Table of Contents

Advertisement

No.1000500-2-01-7

Instruction Manual

for

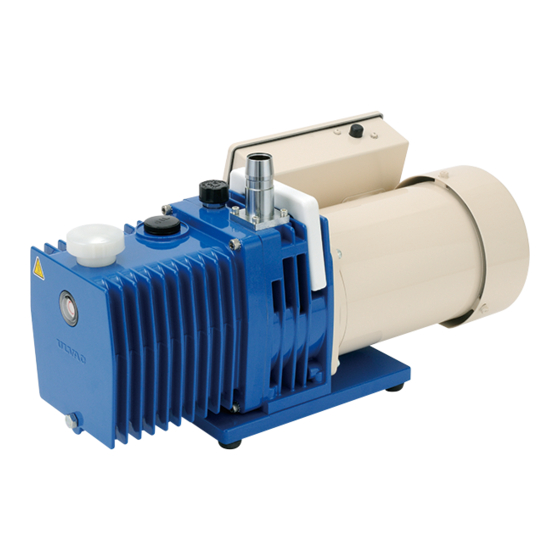

Direct-Drive Oil Sealed Rotary Vacuum Pump

Model

G-101D

G-101S

Before using the product, be sure to read this manual.

Keep this manual in a place where it can be referred to at any time

and look after it carefully.

The contents of this instruction manual are subject to change

without prior notice due to improvements in performance and the

functions of the product.

ULVAC KIKO,Inc

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ulvac G-101D

- Page 1 No.1000500-2-01-7 Instruction Manual Direct-Drive Oil Sealed Rotary Vacuum Pump Model G-101D G-101S Before using the product, be sure to read this manual. Keep this manual in a place where it can be referred to at any time and look after it carefully.

- Page 2 0. Introduction 0.1 Before using the vacuum pump Thank you for purchasing our vacuum pump (hereinafter called “pump”). When you have received the pump, check that the delivered pump is as per your order and that it has not been damaged in transportation, etc.

-

Page 3: Safety Symbols

0.2 Safety symbols In this instruction manual and on warning labels attached to the pump, the following symbols are used so that matters which must be strictly adhered to can be readily understood. These symbols are divided as shown below. Danger When mishandled, there is an imminent danger of the operator suffering a fatal accident or serious injury. -

Page 4: Cautions For Safety

0.3 Cautions for safety Danger When toxic or flammable gases are exhausted from the pump, they may leak not only from the pump outlet but also from the pump unit itself. Take proper measures suitable for the type of gas. Danger After the pump has been used for exhausting toxic gasses, not only the pump itself but also vacuum pump oil (hereinafter called “pump oil”) get toxic. - Page 5 Warning Do not use the pump in an explosive atmosphere. Failure to do so will result in injury or fire. Caution Do not insert fingers or objects into the opening of the motor. Doing so may result in electric shock, injury, or fire. Caution Never touch the rotating section of the motor, shaft or coupling while the pump is in operation.

-

Page 6: Acceptance And Storage Of The Pump

0.4 Acceptance and storage of the pump 0.4.1 Acceptance of the pump Although the pump is delivered with great care, check the following after unpacking. ① The delivered pump is in accordance with your request. ② The specified accessories (enough pump oil to use the pump once; optional equipment) have been provided. - Page 7 Note When you keep it, without using a pump for a long period of time, please put pump oil into a pump and seal a inlet port. Oil is not put into a pump, but if it is kept where a inlet port is opened wide, water absorption may expand vanes of a pump and a pump may stop rotating.

-

Page 8: Table Of Contents

·························· 14 4.3 Stopping the operation ·························· 14 4.4 Backflow preventer(G-101S) ·························· 15 4.5 Thermal protector ·························· 15 4.6 Gas ballast valve(G-101D) ·························· 15 4.7 Operation in cold climates ·························· 16 4.7.1 Operational method ·························· 16 4.7.2 Important points ·························· 16 4.8 An inlet port, exhaust port replacement (at option) ··················... - Page 9 5. Pump Performance ·························· 18 5.1 Ultimate pressure ·························· 18 5.2 Pumping speed ·························· 18 5.3 Power requirement ·························· 18 6. Maintenance, Inspection and Repair ·························· 20 6.1 Maintenance ·························· 20 6.2 Periodic inspection ·························· 20 6.3 Replacement of the pump oil ··························...

