Advertisement

Advertisement

Table of Contents

Summary of Contents for LONGER Cube2

- Page 1 Cube2 Operating Instruction LONGER Cube2...

- Page 2 目录 A. Product information........................3 (1) Model parameter........................3 (2) Machine introduction......................4 (3) Nozzle module exploded view....................4 (4) Install filament bracket......................5 (5)leveling method........................6 B. Machine operation........................7 (1)Machine control........................ 7 (2)Main interface........................8 C. Cura installation and operation software................... 9 (1)Slice software offline printing instructions..............12 (2)Software parameter setting....................

-

Page 3: Safety Precautions

Safety Precautions 1) The temperature of the nozzle parts can reach 250 °C during the operation of the machine. To ensure your safety, it is forbidden to touch the model and nozzle directly with your hand while the printer is printing or cooling. - Page 4 The front end of the consumable should be fixed on the tray to avoid consumables and affect the next print. To use this printer, it is recommended to use the supplies provided by the company. At present, the quality of consumables sold in the retail market is uneven, and printing is prone to breakage.

-

Page 5: Model Parameter

A.Product information (1) Model parameter model Cube2 Machine size 238X228X266.5mm frame ABS Plastic Shell Machine weight 3.5KG Molding FDM (hot melt Package 320X310X375mm production) dimensions Number of nozzles Consumable color Multi-color optional Molding size 120*140*105mm Power requirement Output 24V Layer thickness 0.1-0.4mm... -

Page 6: Machine Introduction

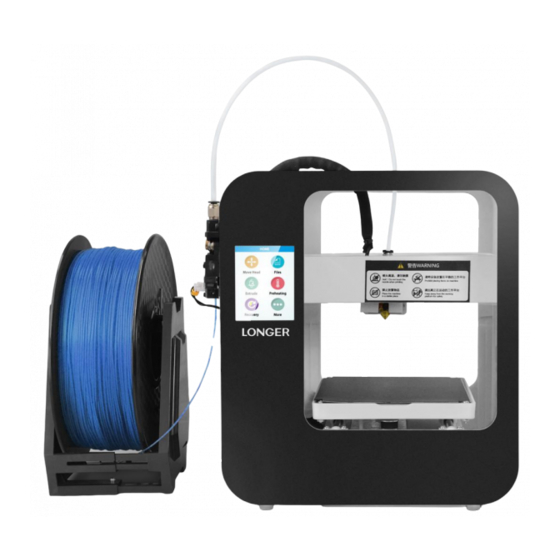

(2) Machine introduction Extruder Screen Nozzle Filament Print platform Filament Rack (3) Nozzle module exploded view 3010 fan 4010 fan Heat block nozzle Air guide Heater... - Page 7 (4) Install filament bracket...

- Page 8 (5)leveling method Turn on the machine and manually move the nozzle to the middle of the printing platform. Then let the z-axis go back to zero. If the copper nozzle is far from the platform or close to the platform or even press down the platform, raise the z-axis.

-

Page 9: Machine Control

Discharge flow Return Pause printing distance 暂停打印 Print interface Parameter Hotbed temperature Stop printing speed of fan Nozzle temperature Cube2 more Extrud Hotbed temperature return Slow in and out Automatic feeding and discharging 料 Adjustment distance stop Top left Leveling... -

Page 10: Main Interface

Click on the file to enter More Refresh Return Save Page flip Recovery Power failure recovery 返回 (2)Main interface Controls the movement of Open the print file Controls the temperature and print interface. coordinates, whether the of the nozzle and the motor is locked, the moving heating platform,... - Page 11 C. Cura installation and operation software...

- Page 14 (1)Slice software offline printing instructions...

- Page 17 (2)Software parameter setting...

- Page 18 Layer thickness:0.1~0.4mm available. 0.1mm high precision but long printing time, 0.4mm low precision but printing time is too short, in general select 0.2mm. Shell thickness: 0.4mm is very thin, in general select 1.2mm,that will increase printing time. Enable retraction: To prevent the wire from leaking when printing quickly, otherwise it will affect the appearance.

- Page 19 Nozzle size: 0.4mm. Retraction Speed: The speed of retraction when printing. Retraction distance: The length of material retraction, generally select 4.5~8mm. Initial layer thickness: The first layer thickness of printing. Select default option. Initial layer line width: 100% will be thicker and denser, Select default option. Cut off object bottom: The length of cutting off the bottom of model.

- Page 20 D. Operation for online printing Power on the printer, connect USB to a computer, the driver will be installed automatically. If it doesn't install automatically, find the driver under the driver folder and install it manually.

- Page 21 2. Ctrl + "," opens the "Preferences" dialog. 3. Click on the menu "Model" "" Model Settings" to open Select the corresponding serial port (different computer serial ports may be different, generally choose the larger one), the baud rate is "AUTO", click "OK".

- Page 22 2.After loading a file, click the status icon above or "Ctrl+P" to start printing, and the print window will pop up. We can click on the gray circle on the window to control the motion of the XYZE axis, respectively, 0.1, 10, 100 means the amount of each movement. The G-code control can be entered in the lower right corner text box.

-

Page 23: Power Outage Recovery

E . Resume printing and filament run-out detection function (1)Power outage recovery When printing for a period of time and the height of the print exceeds 0.5mm, the power-off icon will be displayed. At this time, the power is turned back on, and the icon can be clicked. - Page 24 (2)Filament run-out detection...

- Page 25 F. FAQ manual Question1: How to update the firmware? 1. Copy these two files to the SD card 2. Then restart the machine and wait for the machine progress bar to complete before the firmware is refreshed. 3. Then the user needs to delete the two files in the SD card to be used normally, otherwise the firmware will be refreshed every time the phone is turned on...

- Page 26 Question 3: When the machine returns the filament, it can't be returned. What should I do when stuck in the pneumatic joint? 1. Before returning the material, please heat the nozzle first, and then withdraw the consumables as soon as possible. If you can't pump it, you can re-feed the material with the advanced material, and melt the extruded block formed at...

- Page 27 Question 5:After the machine heats up, the filament is discharged normally. However, when the printing is performed for the first time, the curling occurs on the platform. After printing several layers, the filaments get out of the platform. What can I do? 1.