Table of Contents

Advertisement

Quick Links

No.P8129-2-02-13

Instruction Manual

for

Direct-Drive Oil Sealed Rotary Vacuum Pump

Model

G-5DA,G-10DA

Before using the product, be sure to read this manual.

Keep this manual in a place where it can be referred to

at any time and look after it carefully.

The contents of this instruction manual are subject to

change without prior notice due to improvements in

performance and the functions of the product.

ULVAC KIKO,Inc.

Advertisement

Table of Contents

Summary of Contents for Ulvac G-5DA

- Page 1 Instruction Manual Direct-Drive Oil Sealed Rotary Vacuum Pump Model G-5DA,G-10DA Before using the product, be sure to read this manual. Keep this manual in a place where it can be referred to at any time and look after it carefully.

-

Page 2: Preface

0.Preface 0.1 Before using this pump We, ULVAC KIKO,Inc. thank you for purchasing our vacuum pump. When receiving our vacuum pump, please confirm the product is the same Model No. as you ordered. Also, check to make sure there are no damages. -

Page 3: Safety Precautions (General Expression)

0.2 Safety precautions (General expression) Safety precautions are identified in this manual using headers DANGER, WARNING, CAUTION, and NOTE. "Danger" Indicates major hazardous situations, which present an immediate threat of death or serious injury. "Warning" Indicates hazardous situations, which may present a potential to death or serious injury. -

Page 4: Safety Precautions

0.3 Safety precautions When evacuating toxic or inflammable gas, there may be danger of leaking gas from parts besides inlet port. Practice cautionary steps when working any kind of gases. After evacuating toxic gases, the inside of pump and pump oil is contaminated and toxic. - Page 5 Switch off electric power right away in case of a malfunction to prevent any troubles. In the case of a malfunction, contact your local agent or ULVAC KIKO,Inc. Sales and Service Center immediately. Do not start the pump without pump-oil. Failing to do so will lead to pump...

-

Page 6: Acceptance And Store Of Product

(2) Spare parts (single use of pump oil, optional parts) (3) Any damages during transportation. (4) Any loose screws and nuts. If you find any abnormal circumstances, please contact your local ULVAC KIKO,Inc. Sales or Service Center. 0.4.2 Store of product, Installation, Operating condition This pump is a type of precision equipment;... -

Page 7: Protective Precautions

0.5 Protective precautions ・100 volt ,single phase,50/60 Hz motor is used for this pump. ・A built-in type thermal protector is equipped for the motor. ・Additional(leakage, etc)protectors are recommended. Do not apply any voltages other than specifically rated for the motor of this pump. -

Page 8: Table Of Contents

CONTENTS 0.Preface ・・・・・・・ 1 0.1 Before using this pump ・・・・・・・ 1 0.2 Safety precautions (General expression) ・・・・・・・ 2 0.3 Safety precautions ・・・・・・・ 3 0.4 Acceptance and store of product ・・・・・・・ 5 ・・・・・・・ 5 0.4.1 Acceptance of product ・・・・・・・ 5 0.4.2 Store of product, Installation, Operating condition 0.5 Protective precautions ・・・・・・・... - Page 9 4. Operational instructions ・・・・・・・20 4.1 Operational precautions ・・・・・・・20 4.2 Start up operation ・・・・・・・21 4.3 Shut down operation ・・・・・・・22 4.4 Start up procedures in cold climate ・・・・・・・22 4.5 Thermel protector ・・・・・・・23 4.6 Setup oil mist trap (option) ・・・・・・・23 4.7 The restriction in an operation of oil mist trap (option) ・・・・・・・24 5.

- Page 10 DRAWING AND TABLE LIST Fig-1 General assembly drawing of G-5DA ・・・・・・・14 Fig-2 General assembly drawing of G-10DA ・・・・・・・14 Fig-3 Oil charge to rotary vacuum pump ・・・・・・・16 Fig-4 Vacuum pumping system diagram ・・・・・・・17 Fig-5 Change region of the voltage and frequency ・・・・・・・18...

- Page 11 1.For safety operation 1.1 Hazardous of product and safety precautions Before operating or inspecting the pump, read this manual carefully. And pay attention to ascertain the detail of potential hazardous and preventive procedure so that must be operated or inspected the pump. 1.1.1 Leakage of hazardous gases and materials Cause...

- Page 12 1.1.3 Warning explosion Cause Preventive Procedure Pump explosion is consequence of ⇒ The maximum pressure inside the pump is excessive pressure inside the pump. 0.03 MPa (GAUGE). If inlet pressure of the pump is higher than 0.03 MPa (GAUGE), eliminate any objects which may cause obstruct gas flowing to the inlet port.