- Page 10 Figures and Tables Fig. 1 Dimensional drawing of G-101D oil sealed rotary vacuum pump ·········· 5 Fig. 2 Dimensional drawing of G-101S oil sealed rotary vacuum pump ·········· 5 Fig. 3 Transportation method of the oil sealed rotary vacuum pump ············ 6 Fig.

-

Page 11: Introduction

1. For Safe Operation 1.1 Hazards peculiar to the pump and safety measures Before operating or inspecting the pump, read this section carefully to fully understand potential hazards and prevention methods. 1.1.1 Danger Leakage of hazardous gases and substances Cause Prevention method and measures Leakage of toxic and ⇒... -

Page 12: Warning Explosion

1.1.3 Warning Explosion Cause Prevention method and measures The pressure in the pump ⇒ The maximum internal pump pressure is 0.03 MPa (gauge increased causing the pump pressure). to explode. Measure the pressure at the outlet side and, if the pressure is 0.03 MPa or more (gauge pressure), remove objects which block the passage of gas from the outlet side. -

Page 13: Outline Of The Pump

Since the pump is small, light, and quite simply constructed, it is easily maintained and repaired. Table 1 Pump specification Model G-101D G-101S Type Sliding vane 2stage Sliding vane 1stage... - Page 14 Table 2 Motor specification Model G-101D G-101S W(Poles) 400(4) Motor 100/100(50/60Hz) Single phase 200/200(50/60Hz) 100/100V 6.4/5.9(50/60Hz) Single Full load current phase 200/200V 3.2/2.8(50/60Hz) 100/100V 1,425/1,710(50/60Hz) Single Motor speed phase (r/min) 200/200V 1,450/1,745(50/60Hz) Caution Do not touch the motor while the pump is in operation or when the pump is still hot immediately after it stops.

-

Page 15: Dimensional Drawing

; Single phase, 50/60Hz, 400W, 4Poles, Capacitor start & run, fully-closed external fan Weight ; 23kg Fig. 1 Dimensional drawing of G-101D oil sealed rotary vacuum pump Motor ; Single phase, 50/60Hz, 400W, 4Poles, Capacitor start & run, fully-closed external fan Weight ;... -

Page 16: Environmental Conditions For Storage, Installation And Operation

3. Installation 3.1 Installation The pump should be installed on a level surface in a location with minimal dust, dirt and humidity and be arranged with consideration given to ease of installation, removal, inspection and cleaning. Particular attention should be paid to the ambient temperature when building the pump into equipment. -

Page 17: Fig. 4 Lubrication Of The Oil Sealed Rotary Vacuum Pump

Fig. 4 Lubrication of the oil sealed rotary vacuum pump Caution ① Wear protective equipment such as rubber gloves and safety goggles. ② Be sure to read the attached “Safety Data Sheet” before adding oil. If the oil accidentally comes into contact with your hands or enters your eyes, take proper measures in accordance with the section “First-aid treatment”... -

Page 18: Vacuum Piping

3.3 Vacuum piping (1) Before connecting the pipe to the pump, clean the inner walls of the vacuum chamber, piping and vacuum valve to completely eliminate moisture, fine particles, dust, dirt and rust. Note If fine particles, dust or dirt, etc are evacuated, the pump may malfunction. If moisture is evacuated, not only does the ultimate pressure increase but also the inside of the pump becomes rusty causing the pump to malfunction. -

Page 19: Electric Wiring

3.4 Electric wiring (1) This pump has performed beforehand electric wiring by the side of a pump. When wiring, open the terminal box of the motor and connect the wires as shown in Fig. 6. (2) Confirm that use power supply voltage accords with a working voltage of the motor. (3) The pump rotates in the clockwise direction as seen from the front of the pump (level gauge side). - Page 20 Warning Before connecting wires, turn off the power switch. Never perform wiring with the power supplied as an electric shock will occur. Connect the earth wire correctly. Failure to do so may result in electric shock if a failure or earth leakage occurs.

