Table of Contents

Advertisement

Quick Links

EP2 Pump System

Customer Product Manual

Document Number

1072608-04

Issued 10/21

For parts and technical support, call the Industrial Coating

Systems Customer Support Center at (800) 433-9319 or

contact your local Nordson representative.

This document is subject to change without notice.

Check

http://emanuals.nordson.com

for the latest version.

NORDSON CORPORATION • AMHERST, OHIO • USA

Advertisement

Table of Contents

Summary of Contents for Nordson EP2

- Page 1 For parts and technical support, call the Industrial Coating Systems Customer Support Center at (800) 433-9319 or contact your local Nordson representative. This document is subject to change without notice. Check http://emanuals.nordson.com for the latest version. NORDSON CORPORATION • AMHERST, OHIO • USA...

-

Page 2: Table Of Contents

Nordson Corporation welcomes requests for information, comments, and This is a Nordson Corporation publication which is protected by copyright. inquiries about its products. General information about Nordson can be found on Original copyright date 2004. No part of this document may be photocopied,... - Page 3 Change Record Change Record Revision Date Change 9/21 Revised pump versions and configurations. 10/21 Updated relief valve. 1072608-04 © 2021 Nordson Corporation...

- Page 4 Change Record 1072608-04 © 2021 Nordson Corporation...

-

Page 5: Safety

Intended Use Use of Nordson equipment in ways other than those described in the documentation supplied with the equipment may result in injury to persons or damage to property. Some examples of unintended use of equipment include: •... -

Page 6: Personal Safety

EP2 Pump System Personal Safety To prevent injury follow these instructions. • Do not operate or service equipment unless you are qualified. • Do not operate equipment unless safety guards, doors, or covers are intact and automatic interlocks are operating properly. Do not bypass or disarm any safety devices. -

Page 7: High-Pressure Fluids

EP2 Pump System High-Pressure Fluids High-pressure fluids, unless they are safely contained, are extremely hazardous. Always relieve fluid pressure before adjusting or servicing high pressure equipment. A jet of high-pressure fluid can cut like a knife and cause serious bodily injury, amputation, or death. -

Page 8: Fire Safety

Chlorine “Chloro-” Bromine “Bromo-” Iodine “Iodo-” Check your material SDS or contact your material supplier for more information. If you must use halogenated hydrocarbon solvents, contact your Nordson representative for information about compatible Nordson components. 1072608-04 © 2021 Nordson Corporation... -

Page 9: Action In The Event Of A Malfunction

EP2 Pump System Action in the Event of a Malfunction If a system or any equipment in a system malfunctions, shut off the system immediately and perform the following steps: • Disconnect and lock out system electrical power. Close hydraulic and pneumatic shutoff valves and relieve pressures. -

Page 10: Safety Labels

EP2 Pump System Safety Labels Table 1 contains the part number and description for each safety label on this equipment. Safety labels are provided to help you operate and maintain your equipment safely. See Figure 1 for the location of safety labels. - Page 11 EP2 Pump System Figure 1 Safety Label Location 1072608-04 © 2021 Nordson Corporation...

-

Page 12: Description

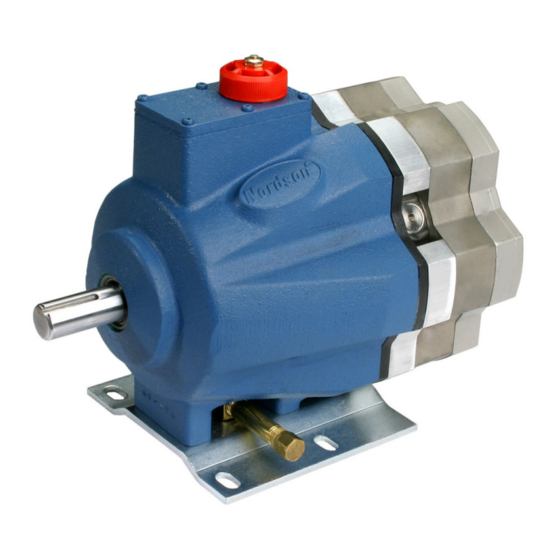

EP2 Pump System Description See Figure 2. The Nordson EP2 Pump System is an electrically powered, positive- displacement, constant-delivery fluid system. It consists of a • panel with load switch and fluid system components. • EP2 three-piston dual-diaphragm rotary pump driven by a constant-speed (1725 RPM) electric motor and gear reducer. -

