Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Unipulse TM500

- Page 1 TM500 TORQUE MONITOR OPERATION MANUAL 01JUN2016REV.1.02...

- Page 2 For good performance, and proper and safe use of the TM500, be sure to read this instruction manual and properly understand the contents of it before use. Also, carefully keep this instruction manual so that it can be referred to at any time.

- Page 3 ● For the entire system to function safely when the TM500 becomes faulty or malfunctions, provide a safety circuit outside the TM500. ● Before using the TM500 as described below, make sure to consult with our sales personnel. - Use in environments not described in the operation manual.

- Page 4 - Do not wipe with a wet rag, or with benzine, thinner, alcohol, etc. Doing so may cause discoloration or deformation of the TM500. In the case of heavy contamination, wipe off the contamination with a cloth after dipping it into a diluted neutral detergent and wringing...

- Page 5 Caution during transportation ● When the TM500 is shipped, spacers made of corrugated cardboard are used as cushioning materials. Though it is factory-designed so that shocks can sufficiently be absorbed, breakage may result if shocks are applied when the spacers are reused for transportation.

-

Page 6: Table Of Contents

Contents Contents 1 OUTLINE ........... . . 1 1-1. - Page 7 Contents 4-2. Y-axis setting ............35 4-3.

- Page 8 Contents ■Error Release............135 ■SD memory card self-check.

- Page 9 Contents M E M O VIII...

-

Page 10: Outline

1-2. Features TM500 is a torque monitor that enables waveform display of changes in torque with respect to displacement (mainly angles), combined with UTMⅡ series with optional rotary encoder. Changes in torque that are hard to grasp numerically can be grasped visually on waveform display. - Page 11 1 OUTLINE ● Drawing of torque-angle waveforms Waveforms of torque with respect to angles at low rotation, linear motion application can be Chapter drawn. Load Time ● Repetitive drawing of waveforms For applications with large fluctuation or low repeatability, inspection can be repeated several times for judgment.

- Page 12 1 OUTLINE ● Control of the position at the measurement completion The position of the measurement completion can be judged by using the End Displacement for Chapter the Use Hold. The End Displacement is different from other hold types, so it judges not based on a wave starting point but based on an original point of the displacement.

- Page 13 1 OUTLINE For the measurement start point and measurement stop point, set “Front” and “Back,” respectively, as “Waveform Reference.” Chapter Normally, “Front” is used; however, use “Back” if displacement of the measurement stop point is set as reference. * In case of “Front”, the waveform of which 0° is the measurement start point is displayed. In case of “Back”, the waveform of which 0°...

-

Page 14: About Connectable Devices

1 OUTLINE - Measurement Stop Condition Chapter < Forced-Stop > < Forced-Stop > (maximum data acquisition) (external input) Load Load Measurement Measurement Section Section Maximum data 2048 points Time or Time or displacement displacement Stop < Load > < Time > Load Load Measurement... -

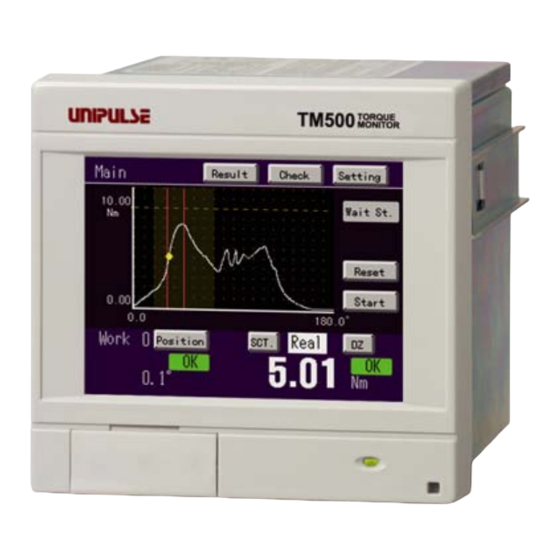

Page 15: Part Names And Functions

1 OUTLINE 1-4. Part names and functions Chapter ■Front panel TM500 TORQUE MONITOR Liquid crystal touch panel display Power lamp SD card slot cover Liquid crystal touch panel display Indicated values and graphs are displayed, and various items are set on this liquid crystal touch panel display. -

Page 16: Rear Panel

1 OUTLINE ■Rear panel Chapter RS-232C connector UTM Ⅱ connection connector Control connector DC power input terminal block Voltage output terminal Frame ground Option board mounting slot Protective ground Rotary encoder connection connector DC power input terminal block Connect the DC power cord. -

Page 17: Terms

1 OUTLINE Control connector Chapter Connector to input external signals and output control signals. The input/output and internal circuits are photocoupler-isolated electrically. Input: Plus common/minus common shared Output: Sink type The adaptable connector is manufactured by FUJITSU COMPONENT. Connector: FCN-361J040-AU (attachments) or equivalent. Cover: FCN-360C040-B Option board mounting slot... -

Page 18: Installation And Connection

2 INSTALLATION AND CONNECTION INSTALLATION AND CONNECTION 2-1. Installation Chapter To install the TM500 into a control panel, use the following procedure. Make a hole in the panel according to the 92mm 0 – panel-cut dimensions. Panel-cut dimensions 92mm 0 –... -

Page 19: Sensor Connection

2 INSTALLATION AND CONNECTION 2-2. Sensor connection ■UTMⅡ connection A UTMⅡ can easily be connected with the attached dedicated cable. The cable is nonpolar. Connect paying attention to the orientation of the connector. Chapter ●Pin assignments Pin arrangement Pin No. Cable color Signal name PWR+... -

Page 20: Voltage Output

External input signals can be connected to sink type or source type; however, external output signals can be connected to sink type only. ■ External output equivalent circuits and example connections (sink type) TM500 PLC, etc. Sink type Plus common connection... -

Page 21: External Input Equivalent Circuits And Example Connections

2 INSTALLATION AND CONNECTION ■ External input equivalent circuits and example connections (Plus common/minus common shared) - In case of plus common connection When you connect the relay and the switch, etc. TM500 Chapter Plus common connection Push Toggle A1 to A8... -

Page 22: Connector Pin Assignments

2 INSTALLATION AND CONNECTION Attention Connect elements that can pass Ic=10mA or more. The leak current of the elements connected should be 400μA or less. Chapter ■Connector pin assignments The adaptable connector Connector: FCN-361J040-AU (attachments) Cover: FCN-360C040-B (attachments) Load Digital Zero Work 1 DPM Positioning Work 2... -

Page 23: How To Assemble The Connector

2 INSTALLATION AND CONNECTION ■How to assemble the connector Nut M2 (four) Pan-head machine screw Pan-head machine screw M2×10 (long) (two) M2×8 (short) (two) Washer (two) Chapter Case (two) Connector Screw (two) Set the connector and screws (two) into the grooves of the case (one side). Cover with the other case, and fit the cases. - Page 24 2 INSTALLATION AND CONNECTION Result, Wave Result, Complete, Load OK, and DPM OK outputs are turned OFF. By turning the signal from ON to OFF, a “Wait Lv.” State is brought about, or the measurement is started according to the Measurement Start Condition. - Stop Stop input It should normally be wired.