-

Page 21: Fluctuation In The Power Voltage And Frequency

Warning Do not connect an input power source to a thermal sign takeoff wire. A motor is damaged. 3.5 Fluctuations in the power voltage and frequency Standard: Rotation electricity machine general rules JIS C 4034-1:1999,JEC-2137-2000 To the voltage change and frequency change in Domain A, in main rated values, it operates continuously, and can be used practically convenient, and to the voltage change and frequency change in Domain B, it shall operate with main rated values and shall be used practically convenient. - Page 22 Warning Before connecting wires, turn off the power switch. Never perform wiring with the power supplied as an electric shock will occur. Connect the earth wire correctly. Failure to do so may result in electric shock if a failure or earth leakage occurs.

-

Page 23: Operation

4. Operation 4.1 Cautions for operation Warning There is a risk of explosion. Never block the outlet or operate the pump with equipment mounted at the outlet side which blocks the passage of gas. Otherwise, the pump internal pressure increases causing the pump to explode, the oil level gauge to protrude or the motor to be overloaded. -

Page 24: Start Of Operation

4.2 Start of operation To start operation, close leak valve (B), open vacuum valve (A) to the inlet port, and turn on the power switch. Then the pump starts beings to exhaust (see Fig. 5). Caution ① Firing hazard. Do not touch the motor or the pump body as these surface temperature should be higher (70~80℃). -

Page 25: Backflow Preventer(G-101S)

Firing hazard. As the surface of the pump body is higher temperature(70~80℃) during operation, do not touch it until cooled down after stopping the pump. 4.6 Gas ballast valve(G-101D) The pump is equipped with a gas ballast valve in order to evacuate vapor and condensable gases such as solvent vapor. -

Page 26: Operation In Cold Climates

pressurization processes of the pump, condensable gas will not liquefy and will be exhausted together with air through the outlet valve. When the gas ballast valve is used, the “gas ballast effect” increases as the pump temperature becomes high. So, before evacuating condensable gas, perform operation for approximately 20 minutes with the gas ballast open, and after the pump temperature reaches approximately 50 ~... -

Page 27: An Inlet Port, Exhaust Port Replacement (At Option)

4.8 An inlet port, exhaust port replacement (an option) 4.8.1 The switching method of the inlet port When I change an inlet port of the pump, please choose 40□ flange of our optional inlet port. The switching method excludes screw fixing an inlet port, and please attach an inlet port to change. -

Page 28: Pump Performance

5. Pump Performance 5.1 Ultimate pressure The term “ultimate pressure” as employed in the catalogue and in this manual is defined as “the minimum pressure obtained by the pump without the introduction of gas from the pump inlet (i.e. the non-load condition).” For this pump, measurement is performed using the specified pump oil with only a Pirani vacuum gauge installed at the pump inlet port. -

Page 29: Fig. 8 Pumping Speed Curve

Fig. 8 Pumping speed curve - 19 -... -

Page 30: Maintenance, Inspection And Repair

6. Maintenance, Inspection and Repair 6.1 Maintenance Check the following during operation at least once every three days. (1) Amount of pump oil (To be within the range shown with red lines on the oil level gauge) (2) Discoloration of the pump oil (3) Abnormal sound (4) Problem with the motor current value (5) Oil leak from the oil seal... - Page 31 Table 4 Periodic inspection table Frequency Item Details Measures Once/3 Amount Refill the oil. days Color (Reddish brown, dark Replace the oil. blown, and cloudy white are not good.) This pump uses carbon in internal member of framework. Oil may become black when it runs.

