BVL V-MIX Fix Plus Operating Manual

Hide thumbs

Also See for V-MIX Fix Plus:

- Operating manual (90 pages) ,

- Assembly and operating manual (74 pages) ,

- Operating manual (103 pages)

Table of Contents

Advertisement

English

V-

MIX Fix Plus

Rev. 6 / 02.19

Printed in Germany –

Translation of the original operating manual

Read and follow this operating manual before putting the machine into operation for the first time!

Store for future reference!

Type of manual

ing manual

Machine designation

Fix Plus

MachineNo

MachineType

chine

Revision status

CustomerName

nard van Lengerich

CustomerNameAffix

chinenfabrik GmbH & Co. KG

CustomerAddress

Operating manual

16

CustomerLocation

48488 Emsbüren

CustomerPhone

(0)5903 951-0

CustomerFax

(0)5903 951-34

CustomerEmail

fo@bvl-group.de

CustomerURL

bvl-group.de

DocuStatus

CustomerPOBox

1154

Year of Manufacture

Item.No. 109165

Operat-

V-MIX

101105

Ma-

5

Ber-

Mas-

Grenzstraße

D-

+49

+49

in-

http://www.

02.19

Postfach

2019

www.bvl-group.de

Advertisement

Table of Contents

Summary of Contents for BVL V-MIX Fix Plus

- Page 1 Mas- chinenfabrik GmbH & Co. KG CustomerAddress Operating manual Grenzstraße CustomerLocation 48488 Emsbüren CustomerPhone (0)5903 951-0 CustomerFax (0)5903 951-34 CustomerEmail fo@bvl-group.de CustomerURL http://www. bvl-group.de DocuStatus 02.19 CustomerPOBox Postfach 1154 Year of Manufacture 2019 MIX Fix Plus Rev. 6 / 02.19 Item.No.

- Page 2 (ISO 4413:2010) The entity authorized to compile the relevant technical documents is Bernard van Lengerich Maschinenfabrik GmbH & Co. KG, Tel.: +49 (0)5903 951-0 Emsbüren, on 02/06/19 Bernard van Lengerich, Managing Director Translation of the Original Operating Manual V-MIX Fix Plus...

- Page 3 Copyright Bernard van Lengerich Maschinenfabrik GmbH & Co. KG, 2019 All rights reserved. Reprints, even in excerpts, only with the written permission of Bernard van Lengerich Maschinenfabrik GmbH & Co. KG. V-MIX Fix Plus Translation of the Original Operating Manual...

- Page 4 Bernard van Lengerich Maschinenfabrik GmbH & Co. KG Operations: Grenzstraße 16 Post address: Postfach 1154 D-48488 Emsbüren Tel: +49 (0)5903 951-0 Fax: +49 (0)5903 951-34 Email: info@bvl-group.de Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 5: Table Of Contents

Capacity limits Operating fluids Information on noise generation Design and function Overview of the V-MIX Fix Plus V-MIX Fix Plus – Overview of assemblies Mixing hopper Ladder and inspection window Anti-spill ring V-MIX Fix Plus Translation of the Original Operating Manual... - Page 6 Gear unit Brevini ECS1512 7.4.2 Gear unit Brevini EM1065 7.4.3 Gear unit Comer PGA1602 7.4.4 Reduction gearbox BvL 108960 (special equipment) Entering the mixing hopper 7.5.1 Discharge opening with protruding cover apron 7.5.2 Discharge opening with tight-fitting cover apron (optional) 7.5.3...

-

Page 7: User Information

The operating manual is part of the machine. Therefore, store this operating manual: at the machine at all times, for future reference. If selling the machine, pass this operating manual on to the purchaser. Locational information in this operating manual V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 8: Illustrations Used

Unordered lists are displayed as lists with bullet points. Example: Item 1 Item 2 Item numbers in illustrations Figures included in round brackets refer to the item numbers included in the adjoining illustration. Example (1) Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 9: Terms Used

... the source of a potential injury or damage to a person's health. Manufacturer ... Bernard van Lengerich Maschinenfabrik GmbH & Co. KG. Machine … the V-MIX Fix Plus stationary mixer. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 10: Safety Instructions