- Page 25 2 INSTALLATION AND CONNECTION Output signals - Hold Result (Load/DPM) It should be wired according to application. Use it for acquiring judgment results by using the hold function. If displacement needs to be judged, also use DPM. It is not used if the hold function is not used.

- Page 26 2 INSTALLATION AND CONNECTION - SD OK It should be wired according to application. Normally use it if the SD card slot option is used. It turns OFF with a memory card error* , or when the measurement start input OFF→ON is ignored because a measurement waveform is not saved in time while being saved automatically* .

-

Page 27: How To Check Wiring

Output Press the output signal key, and check that there is input to the connected equipment. (Pressing the key turns ON the output.) Input Turn ON the output of the connected equipment. The pin recognized by the TM500 turns yellow. -

Page 28: Rs-232C Connection

2 INSTALLATION AND CONNECTION 2-4. RS-232C Connection ■Connector Pin Assignment The adaptable connector is manufactured by Hosiden Corporation TCP8080-015267 or equivalent. Wire connection surface Pin No. Signal name Chapter Metal case Plastic cover Fit the metal cases into the Din connector, and cap with the plastic covers. - Page 29 Transmit any statement from the equipment connected. (Check only when the Communication Mode is Normal.) The data received by the TM500 is displayed. Check that the transmitted data is displayed. If the Parity or Frame lights in red and the data is not displayed properly, go back to Step 1 or 2, and check again the cable or communication settings.

-

Page 30: Power-On

CAUTION ● Connect with no power applied because it may cause an electric shock. ● Since the TM500 has no power switch, install a breaker. ● Be sure to ground the protective ground terminal to prevent electric shocks. Do not use other screws than that attached to the main body. -

Page 31: Screens And Operations

3 SCREENS AND OPERATIONS SCREENS AND OPERATIONS 3-1. Screen configuration Main screen Setting Chapter Check Result Main Main Result screen Wave Check screen * The previously displayed screen appears. Display (The default is [Result (Single)].) Display Setting screen Each setting Set value input screen... - Page 32 3 SCREENS AND OPERATIONS Chapter Main Setting screen First Setting Work Setting Item group screen Main Each setting Each setting item screen Main Each setting Set value input screen...

-

Page 33: Explanation Of Each Screen And Key Operations

3 SCREENS AND OPERATIONS 3-2. Explanation of each screen and key operations ■Main screen Status display Reset key Measurement waveform Start/Stop key display area Digital Zero key Work display Result display(Load) Chapter Indicated value display Indicated value display(Load) (Displacement) DPM positioning key Selected indicated value display Result display(Displacement) Indicated value display selection key... - Page 34 3 SCREENS AND OPERATIONS Result display : The result is displayed. The waveform comparison and the hold results of each section are displayed overall according to the priority. * The displacement result is not displayed if X axis is time. Priority Result Judgment condition HI/LO limit over (HI limit over and LO limit over)

-

Page 35: Comparison Result Screen

3 SCREENS AND OPERATIONS : Simply makes the same movement as the Stop signal. This key is valid when the status display is Wait Lv. or Sampling. When pressed, it changes to : Simply makes the same movement as the DPM Positioning signal. However, it cannot be operated when the X-axis represents time. - Page 36 3 SCREENS AND OPERATIONS The order of priority is as follows: H/L > H,L > NG > OK SCT.1~5: ... Displays the Y-axis (load) and X-axis (displacement or time) values of the judgment point of each section and judgment results. Wave: ..Displays the Y-axis (load) and X-axis (displacement or time) values of the point at which the upper/lower limit comparison waveform is first exceeded, and the Y- axis (load) judgment result.

- Page 37 3 SCREENS AND OPERATIONS Comprehensive judgment: ...Displays the judgments (Y-axis and X-axis) of each section and the judgments of waveform comparisons overall. The order of priority is as follows: H/L > H,L > NG > OK Work No.: ..Displays the work No. used for measurement. SECT.1 to 5:..

-

Page 38: Wave Check Screen

3 SCREENS AND OPERATIONS ■Wave Check screen Waveform display Section display Chapter Cursor readings Display change Display range Display Cursor readings: Display the cursor-positioned load and displacement (time). Also, the HI and LO limits of comparison waveforms and the HI and LO limits of the currently-cursor-positioned section are displayed on waveform display and section display, respectively. - Page 39 3 SCREENS AND OPERATIONS - About the waveform display Reference Point Comparison of Relative Comparison waveform (HI limit) Waveform comparison judgment point Comparison waveform (LO limit) Compare Area Chapter Comparison waveform (HI limit) Comparison waveform (LO limit) Outside the Compare Area Compare Area Outside the Compare Area Comparison waveforms (HI and LO limits):...

-

Page 40: Setting Screen

3 SCREENS AND OPERATIONS Load/displacement HI and LO limits: HI limit of load The HI and LO limits of each section are indicated LO limit of load by red lines. LO limit of HI limit of displacement displacement The measurement waveform display area on the Main screen is as follows: =... -

Page 41: Item Group Screen

3 SCREENS AND OPERATIONS ■Item group screen First Setting Work Setting Chapter Parameter protection display Each group Each group Display First Protect: Displays whether parameters can be changed or not. Select by System Setting. Work Protect: Displays whether parameters can be changed or not. Select by System Setting. Keys Moves to the Main screen. -

Page 42: Each Setting Item Screen

3 SCREENS AND OPERATIONS ■Each setting item screen Normal display screen Each setting item Chapter Setting order display screen Order display Page change Page display Each setting item Display Page display: Displays the page number/total number of pages when there are two or more pages of setting items. -

Page 43: Set Value Input Screen

3 SCREENS AND OPERATIONS ■Set value input screen Numeric keypad input screen 1 Numeric keypad input screen 2 (one input item) (two input items) Numeric display Numeric keypad Chapter Selective input screen (no grouping) Selective input screen (grouped) Selective items Selection keys Graph input Selection keys Setting method display... -

Page 44: Settings And Calibrations

4 SETTINGS AND CALIBRATIONS SETTINGS AND CALIBRATIONS 4-1. Release of parameter protection To change set values, release their respective locks. Chapter Release of Work Setting Parameter Protection Operation Main screen → Setting → First Setting → System Setting → Work Protect → Not Protect Release of First Setting Parameter Protection Operation Main screen →... - Page 45 4 SETTINGS AND CALIBRATIONS Unit Select a unit. Setting range (See "9-3.Unit setting list"on p.141.) Operation Main screen → Setting → First Setting → Y-axis Setting → Unit Zero Calibration Register the present sensor input as zero. Press with the torque meter unloaded. Setting range (-5.555 to 5.555 V) Operation Chapter...

