Summary of Contents for Pfeiffer Vacuum RPT 200

- Page 1 OPERATING INSTRUCTIONS Translation of the Original RPT 200 ∣ RPT 201 Digital Piezo/Pirani gauge...

-

Page 2: Telegram Example

Dear Customer, Thank you for choosing a Pfeiffer Vacuum product. Your new gauge is designed to support you in your individual application with maximum performance and without malfunctions. The name Pfeiffer Vacuum stands for high-quality vacuum technology, a comprehensive and complete range of top-quality products and first-class service. -

Page 3: Table Of Contents

Foreseeable improper use Responsibilities and warranty Owner requirements Personnel qualification 2.8.1 Ensuring personnel qualification 2.8.2 Personnel qualification for maintenance and repair 2.8.3 Advanced training with Pfeiffer Vacuum Operator requirements Product description Function Identifying the product Scope of delivery Transport and storage... - Page 4 10.2 Calibrating the gauge 10.3 Replacing the sensor module Malfunctions Shipping Recycling and disposal 13.1 General disposal information 13.2 Dispose of gauges Service solutions by Pfeiffer Vacuum Spare parts Accessories 16.1 Accessory information 16.2 Order accessories Technical data and dimensions 17.1 General 17.2 Technical data...

- Page 5 List of tables List of tables Tbl. 1: Applicable documents Tbl. 2: Variants Tbl. 3: Abbreviations used Tbl. 4: Features of the RS-485 interface Tbl. 5: Explanation and meaning of the parameters Tbl. 6: Overview of parameters of RPT gauge Tbl.

- Page 6 List of figures List of figures Fig. 1: Structure of the RPT gauge Fig. 2: Establish vacuum connection Fig. 3: Terminal assignment of RS-485 connecting socket Fig. 4: Cross-link via connection RS-485 using connection cables and accessories Fig. 5: Cross-link via RS-485 connection with DPG 202 Fig.

-

Page 7: About This Manual

Variants You can find the part number on the rating plate of the product. Pfeiffer Vacuum reserves the right to make technical changes without prior notification. Information that relates to only one of the products is indicated accordingly. The figures in this document are not to scale. -

Page 8: Conventions

Range 1.0x10 - 1200 hPa Input 24 V DC 2.5 W Made in Germany 2021/03 1.3.4 Abbreviations Abbreviation Explanation Atmosphere Analog relay Display and control unit by Pfeiffer Vacuum for DigiLine gauge Measuring range max. (full scale) Height unit of a 19" rack 8/46... -

Page 9: Trademark Proof

About this manual Abbreviation Explanation High vacuum Mean sea level Overrange [P:xxx] Electronic drive unit control parameters. Printed in bold as a three-digit number in square brackets. Frequently displayed in conjunction with a short description. Example: [P:312] software version Pressure RS-485 Standard for a physical interface for asynchronous serial data transmission (recom- mended standard) -

Page 10: Safety

Safety instructions according to product’s life stages All safety instructions in this document are based on the results of a risk assessment. Pfeiffer Vacuum has taken into account all the relevant life stages of the product. Risks during installation DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. - Page 11 ► Only operate the device in a dry environment. ► Operate the device away from fluids and humidity sources. ► Do not switch on the device if fluid has penetrated into it, instead contact Pfeiffer Vacuum Serv- ice. ► Always disconnect the current supply before cleaning the device.

-

Page 12: Safety Precautions

Safety WARNING Health hazard through poisoning from toxic contaminated components or devices Toxic process media result in contamination of devices or parts of them. During maintenance work, there is a risk to health from contact with these poisonous substances. Illegal disposal of toxic sub- stances causes environmental damage. -

Page 13: Proper Use

► Provide suitable touch protection, if the surface temperature exceeds 70 °C. ► Inform yourself about any contamination before starting work. 2.4 Proper use The RPT 200 gauge is used for vacuum measurement of air, gases and gauges outside their explosion limits, within the range of 1 × 10 to 1200 hPa. -

Page 14: Owner Requirements

Such training must ensure that individuals are capable of carrying out the required activi- ties and work steps safely and properly. 2.8.2 Personnel qualification for maintenance and repair Advanced training courses Pfeiffer Vacuum offers advanced training courses to maintenance levels 2 and 3. 14/46... -

Page 15: Advanced Training With Pfeiffer Vacuum

─ Customer with Pfeiffer Vacuum service training ─ Pfeiffer Vacuum service technician 2.8.3 Advanced training with Pfeiffer Vacuum For optimal and trouble-free use of this product, Pfeiffer Vacuum offers a comprehensive range of courses and technical trainings. For more information, please contact Pfeiffer Vacuum technical training. -

