Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Metrohm 823 Membrane Pump Unit

- Page 1 823 Membrane Pump Unit Manual 8.823.8001EN / 2019-11-29...

- Page 3 Metrohm AG CH-9100 Herisau Switzerland Phone +41 71 353 85 85 Fax +41 71 353 89 01 info@metrohm.com www.metrohm.com 823 Membrane Pump Unit Manual 8.823.8001EN / 2019-11-29...

- Page 4 Technical Communication Metrohm AG CH-9100 Herisau techcom@metrohm.com This documentation is protected by copyright. All rights reserved. This documentation has been prepared with great care. However, errors can never be entirely ruled out. Please send comments regarding possible errors to the address above.

-

Page 5: Table Of Contents

Connection to the 731 Relay Box .......... 11 4 Operation 5 Operation and maintenance General notes ..............14 5.1.1 Care ..................14 5.1.2 Maintenance by Metrohm Service .......... 14 Tubings ................15 6 Troubleshooting Problems ................16 7 Technical specifications Membrane pump ..............17 ■■■■■■■■... - Page 6 ■■■■■■■■■■■■■■■■■■■■■■ Table of contents Power supply ..............17 Interfaces and connectors ..........17 Safety specifications ............17 Electromagnetic compatibility (EMC) ........ 18 Ambient temperature ............18 Reference conditions ............18 Dimensions/material ............19 8 Accessories Index ■■■■■■■■...

- Page 7 Figure 4 Screwing the union nuts tightly ............9 Figure 5 823 Membrane Pump Unit connected directly to the Sample Pro- cessor ..................... 10 Figure 6 823 Membrane Pump Unit via the Remote Box and 731 Relay Box .. 11 ■■■■■■■■...

-

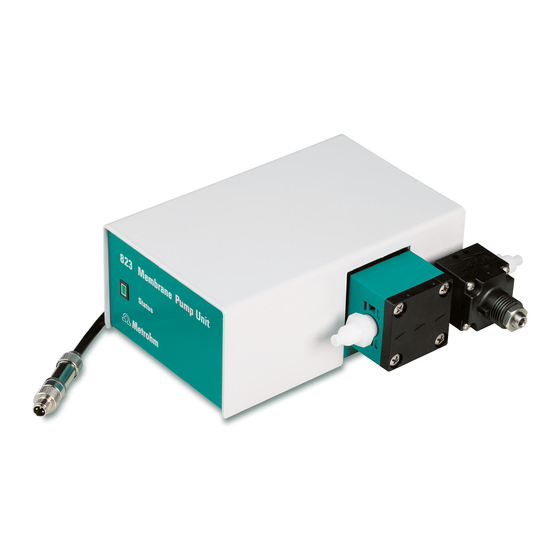

Page 9: Introduction

1 Introduction 1 Introduction Instrument description The 823 Membrane Pump Unit is a versatile membrane pump. It was designed specifically for the production operation and laboratory environ- ment and enables a wide range of applications. Particularly when used in a Metrohm automation system with Sample Processor and various analysis... -

Page 10: Connectors

This instrument is suitable for pumping chemicals and flammable samples. Use of the 823 Membrane Pump Unit therefore requires the user to have basic knowledge and experience in handling toxic and caustic substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also mandatory. -

Page 11: Safety Instructions

1.3.2 Electrical safety The electrical safety when working with the instrument is ensured as part of the international standard IEC 61010. WARNING Only personnel qualified by Metrohm are authorized to carry out service work on electronic components. ■■■■■■■■... -

Page 12: Tubing And Capillary Connections

■■■■■■■■■■■■■■■■■■■■■■ 1.3 Safety instructions WARNING Never open the housing of the instrument. The instrument could be damaged by this. There is also a risk of serious injury if live components are touched. There are no parts inside the housing which can be serviced or replaced by the user. -

Page 13: Flammable Solvents And Chemicals

■■■■■■■■■■■■■■■■■■■■■■ 1 Introduction 1.3.4 Flammable solvents and chemicals WARNING All relevant safety measures are to be observed when working with flammable solvents and chemicals. Set up the instrument in a well-ventilated location (e.g. fume cup- ■ board). Keep all sources of flame far from the workplace. ■... -

Page 14: Overview Of The Instrument

■■■■■■■■■■■■■■■■■■■■■■ 2.1 Mode of operation of the membrane pump 2 Overview of the instrument Figure 1 Front 823 Membrane Pump Unit Status LED Inlet connector For displaying the operating state. With union nut for the aspiration tubing. Membrane pump Pressurizing valve With arrows to indicate the flow direction. - Page 15 ■■■■■■■■■■■■■■■■■■■■■■ 2 Overview of the instrument Pump chamber PTFE membrane Eccentric Principle The membrane pump is located in the pump head. The membrane made of PTFE 4 is moved up and down by an eccentric 5. This results in a peri- odic volume change of the pump chamber 3.