- Page 46 4 SETTINGS AND CALIBRATIONS Increment Set the minimum unit of load display. Loads are displayed in the set increments. Setting range (1, 2, 5, 10) Operation Main screen → Setting → First Setting → Y-axis Setting → Next → Increment Analog Filter The low-pass filter of the set cut-off frequency is inserted with respect to the input of the torque meter.

-

Page 47: X-Axis Setting

4 SETTINGS AND CALIBRATIONS 4-3. X-axis setting Calibrate and set the rotary encoder by X-axis Setting. Set each item according to the setting order. Settings vary depending on whether the X-axis represents time or displacement. X-axis: Time Chapter X-axis: Displacement, Continuous, Average Operation Main screen →... - Page 48 4 SETTINGS AND CALIBRATIONS < In case of time > < In case of displacement > Load Load Time Displacement When the X-axis represents time Measurement Length Set the time for waveform acquisition. Chapter Setting range (0.5, 1.0, 2.0, 5.0, 10.0 s) Operation Main screen →...

- Page 49 4 SETTINGS AND CALIBRATIONS Waveform Reference Select whether the waveform reference is front or back. Setting range Front: The measurement start point becomes the waveform reference. Back: The measurement stop point becomes the waveform reference. Operation Main screen → Setting → First Setting → X-axis Setting → Wave Reference Point When the Waveform Reference is set at Back, Change of Section cannot be made externally.

- Page 50 4 SETTINGS AND CALIBRATIONS Equivalent Input Calibration Input the relationship between the number of pulses (rated output) and displacement value (display value) determined from the data sheet of the rotary encoder. Also, set the decimal place here. Input the decimal point together when inputting the display value.

-

Page 51: Work No. Selection And Work Copy

4 SETTINGS AND CALIBRATIONS Repetitive displacement In "Continuous" "Average" mode, set the repetitive displacement of measurement. Setting range (720, 810, 900, 990, 1080, 1170, 1260, 1350, 1440, 1530, 1620, 1710, 1800, 2000 × Measurement Length/2000) Operation Main screen → Setting → First Setting → X-axis Setting → Next → Next →... -

Page 52: Measurement Start Condition Setting

4 SETTINGS AND CALIBRATIONS 4-5. Measurement start condition setting Set measurement conditions by Measurement Start Condition Setting. The Measurement Start Condition is as follows: Chapter Operation Main screen → Setting → Work Setting → Start Setting Measurement Start Condition Set the measurement start timing. If the X-axis represents continuous or average, set "Only external input". - Page 53 4 SETTINGS AND CALIBRATIONS ③External Input + Displacement Load Measurement Measurement starts when the displacement crosses the Section Measurement Start Level after the external input signal “Start” turns OFF → ON → OFF. Start Displace- Start displacement ment Start point Start point Start Start Start...

- Page 54 4 SETTINGS AND CALIBRATIONS ① Only Forced-Stop Setting of “4. Measurement Stop Level” is disabled. - 2048 points Load Measurement Measurement stops when the number of points of Section measurement data exceeds 2048. 2048 points Time or displacement - External input Load Measurement Measurement stops when the external input signal...

- Page 55 4 SETTINGS AND CALIBRATIONS ④Displacement Load Measurement Measurement stops when the forced-stop or the Section displacement reaches the Measurement Stop Level. Stop Displace- ment displacement Stop point Stop point Stop Stop Stop Stop level level level level Displace- Displace- Displace- Displace- ment ment ment...

-

Page 56: Measurement Data

4 SETTINGS AND CALIBRATIONS ■Measurement data ・ The sampling rate is fixed at 4000sps (samples per second). ・ Measurement is carried out at 4000sps, but the data kept in a waveform is 2000 pieces per the Measurement Length. (Maximum data: 2048) Therefore, the waveform resolution is the Measurement Length/2000. -

Page 57: When The Displacement Advances Suddenly

4 SETTINGS AND CALIBRATIONS * Out of the points not kept in a waveform, those meeting the following conditions are kept in the waveform by priority. ① Data kept as judgment points but not kept in a waveform when Peak Hold, Bottom Hold, Peak to Peak Hold, Relative Maximum Hold, Relative Minimum Hold, or Inflection Point Hold is used ②... -

Page 58: Measurement

4 SETTINGS AND CALIBRATIONS Example) When the section start point is 1.2° and Sample Hold is used Load sampling: 4000sps (every 250μs) Load ○ Load sampled by 250μs ● Load kept in a waveform ○ Hold point Not held here No-sampling section This data is held Displacement Resolution... -

Page 59: Adjustment Of Waveform Display

4 SETTINGS AND CALIBRATIONS 4-7. Adjustment of waveform display Adjust the waveform display axis by Display Range Setting. Chapter Operation Main screen → Setting → Work Setting → Display Setting Y-axis Start Point Set the Y-axis start point of the waveform. Setting range (-10000 to 10000) Operation Main screen →... - Page 60 4 SETTINGS AND CALIBRATIONS X-axis Start Point Set the X-axis start point of the waveform. The setting range differs according to the setting of Wave Reference and Measurement Length. Setting range Time or displacement (Front) (0 to 2000 × Measurement Length/2000) Displacement (Back) (-2000 to 0 ×...

-

Page 61: Hold Setting

4 SETTINGS AND CALIBRATIONS 4-8. Hold setting ■What is the hold function? - By dividing a measurement waveform into up to five sections and specifying the HI limit, LO limit and the method of judgment for each section, the waveform can be judged on each section. - The method of judgment can be changed by selection under “Use Hold.”... - Page 62 4 SETTINGS AND CALIBRATIONS - Change of Section Select whether Change of Section is made by External Input or Setting. Setting range (External Input or Setting) Operation Main screen → Setting → Work Setting → Hold Setting → Change (Change of Sct.) Point When the Waveform Reference is set at Back, Change of Section cannot be made externally.