Do not operate the machine unless all of its safety features are in proper working order. Organizational measures The operating manual: must always be stored at the location of the machine, must be freely accessible to operator and maintenance personnel at all times. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 11: Responsibilities Of The Owner

If the correction of a fault is not part of the operator's responsibilities or the operator lacks the necessary expertise, the operator must report the defect to his supervisor or the owner. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 12: Qualification Of The Personnel

Note: A qualification that is equivalent to professional technical training can be acquired by working in the respective field for several years. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 13: Intended Use

2.2.4 Intended use The stationary mixer V-MIX Fix Plus is designed exclusively for collecting, reducing, homogeneously mixing and discharging any type of silage as well as feeding stuff that is commonly used in animal husbandry and whose content of dry substance makes up more than 30% of the overall mix. -

Page 14: Product Safety

The manufacturer does not accept any liability for damages caused by: unauthorized modifications of the machine, unapproved modification and accessory parts, welding and drilling operations on load-bearing sections of the machine. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 15: Replacement And Wear Parts As Well As Auxiliary Supplies

Unauthorized structural modifications on the machine, Insufficient monitoring of machine parts that are subject to wear, Improperly performed repairs, Natural disasters caused by the impact of foreign objects and force majeure. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 16: General Safety Instructions

Never reach into the mixing hopper through one of the discharge openings while the machine is running. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 17: Hydraulic System

Use only the designated fuses. Using higher amperage fuses may destroy the electrical system – as there is a risk of fire. Make sure all electrical installations are completed by trained and qualified personnel and as specified in the circuit diagram. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 18: Cleaning, Maintenance And Repairs

Replacement parts must meet the minimum technical requirements specified by the manufacturer. Compliance is ensured by the use of original spare parts. Observe the maintenance intervals applicable to wear parts. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 19: Action-Related Safety Instructions And Important Information

Failure to observe safety instructions marked with the "CAUTION" symbol may po- tentially result in minor or moderate injury. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 20: Important Information

This information must be kept clean and in legible condition at all times. Replace infor- mation that has become illegible. Order warnings and instructions from your dealer by providing their order number. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 21: Warnings

The instruction(s) on how to avoid the hazard, e.g. "Never reach into the hazard area as long as parts are still moving in this area." V-MIX Fix Plus Translation of the Original Operating Manual... - Page 22 Risk of arms becoming entangled or caught caused by powered work tools! These hazards may cause serious injury, including the loss of body parts. Never reach into the hazard area as long as the engine is running. Translation of the Original Operating Manual V-MIX Fix Plus...

- Page 23 Risk of bodily injury from becoming entangled or caught! These hazards may cause serious injury, including the loss of body parts. Never reach into the hazard area as long as the engine is running. V-MIX Fix Plus Translation of the Original Operating Manual...

- Page 24 Operating manual in the document box. Read and follow the operating manual and the safety instruc- tions before putting the machine into operation! 103878 Warning Warning that the machine may start up automatically. Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 25: Instructions

Instruction Block ball valve securing the open dosing gate against inad- vertent lowering: Position lock closed – block ball valve closed Position lock open – block ball valve open V-MIX Fix Plus Translation of the Original Operating Manual... - Page 26 This pictogram identifies attachment points for fastening lifting gear that can be used to load and unload the machine onto and from a load carrier. Only fasten your lifting gear at / on the identified attachment points. Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 27: Positioning Of Warnings And Instructions

Safety instructions 2.6.3 Positioning of warnings and instructions The following illustrations show the arrangement of warnings and instructions on the machine. Fig. 2-1 and Fig. 2-2 V-MIX Fix Plus with conveyor belt V-MIX Fix Plus Translation of the Original Operating Manual... - Page 28 Safety instructions Fig. 2-3 and Fig. 2-4 V-MIX Fix Plus with discharge gate on the side Translation of the Original Operating Manual V-MIX Fix Plus...

- Page 29 Safety instructions Fig. 2-5 and Fig. 2-6 V-MIX Fix Plus with discharge gate at the rear V-MIX Fix Plus Translation of the Original Operating Manual...

