Summary of Contents for Pfeiffer Vacuum PPT 200

- Page 1 OPERATING INSTRUCTIONS Translation of the Original PPT 200 Digital Pirani gauge...

-

Page 2: Telegram Example

Dear Customer, Thank you for choosing a Pfeiffer Vacuum product. Your new gauge is designed to support you in your individual application with maximum performance and without malfunctions. The name Pfeiffer Vacuum stands for high-quality vacuum technology, a comprehensive and complete range of top-quality products and first-class service. -

Page 3: Table Of Contents

Transporting the product Storing the product Installation Establish vacuum connection Creating "RS-485" connection Interfaces Interface RS-485 Pfeiffer Vacuum protocol for RS-485 interface 6.2.1 Telegram frame 6.2.2 Telegram description 6.2.3 Telegram example 1 6.2.4 Telegram example 2 6.2.5 Data types Parameter set... - Page 4 Table of contents Malfunctions Shipping Recycling and disposal 13.1 General disposal information 13.2 Dispose of gauges Service solutions by Pfeiffer Vacuum Spare parts Accessories 16.1 Accessory information 16.2 Ordering accessories Technical data and dimensions 17.1 General 17.2 Technical data 17.3 Dimensions...

- Page 5 List of tables List of tables Tbl. 1: Applicable documents Tbl. 2: Variants Tbl. 3: Abbreviations used Tbl. 4: Permissible ambient conditions Tbl. 5: Features of the RS-485 interface Tbl. 6: Explanation and meaning of the parameters Tbl. 7: Overview of parameters of PPT gauge Tbl.

- Page 6 Fig. 7: Gas type dependency of the Pirani sensor Fig. 8: Cleaning measuring chamber Fig. 9: Replace sensor module Fig. 10: Sensor module Fig. 11: PPT 200 with DN 16 ISO-KF Fig. 12: PPT 200 with DN 16 CF-F 6/46...

-

Page 7: About This Manual

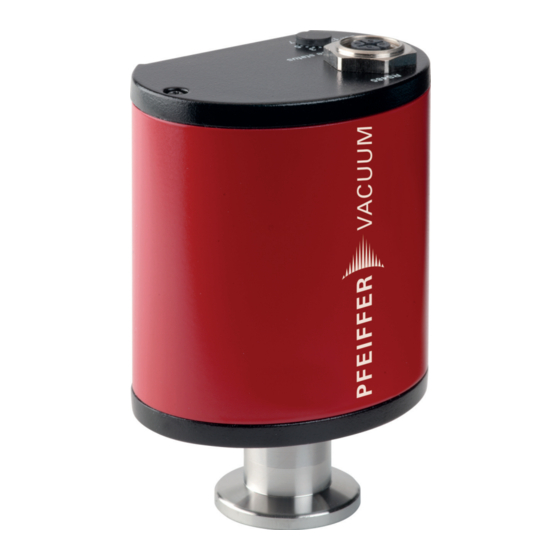

Variants You can find the part number on the rating plate of the product. Pfeiffer Vacuum reserves the right to make technical changes without prior notification. Information that relates to only one of the products is indicated accordingly. The figures in this document are not to scale. -

Page 8: Conventions

This section describes all the stickers on the product along with their meanings. Rating plate The rating plate is located on the back of the device. D-35614 Asslar Mod. PPT 200 PT R38 xxx 12345678 Range 1.0x10 - 1000 hPa Input 24 V DC 2.5 W Made in Germany 2023/01 1.3.4 Abbreviations... -

Page 9: Trademark Proof

About this manual Abbreviation Explanation Mean sea level Overrange [P:xxx] Electronic drive unit control parameters. Printed in bold as a three-digit number in square brackets. Frequently displayed in conjunction with a short description. Example: [P:312] software version Pressure RS-485 Standard for a physical interface for asynchronous serial data transmission (recom- mended standard) Voltage supply (turbo power supply) Underrange... -

Page 10: Safety

Safety instructions according to product life stages All safety instructions in this document are based on the results of a risk assessment. Pfeiffer Vacuum has taken into account all the relevant life stages of the product. Risks during installation DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. - Page 11 ► Only operate the unit in a dry environment. ► Operate the unit away from fluids and sources of moisture. ► Do not switch on the unit if fluid has entered it. Instead contact Pfeiffer Vacuum Service. ► Always disconnect the power supply before cleaning the unit.

-

Page 12: Safety Precautions

Safety WARNING Health hazard through poisoning from toxic contaminated components or devices Toxic process media result in contamination of devices or parts of them. During maintenance work, there is a risk to health from contact with these poisonous substances. Illegal disposal of toxic sub- stances causes environmental damage. -

Page 13: Limits Of Use Of The Product

Tbl. 4: Permissible ambient conditions 2.5 Proper use The PPT 200 gauge is used for vacuum measurement of air, gases and gauges outside their explosion limits, within the range of 1 × 10 to 1000 hPa. Use the product according to its intended purpose ►... - Page 14 Safety ● Use outdoors ● Use after technical changes (inside or outside on the product) ● Use with replacement or accessory parts that are not suitable or not approved 14/46...

