Advertisement

EVCO S.p.A. | c-pro 3 giga | Instruction sheet ver. 1.0 | Code 104CP3GE103 | Page 1 of 2 | PT 07/19

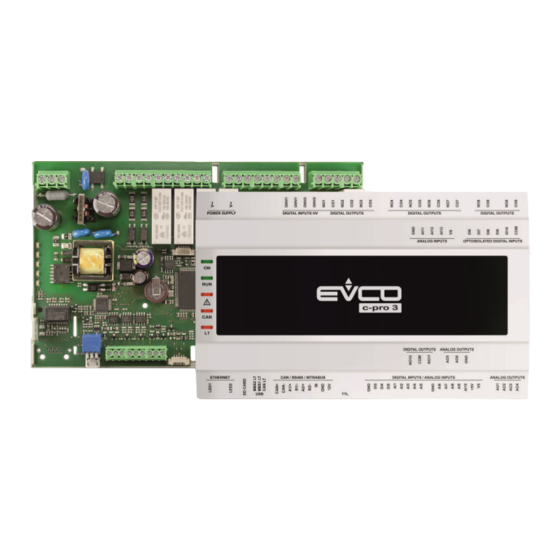

c-pro 3 giga

EN

ENGLISH

-

blind open frame models or with enclosure

-

power supply 115... 230 VAC

-

clock

-

10 analogue inputs (can be configured also for dry contact digital input)

-

3 dry contact digital inputs

-

2 high voltage digital inputs

-

4 analogue outputs

-

9 electro-mechanical relay digital outputs

-

TTL MODBUS port

-

INTRABUS port (RS-485 MODBUS master/slave by connecting the serial interface

EVIF22ISX)

-

RS-485 MODBUS slave port

-

RS-485 port (MODBUS master/slave, BACnet MS/TP)

-

CAN port

-

USB port

-

models with Ethernet port (MODBUS TCP, WebServer, BACnet IP)

(1)

the BACnet communication protocol can be used only in alternative to the Web Server

function

Purchasing codes

Version

Power supply

EPG9O

blind open frame

EPG9B

blind with

enclosure

115... 230 VAC

EPG9OHX

blind open frame

EPG9BHX

blind with

enclosure

1

MEASUREMENTS AND INSTALLATION

Measurements in mm (inches). To be fitted on a DIN rail, in a control panel.

2.2

Electrical connection

Example of electrical connection.

Programmable controllers (28 I/O)

To install the device operate as shown in pictures 1 and 2.

(1)

(1)

I/O

Communication ports

TTL, INTRABUS,

2 RS-485, CAN and

USB

28

To remove the device, first remove any screw-in removable terminal blocks mounted in the

TTL, INTRABUS,

lower part, then operate as shown in pictures 3 and 4.

2 RS-485, CAN, USB

and Ethernet

To install the device again press down the clip before.

INSTALLATION PRECAUTIONS

-

Ensure that the working conditions are within the limits stated in the TECHNICAL

SPECIFICATIONS section

Do not install the device close to heat sources, equipment with a strong magnetic field,

-

in places subject to direct sunlight, rain, damp, excessive dust, mechanical vibrations

or shocks

In compliance with safety regulations, the device must be installed properly to ensure

-

adequate protection from contact with electrical parts. All protective parts must be

fixed in such a way as to need the aid of a tool to remove them.

2

ELECTRICAL CONNECTION

N.B.

- Use cables of an adequate section for the current running through them

- To reduce any electromagnetic interference connect the power cables as far away

as possible from the signal cables and, if necessary, connect to a RS-485 MODBUS

network and/or a CAN network by using a twisted pair.

2.1

Connectors

Description of connectors.

N.

DESCRIPTION

V~

device power supply (115... 230 VAC)

V~

device power supply (115... 230 VAC)

N.

DESCRIPTION

DIHV1

high voltage digital input; DI1

DIHV2

high voltage digital input; DI2

COM

high voltage digital inputs common contact

N.

DESCRIPTION

NO1

K1 digital output normally open contact (3 A res. @ 250 VAC)

CO1

K1 digital output common contact

NO2

K2 digital output normally open contact (3 A res. @ 250 VAC)

CO2

K2 digital output common contact

NO3

K3 digital output normally open contact (3 A res. @ 250 VAC)

CO3

K3 digital output common contact

N.

DESCRIPTION

NO4

K4 digital output normally open contact (3 A res. @ 250 VAC)

CO4

K4 digital output common contact

NO5

K5 digital output normally open contact (2 A res. @ 250 VAC)

CO5

K5 digital output common contact

NO6

K6 digital output normally open contact (3 A res. @ 250 VAC)

CO6

K6 digital output common contact

NO7

K7 digital output normally open contact (8 A res. @ 250 VAC)

CO7

K7 digital output common contact

N.