- Page 63 4 SETTINGS AND CALIBRATIONS If Sample is selected to Hold, the setting items of the right screen are displayed. - Detection Start Load Set the load to judge displacement while regarding a load as a trigger. It is convenient for judging displacement with respect to the initial torque.

- Page 64 4 SETTINGS AND CALIBRATIONS - Detection Rate Set the rate to detect Relative Maximum (Relative Minimum). Relative Maximum (Relative Minimum) is detected when the detection rate is exceeded based on the relative minimum. Setting range (1/4, 1/2, 3/4, 1, 1.25, 1.5, 1.75, 2, 3, 4 Times) Operation Main screen →...

- Page 65 4 SETTINGS AND CALIBRATIONS If Inflection Point is selected to Hold, the setting items of the right screen are displayed. - Detection Interval AB Set Detection Interval A and Detection Interval B. Setting range (The range is the same for A and B.) (1 to 999 ×...

- Page 66 4 SETTINGS AND CALIBRATIONS - Detection Start Load Set the load to start the detection of Inflection Point. If you do not use Detection Start Load, press Setting range (-9999 to 9999) Operation Main screen → Setting → Work Setting → Hold Setting → Use Hold → Inflect. →...

- Page 67 4 SETTINGS AND CALIBRATIONS - Section Start-End (only when Change of Section is made by Setting) Set the start point and end point of the selected section. Setting range (The range is the same for the start point and end point.) Time or displacement (Front) (0 to 2047 ×...

- Page 68 4 SETTINGS AND CALIBRATIONS Point About the Load HI and LO Limit set values for “Peak to Peak” “Peak to Peak” judgment is made by the maximum value – minimum value. Therefore, the judgment value will never be negative. So, set the Load HI/ LO Limit in the range of 0 to 9999.

-

Page 69: Types Of Holds

4 SETTINGS AND CALIBRATIONS ■Types of holds All holds are to carry out detection in each valid section. The valid section is as follows: When the setting of Change of Section is External Input: As long as the Hold input is ON When the setting of Change of Section is Setting: Between the start point and end point of the set section - Always... - Page 70 4 SETTINGS AND CALIBRATIONS - Bottom The minimum value (bottom value) is held. Valid section Sensor input Indicated value value Detection and hold Hold Hold input Section (Time or DPM (Front)) Start point End point Section (DPM (Back)) End point Start point - P-P (Peak to Peak) Chapter The difference between the peak value and...

- Page 71 4 SETTINGS AND CALIBRATIONS - Inflection Point Valid section The point at which the load changes Sensor input Indicated drastically is held. value value Detection is carried out from the point at which the Detection Start Load is crossed, Detection and when the inflection point detection Start Load Detection Hold...

-

Page 72: Waveform Comparison Setting

4 SETTINGS AND CALIBRATIONS 4-9. Waveform comparison setting ■What is the waveform comparison function? - Whether or not a measurement waveform is between comparison waveforms is judged by preparing the comparison waveforms in advance. < Non-defective > < Defective > Measurement waveform Comparison waveform Load Load... -

Page 73: Waveform Comparison Setting

4 SETTINGS AND CALIBRATIONS ■Waveform Comparison Setting Set the waveform comparison function by Wave Comparison Setting. Set each item according to the setting order. Skip unnecessary setting items. Chapter Operation Main screen → Setting → Work Setting → Wave Setting (→ Next → Next) Registration of Reference Waveform. - Page 74 4 SETTINGS AND CALIBRATIONS ⑤ To input a waveform again, repeat ② to ④. ⑥ Pressing registers the reference waveform(s). In the case of one reference waveform, it is Load 1st waveform recognized that the HI limit waveform and LO limit waveform are the same.

- Page 75 4 SETTINGS AND CALIBRATIONS Shift This is one of the waveform processing methods. A part of waveform can be shifted up/down. Setting range (range set under “Compare Area”) Operation Main screen → Setting → Work Setting → Wave Setting → Shift ①...

- Page 76 4 SETTINGS AND CALIBRATIONS ③ To add point(s), repeat the operation in ②. To correct already-created point(s), touch the left side of the point(s) you want to correct. All the points on the right side from the touched place are erased, and a new point is created at the touched place.

- Page 77 4 SETTINGS AND CALIBRATIONS Load Reversing When measuring, reverse load sign before acquiring data. Waveform data is reversed without change in the indicated value display during measurement. Setting range (Off, On) Operation Main screen → Setting → Work Setting → Wave Setting → Next → Load Reversing Displacement Reversing When measuring, reverse displacement direction before acquiring data.

-

Page 78: 4-10.Parameter Protection

4 SETTINGS AND CALIBRATIONS Point Upon completion of creation/processing of a waveform, be sure to check and save it by Waveform Save. When not using comparison waveforms ... Press on the Registration of Reference Waveform screen, and select Since the Registration of Reference Waveform screen is restored, press Chapter If the setting of Relative Comparison is On, set it to Off. -

Page 79: 4-11.Measuring Work Specification

4-11. Measuring work specification Up to 16 types of work set values can be stored in the TM500, and the work No. (measuring work) used for measurement must be specified. For this, the external input signals “Work 1 to Work 8” are used. -

Page 80: Judgment Timing Chart

4 SETTINGS AND CALIBRATIONS 4-12. Judgment timing chart Here, some example timing charts using the hold function and waveform comparison function are given. ■Example timing chart by the hold function - External control (only time or displacement (Reference; Front)) Load Measurement section Calculating Sct 1;... - Page 81 4 SETTINGS AND CALIBRATIONS - Turning OFF → ON the external input signal “Start” releases the hold, and turns OFF all outputs but Run. (Reset operation by the Start input) - Turning OFF → ON the external input signal “Hold” changes the section and gets the start point of the section.

- Page 82 4 SETTINGS AND CALIBRATIONS - Internal setting control (time or displacement (Reference; Front)) Load Measurement section Calculating Sct 1; Sct 2; Sct 3; Sct 4; Sample Always Bottom Peak Previously held value Indicated value Start load Sensor input value Constant judgment Hold Detection Hold...

- Page 83 4 SETTINGS AND CALIBRATIONS - Specify the start point and end point of the section by time or displacement. - During measurement, each hold operation is performed by the set Section Start-End. - Turning OFF → ON the external input signal “Start” releases the hold, and turns OFF all outputs but Run.

