lb-ft 10.2 OPM 260 en-GB © Scania CV AB 2021, Sweden... -

Page 89: Hose Clamps

A = width Tightening torque (mm) Lb-ft 7.5-9 Tightening torque for new unfitted hose clamp is max 1 Nm (0.7 lb-ft). A = width Tightening torque (mm) Lb-ft OPM 260 en-GB © Scania CV AB 2021, Sweden...

Need help?

Do you have a question about the DI13 XPI and is the answer not in the manual?

Questions and answers