Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Metrohm 895

- Page 1 895 Professional PVC Thermomat Manual 8.895.8001EN / 2020-02-25...

- Page 3 Metrohm AG CH-9100 Herisau Switzerland Phone +41 71 353 85 85 Fax +41 71 353 89 01 info@metrohm.com www.metrohm.com 895 Professional PVC Thermomat Manual 8.895.8001EN / 2020-02-25...

- Page 4 Technical Communication Metrohm AG CH-9100 Herisau techcom@metrohm.com This documentation is protected by copyright. All rights reserved. This documentation has been prepared with great care. However, errors can never be entirely ruled out. Please send comments regarding possible errors to the address above.

-

Page 5: Table Of Contents

Replacing fuses ..............16 3.3.3 Switching the instrument on and off ........17 Connecting a computer ............18 3.4.1 Connecting the 895 Professional PVC Thermomat and the computer ................18 4 Operation Thermomat method ............20 Calibration functions ............21 4.2.1... - Page 6 Cleaning the accessories ............27 5 Operation and maintenance General notes ..............29 5.1.1 Care ..................29 5.1.2 Maintenance by Metrohm Service .......... 29 5.1.3 Cleaning the instrument ............30 6 Troubleshooting Problems ................32 7 Technical specifications General data ................ 36 Temperature control and measurement ......

- Page 7 ■■■■■■■■■■■■■■■■■■■■■■ Table of figures Table of figures Figure 1 Front 895 Professional PVC Thermomat ..........6 Figure 2 895 Professional PVC Thermomat rear ..........7 Figure 3 Instrument display ................8 Figure 4 Nitrogen supply connector .............. 10 Figure 5 Equipping the reaction and measuring vessels .........

-

Page 9: Introduction

The measurements at the individual measuring positions can be started individually for this. The 895 Professional PVC Thermomat is controlled by means of the StabNet computer software and a computer that is connected via the USB interface. Up to 4 instruments can be controlled and monitored by each computer, hence allowing a maximum of 32 samples to be analyzed at the same time. -

Page 10: Symbols And Conventions

WARNING This symbol draws attention to a possible biological hazard. CAUTION This symbol draws attention to possible damage to instruments or instrument parts. NOTE This symbol highlights additional information and tips. ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 11: Safety Instructions

Flammable substances WARNING The heating block of the 895 Professional PVC Thermomat can be heated to 229.9 °C. Flammable substances may ignite at such temperatures. Adjust the oven's maximum heating temperature to the sample that is to be analyzed. -

Page 12: Flammable Solvents And Chemicals

Set up the instrument in a well-ventilated location (e.g. fume cup- ■ board). Keep all sources of flame far from the workplace. ■ Clean up spilled liquids and solids immediately. ■ Follow the safety instructions of the chemical manufacturer. ■ ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 13: Recycling And Disposal

The correct disposal of your old instrument will help to prevent negative effects on the environment and public health. More details about the disposal of your old instrument can be obtained from your local authorities, from waste disposal companies or from your local dealer. ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 14: Overview Of The Instrument

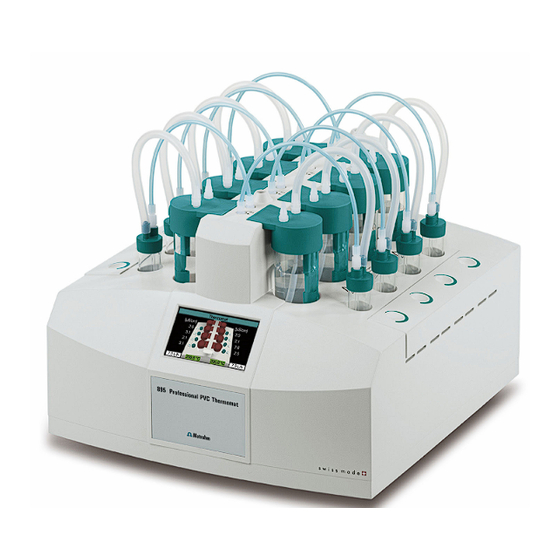

2.1 Front of the instrument 2 Overview of the instrument Front of the instrument Figure 1 Front 895 Professional PVC Thermomat Silicone tubing (6.1816.010) Measuring vessel cover (6.0913.130) For connecting the reaction vessel to the Contains an integrated conductivity measur- measuring vessel. -

Page 15: Rear Of The Instrument

■■■■■■■■■■■■■■■■■■■■■■ 2 Overview of the instrument Rear of the instrument Figure 2 895 Professional PVC Thermomat rear Electrode connector Air supply connector For connecting the conductivity measuring For connecting the FEP tubing 250 mm. cell integrated in the measuring vessel cover. -