-

Page 32: Replacement Of The Pump Oil

6) Inspection of the coupling Check the coupling which connects the main pump unit and motor of the pump for damage. If cracks or fractures are found on the coupling, replace it in accordance with “6.4 Replacement of the coupling.” 7) Inspection of the oil mist trap When using the oil mist trap in replacement of the standard exhaust port, pay attention to the clogging of the filter in the oil mist trap. - Page 33 Danger Keep in mind that if the pump is used for exhausting toxic gas, both the main pump unit and pump oil will become contaminated. Caution ① Wear protective equipment such as rubber gloves and safety goggles. ② Be sure to read the attached “Safety Data Sheet” before adding oil. If the oil accidentally comes into contact with your hands or enters your eyes, take proper measures in accordance with the section “First-aid treatment”...

-

Page 34: Replacement Of The Coupling

6.4 Replacement of the coupling A coupling is used at the section connecting the pump main unit and the motor. It is recommended that this coupling be periodically inspected once a year or so. If the corner is chipped or cracked, replace it. If the pump is started and stopped hundreds of times a day, increase the inspection frequency. -

Page 35: Trouble Check List

6.5 Trouble check list Table 5 Trouble check list Problem Cause Measures Reference The pump ① The pump is not connected to the ① Connect the pump to the power does not rotate. power supply. supply. ② The power switch is not turned on. ②... - Page 36 Problem Cause Measures Reference The pressure ⑥ The specified amount of oil has not ⑥ Add the specified amount of oil. does not been added. decrease. ⑦ The oil has deteriorated. ⑦ Replace the oil. ⑧ Leakage occurs from the pipe ⑧...

-

Page 37: Disposal

7. Disposal Follow state law and local government regulations for disposal of the pump. Caution ① When a harmful toxic gas has been exhausted, ask a specialist for waste disposal. Not only the pump itself but also the pump oil become toxic. ②... -

Page 38: Maintenance Parts

8. Maintenance parts 8.1 Maintenance parts list Table 6 G-101D Maintenance parts list Product name O’ty Parts name Outlet valve Outlet valve spring O-ring _S-6 O-ring _S-24 O-ring _S-55 O-ring _P-8 G-101D O-ring _P-12 Maintenance kit A O-ring _P-24 O-ring _V-160... - Page 39 Table 7 G-101S Maintenance parts list Product name O’ty Parts name Outlet valve Outlet valve spring O-ring _S-4 O-ring _S-6 O-ring _S-18 O-ring _S-24 O-ring _S-55 G-101S O-ring _P-8 Maintenance kit A O-ring _P-24 O-ring _V-160 Oil seal_HTC-17-40-9 Oil seal_SCY-17-30-7 Oil seal_VC-15-30-5 O-ring _P-20 Vane...

-

Page 40: Disassembly Drawing

8.2 Disassembly drawing Fig. 10 Disassembly drawing of G-101D oil sealed rotary vacuum pump - 30 -... -

Page 41: Fig.11 Disassembly Drawing Of G-101S Oil Sealed Rotary Vacuum Pump

Fig. 11 Disassembly drawing of G-101S oil sealed rotary vacuum pump - 31 -... -

Page 42: Warranty

Warranty (1) The warranty for this pump (this equipment) extends for a period of one year from the date of shipment. (2) Any malfunctions or defects which occur under normal usage conditions during the warranty period will be repaired free of charge. Note, the warranty stated here is an individual warranty covering the pump. - Page 43 Usage Status Check Sheet (for use in Instruction Manual) * For the purpose of safety control of repair personnel, fill in within the heavy line frame and attach the sheet to the item of which repair is requested. * In case this sheet were not attached or filled in, your request of repair and service may not be accepted. * In accordance with the Private Information Protection Law, the provided information will be used only for determining the cause of failure and whether detoxifying washing should be conducted.

Need help?

Do you have a question about the G-101D and is the answer not in the manual?

Questions and answers