- Page 30 Safety instructions Fig. 2-7 and Fig. 2-8 V-MIX Fix Plus with cross conveyor at the rear Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 31: Risks Resulting From Failure To Observe The Safety Instructions And Warnings

result in the loss of any and all claims for damages. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 32: Technical Data

Technical data Technical data V-MIX Fix Plus 6.5-1S to 15-1S Type Unit 6.5-1S 8N-1S 8-1S 9-1S Capacity m³ Overall length - mixing hopper 2890 3090 2950 3200 Overall width - mixing hopper 2050 2270 2030 2270 Overall width with one side door... -

Page 33: V-Mix Fix Plus 13-2S To 25-2S

Technical data V-MIX Fix Plus 13-2S to 25-2S Type Unit 13-2S 15-2S 15N-2S 17-2S 17N-2S Capacity m³ 14.8 15.4 16.6 17.1 Overall length - mixing hopper 4860 4975 5300 5060 5380 Overall width - mixing hopper 2050 2050 2270 2050... - Page 34 Machine height with standard features measured from bottom edge of base 3025 3380 plate (700 mm support frame) Minimum machine height with standard features measured from bottom 3125 3480 edge of base plate (600 mm support frame) Unladen weight 7370 7370 Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 35: Type Plate And Ce Mark

Year of manufacture Fig. 3-2 Hydraulic unit Manufacturer Laimer Hydraulik Laimer Hydraulik Driving power 1.5 kW 5.5 kW System pressure 150 bar 150 bar Volume flow 5.2 l/min 16 l/min V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 36: Capacity Limits

The sound pressure level generated by the machine is less than 70 dB(A). This measurement was taken in an assembly hall without nearby equipment at a distance of approx. 5 m. Translation of the Original Operating Manual V-MIX Fix Plus... -

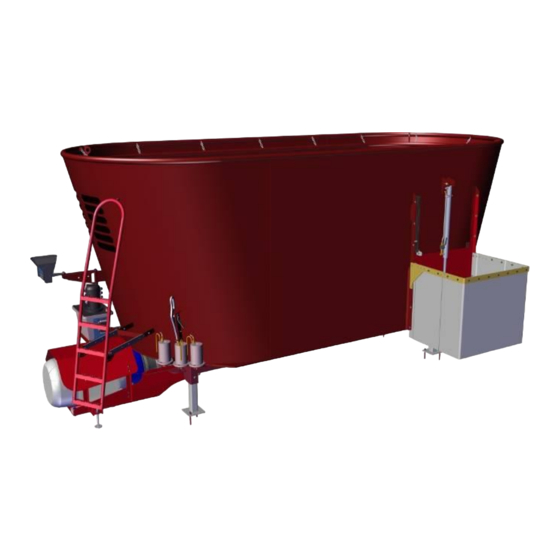

Page 37: Design And Function

Overview of the V-MIX Fix Plus The stationary mixer V-MIX Fix Plus is designed exclusively for collecting, reducing, homogeneously mixing and discharging any type of silage as well as feeding stuff that is commonly used in animal husbandry. The V-MIX Fix is available in different sizes and in variants. -

Page 38: V-Mix Fix Plus - Overview Of Assemblies

Design and function V-MIX Fix Plus – Overview of assemblies Fig. 4-3 Overview of assemblies (example V-MIX Fix Plus 1S) Mixing hopper Discharge area Counter blades (2x) Ladder Mixing and dispenser unit Hydraulic unit (optional) Weighing system (optional) Inspection window... -

Page 39: Mixing Hopper

Fig. 4-4 Ladder and inspection window The V-MIX Fix Plus is equipped with an inspection win- dow (1) and a ladder (2). The inspection window (1) al- lows the operator to look into the mixing hopper and monitor the mixing process. -

Page 40: Anti-Spill Ring

Vario ring (2), (special equipment). The Vario ring (2) is recommended for processing long- fiber round or square bales as it keeps silage bales from becoming stuck. Fig. 4-6 Fig. 4-7 Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 41: Mixing And Dispenser Unit

Design and function Mixing and dispenser unit The mixing and dispenser unit on the V-MIX Fix Plus 1S comprises: a mixing auger (1), a gear unit (2), a gear motor (3). The gear motor (3) drives the gear unit (2). The rotation- al movement of the mixing auger (1) is, in turn, initiated by the gear unit (2). -