- Page 84 4 SETTINGS AND CALIBRATIONS - Internal setting control (displacement (Reference; Back)) Load Measurement section Calculating Sct 4; Sct 3; Sct 2; Sct 1; Sample Always Bottom Peak Previously held value Indicated value Start load Sensor input value Displacement Reset operation by the Start input Chapter Sct 1 Sct 2...

- Page 85 4 SETTINGS AND CALIBRATIONS - Specify the start point and end point of the section by displacement. - After completion of measurement, the waveform is scanned from the front, and each hold operation is performed by the set Section Start-End. - Turning OFF → ON the external input signal “Start” releases the hold, and turns OFF all outputs but Run.

-

Page 86: Example Timing Chart Using The Waveform Comparison Function

4 SETTINGS AND CALIBRATIONS ■Example timing chart using the waveform comparison function - Reference; Front (Relative Comparison not in use) Load Measurement section Calculating Compare area Waveform comparison judgment point Sensor input value Start load Time or displacement Reset operation by the Start input Chapter Result of the previous... - Page 87 4 SETTINGS AND CALIBRATIONS - Reference; Back, or Relative Comparison in use Load Measurement section Calculating Compare area Waveform comparison judgment point Sensor input value Start load Reset operation Time or displacement by the Start input Result of the previous Wave Result Output OFF HI output measurement...

- Page 88 4 SETTINGS AND CALIBRATIONS - Continuous mode When repeated twice at HI limit: three times and LO limit: twice Load Measurement section Measurement section Calculating Compare area Compare area Sensor input value Waveform comparison judgment point Displacement Reset operation Repetitive displacement Repetitive displacement by the Start input Chapter...

- Page 89 4 SETTINGS AND CALIBRATIONS - Average mode When repeated twice Load Measurement section Measurement section Calculating Compare area Waveform Sensor Average waveform comparison input value judgment point Displacement Reset operation Repetitive displacement Repetitive displacement by the Start input Chapter Result of the previous Wave result Output OFF...

-

Page 90: Communications

5 COMMUNICATIONS COMMUNICATIONS 5-1. RS-232C ■Outline - Results can be read. - Hold results can be read. - Measurement waveforms can be read. - Comparison waveforms can be read and written. - Set values can be read and written. - Wave Nos. can be read and written. - Hold results can be automatically output upon completion of measurement. - Page 91 5 COMMUNICATIONS - Stop Bit Setting range (1, 2 bit) Operation Main screen→Setting→First Setting→Com. Setting→Stop Bit - Parity Bit Setting range (None, Even, Odd) Operation Main screen→Setting→First Setting→Com. Setting→Parity Bit - Delimiter Chapter Setting range (CR, CR+LF) Operation Main screen→Setting→First Setting→Com. Setting→Delimiter - Header Setting range (None, STX) Operation...

-

Page 92: Communication Method (When The Communication Mode Is Normal)

5 COMMUNICATIONS ■ Communication method (when the Communication Mode is Normal) By transmitting commands from the host, operations corresponding to the commands are executed. -List of items that can be communicated Set value, operation, Item group Read Write Cal. Reference display item Main Load (display) ×... - Page 93 5 COMMUNICATIONS Set value, operation, Item group Read Write Cal. Reference display item First Setting X-axis Setting Time/DPM Change Set value read/ × 〇 〇 set value write command Phase Select Set value read/ × 〇 〇 set value write command Wave Reference Set value read/ ×...

- Page 94 5 COMMUNICATIONS Set value, operation, Item group Read Write Cal. Reference display item Settings by Work Setting Work No. (for RS-232C Set value read/ × 〇 〇 work communications) set value write command [Work 0 to 15] Measurement Start Condition Set value read/ ×...

- Page 95 5 COMMUNICATIONS Set value, operation, Item group Read Write Cal. Reference display item Settings by Waveform Relative Set value read/ × 〇 〇 work Comparison set value write command [Work 0 to 15] Setting Compare Area Set value read/ × 〇 〇...

- Page 96 Y-axis Setting in the example TM500’s return (In normal processing) Delimiter (STX) Data of the specified set value Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) Delimiter (STX)...

- Page 97 Display Range Setting in the example TM500’s return (In normal processing) Delimiter (STX) Data of the specified set value Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) (STX) Delimiter Chapter NG No.

- Page 98 Item group (See the list of set value commands.) Work Setting in the example TM500’s return (In normal processing) (STX) Delimiter Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return Chapter (In abnormal condition) Delimiter (STX)...

- Page 99 Item group (See the list of Zero Calibration commands.) Y-axis Setting in the example TM500’s return (In normal processing) Delimiter (STX) Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) (STX) Delimiter Chapter NG No.

- Page 100 If "1" is read to Waveform update, go to step ②, and if "1" is not read, repeat step ①. (For transmitting the SAMPLE command continuously, do it at intervals of 100ms or more.) Host (Transmission to the TM500) S A M Delimiter TM500’s return...

- Page 101 If the first section = the last section, only the specified section can be read. Space (20H) TM500’s return (In normal processing) (STX) , Command received by the TM500 Data of the specified first section Chapter , , , ,...

- Page 102 If "1" is read to Waveform update, go to step ②, and if "1" is not read, repeat step ①. (For transmitting the SAMPLE command continuously, do it at intervals of 100ms or more.) Host (Transmission to the TM500) S A M Delimiter TM500’s return...

- Page 103 5 COMMUNICATIONS ② Read the measurement results. Host (Transmission to the TM500) R E S Delimiter Displacement Displacement Displacement Displacement TM500’s return (In normal processing) Load Load Load Load (STX) , , 2 , , Command received Total result Section1 Section2...

- Page 104 If "1" is read to Waveform update, go to step ②, and if "1" is not read, repeat step ①. (For transmitting the SAMPLE command continuously, do it at intervals of 100ms or more.) Host (Transmission to the TM500) S A M Delimiter TM500’s return...

- Page 105 (Back): fixed at 0000 fixed at 2047 displacement (Back): Hyphen(2dH) 0000 to 2047 Space (20H) Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return Chapter (In abnormal condition) (STX) Delimiter NG No.

- Page 106 5 COMMUNICATIONS TM500’s return (In normal processing) SP 0 (STX) Command received by the TM500 Waveform data ・ ・ ・ ・ ・ Waveform data at the start of the range at the end of the range Waveform data Amount of data: Data for the specified range “the end of the range –...