-

Page 15: Product Description

You will need all the data from the rating plate to safely identify the product when communicating with Pfeiffer Vacuum. ► To ensure clear identification of the product when communicating with Pfeiffer Vacuum, always keep all of the information on the rating plate to hand. -

Page 16: Transport And Storage

Transport and storage 4 Transport and storage 4.1 Transporting the product NOTICE Damage caused by incorrect transport Transport in unsuitable packaging or failure to install all transport locks can result in damage to the product. ► Comply with the instructions for safe transport. Packing We recommend keeping the transport packaging and original protective cover. -

Page 17: Installation

Installation 5 Installation 5.1 Establish vacuum connection DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. ► Connect the product galvanically with the earthed vacuum chamber. ► Ensure that the connection complies with the requirements of a protective bonding according to EN 61010. -

Page 18: Creating "Rs-485" Connection

● Requirements of the earthed protective extra-low voltage (PELV) ● Limited power source (LPS) Class 2 ► Secure the line to the product. – Pfeiffer Vacuum measuring and control equipment complies with this requirement. NOTICE Property damage due to ground contact of electronics Disconnecting or connecting the "RS-485"... - Page 19 2. Make sure that all devices connected to the bus have different RS-485 device addresses. 3. Connect all devices with RS-485 D+ and RS-485 D- to the bus. Connect Pfeiffer Vacuum display and control units or a PC ► Use a connecting cable from the DigiLine accessories range.

-

Page 20: Interfaces

3 GND 6.2 Pfeiffer Vacuum protocol for RS-485 interface 6.2.1 Telegram frame The telegram frame of the Pfeiffer Vacuum protocol contains only ASCII code characters [32; 127], the exception being the end character of the telegram C . Basically, a host (e.g. a PC) sends a tele- gram, which a device (e.g. -

Page 21: Telegram Description

Interfaces 6.2.2 Telegram description Data query --> Control command --> Data response / Control command understood --> Error message --> NO_DEF Parameter number n2–n0 no longer exists _RANGE Data dn–d0 outside the permissible range _LOGIC Logical access error 6.2.3 Telegram example 1 Query pressure value Current measured pressure (parameter [P:740], device address: "001") -->... -

Page 22: Data Types

Interfaces 6.2.5 Data types Data type Description Length Example l1 – l0 boolean_old Logical value (false/true) 000000 is equivalent to false 111111 is equivalent to true u_integer Positive whole number 000000 to 999999 u_real Positive fixed point number 001571 corresponds with 15.71 string Any character string with 6 charac-... -

Page 23: Parameter Set

All variables relevant for the function are stored as parameters in the gauge. Each parameter has a three-digit number and a description. The parameter can be accessed via Pfeiffer Vacuum display and control units or via RS-485 using Pfeiffer Vacuum protocol. -

Page 24: Status Requests

Parameter set 7.3 Status requests Description Functions Data Access Unit min. max. type type fault Error code 000000 = No error Err001 = Sensor defective Err002 = Memory defective Gauge firmware Example of first firmware version: version 010100 Device name PPT200 Hardware version Example for first hardware version: 010100... -

Page 25: Operation

Operation 8 Operation Once the supply voltage has been established, the measurement signal is available at the electrical connection. Meaning No power supply Lights up green Supply voltage OK, measuring mode, valid pressure values Lights up yellow Other mode (e.g. Zero Adjust), measuring range exceeded/under- shot, temporarily no valid measured values Lights up red Software or gauge error... -

Page 26: Determining Effective Pressure With Correction Factors

Operation 8.1 Determining effective pressure with correction factors The measuring signal of the gauge depends on the type of gas. Pfeiffer Vacuum has calibrated the gauge to nitrogen (N ) or dry air. The correction factor can be used to compensate for the gas type de- pendency. -

Page 27: Reading And Setting Relay And Switch-Points

Operation Reading and setting Pirani correction factor [P:742] ► Read the current correction factor via parameter [P:742]. ► Via parameter [P:742], set the correction factor to a value between 0.2 and 8.0 with 2 decimal places. – Example: Correction factor 0.20 = 000020 –... -

Page 28: Disassembly

Disassembly 9 Disassembly DANGER Risk to life due to electric shock An improperly earthed product is potentially fatal in the event of a fault. ► Connect the product galvanically with the earthed vacuum chamber. ► Ensure that the connection complies with the requirements of a protective bonding according to EN 61010. -

Page 29: Maintenance

► Only operate the unit in a dry environment. ► Operate the unit away from fluids and sources of moisture. ► Do not switch on the unit if fluid has entered it. Instead contact Pfeiffer Vacuum Service. ► Always disconnect the power supply before cleaning the unit. - Page 30 ► Operate the unit away from fluids and sources of moisture. ► Take special precautions if there is a risk of dripping water. ► Do not switch on the unit if fluid has penetrated into it, instead contact the Pfeiffer Vacuum Serv- ice Center.