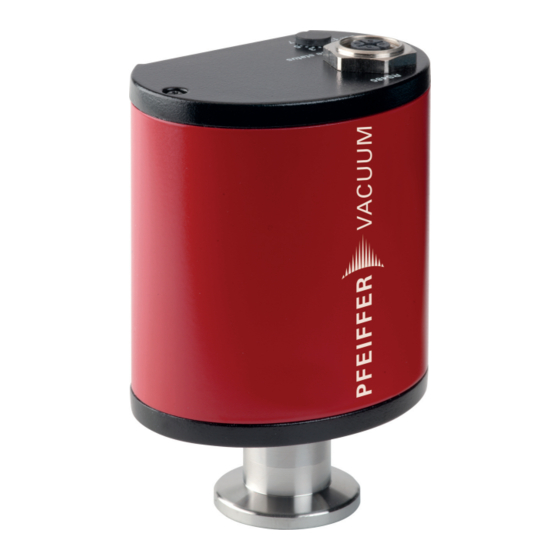

Page 16: Product Description

2 Status LED for the gauge 3.2 Identifying the product You will need all the data from the rating plate to safely identify the product when communicating with Pfeiffer Vacuum. 1. Read the data on the product rating plate. 2. Record this data. -

Page 17: Transport And Storage

Transport and storage 4 Transport and storage 4.1 Transporting the product NOTICE Damage caused by incorrect transportation Transportation in unsuitable packaging, or failure to install all transport locks, can damage the prod- uct. ► Comply with the instructions for safe transportation. Packing We recommend keeping the transport packaging and original protective cover. -

Page 18: Installation

Installation 5 Installation 5.1 Establish vacuum connection DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. ► Connect the product galvanically with the earthed vacuum chamber. ► Ensure that the connection complies with the requirements of a protective bonding according to EN 61010. -

Page 19: Create "Rs-485" Connection

● Requirements of the earthed protective extra-low voltage (PELV) ● Limited power source (LPS) Class 2 ► Secure the line to the product. – Pfeiffer Vacuum measuring and control equipment complies with this requirement. NOTICE Property damage due to ground contact of electronics Disconnecting or connecting the "RS-485"... - Page 20 Installation Connection to DPG 202 display and control unit You can only connect the RPT 200 to the DPG 202. Connecting the RPT 201 is not possi- ble. The connector designated "RS-485" is intended for connecting an external power supply pack (TPS), a measuring instrument and control unit (DPG) or a PC.

-

Page 21: Interfaces

1 Supply cable DigiLine USB/RS-485 converter 2 Y-connector for RS-485 3 Interface cable M12 Connection to DPG 202 display and control unit You can only connect the RPT 200 to the DPG 202. Connecting the RPT 201 is not possi- ble. 21/46... -

Page 22: Pfeiffer Vacuum Protocol For Rs-485 Interface

3. Connect all devices with RS-485 D+ and RS-485 D- to the bus. 6.2 Pfeiffer Vacuum protocol for RS-485 interface 6.2.1 Telegram frame The telegram frame of the Pfeiffer Vacuum protocol contains only ASCII code characters [32; 127], the exception being the end character of the telegram C . Basically, a master (e.g. -

Page 23: Telegram Example

Interfaces Control command --> Data response / Control command understood --> Error message --> NO_DEF Parameter number n2–n0 no longer exists _RANGE Data dn–d0 outside the permissible range _LOGIC Logical access error 6.2.3 Telegram example 1 Query pressure value Current measured pressure (parameter [P:740], slave device address: "001") -->... - Page 24 Interfaces Data type Description Length Example l1 – l0 u_expo Positive exponential number 1.2E-2 is equivalent to 1,2 · 10 005E8 is equivalent to 5 · 10 string Any character string with 6 charac- TC_110, TM_700 ters. ASCII codes between 32 and boolean_new Logical value (false/true) 0 is equivalent to false...

-

Page 25: Parameter Set

All variables relevant for the function are stored as parameters in the gauge. Each parameter has a three-digit number and a description. Parameters can be used via Pfeiffer Vacuum display and control units or via RS-485 with the Pfeiffer Vacuum protocol. -

Page 26: Status Requests

Parameter set 7.4 Status requests Description Functions Data Access Unit min. max. can be type type fault stored Error code 000000 = No error Err001 = Sensor defective Err002 = Memory defective Gauge firmware Example of first firmware ver- version sion: 010100 Device name RPT200 RPT201... -

Page 27: Operation

Operation 8 Operation Once the supply voltage has been established, the measurement signal is available at the electrical connection. Meaning No power supply Lights up green Supply voltage OK, measuring mode, valid pressure values, sensor for low pressure range active Green flashing (1 Hz) Sensor for high pressure range active Lights up yellow Other mode (e.g. -

Page 28: Determine Effective Pressure With Calibration Factors

Operation direct switching at 1 hPa between Piezo sensor and Pirani sensor to measure independent of the gas type in the upper pressure range between 1 and 1200 hPa). Pirani Piezo 1 × 10 1200 hPa Fig. 7: Switching range with continuous transition Pirani Piezo 1 ×... -

Page 29: Tbl. 11: Calibration Factors For The Pressure Range < 1 Hpa

Operation p [hPa] 1E-1 1E-2 1E-3 1E-3 1E-2 1E-1 [hPa] Fig. 9: Displayed pressure Within the pressure range < 1 hPa, the display is linear. Gas and vapor mixtures Process gases are mostly mixtures of gas and vapor. Precise measuring of gas and vapor mixtures is only possible using partial pressure measurement instruments, for example a quadrupole mass spectrometer. -