- Page 107 5 COMMUNICATIONS TM500’s return (In normal processing) Delimiter (STX) Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) (STX) Delimiter NG No. 1: Receipt of a statement different from the command format...

- Page 108 Alphanumeric characters and symbols from 1 to 20 digits Setting range (20H to 7EH, 80H to FCH) TM500’s return (In normal processing) (STX) Delimiter Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) Delimiter (STX)...

- Page 109 -9999 to +9999 1: OK 4: H/L (with a decimal point) 2: HI 5: NG Command received by the TM500 Header (If there is no header, no data will result.) , , Load error status Displacement: -9999 to +32000 (with a decimal point)

- Page 110 TM500’s return (In normal processing) 9 SP 2 Delimiter (STX) : : Command received by the TM500 Header (If there is no header, no data will result.) TM500’s return (In abnormal condition) (STX) Delimiter NG No. 1: Receipt of a statement different from the command format...

- Page 111 5 COMMUNICATIONS - List of commands to read set values Item group Setting item Command (transmission to the TM500) First Setting Y-axis Unit Delimiter Setting (CR,CR+LF) Decimal Place Delimiter (CR,CR+LF) Zero Calibration Delimiter (CR,CR+LF) Equiv. Cal. Delimiter (rated output) (CR,CR+LF) Equiv. Cal.

- Page 112 5 COMMUNICATIONS Return (by the TM500) Input range (display range) Delimiter See"9-3 Unit setting list"on page ± 149. (CR,CR+LF) Delimiter 0: 0 1: 0.0 ± 2: 0.00 3: 0.000 (CR,CR+LF) Delimiter ± -5.555~5.555 [V] (CR,CR+LF) Delimiter ± -9.999~9.999 [V] (CR,CR+LF) Delimiter ±...

- Page 113 5 COMMUNICATIONS Item group Setting item Command (transmission to the TM500) First Setting Commu- Speed Delimiter nication (CR,CR+LF) Setting Data Bit Delimiter (CR,CR+LF) Parity Bit Delimiter (CR,CR+LF) Stop Bit Delimiter (CR,CR+LF) Delimiter Delimiter (CR,CR+LF) Header Delimiter (CR,CR+LF) Flow Control Delimiter (CR,CR+LF)

- Page 114 5 COMMUNICATIONS Return (by the TM500) Input range (display range) Delimiter 0: 1200 1: 2400 2: 4800 ± 3: 9600 4: 19.2k 5: 38.4k [bps] (CR,CR+LF) Delimiter ± 0: 7 1: 8 [bit] (CR,CR+LF) Delimiter 0: None 1: Even ± 2: Odd...

- Page 115 5 COMMUNICATIONS Item group Setting item Command (transmission to the TM500) Settings by Work Setting Delimiter Work No. (for RS-232C) work (CR,CR+LF) [Work 0 to 15] Measurement Start Condition Start Delimiter Condition (CR,CR+LF) Setting Start Level Delimiter (CR,CR+LF) Stop Condition Delimiter...

- Page 116 5 COMMUNICATIONS Return (by the TM500) Input range (display range) Delimiter ± 0 to 15 (CR,CR+LF) 0: Only External Input 1: External Input + Load Delimiter ± 2: External Input + Displacement (CR,CR+LF) (2 can be set only when the X-axis of the waveform represents displacement.)

- Page 117 5 COMMUNICATIONS Item group Setting item Command (transmission to the TM500) Settings by Hold Setting Change of Sct. Delimiter work (common to all (CR,CR+LF) work) [Work 0 to 15] Use Sct. Delimiter (CR,CR+LF) Sct. No. Delimiter (for RS-232C (CR,CR+LF) communications) Use Hold...

- Page 118 5 COMMUNICATIONS Return (by the TM500) Input range (display range) 0: External Input 1: Setting Delimiter ± (0 can be set only when the (CR,CR+LF) time or displacement (Front)) Delimiter ± 1 to 5 (CR,CR+LF) 0: Sct1 1: Sct2 2: Sct3 Delimiter ±...

- Page 119 5 COMMUNICATIONS Item group Setting item Command (transmission to the TM500) Settings by Waveform Relative Delimiter work Comparison (CR,CR+LF) Setting [Work 0 to 15] Compare Area (start point) Delimiter (CR,CR+LF) Compare Area (end point) Delimiter (CR,CR+LF) Compare Margin Delimiter (CR,CR+LF) Relative Point...

- Page 120 5 COMMUNICATIONS Return (by the TM500) Input range (display range) Delimiter ± 0: Off 1: On (CR,CR+LF) Time or displacement (Front) 0 to 2047 (× Measurement Length/2000) Delimiter ± (CR,CR+LF) Displacement (Back) -2047 to 0 (× Measurement Length/2000) Time or displacement (Front) 0 to 2047 (×...

- Page 121 5 COMMUNICATIONS - List of commands to write set values Item group Setting item Command First Setting Y-axis Setting Unit ± Decimal Place ± Equiv. Cal. ± (rated output) Equiv. Cal. ± (rated capacity) Overload ± Increment ± Analog Filter ± Digital Filter ±...

- Page 122 5 COMMUNICATIONS (transmission to the TM500) Input range (display range) Delimiter "9-3 Unit setting list"on page 149. (CR,CR+LF) Delimiter 0: 0 1: 0.0 (CR,CR+LF) 2: 0.00 3: 0.000 Delimiter -9.999~9.999 [V] (CR,CR+LF) Delimiter -9999 to 9999 (CR,CR+LF) Delimiter 0 to 9999...

- Page 123 5 COMMUNICATIONS Item group Setting item Command First Setting Communication Speed ± Setting Data Bit ± Parity Bit ± Stop Bit ± Delimiter ± Header ± Flow Control ± Com. Mode ± Chapter System Setting Backlight ± (ON Time) Language ± Work Protect ±...

- Page 124 5 COMMUNICATIONS (transmission to the TM500) Input range (display range) Delimiter 0: 1200 1: 2400 2: 4800 (CR,CR+LF) 3: 9600 4: 19.2k 5: 38.4k [bps] Delimiter 0: 7 1: 8 [bit] (CR,CR+LF) Delimiter 0: None 1: Even (CR,CR+LF) 2: Odd Delimiter 0: 1 1: 2 [bit]...

- Page 125 5 COMMUNICATIONS Item group Setting item Command Settings by work Work Setting Work No. ± [Work 0 to 15] (for RS-232C communications) Measurement Start Condition Start Condition Setting ± Start Level ± Stop Condition ± Stop Level ± Chapter Display Range Y Start Point ±...