Page 13: Pump Operation

EP2 Pump System Figure 3 EP2 Pump Assembly with Frame Only (Shown with Shroud Removed) 1. Motor 4. Guard 6. Oil fill cap 2. Gear reducer 5. Pump 7. Shroud 3. Coupling Pump Operation See Figure 4. Coating material can be supplied by a pressure-feed, gravity feed, or siphon system. -

Page 14: System Operation

10 EP2 Pump System System Operation See Figure 5. Coating material enters the pump inlet through a low-pressure gravity or siphon feed system. The pressurized coating material passes through the manifold and then is either routed to the spray system through the outlet fitting or, if the two-way ball valve is opened, through the drain rod to a waste container. - Page 15 Pump 2-Way Pressure Ball Valve Spray System Relief Valve Drain Back Pressure Regulator Dump Supply Valve Handle Positions Normal Operation Priming Flushing 2-Way 3-Way 2-Way 3-Way 2-Way 3-Way Figure 5 EP2 Pump System Hydraulic Diagram 1072608-04 © 2021 Nordson Corporation...

-

Page 16: Specifications

0.238 bar (7 in. Hg) maximum Inlet and Outlet Port Sizes Inlet: 3/4 in. NPT Outlet: 1/2 in. NPT Pump Oil Capacity 1.04 liter (1.1 qt) (use only Nordson EP2 pump oil) Electrical 380−420 volt, 3 phase (Wye), 50/60 Hz Motor Speed 1725 rpm Drive Capacity 2.0 hp... -

Page 17: Installation

EP2 Pump System Installation WARNING: Allow only qualified personnel to perform the following tasks. Follow the safety instructions in this document and all other related documentation. Oil Change Kit Installation The pump is shipped filled with oil. If you ordered an optional oil change kit, part 179490, install the quick-disconnect fitting included in the kit on the oil drain tube on the left side of the pump. -

Page 18: Pump Oil Level

CAUTION: To prevent damage to the pump, do not allow the oil to drop below the recommended level. Use only Nordson EP2 pump oil, part 1049265. Do not use EP1 pump oil, as it will damage the pump. See Figure 3. Unscrew the oil fill cap (7) and check the pump oil level . The oil level should be within 6 mm (1/4 in.) from the top. -

Page 19: Wiring Diagram

EP2 Pump System Wiring Diagram CUSTOMER-SUPPLIED POWDER CORD ♦ USE LIQUID-TIGHT CONDUIT CONNECTORS AND CONDUIT LOAD SWITCH WIRING DETAIL MOTOR JUNCTION BOX WIRING DETAIL ATTACH WIRE TO CHASSIS GROUND INSIDE JUNCTION BOX 380 - 420 VOLT, 3 PHASE (WYE) 50/60 HZ... -

Page 20: Fluid System Installation

• For pressure feed systems, install an inline strainer/filter on the siphon side of the pump with a 350 micron element. The filter should be as close to the EP2 pump as possible but with a hose at least 1.5 m (5 ft) long between the filter and the pump. -

Page 21: Operation

CAUTION: Make sure your coating materials and solvents are compatible with the diaphragms and seals in the EP2 pump. Some coating materials and solvents can damage the diaphragms and seals. Your Nordson representative can provide you with information on compatible materials. - Page 22 18 EP2 Pump System Step Task Procedure Continued... System Relief Valve Setting and 10. Check the pressure relief valve operation by adjusting the back Fluid Pressure Setting pressure regulator until the valve opens. For lacquer coating systems the valve is typically set to open at 89.6−91.4 bar (1300−1325 psi).

-

Page 23: Changing Coating Materials/Flushing The System

Refer to the System Startup procedures on page 17. 1. Turn the back pressure regulator knob fully counterclockwise to de-pressurize the system. 2. Turn off the EP2 pump. 3. If used, shut off the pressure feed. 4. Trigger the applicators. -

Page 24: Shutdown

Long-Term Shutdown CAUTION: To prevent damage to the fluid diaphragms and seals, consult a Nordson representative for types of solvents that can be left in the system for long periods of time. 1. If used, turn off the fluid heaters 12−15 min prior to shutdown. Refer to the heater manual for procedures. -

Page 25: Pressure Relief Valve Adjustment

EP2 Pump System Pressure Relief Valve Adjustment WARNING: System pressurized! Use extreme care when making adjustments. The system pressure relief valve opens if the fluid pressure exceeds the valve setting to protect the system and the operators from excessive pressure. If the relief valve fails to operate correctly, replace it immediately. -

