Subscribe to Our Youtube Channel

Summary of Contents for Bentone B 55-2 FAME

- Page 1 CR00445 178 076 66-4 2021-11-15 Providing sustainable energy solutions worldwide Installation- and maintenance instruction B 55-2 FAME/RME LMO24.255C2E E4NC-1069 7P Translation of the original instructions.

- Page 2 1~230V 1,0A 50Hz IP 20 Motor supply MADE IN SWEDEN BY 1. Manualer på övriga språk 1. Manuals in other languages 1. Manualer på andre sprog 2. www.bentone.com\ 2. www.bentone.com\download 2. www.bentone.com\download nedladdning or scan QR-code. eller scan QR-koden. eller scanna QR-koden.

-

Page 3: Table Of Contents

6.3 Replacing the damper motor _______________________ 26 6.4 Replacement of oil pump __________________________ 27 6.6 Replacement of electrical components ______________ 28 6.5 Check oil line seals _______________________________ 28 6.7 Vibration ________________________________________ 29 6.7 Settings Damper motor 2-stage ___________________ 30 Bentone... -

Page 4: Safety Information

• The surface temperature of the burner’s components can exceed 60 °C. • Caution: The burner has moving parts, and there is risk of crushing injuries. • The electrical installation must be professionally carried out in accordance with applicable high voltage regulations, as per Enertech’s recommendations. 165 105 85 Bentone... - Page 5 - fl ue gas ducts and combustion air ducts are not blocked - all actuators and control and safety devices are in working order and correctly set • After commissioning - If the gas burner control has a solid red light, contact your installer. Bentone...

- Page 6 Oil hoses must be of high-quality fluoride rubber or PTFE intended for FAME, B-100 (RME). The hoses must be fitted with fire-retardant sleeves in order to satisfy requirements according to EN-ISO 6806. Bentone...

- Page 7 Delivery check • Make sure everything is delivered and the goods have not been damaged during transit. • If something is wrong with a delivery, report it to the supplier. • Transport damage must be reported to the shipping company. Bentone...

-

Page 8: Technical Data

Type Motor supply Main supply Sound B 55-2 230/400V 3,1/1,8A 230V 0,38A 50Hz 89 dBA ± 0,5 dBA B 65-2 230/400V 5,9/3,4A 230V 0,38A 50Hz 89 dBA ± 0,5 dBA Max operating current, see data plate. 165 205 86-3 Bentone... -

Page 9: Working Field B 55-2

2.3 Working field B 55-2 13.0-67.5 kg/h 155-800 kW mbar -1,0 2.4 Working field B 65-2 22.0-99.5 kg/h 260-1180 kW mbar 13,0 12,0 11,0 10,0 -1,0 1000 1100 1200 Bentone... -

Page 10: Adjusting The Ignition Electrodes And Brake Plate

10 bar (8-25 bar) depending on pump model 2.7 Burner installation 2.7.1 Hole patten Make sure the hole pattern on the boiler is designed for burner flange. Combustion device B 55-2 ø (155) 165 ø (226) 254-300 B 65-2 ø (155) 205 ø (226) 254-300 Bentone... -

Page 11: Nozzle Table

89,36 1060 93,70 1111 97,88 1161 101,85 1208 1039 26,00 96,81 1148 101,50 1204 1035 106,04 1258 1081 110,33 1308 1168 The table applies to oil with a viscosity of 4.4 mm /s at a density of 830 kg/m Bentone... - Page 12 1057 1267 1089 24,00 1254 1078 1297 1116 1341 1153 1382 1188 26,00 1359 1168 1406 1209 1453 1249 1497 1287 The table applies to oil with a viscosity of 4.4 mm /s at a density of 830 kg/m Bentone...