Page 16: Instrument Display

Shows the gas flow measured on block A Shows the measured conductivity. (gray background: gas flow switched off; Dash (-) is displayed = Conductivity cannot white background: gas flow switched on). be displayed (no sensor connected or no valid measuring signal). ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 17: Setting Up The Instrument

The instrument should be protected against excessive temperature fluctua- tions and direct sunlight. NOTICE In order to improve accessibility of the measuring positions, the instru- ment can also be placed on the optionally available turning ring (6.2059.000). ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 18: Mounting Accessories

Nitrogen supply connector "Air/N in" connector The following accessories have to be mounted on the rear of the 895 Pro- fessional PVC Thermomat for the feed line: Mount the accessories for the external nitrogen supply as follows: 1 Mounting the connection tubing Screw one end of the connection tubing (6.1805.030) (150 cm) -

Page 19: Assembling The Reaction And Measuring Vessels

10 Tubing adapter M8/olive (6.1808.050) For connecting the silicone tubing to the In opening. 11 Opening "Out" 12 Opening "In" For removing the nitrogen from the measur- For supplying the nitrogen to the measuring ing vessel. vessel. ■■■■■■■■ 895 Professional PVC Thermomat... - Page 20 This slightly lubricates the glass and facilitates removal of the covers after the measurement. Place the reaction vessel cover on the reaction vessel. ■ NOTICE The air tube must be in a vertical position in the reaction vessel. ■■■■■■■■ 895 Professional PVC Thermomat...

-

Page 21: Inserting Vessels / Establishing Tubing Connections

Inserting vessels / Establishing tubing connections After you have assembled the reaction and measuring vessels, insert them in the 895 Professional PVC Thermomat and establish the tubing connec- tions (see chapter 2.1, page 6) as follows: 1 Inserting the measuring vessel Fill distilled water into the measuring vessel. -

Page 22: Mounting The Exhaust Air Collection Tube

3.2.4 Mounting the exhaust air collection tube The optional exhaust air collection tube (6.2757.000) can be mounted on the 895 Professional PVC Thermomat for targeted removal of the exhaust air. NOTICE A total of 8 pieces of silicone tubing (6.1816.010) (220 mm) are required in addition to the exhaust air collection tube. -

Page 23: Power Connection

Unplug the power plug immediately if you suspect that moisture has ■ gotten inside the instrument. Only personnel who have been issued Metrohm qualifications may ■ perform service and repair work on electrical and electronic parts. Connecting the power cord... -

Page 24: Replacing Fuses

Proceed as follows to replace defective fuses: 1 Pulling out the power cord Pull the power cord out of the power socket of the 895 Profes- ■ sional PVC Thermomat. 2 Removing the fuse holder Release the fuse holder located on the rear of the instrument ■... -

Page 25: Switching The Instrument On And Off

■■■■■■■■■■■■■■■■■■■■■■ 3 Installation 3.3.3 Switching the instrument on and off The 895 Professional PVC Thermomat is switched on and off using the power switch (2-3). The instrument display is switched on when the instrument is switched on. Figure 7 Instrument display with instrument name... -

Page 26: Connecting A Computer

Connect and set up the 895 Professional PVC Thermomat as follows: 1 Establish a connection between the USB interface (2-10) of the 895 Professional PVC Thermomat and the required USB interface on the computer using the USB cable (6.2151.130). - Page 27 ■■■■■■■■■■■■■■■■■■■■■■ 3 Installation NOTICE You will find detailed information regarding the StabNet com- puter program in the Tutorial. The instrument name entered in the configuration must appear on the instrument display (3-3). ■■■■■■■■ 895 Professional PVC Thermomat...

-

Page 28: Thermomat Method

50 µS/cm has been achieved. The induction time is the time that is required to reach the break point of the conductivity curve. This method is used for testing PVC at all stages of fabrication and for testing stabilizers. ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 29: Calibration Functions

The cell constants can be either entered manually or determined automat- ically by means of a defined standard solution, e.g. the conductivity stan- dard 100 µS/cm (6.2324.010). NOTICE You will find detailed information regarding the StabNet computer program in the Tutorial. ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 30: Determining The Temperature Correction

FEP tubing 250 mm (6.1805.080) Pt100 temperature sensor (6.1111.010) For supplying air into the reaction vessel. Thread adapter M8/M6 (6.1808.090) O-ring (6.1454.040) Temperature sensor opening Connector For inserting the temperature sensor. For connecting the thread adapter M8/M6. ■■■■■■■■ 895 Professional PVC Thermomat... - Page 31 895 Professional PVC Thermomat. Connect the temperature sensor to the Pt100 connector (2-9) on ■ the rear of the 895 Professional PVC Thermomat. NOTICE You will find detailed information regarding the StabNet computer program in the Tutorial.