Page 42: Mixing Auger With Cutting Blades

Extends the service life of the mixing auger under extensive stress. Perfect for retrofitting mixing augers that show a medium degree of wear. Fig. 4-12 Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 43: Discharge Area (Discharge Opening)

(4). The switching strip (3) has six slotted holes which can be used to affix and continuously adjust the sensor (4). Fig. 4-15 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 44: Conveyor Belt (Optional)

Design and function Conveyor belt (optional) Special equipment: The V-MIX Fix Plus is available with an optional convey- or belt (1). The conveyor belt (1) makes it possible to discharge fodder into elevated and hard-to-reach feed troughs. Fig. 4-16 Conveyor belt (sample photo) -

Page 45: Counter Blades

(2) and fixed in place at one of the three possible positions by inserting the bolt (3) into the corresponding hole. Fig. 4-19 Hydraulic counter blades (5) are swung in or out hydrau- lically. Fig. 4-20 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 46: Weighing System (Optional)

USB stick and PC interface. Also observe the supplied operating manual of the weighing equipment. Fig. 4-21 Machines equipped with the cleaning mode are only available with the weighing system PTM HL50E Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 47: Hydraulic Unit (Optional)

Electrohydraulic control block (3) 4.12.1 Electrohydraulic control block Open dosing gate Close dosing gate (3, 4) Optional for controlling an additional dosing gate or conveyor belt. Bypass valve Fig. 4-23 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 48: Hydraulic Hand Pump (Optional)

The hydraulic hand pump (1) is used to perform hydrau- lic functions such as opening and closing the dosing gate. Also observe the supplied operating manual of the hand pump. Fig. 4-24 Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 49: Oilcooling

The Oilcooling system has an integrated filter (5) which cleans the oil Abb. 4-25: Overview Oilcooling 1 Electric motor Gear pump 3 Oil-/Aircooler Level-/Temperatureswitch 5 Filter Tank 7 Filler pipe Sight glas Clean all filters and cooling fins daily. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 50: Control Switch Cabinet

4.15 Control switch cabinet The V-MIX Fix Plus comes with a control switch cabinet that is set up next to the mixer, offering the operator a simple and convenient way to view and control the mixer. Found on the front panel are the main switch (2), the emergency stop button (5) and all operating elements and controls (4) essential to operating the machine. -

Page 51: Main Switch

“OFF” position. Fig. 4-27 4.15.2 Emergency stop button EMERGENCY STOP A press on the emergency stop button at the switch cab- inet stops all movements at the machine. Fig. 4-28 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 52: Operating Elements And Controls

To execute this function, you must press and hold the button. Push button Open the dosing gate. To execute this function, you must press and hold the button. Push button Reset Reset alarm. Selector switch Preselect mixing process. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 53: Display

The display and its screens are organized as follows. Fig. 4-30: Main screen Pos. Name Function Configuration Switch to the Configuration screen. Only for BvL service staff. The input is password-protected. Settings Switch to the Settings screen. Only for BvL service staff. The input is password-protected. Alarm Switch to the Faults/errors screen. - Page 54 Fig. 4-31: Alarm screen Pos. Name Function Overview of error messages Display error messages. Every message is stored including the date and the time. Back Return to the main screen. Reset Reset error messages. Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 55: Safety Devices And Guards

Fig. 4-32 (Optional) The discharge openings are protected by tightly fitted, pivoting cover aprons (2) which prevent anyone from reaching into the hopper during operation. Fig. 4-33 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 56: Block Ball Valve

(1). A press on the emergency stop but- ton (1) stops all movements at the machine. Fig. 4-36 The emergency stop button is not intended to stop the machine during normal operation. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 57: Transport, Setup, And Initial Commissioning

Observe these chapters for your own safety. Scope of delivery as supplied Included in the scope of delivery is a variant of the V-MIX Fix Plus mixer including drive shaft, gear motor and hydraulic unit (optional). Stationary mixer V-MIX Fix Plus... -

Page 58: Loading And Unloading The Machine Using Lifting Devices

Stay out from under the lifting zone below the raised machine at all times. There are attachment points on the machine that are labeled with the pictogram and can be used to attach lifting gear. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 59: Machine Setup