-

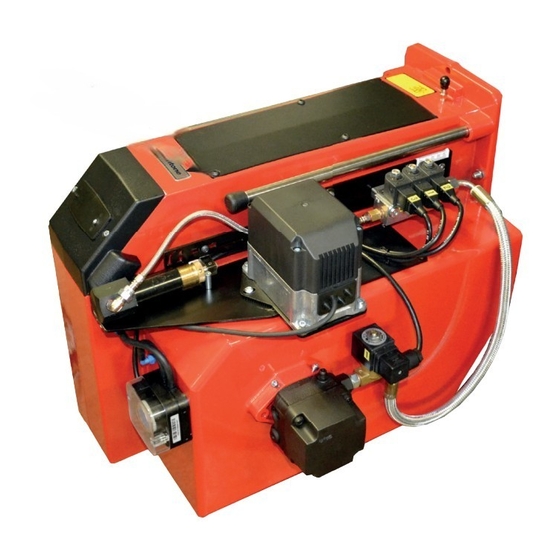

Page 13: Components

Scale, nozzle assembly Nozzle Indicating lamp Stage 2 Solenoid valve bloc Stage 2 Nozzle assembly Switch l-ll Solenoid valves Ignition electrodes Indicating lamp Stage 1 Connecting pipe Electric panel Switch 0-l Damper motor Motor Cover, inspection glass Adjustment device, air damper Bentone... - Page 14 Ignition wires Damper motor Damper motor Air damper Solenoid valve Fan wheel Air intake Scale, Nozzle assembly Thermal overload protection Solenoid valve bloc Stage 2 Solenoid valve bloc Stage 3 Contactor Connecting pipe Hydraulic hose Control box Solenoid valve Bentone...

-

Page 15: General Instructions

The system must be fine-tuned at start-up. The temperature in the chimney must be at least 60 °C at 0.5 m down in the chimney to prevent condensation. 165 205 33 Bentone... -

Page 16: Installation

4. Installation 4.1 Handling and lifting instruktion The lifting aid we used here are available as spare parts. Bentone... -

Page 17: Acceptance Inspection

• The connection should be made in accordance with the wiring diagram. • Fuse rating is as required. If any electrical connection is used other than that recommended by Bentone, there may be a danger of damage to property and personal injury. Bentone... -

Page 18: Mount The Burner On The Boiler

Once the burner has been installed and commissioned, the seals of the various coupling elements should be checked. When a leak is detected, it is usually suffi cient to tighten the coupling element that is leaking. 165 105 61 2020-11-02 Bentone... -

Page 19: Basic Settings

Stage 1 and Stage 2. The positions of MV 2 are determined by the boiler characteristics when switching between stages, but for a basic setting the black cam should be placed in the middle. 165 205 35-3 Bentone... - Page 20 See under Basic settings Note that it is simply a matter of a basic setting that should be adjusted retrospectively once the burner has started. A flue gas analysis and soot quantity measurement must be carried out when fine-tuning the burner. Bentone...

-

Page 21: Setting Values For Nozzle Assembly And Air Damper B 55-2/-2H/-2R/-3R

5.2 Setting values for nozzle assembly and air damper B 55-2/-2H/-2R/-3R Air settings Nozzle assembly Scale Burner output 5.3 Setting values for nozzle assembly and air damper B 65-2/-2H/-2R/-3R Air settings Nozzle assembly Scale 1000 1100 1200 Burner output Bentone... -

Page 22: Nozzle Assembly Regulation - Fixed Brake Plate

Adjust to the desired position on the scale (A) using the set screw (D) (turning anti-clockwise reduces the pressure drop and moves the brake plate outwards). If pulsation occurs, the pressure drop across the brake plate can be alte-red until pulsation stops. Bentone... -

Page 23: Hydraulic Air Adjustment

(3.6, 3.7). Read the damper angle for each of the power stages This must then be used when the settings are made in the burner’s control system (se punkt 3.3) Check the air settings by conducting a flue gas analysis. Bentone... -

Page 24: Maintenance

Close the boiler / spectacle fl ange. Turn on the mains power. Check combustion. When soiled, always replace nozzles with new nozzles. When servicing/replacing components that affect combustion, an analysis and soot test must be carried out on the installation. 165 205 36 2020-11-02 Bentone... -

Page 25: Servicing Air Dampers

Slide the burner together and secure it with the nuts (H). Connect the Eurostecker connectors and turn on the main power switch. Check combustion. When servicing/replacing components that affect combustion, an analysis and soot test must be carried out on the installation. 165 205 36 2020-11-02/2 Bentone... -