Page 30: Read And Set Relay And Switch-Points

Operation Read and set Pirani calibration factor [P:742] ► Read the current calibration factor via parameter [P:742]. ► Via parameter [P:742], set the calibration factor to a value between 0.2 and 8.0 with 2 decimal places. – Example: Calibration factor 0.20 = 000020 –... -

Page 31: Disassembly

Disassembly 9 Disassembly DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. ► Connect the product galvanically with the earthed vacuum chamber. ► Ensure that the connection complies with the requirements of a protective bonding according to EN 61010. -

Page 32: Maintenance

► Only operate the device in a dry environment. ► Operate the device away from fluids and humidity sources. ► Do not switch on the device if fluid has penetrated into it, instead contact Pfeiffer Vacuum Serv- ice. ► Always disconnect the current supply before cleaning the device. -

Page 33: Calibrating The Gauge

► Operate the device away from fluids and humidity sources. ► Take special precautions if there is a risk of dripping water. ► Do not switch on the device if fluid has penetrated into it, instead contact the Pfeiffer Vacuum Service Center. -

Page 34: Replacing The Sensor Module

Maintenance 10.3 Replacing the sensor module NOTICE Impairment from contamination and damage Touching the devices or components with bare hands increases the desorption rate and leads to in- correct measurements. Dirt (e.g. dust, fingerprints, etc.) and damage impair the function. ► When working on high or ultra high vacuum systems, always wear clean, lint-free and powder- free laboratory gloves. -

Page 35: Malfunctions

Malfunctions 11 Malfunctions Warranty Malfunctioning of the equipment as a direct result of contamination or wear, as well as wear parts, is not covered by the warranty. Disturbance Possible cause Remedy Communication error: Gauge No power supply Connect a data cable or power supply pack. -

Page 36: Shipping

► Comply with the instructions for safe distribution. Decontamination subject to charge Pfeiffer Vacuum decontaminates products not clearly declared "Free of contamination" at your expense. Instructions for safe shipping ► Do not ship microbiological, explosive or radioactively contaminated products. -

Page 37: Recycling And Disposal

13.1 General disposal information Pfeiffer Vacuum products contain materials that you must recycle. ► Dispose of our products according to the following: – Iron –... -

Page 38: Service Solutions By Pfeiffer Vacuum

We are always focused on perfecting our core competence – servicing of vacuum components. Once you have purchased a product from Pfeiffer Vacuum, our service is far from over. This is often exactly where service begins. Obviously, in proven Pfeiffer Vacuum quality. - Page 39 Service solutions by Pfeiffer Vacuum 5. Prepare the product for transport in accordance with the provisions in the contamination declaration. a) Neutralize the product with nitrogen or dry air. b) Seal all openings with blind flanges, so that they are airtight.

-

Page 40: Spare Parts

Sensor 2 Sealing washers Article number Designation Filament Replacement sensor module PT R37 13x RPT 200 (DN 16 ISO-KF) Tungsten PT 120 213 -T PT R37 13x A PT 120 233 -T PT R37 31x RPT 200 (DN 16 CF-F) -

Page 41: Accessories

Cables and fasteners for creating an RS-485 field bus Supply and interface cable Cable in various lengths, for connecting to a Pfeiffer Vacuum power supply unit or a PC Seals with centering ring and filter Filter available in different pore sizes to protect the measuring system against contamination in the event of potential contaminating applications 16.2 Order accessories... -

Page 42: Technical Data And Dimensions

Tbl. 16: Conversion table: Units for gas throughput 17.2 Technical data Parameter Value Measuring range (air, O , CO, N RPT 200 1 × 10 – 1200 hPa RPT 201 5 × 10 – 1200 hPa Maximum pressure (absolute) 4000 hPa... -

Page 43: Tbl. 18: Electrical Data

≤100 m Tbl. 18: Electrical data Parameter Value Protocol ASCII, addressable (RS-485), Pfeiffer Vacuum protocol Data format Bidirectional data traffic, data word length 8 bits, 1 stop bit, no parity bit Baud rate 9600 Connection Binder M12 connector, 5-pole, A-coded Tbl. -

Page 44: Dimensions

Technical data and dimensions Parameter Value Filament RPT 200 Tungsten RPT 201 Platinum/rhodium Tbl. 23: Substances in contact with the media 17.3 Dimensions Ø 30 DN 16 ISO-KF Fig. 12: RPT 20x with DN 16 ISO-KF Dimensions in mm Ø 34 DN 16 CF-F Fig. -

Page 45: Declaration Of Conformity

Declaration of conformity Declaration for product(s) of the type: Digital Piezo/Pirani gauge RPT 200 RPT 201 We hereby declare that the listed product satisfies all relevant provisions of the following European Directives. Electromagnetic compatibility 2014/30/EU Restriction of the use of certain hazardous substances 2011/65/EU...

Need help?

Do you have a question about the RPT 200 and is the answer not in the manual?

Questions and answers