Transport, setup, and initial commissioning Machine setup The V-MIX Fix Plus is essentially supplied ready-for-operation. Simply place the ma- chine on the designated pre-constructed substructure and secure it. The ground bearing capacity at the installation location must be sufficient to accom- modate the machine weight (for weight specifications, refer to chapter "Technical da-... - Page 60 2.1 Re-tighten the clamping screws (2) firmly. Drill holes through the base plates (3) into the foun- dation. Fasten the machine in place with suitable fasteners, e.g. heavy-duty anchors. Fig. 5-2 Fig. 5-3 Translation of the Original Operating Manual V-MIX Fix Plus...

-

Page 61: Connecting The Electrical System

Check the oil level in the hydraulic oil tank. For this purpose, refer to chapter "Cleaning, maintenance and repairs", starting on page "70". Check all functions of the machine before filling container for the first time. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 62: Use And Operation

Press the “Alarm Reset” push button (see chapter “Operating elements and controls“, page 52) or the “Reset” button on the “Alarm” operating screen (see chapter “Display”, page 53). The machine can be started again. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 63: Starting And Ending The Mixing Process

To end the mixing process, allow the preset time to elapse or set the “1” selector switch at the control switch cabinet to the “Off” position (see chapter “Operating elements and controls”, page 52). The mixing process has ended. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 64: Filling The Mixing Hopper

To avoid high starting torque levels, we recommend that you fill the mixing hopper with the mixing auger under power (see chapter “Starting and ending the mixing process”, page 63). Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 65: Recommended Order During Filling

Add feed components with a high water content, e. g. brewer's grains, potato pulp or sugar beet pulp. Add liquid components such as liquid yeast or molasses through the filling funnel used for mineral feed (special equipment). V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 66: Discharging Fodder

- if present - must be opened manually. When operating in “Deliver” mode, conveyor belt 1 will start on its own after dosing gate 1 has opened. Translation of the Original Operating Manual V-MIX Fix Plus... - Page 67 “1” selector switch at the control switch cabinet to the “Off” position (see chapter “Operating elements and controls“, page 52). The machine including all of its functions switches off. The discharge process has ended. V-MIX Fix Plus Translation of the Original Operating Manual...

-

Page 68: Removing Clogs

52) to close the dosing gate (3). Automatic opening will stop at the open- ing width at which the sensor (1) has been in- stalled. Resume discharging the fodder. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 69: Starting And Ending Cleaning Mode

To end the cleaning process, set the “1” selector switch at the control switch cabinet to the “Off” position (see chapter “Operating elements and controls”, page 52). Cleaning mode has ended. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 70: Cleaning, Maintenance And Repairs

The following is prohibited as a general rule: drilling on the frame. drilling out holes already existing on the frame. welding on load-bearing parts. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 71: Cleaning

Remove all dirt from the lubrication nipples. Use environmentally safe and biodegradable oils and greases if lubricants might en- ter feedstuffs or the soil. Contact your authorized farm equipment dealer for more in- formation. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 72: Lubrication Points

100 h Drive shaft guard tube Lubricating 100 h Further information on how to lubricate the drive shaft can be found in the documents pro- vided by the drive shaft manufacturer. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 73: Maintenance Schedule - Overview

Inspect and resharpen or replace as necessary. monthly Container wall and base plate General visual inspection and check of wall thickness quarterly (base plate, at least 10 mm; container wall, at least 4 mm). V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 74: Oil Change At The Gear Unit

every 1000 operating hours thereafter, at least once per year (whichever interval comes first). Change the gear oil for the reduction gearbox BvL 108960: for the first time after 50 operating hours, every 600 operating hours thereafter, ... -

Page 75: Gear Unit Brevini Ecs1512

15. Close the lid (4) on the oil tank. 16. Check the oil level after 5 hours of operation. The oil level must lie between the two marks (5), refill if necessary. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 76: Gear Unit Brevini Em1065

Unscrew the venting screw (1) on the gear unit. Fill in 1.6 liters of gear oil via the venting screw (1). Screw in the venting screw (1) and firmly tighten it (use a suitable sealant). Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 77: Gear Unit Comer Pga1602