- Page 126 5 COMMUNICATIONS (transmission to the TM500) Input range (display range) Delimiter 0 to 15 (CR,CR+LF) 0: Only External Input 1: External Input + Load Delimiter 2: External Input + Displacement (CR,CR+LF) (2 can be set only when the X-axis of the waveform represents displacement.)

- Page 127 5 COMMUNICATIONS Item group Setting item Command Settings by work Use Hold [Work 0 to 15] ± Sct. Start-End (start point) Note1) ± Sct. Start-End (end point) Note1) ± Chapter Load HI/LO Limit (HI limit) ± Note1) Load HI/LO Limit (LO limit) ±...

- Page 128 5 COMMUNICATIONS (transmission to the TM500) Input range (display range) 0: Always 1: Sample 2: Peak 3: Bottom 4: Peak to Peak Delimiter 5: Relative Maximum 6: Relative Minimum (CR,CR+LF) 7: Inflection Point 8: Average 9: End Displacement Time or displacement (Front) 0 to 2047 (×...

- Page 129 5 COMMUNICATIONS Item group Setting item Command Settings by work Waveform Relative ± [Work 0 to 15] Comparison Setting Compare Area (start point) Note1) ± Compare Area (end point) Note1) ± Compare Margin ± Chapter Relative Point (X-axis) ± Relative Point (Y-axis) ±...

- Page 130 5 COMMUNICATIONS (transmission to the TM500) Input range (display range) Delimiter 0: Off 1: On (CR,CR+LF) Time or displacement (Front) 0 to 2047 (× Measurement Length/2000) * Setting Start point > End point is unacceptable. Delimiter (CR,CR+LF) Displacement (Back) -2047 to 0 (× Measurement Length/2000) * Setting Start point <...

- Page 131 Point of Section 1, Start Point of Section 2, …… Start Point of Section 5 Chapter and End Point of Section 5. - List of zero calibration commands Item group Setting item Command (transmission to the TM500) Y-axis Zero Delimiter Setting Calibration...

-

Page 132: Communication Method (When The Communication Mode Is Hold Point Mode)

Once Work No. is written, it will be reflected afterward throughout reading and writing of settings by work. This work No. is just for RS-232C communications. The TM500’s work is not changed. Also, the Work No. display in Work Setting is not changed. - Page 133 5 COMMUNICATIONS ・About messages Unless otherwise noted, all the messages are in ASCII code. Chapter...

-

Page 134: System Settings

6 SYSTEM SETTINGS SYSTEM SETTINGS 6-1. System setting Select language and adjust contrast, etc., by System Setting. Operation Chapter Main screen→Setting→First Setting→System Setting - Backlight This function changes the brightness of the backlight when touch screen has not been used for certain period of time. The ON time ( lighting time of the backlight) and the Low time ( bright →dark switching time of the backlight) are set up. - Page 135 Work Setting: All work setting parameters All: First Setting + Work Setting (The TM500's specific settings are the set values marked with * in "9-2 Setting item list" on p.144.) Operation Main screen→Setting→First Setting→System Setting→Initialization - Self-Check Make self-checks.

- Page 136 6 SYSTEM SETTINGS ① LCD Check Check that the display is free from defects in color and indication. The screen changes as red → green → blue → horizontal stripes → vertical stripes. Touching the screen restores the original screen. Operation Main screen→Setting→First Setting→System Setting→Self-Check→LCD Check ②...

- Page 137 6 SYSTEM SETTINGS ⑥ FLT. Check Check the filter circuit. - Analog Filter Voltage/current input (Load input): When the input is changed from 0V to 10V or 0mA to 10mA (step input), use the following alues as a guide for normal. 30Hz: 23±2 100Hz:...

- Page 138 6 SYSTEM SETTINGS - Password This setting is for maintenance and inspection. Do not operate it. Setting range (0 to 9999) Operation Main screen→Setting→First Setting→System Setting→Password - Time Adjust Set the present time displayed on the Setting screen. Setting range (2000/01/01 00:00:00 to 2079/12/31 23:59:59) Operation Main screen→Setting→First Setting→System Setting→Time Adjust Press...

-

Page 139: Sd Card Slot Option

7 OPTION OPTION 7-1. SD card slot option ■Outline - Set values and comparison waveform data can be preserved on an SD memory card. - Settings can be reconstructed by reading the set values and comparison waveform data having been preserved on an SD memory card. - Measurement waveform data and judgment points can be automatically preserved on an SD memory card upon completion of measurement. -

Page 140: Sd Memory Card Ejection

Pick the SD memory card, and draw it out frontward. Close the SD card slot cover. ■Settings - Equipment ID By setting its ID, an TM500 can be controlled to differentiate from other TM500s. Setting range (0 to 999) Operation Main screen→Setting→First Setting→Option Setting →... -

Page 141: Setting A Wave No. On A Measurement Waveform

7 OPTION Point It takes about 1s to write a measurement waveform on average. (It varies depending on conditions.) When Measurement Waveform Preservation by the Automatic Operation is “On (Overwrite)” and SD memory card is full, present waveform is preserved by overwriting on the oldest file.In this case, it is possible to take about several seconds to write in the waveform. -

Page 142: Reading Of Set Values From An Sd Memory Card

do not remain, and all the parameters are restored. Comparison Wave: Only comparison waveform data are reconstructed. (The TM500's specific settings are the set values marked with * in "9-2 Setting item list" on p.144.) Operation Main screen→Setting→First Setting→Option Setting →SD Card→Reading of Set Press to start reading. -

Page 143: Format Of An Sd Memory Card

Main screen→Setting→First Setting→Option Setting →SD Card→Format To format, press CAUTION ● Format an SD memory card on the TM500 or with dedicated formatting software. Formatting it in other ways disables writing of measurement waveforms at an average of approximately 1s because the SD memory card processing speed becomes slow due to an inappropriate format for the TM500. -

Page 144: Error Release

7 OPTION ■Error Release When an error is displayed, release the error by this function. If such an error is displayed, SD memory card processing cannot be performed until it is released. Also, the SD memory card error cannot be released with on the Main screen. -

Page 145: Sd Memory Card Self-Check

7 OPTION Point The data in processing can also be annulled to release the error by turning the power off and then on again, or setting Measurement Waveform Preservation by the Automatic Operation to Off. ■SD memory card self-check Go to the SDC Check screen under Self-check. Operation Main screen→Setting→First Setting→System Setting→Self-Check→SDC Check Press... -