- Page 13 (vacuum pump oil), which is described on SDS sheet. When applying other vacuum pump oils besides the description in this manual, contact your local ULVAC KIKO,Inc. Sales and Service Center. SDS presents the reference information of hazardous chemical material to keep safety precautions.

- Page 14 This oil rotary vacuum pump is a sliding vane type (so called Gaede type), with direct driven motor. As it is a small sized, lightweight, and simple structure, it is easy to maintain or over-haul. Table-1 Specification Model Unit G-5DA G-10DA Type Sliding vane 2 stages 50Hz Pumping speed...

-

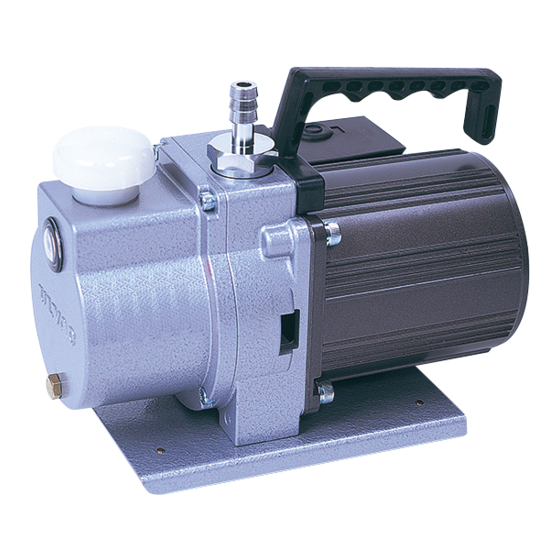

Page 15: Fig-1 General Assembly Drawing Of

2.2 Dimensional drawings Fig-1 General assembly drawing of G-5DA Motor ; Single phase, 100V, 40W, 4Poles, capacitor run Weight ; 5.0kg(with motor) Fig-2 General assembly drawing of G-10DA Motor ; Single phase, 100V, 60W, 4Poles, capacitor run Weight ; 5.5kg(with motor) - Page 16 3. Setting up 3.1 Installation Installation must be done at a place of low moisture, low dust particle, and also level. The layout arrangement should be considered for setting up, overhaul, checking, or cleaning the pump. When setting up the pump in any systems, pay attention to temperature in atmosphere.

-

Page 17: Fig-3 Oil Charge To Rotary Vacuum Pump ・・・・・・・16

Fig-3 Oil charge to rotary vacuum pump ・Wear protective rubber gloves or goggles. ・Before charging oils ,read the 「1.2 Safety Data Sheet」. When the contaminated oil touching the skin or coming into the eye accidentally, follow the item first-aid-treatment of「1.2 Safety Data Sheet」. -

Page 18: Fig-4 Vacuum Pumping System Diagram

3.3 Vacuum tubing (1) Clean inner surfaces of vacuum vessel, tubing and valve. Then, after eliminating water moisture, small particle, dust or rust carefully, connect tube to the pump. If evacuating small size powder or dust particle, vacuum pump may cause trouble. -

Page 19: Fig-5 Change Region Of The Voltage And Frequency ・・・・・・・18

3.5 Fluctuations in the power voltage and frequency Standard: Rotation electricity machine general rules JIS C 4034-1:1999,JEC-2137-2000 To the voltage change and frequency change in Domain A, in main rated values, it operates continuously, and can be used practically convenient, and to the voltage change and frequency change in Domain B, it shall operate with main rated values and shall be used practically convenient. - Page 20 Switch off power before electric wiring. Never connect electric wire cord when power line is hot. This may cause electric shock. Perform electric wiring correctly in accordance with the “Electric Equipment Technical Standard” and “Internal Wiring Regulation.” Incorrect wiring will result in fire. Electric wiring should be carried out in accordance with Electric Regulation and Standard.

- Page 21 4.Operating instructions 4.1 Operating precautions Explosion hazard. Do not plug the exhaust port or place any materials inside of the exhaust port, because it will reduce pumping speed during operation. Pump explosion, oil level gauge bursting, or over loading of the motor are consequences of excessive pressure inside the pump.

- Page 22 After operating the pump for several hours, oil temperature inside the pump may be risen up to 70 ~80℃. If the temperature is over this, the pump may have troubles. Maintain the pump, or contact ULVAC KIKO,Inc.

- Page 23 4.3 Shut down operation Close shut off valve (A), open pump vent valve (B), then turn off power switch of the pump. If stopping the pump by no opening pump vent valve, the oil will be filled inside the pump cylinder within several minutes. This may cause back flowing oil to the vacuum vessel.

- Page 24 4.6 Set up oil mist trap (option) Oil mist trap OMT-050A for G-5DA,G-10DA can be equipped for trapping oil mist out of the pump. After eliminating the standard exhaust port, equip the oil mist trap to the exhaust port. This can reduce oil mists and exhausting noise. Read...