DESCRIPTION

NO8

K8 digital output normally open contact (2 A res. @ 250 VAC)

CO8

K8 digital output common contact

NC9

K9 digital output normally closed contact

NO9

K9 digital output normally open contact (3 A res. @ 250 VAC)

CO9

K9 digital output common contact

N.

DESCRIPTION

CAN+

signal + CAN port

CAN-

signal - CAN port

A1/+

signal + RS-485 MODBUS slave port

B1/-

signal - RS-485 MODBUS slave port

A2/+

signal + RS-485 port (MODBUS master/slave, BACnet MS/TP)

B2/-

signal - RS-485 port (MODBUS master/slave, BACnet MS/TP)

IB

data INTRABUS port

GND

reference (GND)

12V

power supply remote user interfaces (13 VDC)

The actual UNI-PRO 3.13 version implements a BACnet® standardized device profile B-ASC,

which doesn't require the managing of Scheduler and Calendar objects, instead required for the

B-AAC profile.

N.

DESCRIPTION

GND

reference (GND)

DI3

digital input 3 (dry contact and for pulse trains up to 2 KHz); DI3

DI4

digital input 4 (dry contact and for pulse trains up to 2 KHz); DI4

DI5

digital input 5 (dry contact and for pulse trains up to 2 KHz); DI5

AI1

analogue input 1 (for PTC, NTC or Pt 1000 probes); AI1

can be configured also for dry contact digital input

AI2

analogue input 2 (for PTC, NTC or Pt 1000 probes); AI2

can be configured also for dry contact digital input

AI3

analogue input 3 (for PTC, NTC or Pt 1000 probes); AI3

can be configured also for dry contact digital input

AI4

analogue input 4 (for PTC, NTC or Pt 1000 probes); AI4

can be configured also for dry contact digital input

AI5

analogue input 5 (for PTC, NTC or Pt 1000 probes); AI5

can be configured also for dry contact digital input

N.

DESCRIPTION

GND

reference (GND)

AI6

analogue input 6 (for PTC, NTC or Pt 1000 probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers); AI6

can be configured also for dry contact digital input

AI7

analogue input 7 (for PTC, NTC or Pt 1000 probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers); AI7

can be configured also for dry contact digital input

AI8

analogue input 8 (for PTC, NTC or Pt 1000 probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers); AI8

can be configured also for dry contact digital input

AI9

analogue input 9 (for PTC, NTC or Pt 1000 probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers); AI9

can be configured also for dry contact digital input

AI10

analogue input 10 (for PTC, NTC or Pt 1000 probes, 0-5 V, 0-10 V, 0-20 mA or 4-20

mA transducers); AI10

can be configured also for dry contact digital input

+5V

power supply 0-5 V ratiometric transducers (5 VDC)

VS

power supply transducers (13 VDC)

N.

DESCRIPTION

AO1

analogue output 1 (for 0-10 V or PWM)

AO2

analogue output 2 (for 0-10 V or PWM)

AO3

analogue output 3 (for 0-10 V or PWM)

AO4

analogue output 4 (for 0-10 V or PWM)

2.3

Fitting the termination resistor of RS-485 networks and CAN network

To fit the termination resistor of the RS-485 network connected to the RS-485 MODBUS slave

port, place micro-switch MBS1LT in position ON.

To fit the termination resistor of the RS-485 network connected to the RS-485 port (MODBUS

master/slave, BACnet MS/TP), place micro-switch MBS2LT in position ON.

To fit the CAN network termination resistor, place micro-switch CANLT in position ON.

Advertisement

Table of Contents

Summary of Contents for Evco C-pro 3 giga

- Page 1 EVCO S.p.A. | c-pro 3 giga | Instruction sheet ver. 1.0 | Code 104CP3GE103 | Page 1 of 2 | PT 07/19 c-pro 3 giga Programmable controllers (28 I/O) DESCRIPTION device power supply (115... 230 VAC) device power supply (115... 230 VAC)

- Page 2 EVCO S.p.A. | c-pro 3 giga | Instruction sheet ver. 1.0 | Code 104CP3GE103 | Page 2 of 2 | PT 07/19 PRECAUTIONS FOR ELECTRICAL CONNECTION If using an electrical or pneumatic screwdriver, adjust the tightening torque If the device has been moved from a cold to a warm place, the humidity may have caused condensation to form inside.

Need help?

Do you have a question about the C-pro 3 giga and is the answer not in the manual?

Questions and answers