Page 146: Specifications

8 SPECIFICATIONS SPECIFICATIONS 8-1. Specifications ■Analog section Sensor input for torque (voltage input) Input resistance 1MΩ Signal input range ±5V Non-linearity 0.02%/F.S.±1digit Zero drift Within 0.2mV/℃ RTI Gain drift Within 0.01%/℃ Analog filter First-order low-pass filter (-6dB/oct) Selectable from 30, 100, 300, and 1k Hz. Sampling speed 4000 times/sec. -

Page 147: Display Section

8 SPECIFICATIONS ■Display section Display 3.5-inch TFT color LCD module Display area 71W×53H [mm] Dot configuration 320×240 [dot] Indicated value Load -9999 to +9999 Displacement -9999 to +32000 Decimal point; The decimal place is to be input together with a value at the time of calibration. 0.000, 0.00, 0.0, 0 Number of display times Fixed at 3 times/sec... -

Page 148: Options

8 SPECIFICATIONS Output signals 16 points Output type; sink type Output transistor ON at signal ON. To connect an input unit like a PLC, connect plus common. Rated voltage; Rated current; 30mA Isolation; photocoupler ■Options SD card slot [SDC] All parameters can be preserved and reconstructed. All comparison waveforms can be preserved and reconstructed. -

Page 149: Outside Dimensions

8 SPECIFICATIONS 8-2. Outside dimensions Chapter... -

Page 150: Block Diagram

8 SPECIFICATIONS 8-3. Block diagram + Change MONITOR - constant SIG IN (±5V DC) Low-pass filter SIG GND PWR + (+24V) DC24V PWR - (0V) Reference converter voltage Watch 32bit Lithium battery Serial port Serial SRAM port Pulse input for displacement External (standard: open collector) flash... -

Page 151: Supplements

9 SUPPLEMENTS SUPPLEMENTS 9-1. Setting tree Main screen Setting First Setting Y-axis Setting X-axis Setting [Time] [Displacement] (P36) ・Unit ・Zero Cal. (P36) ・Time/DPM Change (P38) ・Time/DPM Change (P38) ・Measure Length (P39) ・Phase Select (P39) ・Equiv. Cal. (P36) ・Wave Reference (P40) ・Actual Cal. (P36) (P40) ・Unit... - Page 152 9 SUPPLEMENTS Communication Setting System Setting Option Setting SD Card Slot Option ・Speed (P81) ・Backlight (P125) (P130) ・Data Bit (P81) (P126) ・Language ・Stop Bit (P82) ・Work Protect (P126) ・Equipment ID (P131) ・Parity Bit (P82) ・First Protect (P126) ・Auto Preserv. (P131) ・Delimiter (P82) ・Initialization (P126)

-

Page 153: Setting Item List

9 SUPPLEMENTS 9-2. Setting item list ■First Setting *2 Item Set value Input range (display range) Initial value Memory *1 Y-axis Setting See "9-3 Unit setting list" on p.149 Unit *1 0.000V Zero Cal. -5.555~5.555 [V] *1 Equiv. Cal. 5.000V -9.999~9.999 [V] (rated output) *1 Equiv. - Page 154 9 SUPPLEMENTS *2 Item Set value Input range (display range) Initial value Memory *1 Option 0 to 999 Equipment ID Setting Auto Preserv. 0: Off 1: On (Overwrite) 2: On (Not Overwrite) Preserv. of Set 0 : All Parameter 1 : Comparison Waveform Parameter Reading of Set 0 : All Parameter (Not Include)

- Page 155 9 SUPPLEMENTS ■Settings by work [Work 0 to 15, All] Item Set value Input range (display range) Initial value *2 Memory Settings by Work No. 0 to 15 work Copy No. 0 to 15 Measurement Start Condition 0 : Only External Input External Start 1 : External Input + Load...

- Page 156 9 SUPPLEMENTS Initial Item Set value Input range (display range) *2 Memory value Display X Start Point Time or displacement (Front) 0.00 Range 0 to 2000 × Measurement Length/2000 Setting Displacement (Back) -2000 to 0 × Measurement Length/2000 X End Point Time or displacement (Front) 400.0°...

- Page 157 9 SUPPLEMENTS Initial Item Set value Input range (display range) *2 Memory value Section 1 to 5 Start Load -9999 to 9999 1.00Nm Load Difference 1 to 19998 1.00Nm Rate 0 : 1/4 1 : 1/2 3/4 Times 2 : 3/4 3 : 1 4 : 1.25 5 : 1.5...

-

Page 158: Unit Setting List

9 SUPPLEMENTS 9-3. Unit setting list * Numbers are values in the RS-232C input range. Also, “0” results in no unit. Weight Force Pressure Length Angle Other μg μN μPa μm None g/cm ° kg/m l/min μA g/ml μNm mg/m kg/m dyne kgm/s μV... -

Page 159: Error Messages

9 SUPPLEMENTS 9-4. Error messages ■Load errors Error Description The sensor input signal in performing zero calibration is outside the zero calibration range. Check that unwanted force is not applied to the sensor and that there is no break in the cables and there is no mistake in wiring, and then perform zero calibration again. -

Page 160: Displacement Errors

Check that they are not different from the data sheet of the sensor, and then perform calibration again. The sensor output pulse count is beyond the TM500 internal count range. Set so that the sensor output pulse count will not go beyond the internal count range. -

Page 161: Error Release

9 SUPPLEMENTS ■Error release - Common to load errors and displacement errors Error Error release Perform zero calibration within the zero calibration range. Perform actual load calibration within the actual load calibration range. Or, perform equivalent input calibration within the equivalent input calibration range. -

Page 162: Troubleshooting

The set data are not erased even if the power is turned off. power is turned off? The TM500 preserves the settings for approx. 5 years with the power Are the set data erased if no off. power is applied for a long... -

Page 163: Conformity With Ec Directives

CAUTION ● Since the TM500 is defined as open type (built-in equipment), be sure to use it as installed and fixed to a panel, etc. ● Use shielded cables (for encoder, RS-232C, external input/output, and UTM). -

Page 164: Connection Of A Lightning Surge Protector

9 SUPPLEMENTS ■Connection of a lightning surge protector Attach a lightning surge protector against lightning surge. EMC Directive EN61000-4-5 (Lightning Surge Immunity) is met by the TM500 body in combination with a lightning surge protector. Lightning surge protector PT 2-PE/S-24AC-ST PT-BE/FM...

Need help?

Do you have a question about the TM500 and is the answer not in the manual?

Questions and answers