15. Close the lid (4) on the oil tank. 16. Check the oil level after 5 hours of operation. The oil level must lie between the two marks (5), refill if necessary. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 78: Reduction Gearbox Bvl 108960 (Special Equipment)

Cleaning, maintenance and repairs 7.4.4 Reduction gearbox BvL 108960 (special equipment) An oil change requires approx. 9 liters of type SAE 80W- 85 (API GL5, VG 150). Only perform an oil change when the oil has reached its operating temperature. The oper- ating temperature is approx. -

Page 79: Entering The Mixing Hopper

Cover the sharp-edged cutting blades before you move around inside the mixing hopper. Remove all feed remains and moisture before you move around inside the mixing hopper. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 80: Discharge Opening With Protruding Cover Apron

(2) when all necessary work on the mixing Fig. 7-8 hopper is complete: 7.1 Swing the cover apron (4) back. 7.2 Screw the cover apron (4) to the mixing hop- per. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 81: Discharge Opening With Tight-Fitting Cover Apron (Optional)

8.2 Slightly raise the cover apron (4) to slide the flat iron of the cover apron into the bracket (5) (not shown). 8.3 Screw the cover apron (4) to the mixing hop- per. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 82: Discharge Opening With Tight-Fitting Cover Apron And Conveyor Belt (Optional)

The mixing augers need to be installed in the following position and, naturally, be interlinked accordingly in the drive train via the drive shafts. Fig. 7-11 V-MIX Fix Plus 2S Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 83: Cutting Blades Of The Mixing Auger

Wear protective goggles and protective gloves. Remove all foreign objects (tools, etc.) from the mixing hopper. After the work is completed, exit the mixing hopper via the discharge opening. Fig. 7-12 V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 84: Swiveling/Replacing Cutting Blades

Remove all foreign objects (tools, etc.) from the mixing hopper. After the work is completed, exit the mixing hopper via the discharge opening. Fig. 7-14 (sample image current screws) Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 85: Hydraulic System

Dispose of the used oil as stipulated by law. If you experience problems with disposal, contact your oil supplier. Store hydraulic oil in a place inaccessible to children. Make sure that no hydraulic oil can seep into the soil or water. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 86: Checking The Hydraulic Oil Level

3.1 Use the dipstick to measure the oil level. Make sure the hydraulic oil level is between the min. and the max. mark. Carefully screw the lid (1) onto the hydraulic oil tank. Fig. 7-16 Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 87: Markings On Hydraulic Hose Lines

Example (Fig. 7-17): The date of manufacture of the hydraulic hose line is specified on the fitting, e.g. (07/10 = year/month = October 2007). The period of use will, thus, end in October of 2013. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 88: Installing And Removing Hydraulic Hose Lines

Fasten the hydraulic hose lines at the designated attachment points. Avoid any addi- tional hose brackets which impair the natural movement and length adjustment of the hydraulic hose lines. It is prohibited to refinish hydraulic hose lines. Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 89: Conveyor Belt (Optional)

The alignment of the conveyor belt is not straight unless the clearance is identical on both sides of the conveyor belt. Fig. 7-19 Re-tighten both lock nuts (1) firmly. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 90: Tightening Torques For Bolt Joints

16 (17) M10x1 18 (19) M12x1.5 M14x1.5 M16x1.5 M18x1.5 M20x1.5 M22x1.5 1050 1000 1200 M24x2 1100 1300 1050 1500 1800 M27x2 1150 1600 1950 1450 2000 2400 M30x2 1600 2250 2700 Translation of the Original Operating Manual V-MIX Fix Plus... -

Page 91: Faults

The plug connector is dirty Clean and dry the plug (do not use contact spray). Electrical control system Error in the electrical control system Observe the operating manuals provided by the suppliers. V-MIX Fix Plus Translation of the Original Operating Manual... -

Page 92: Appendix

Gear unit ECS 1512 Brevini Gear unit EM 1065 Comer industries Gear unit PGA 1602 Circuit diagrams You will find the circuit diagrams of the machine at the control switch cabinet. Translation of the Original Operating Manual V-MIX Fix Plus...

Need help?

Do you have a question about the V-MIX Fix Plus and is the answer not in the manual?

Questions and answers