Page 26: Maintenance

Disconnect the suction gun fitting from the drain fitting. 5. Fill the pump with new EP2 pump oil to within 6 mm (1/4 in.) from the top. Install the fill cap. 1072608-04 © 2021 Nordson Corporation... -

Page 27: Daily Maintenance Procedures

2. Inspect the filter screens for ruptures or distortion. 3. Replace the filter screens if necessary. Pump oil 1. Check the pump oil; add EP2 oil as necessary. 2. If the oil appears contaminated, refer to Troubleshooting on page 24. Fittings and hoses Check the fittings, hose connections, and hoses for leaks. -

Page 28: Monthly Maintenance Procedures

Annual Maintenance Procedures Refer to the EP2 Three-Piston Pump manual for disassembly and repair procedures: • Examine the shaft seals and piston assemblies in the oil-filled section. Replace if worn. • Examine the cam shaft bearings in the oil-filled section. Replace the pump if the bearings are worn. -

Page 29: Troubleshooting

The troubleshooting procedures in this section cover only the most common problems that you may encounter. If you cannot solve the problem with the information given here, contact your local Nordson representative for help. Problem Possible Cause... - Page 30 The operating pressure should not exceed 83 bar (1200 psi). failure Excessive pressure Check the pressure relief valve setting. Diaphragm material incompatible with coating Contact your Nordson representative for compatibility information. material or solvent 7. Broken piston Cavitation Replace the piston return springs. return spring 8.

-

Page 31: Repair

SERVICING - Before servicing, cleaning, or removal of any part, set trigger lock on gun, and always shut off power source; then carefully release pressure in fluid portions of the system. For EP2 pump assembly repair, refer to the pump manual: EP2 Three-Piston Pump - Part 1049229 1072608-04... - Page 32 28 EP2 Pump System This page is intentionally left blank. 1072608-04 © 2021 Nordson Corporation...

-

Page 33: Parts

A dash (—) is used when the part number applies to all parts in the illustration. The number in the Part column is the Nordson Corporation part number. A series of dashes in this column (- - - - - -) means the part cannot be ordered separately. -

Page 34: Ep2 Pump System

30 EP2 Pump System EP2 Pump System See Figure 12 and the following parts list. Figure 12 EP2 Pump Parts (shown with panel and frame version) 1072608-04 © 2021 Nordson Corporation... - Page 35 • • ACCESSORY GROUP, EP2 PUMP, PANEL, MOTOR 1054527 • • ACCESSORY GROUP, EP 2 PUMP 1617336 • ASSEMBLY, EP2 PUMP, FRAME, 5HP MOTOR 1615012 • • ASSEMBLY,MOTOR, 5HP, REDUCER, 2.62:1, C-FACE 981315 • • SCREW, HEX, 5/16-18 X 1.000, CAP, ZINC 983150 •...

-

Page 36: Accessory Groups

• OIL, EP2, 2 QT 900431 • ADHESIVE, PIPE/THREAD/HYD SEALANT - - - - - - • WIRE GROUP, SHIELDED, EP2 PUMP 1076333 • ELBOW, 37 DEGREES, 1/2 TX 3/8 NPT, STAINLESS STEEL NS: Not Shown Frame and Motor Assembly... -

Page 37: Options

EP2 Pump System Options Oil Change Kit Part Description 179490 GUN, suction, oil change PTFE High-Pressure Fluid Hose Assemblies These hose assemblies feature: • 1/2−20 JIC female swivel fittings • 6.3-mm (1/4-in.) ID hose • 207 bar (3000 psi) working pressure rating... - Page 38 34 EP2 Pump System 1072608-04 © 2021 Nordson Corporation...

- Page 39 Certificates: DNV ISO9001 (Houston, Texas) __________________ Date: 02Sept21 Jeremy Krone Engineering Manager Industrial Coating Systems Amherst, Ohio, USA Nordson Authorized Representative in the EU Person authorized to compile the relevant technical documentation. Contact: Operations Manager Industrial Coating Systems Nordson Deutschland GmbH Heinrich-Hertz-StraBe 42-44 D-40699 Erkrath Nordson Corporation •...

- Page 40 Date: 02Sept21 Jeremy Krone Engineering Manager Industrial Coating Systems Amherst, Ohio, USA Nordson Authorized Representative in the UK Contact: Technical Support Engineer Nordson UK Ltd.; Unit 10 Longstone Road Heald Green; Manchester, M22 5LB. England Nordson Corporation • Westlake, Ohio DOC12031-02...

Need help?

Do you have a question about the EP2 and is the answer not in the manual?

Questions and answers