Exmark LAZER Z XS Setup Instructions

Diesel model

Hide thumbs

Also See for LAZER Z XS:

- Operator's manual (60 pages) ,

- Parts manual (32 pages) ,

- Setup instructions (5 pages)

Table of Contents

Advertisement

Quick Links

Loose Parts

Use the chart below to verify that all parts have been shipped.

109-8400

Part #

323-6

98-5975

3290-357

103-7599-03

109-2394

3296-39

103-1309

103-2106

1-603511

109-8399

Part #

—

—

109-3498

—

Installing the Rollover Protection

System (Roll Bar)

1. Remove sides and top of crate from the base.

2. Remove roll bar components from the crate.

3. Remove roll bar tubes from sides of crate.

4. Remove the two brackets used to mount the bottom

of the upper roll bar tube to the crate.

5. Remove the 1/2-13 x 3 1/4 inch capscrews and

1/2-13 inch hex flange lock nuts from the two

brackets at each end of the upper roll bar tube and

retain for later use (Figure 1).

6. Remove the four 1/4 inch lag screws holding the

wheel hub brackets to the crate bottom and discard.

© 2004–2007—Exmark Mfg. Co., Inc.

P.O. Box 808

Beatrice, NE 68310

Dealer Pack

Description

Cap Screw, Hex 3/8-16 x 1 inch

Washer, Spring Disc

Nut, Hex Flange 3/8-16 inch

Guard

U-Bolt

Nut, Nyloc 3/8-16 inch

Warranty Registration Form

Key, Exmark Logo

Key, Standard

Literature Pack

Description

Manual, Operator's

Manual, Parts

DVD, Exmark Safety Video

Manual, Engine Operators

Qty.

8

Installing the Rollover Protection

8

System (Roll Bar).

8

1

2

4

1

Fill out warranty registration form and

1

place keys into literature pack.

1

Qty.

1

Read before operating the machine.

1

1

View before operating the machine.

For units with Kubota engines–Read

1

before operating the machine.

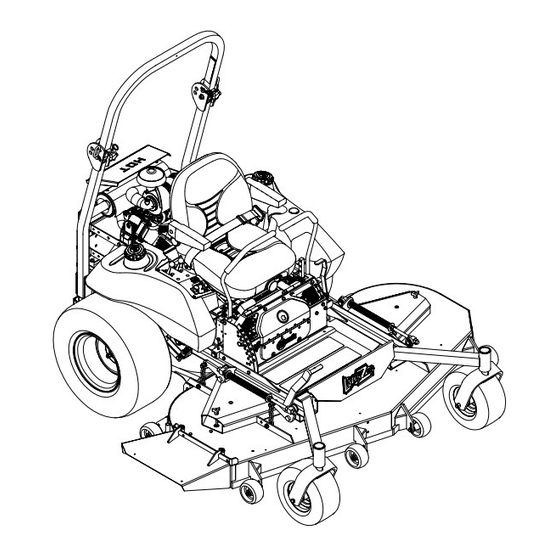

Figure 1

1. 1/2-13 x 3/4 1/4 inch

Capscrew

2. 1/2-13 inch hex flange lock

nuts

LAZER Z

®

Diesel Models

Setup Instructions

For Serial Nos. 720,000 & Higher

Use

Use

3. Upper roll bar tube

Part No. 4500-171 Rev. A

Printed in the USA.

All Rights Reserved

XS

Advertisement

Table of Contents

Summary of Contents for Exmark LAZER Z XS

- Page 1 1. 1/2-13 x 3/4 1/4 inch wheel hub brackets to the crate bottom and discard. Capscrew 2. 1/2-13 inch hex flange lock nuts © 2004–2007—Exmark Mfg. Co., Inc. Part No. 4500-171 Rev. A P.O. Box 808 Printed in the USA. Beatrice, NE 68310...

- Page 2 7. Raise the rear of the unit approximately 10–12 inches and support it with jack stands or equivalent support. Caution Raising the rear of the unit for assembly relying solely on mechanical or hydraulic jacks could be dangerous. The mechanical or hydraulic jacks may not be enough support or may malfunction allowing the unit to fall, which could cause injury.

- Page 3 Servicing the Battery latch pin from outer surface of roll bar assembly and secure with the hairpin to the inside. 16. Torque all lower roll bar hardware attached to the Warning machine frame to 30-35 ft-lb. (41-47 N-m). CALIFORNIA Proposition 65 Warning Installing the Air Cleaner Guard 1.

- Page 4 Servicing the Engine Coolant Percent Voltage Maximum Charging Reading Charge Charger Interval The machine is shipped filled with engine coolant. Settings 12.6 or 100% No Charging 16 volts/7 Warning greater amps Required 12.4 – 12.6 75–100% 30 Minutes 16 volts/7 Discharge of hot pressurized coolant or amps touching hot radiator and surrounding parts...

- Page 5 level depending upon the temperature of the oil. For example: If the oil is about 150° F (65°C). Fill to halfway between the “HOT” and “COLD” levels. If the oil is at room temperature (about 75° F (24°C)), fill only to the “COLD”...

Need help?

Do you have a question about the LAZER Z XS and is the answer not in the manual?

Questions and answers