- Page 25 4.7 The restriction in an operation of oil mist trap (option) When using oil mist trap OMT-050A the following items should be restricted in an operation. ① When the filter clogged with oil, change the filter. ② The maximum pressure inside this pump is 0.03MPa(GAUGE). ③...

- Page 26 The 「Ultimate Pressure」described in the catalog or this manual means obtainable minimum pressure by vacuum pumping at inlet port without conducting gas (no load operating). Our ULVAC KIKO,Inc. applies the specified pump oil and measures the pressure at inlet port attached the sensor of only the PIRANI gauge.

-

Page 27: Fig-6 Characteristics Of Vacuum Pumping Speed ・・・・・・・26

Fig-6 Characteristics of vacuum pumping speed Fig-7 Characteristics of motor power... - Page 28 6.Maintenance, inspection, repair 6.1 Maintenance Check and confirm the following items at least every 3 days while operating. (1) Oil level is in red ring marking of oil gauge. (2) Change in color of the oil. (3) Usual sound or not? (4) Motor current, normal or not? (5) Oil leak from oil seal assembly.

- Page 29 When happening the oil leakage from shaft seals or drain-plug seals, repair must be needed. As our service center provides the specified O-rings or seals, please contact your local ULVAC KIKO,Inc. service center. (4) Inspecting the mesh filter in the inlet port Any dust included in evacuated gases may cause clog the mesh filter and down pumping efficiency.

- Page 30 Besides the inspecting items mentioned above, overhaul is useful when continuing the operation for long term or observing heavy contaminated oils. Please contact your local ULVAC KIKO,Inc. Sales and Service Center. When requesting overhaul or repair the pump, inform the sort of evacuated gases on the "Check sheet for repair"...

- Page 31 When evacuating toxic gases, the pump body and the pump oil may cause toxic. Pay attention certainly. ・Wear suitable protector (rubber gloves, goggles). ・Before charging the oil, read the「1.2 Safety Data Sheet(SDS)」. When the contaminated oil touched skin or came into eye accidentally, follow the first-aid-treatment of「1.2 Safety Data Sheet」.

- Page 32 6.4 Replacement of the coupling A coupling is used at the section connecting the pump main unit and the motor. It is recommended that this coupling be periodically inspected once a year or so. If the corner is chipped or cracked, replace it. If the pump is started and stopped hundreds of times a day, increase the inspection frequency.

- Page 33 6.5 Trouble shooting list Table-4 Trouble shooting list Trouble Cause Procedure Note No rotating pump ①No connecting power ①Connect power cord ②Power switch off ②Turn on power switch ③Abnormal input voltage Adjust input voltage within ±10% ④Overload relay operated ③Reset button switch ⑤Inferior motor ④Replace motor ⑥High oil viscosity at low...

- Page 34 Trouble Cause Procedure Note ⑧Leakage from the tube ⑧Detect leakage by the leak connection with the pump detector, and stop leakage ⑨Applying no specified oil ⑨Charge specified oil after overhauling or repairing ⑩No circulating oil. ⑩Overhauling and repairing, Clogging the oil aperture of clean the oil aperture the pump cover Unusual sound...

- Page 35 7.Product disposal When disposing the pump, check and dispose the pump in accordance with laws and regulations by the local administration. When evacuating toxic gases which present hazardous situations to the human body entrust the pump should be disposed with authorized professional specialist.

- Page 36 8. Maintenance parts 8.1 Maintenance parts list Table-5 G-5DA Maintenance parts list Product name Parts name Q’ty Vane Vane spring Outlet valve Coupling Oil level gauge G-5DA Oil seal_HTC-9-22-7 Maintenance kit Oil seal_VC-10-20-4 O-ring _S-9 O-ring _P-6 O-ring _P-18 O-ring _S-101.1...

-

Page 37: Fig-9 Disassembly Drawing Of

8.2 Disassembly drawing Fig-9 Disassembly drawing of G-5DA... -

Page 38: Fig-10 Disassembly Drawing Of

Fig-10 Disassembly drawing of G-10DA... - Page 39 Warranty (1) The warranty for this pump (this equipment) extends for a period of one year from the date of shipment. (2) Any malfunctions or defects which occur under normal usage conditions during the warranty period will be repaired free of charge. Note, the warranty stated here is an individual warranty covering the pump.

- Page 40 Usage Status Check Sheet (for use in Instruction Manual) * For the purpose of safety control of repair personnel, fill in within the heavy line frame and attach the sheet to the item of which repair is requested. * In case this sheet were not attached or filled in, your request of repair and service may not be accepted. * In accordance with the Private Information Protection Law, the provided information will be used only for determining the cause of failure and whether detoxifying washing should be conducted.

Need help?

Do you have a question about the G-5DA and is the answer not in the manual?

Questions and answers