-

Page 32: Determinations

Insert the measuring vessels with the measuring vessel covers into ■ the openings provided for this on the 895 Professional PVC Ther- momat while carefully guiding the connector plugs of the cover into the electrode connectors. -

Page 33: Preparing The Determination

A area and select a Method for block A. If required, also select a method for block B. ■ NOTICE Different methods with different temperatures and gas flows can be selected for block A and block B. ■■■■■■■■ 895 Professional PVC Thermomat... - Page 34 If required, also switch on the heater for Block B. ■ The color of the temperature display on the 895 Professional PVC Thermomat changes to red during the heating phase. The color of the temperature display on the 895 Professional PVC Thermomat changes to green once the setpoint temperature has been reached.

-

Page 35: Cleaning The Accessories

Screw the pieces of FEP tubing 250 mm to the M8/M6 thread ■ adapters of the reaction vessel covers and the air supply connec- tors of the 895 Professional PVC Thermomat. Insert the prepared reaction vessels into the recesses of the heat- ■... - Page 36 Clean the silicone tubing with acetone or 2-propanol or in the ■ dishwasher and rinse with distilled water. Pre-clean with dishwashing detergent in the case of severe con- tamination. Then heat the silicone tubing in the drying oven for 2 hours at ■ 80 °C. ■■■■■■■■ 895 Professional PVC Thermomat...

-

Page 37: Operation And Maintenance

5.1.2 Maintenance by Metrohm Service Maintenance of the 895 Professional PVC Thermomat is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. If you are frequently working with caustic and corrosive chemi- cals, we recommend a shorter maintenance interval. -

Page 38: Cleaning The Instrument

■ sockets) from moisture. If you suspect that moisture has gotten into the instrument, discon- ■ nect the instrument from the energy supply. Then, notify Metrohm Service. Only personnel who have been issued Metrohm qualification may ■ perform service and repair work on electric and electronic parts. - Page 39 NOTICE If the suspicion arises that liquids have found their way into the product, disconnect the instrument from the power grid and con- tact your Metrohm service engineer. NOTICE Water or ethanol can be used as a cleaning medium. NOTICE The connectors at the rear of the product must only be cleaned with a dry cloth.

-

Page 40: Troubleshooting

Only use new, unused reaction vessels. ■ The reaction vessels used Only use new, unused reaction vessels. are scratched on the inside. ■■■■■■■■ 895 Professional PVC Thermomat... - Page 41 Check whether the Sample temperature ■ and the Temperature correction are indi- cated correctly in the method. See also: The induction times are not reproducible for multiple determina- tions. ■■■■■■■■ 895 Professional PVC Thermomat...

- Page 42 These resi- red in previous dues are then transferred measurements. to the measuring vessel with the flow of warm air during a new measure- ment. ■■■■■■■■ 895 Professional PVC Thermomat...

- Page 43 Increase the value for time or conductivity. ■ before the endpoint. Deactivate time or conductivity as stop cri- ■ terion. ■■■■■■■■ 895 Professional PVC Thermomat...

-

Page 44: Technical Specifications

< 0.3 °C ature difference between different measuring posi- tions per block Temperature fluc- typ. < 0.1 °C tuations (With operating temperature attained, reaction vessels inserted and identically filled and 20 L/h air throughput.) ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 45: External Temperature Sensor

7 Technical specifications Shutdown temper- 260 ± 15 °C ature (Resetting and troubleshooting carried out by Metrohm Service.) Heating time for approx. 45 min (from 20 °C to 120 °C) the instrument approx. 60 min (from 20 °C to 220 °C) External tempera- <... -

Page 46: Gas Flow Regulation

Fuse Diameter 5 mm, length 20 mm 4.0 ATH (slow-acting) Ambient temperature Nominal function +5 - +45 °C range (at 20 - 80% humidity) Storage –20 - +70 °C Transport –40 - +70 °C ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 47: Dimensions/Material

383 mm Height 277 mm (without accessories) Depth 393 mm Weight 15.4 kg (without accessories) ® Cover material Baydur 110 FR-6 with flame retardation for fire class UL94VO, CFC- free Base material Steel sheet, coated ■■■■■■■■ 895 Professional PVC Thermomat... -

Page 48: Accessories

Downloading the accessories list 1 Enter https://www.metrohm.com/ into your Internet browser. 2 Enter the article number (e.g. 895) into the search field. The search result is displayed. 3 Click on the product. Detailed information regarding the product is shown on various tabs. -

Page 49: Index

Measuring range ....36 Connect Heating time ......37 Reproducibility ....36 Power grid ......15 Resolution ......36 Measuring vessel Determination Assemble ......11 Prepare ....... 25 Power connection ....15, 16 Electrostatic charge ....4 ■■■■■■■■ 895 Professional PVC Thermomat...

Need help?

Do you have a question about the 895 and is the answer not in the manual?

Questions and answers