Page 26: Replacing The Damper Motor

Reset the damper motor cams. Connect the Eurostecker connectors and turn on the main power switch. Check combustion. When servicing/replacing components that affect combustion, an analysis and soot test must be carried out on the installation. 165 205 36 2020-11-02/3 Bentone... -

Page 27: Replacement Of Oil Pump

When servicing oil bearing components, check the oil density when the burner is commissioned after servicing. When servicing/replacing components that affect combustion, an analysis and soot test must be carried out on the installation. 165 205 36 2020-11-02/4 Bentone... -

Page 28: Replacement Of Electrical Components

Check the function of the new component. may be hot. Start the burner and check the combustion. When servicing/replacing components that affect combustion, an analysis and soot test must be carried out on the installation. 165 205 36 2020-11-02/5 Bentone... -

Page 29: Vibration

• Check all bolts and nuts for correct torque. • Check fan wheel for damage and contamination. Change when dirty/ unbalanced. • Check motor bearings. If worn change motor/bearings. Use lid screw hole for sensor mounting. 165 205 36 2020-11-02/6 Bentone... -

Page 30: Settings Damper Motor 2-Stage

90° to increase airfl ow. • Return the control switch to position I (low load) and check the combustion values. Solenoid valve High load (black) High load (red) Low load (orange) Closed air damper (blue) Release button 172 511 14-2 2021-05-03 Bentone... -

Page 31: Pump Instruction E4Nc-1069 7P

Change the oil pump oil fi lter in accordance with the following. - Close the oil valves - Unscrew the cover on the pump. - Replace the oil fi lter. - Replace head gasket. - Mount the cover on the pump. - Open the oil valves. 165 105 86 Bentone... -

Page 32: Function

Vacuum gauge port 5. Inlet Oil under pressure 1. Gear set By passed oil returned to tank, or to suction 2. By-pass hole 6. Pressure adj u stment 7. To nozzle 3. Pressure gauge port 4. By-pass plug installed 8. Return Bentone... -

Page 33: Oil Burner Control

8. Oil burner control 8.1 Wiring diagram B 55/B 65, 2-step, LMO24, FAME/RME 165 305 28 Bentone... -

Page 34: Function Lmo24

< 1 s < 1 s Ambient temperature -5 - +60°C -20 - +60°C Min detector current required (with fl ame) 45 µA dc 45 µA dc Max perm. detector current (without fl ame) 5.5 µA dc 5.5 µA dc Bentone... -

Page 35: Colour Codes Lmo24

If the reset button is instead kept pressed a second time for at least 3 seconds, you can, via an interface, obtain the corresponding information on a computer or flue gas analyser. To return to normal operation: Press the reset button for 1 second. Bentone... -

Page 36: Fault Location

Preheater temperature too low Check preheater function New oil type Adjust the preheater‘s set operating temperature Check that the oil used has the physical parameters that the burner is rated for. If not, change the oil. 165 105 09-2 2021-01-21 Bentone... -

Page 37: Delayed Ignition

Check that the oil used has the physical parameters that the burner is rated for. If not, change the oil. Temperature of the oil from the tank is too low, increase the temperature of oil from tank Clean the pump filter 165 105 09-2 2021-01-21/2 Bentone... -

Page 38: Pump Pressure

Pump worn Replace the pump Pump run using impure oil that has worn the Replace pump and install self-cleaning pump out prematurely filter in the oil system Blocked pump filter Check, clean pump filter 165 105 09-2 2021-01-21/3 Bentone... -

Page 39: Log Of Flue Gas Analysis

10. Log of flue gas analysis Owner Adresss Tel. no: Installation Tel. no: Boiler Type Make Power Bentone Burner Serial no. Type Model Fuel Step 1 Step 2 Step 3 Draught in fireplace Fan Press mbar Filter smoke number Flue gas temp. °C... -

Page 40: Oil Burners Maintenance Instructions

11. Oil burners maintenance instructions General information If the burner starts but does not ignite Make an attempt to start the burner. Keep the boiler room clean. Ensure that the boiler room has permanent fresh air intake. Switch off before Never make close repeated start attempts. - Page 44 Enertech AB. P.O Box 309, SE-341 26 Ljungby. www.bentone.com...

Need help?

Do you have a question about the B 55-2 FAME and is the answer not in the manual?

Questions and answers