-

Page 31: Calibrating Gauge

Maintenance 10.2 Calibrating gauge Pfeiffer Vacuum has calibrated the gauge to default values at the factory. Preparing for calibration 1. Ensure the same installation and ambient conditions as those applicable for normal use. 2. Check the filter for contamination as required. - Page 32 Maintenance Fig. 9: Replace sensor module 1 Torx screws Seal 2 Sealing washers Housing 3 Sensor Procedure 1. Remove the gauge from the vacuum system. 2. Loosen the Torx screws and sealing washers. 3. Carefully remove the sensor from the housing. 4.

-

Page 33: Malfunctions

Malfunctions 11 Malfunctions Warranty Malfunctioning of the equipment as a direct result of contamination or wear, as well as wear parts, is not covered by the warranty. Malfunction Possible cause Remedy Communication error: Gauge No power supply Connect a data cable or power supply pack. -

Page 34: Shipping

► Comply with the instructions for safe distribution. Decontamination subject to charge Pfeiffer Vacuum decontaminates products not clearly declared "Free of contamination" at your expense. Ship product safely ► Do not ship microbiological, explosive or radioactively contaminated products. -

Page 35: Recycling And Disposal

● Help to reduce the wastage of natural resources. ● Prevent contamination. 13.1 General disposal information Pfeiffer Vacuum products contain materials that you must recycle. ► Dispose of our products according to the following: – Iron – Aluminium –... -

Page 36: Service Solutions By Pfeiffer Vacuum

We are always focused on perfecting our core competence – servicing of vacuum components. Once you have purchased a product from Pfeiffer Vacuum, our service is far from over. This is often exactly where service begins. Obviously, in proven Pfeiffer Vacuum quality. - Page 37 Service solutions by Pfeiffer Vacuum 5. Prepare the product for transport in accordance with the provisions in the contamination declaration. a) Neutralize the product with nitrogen or dry air. b) Seal all openings with blind flanges, so that they are airtight.

-

Page 38: Spare Parts

Spare parts 15 Spare parts Ordering spare parts ► Have the part number to hand, along with other details from the rating plate as required. ► Install original spare parts only. Fig. 10: Sensor module 1 Torx screws Sensor 2 Sealing washers Article number Size Replacement sensor module... -

Page 39: Accessories

Power supply packs for wall- and standard rail mounting to supply power to DigiLine gauges OmniControl control unit Universal control unit for all products with Pfeiffer Vacuum RS-485 protocol. It supplies up to two trans- mitters and is equipped with a display for displaying the pressure of up to 16 measuring channels. -

Page 40: Technical Data And Dimensions

Connection (electrical) Binder M12 connector, 5-pole, A-coded Cable length ≤100 m Tbl. 18: Electrical data Parameter Value Protocol ASCII, addressable (RS-485), Pfeiffer Vacuum protocol Data format Bidirectional data traffic, data word length 8 bits, 1 stop bit, no parity bit 40/46... -

Page 41: Tbl. 19: Rs-485 Interface

Technical data and dimensions Parameter Value Baud rate 9600 Connection Binder M12 connector, 5-pole, A-coded Tbl. 19: RS-485 interface Parameter Value Weight DN 16 ISO-KF 190 g DN 16 CF-F 220 g Tbl. 20: Connection flanges and weight Parameter Value Air pressure 800 –... -

Page 42: Dimensions

Technical data and dimensions 17.3 Dimensions Ø 30 DN 16 ISO-KF Fig. 11: PPT 200 with DN 16 ISO-KF Dimensions in mm Ø 34 DN 16 CF-F Fig. 12: PPT 200 with DN 16 CF-F Dimensions in mm 42/46... -

Page 43: Ul/Csa Certification

The product PPT 200 - conforms to the UL standards UL 61010-1, 3rd edition (2016) Safety requirements for electrical equipment for measurement, control and laboratory use Part 1: General requirements - is certified to the CSA standards CSA C22.2 No. 61010-1-12, UPD1:2015, UPD2:2016... -

Page 44: Ec Declaration Of Conformity

This declaration of conformity has been issued under the sole responsibility of the manufac- turer. Declaration for product(s) of the type: Digital Pirani gauge PPT 200 We hereby declare that the listed product satisfies all relevant provisions of the following European Directives. Electromagnetic compatibility 2014/30/EU... -

Page 45: Declaration Of Conformity

EN IEC 61326-1:2021 EN IEC 63000:2018 The manufacturer's authorized representative in the United Kingdom and the authorized agent for compiling the technical documentation is Pfeiffer Vacuum Ltd, 16 Plover Close, In- terchange Park, MK169PS Newport Pagnell. Signature: Pfeiffer Vacuum GmbH Berliner Straße 43...

Need help?

Do you have a question about the PPT 200 and is the answer not in the manual?

Questions and answers