-

Page 16: Installation

■■■■■■■■■■■■■■■■■■■■■■ 3.1 Setting up the instrument 3 Installation Setting up the instrument 3.1.1 Packaging The instrument is supplied in protective packaging together with the sepa- rately packed accessories. Keep this packaging, as only this ensures safe transportation of the instrument. 3.1.2 Checks Immediately after receipt, check whether the shipment has arrived com-... -

Page 17: Figure 3 Connecting The Tubings

■■■■■■■■■■■■■■■■■■■■■■ 3 Installation 2 Connect the tubings to the tubing olives of the pump tubing using union nuts. Figure 3 Connecting the tubings NOTICE To fasten PTFE tubings in place, you have to widen their openings (e.g. using a Phillips screwdriver). You can use a piece of sandpa- per to make the PTFE tubing easier to handle. -

Page 18: Connecting The Membrane Pump

Voltage The 823 Membrane Pump Unit needs 16 - 24 V DC voltage. It can be con- nected directly to Sample Processor models 814, 815, 855 or 864. When using the 823 Membrane Pump Unit in an automation system with remote control, we recommend using a 731 Relay Box for the power sup- ply. -

Page 19: Connection To The 731 Relay Box

■■■■■■■■■■■■■■■■■■■■■■ 3 Installation NOTICE The 823 Membrane Pump Unit is not suitable for use in conjunction with the 824 Easy Sample Changer processor. 3.3.2 Connection to the 731 Relay Box Connect the 823 Membrane Pump Unit with connection via the Remote Box (6.2148.010) and the 731 Relay Box to a remote interface. - Page 20 (negative pole) belongs in the black socket. NOTICE For information on controlling the 823 Membrane Pump Unit using the 731 Relay Box and a suitable control device, refer to the manual of the 731 Relay Box.

-

Page 21: Operation

■■■■■■■■■■■■■■■■■■■■■■ 4 Operation 4 Operation The 823 Membrane Pump Unit does not have its own operating units. It is operated and controlled via the main instrument in the linked system. ■■■■■■■■... -

Page 22: Operation And Maintenance

5.1.2 Maintenance by Metrohm Service Maintenance of the 823 Membrane Pump Unit is best carried out as part of an annual service, which is performed by specialist personnel of the Metrohm company. If working frequently with caustic and corrosive chemicals, a shorter maintenance interval could be necessary. -

Page 23: Tubings

■■■■■■■■■■■■■■■■■■■■■■ 5 Operation and maintenance Tubings The tubing requires regular inspection in order to work properly: Do not kink PTFE tubing. ■ Ensure resistance to solvents . ■ Check the tubing regularly for any damage. ■ ■■■■■■■■... -

Page 24: Troubleshooting

The membrane The inlet valve or the outlet Contact Metrohm Service at your Metrohm pump does not aspi- valve is blocked. representative. rate the solution. The membrane... -

Page 25: Technical Specifications

≤ 650 mA Power consump- tion Interfaces and connectors The 823 Membrane Pump Unit does not have any control interfaces. It is operated and controlled via the power supply. Safety specifications This instrument fulfills the following electrical safety requirements: CE designation in accordance with the EU directives: 2006/95/EC (Low Voltage Directive, LVD) ■... -

Page 26: Electromagnetic Compatibility (Emc)

■■■■■■■■■■■■■■■■■■■■■■ 7.5 Electromagnetic compatibility (EMC) Electromagnetic compatibility (EMC) Emission Standards ful- EN/IEC 61326-1 ■ filled EN/IEC 61000-6-3 ■ EN 55011 / CISPR 11 ■ Immunity Standards ful- EN/IEC 61326-1 ■ filled EN/IEC 61000-6-2 ■ EN/IEC 61000-4-2 ■ EN/IEC 61000-4-3 ■ EN/IEC 61000-4-4 ■... -

Page 27: Dimensions/Material

■■■■■■■■■■■■■■■■■■■■■■ 7 Technical specifications Dimensions/material Width 160 mm Height 70 mm Depth 200 mm Weight 1.68 kg (without accessories) Material Housing: steel sheet, stove-enameled ■■■■■■■■... -

Page 28: Accessories

Internet. You can download this information using the article number as follows: Downloading the accessories list 1 Enter https://www.metrohm.com/ into your Internet browser. 2 Enter the article number (e.g. Variable Produktnummer) into the search field. -

Page 29: Index

■■■■■■■■■■■■■■■■■■■■■■ Index Index Voltage ......17 Connect Instrument description ....1 731 Relay Box ....11 Membrane pump ....10 Safety instructions ...... 3 Material ........19 Sample Processor ....10 Service ........3 Membrane pump Standards ......17, 18 Flow rate ......

Need help?

Do you have a question about the 823 Membrane Pump Unit and is the answer not in the manual?

Questions and answers