Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Bauer S300

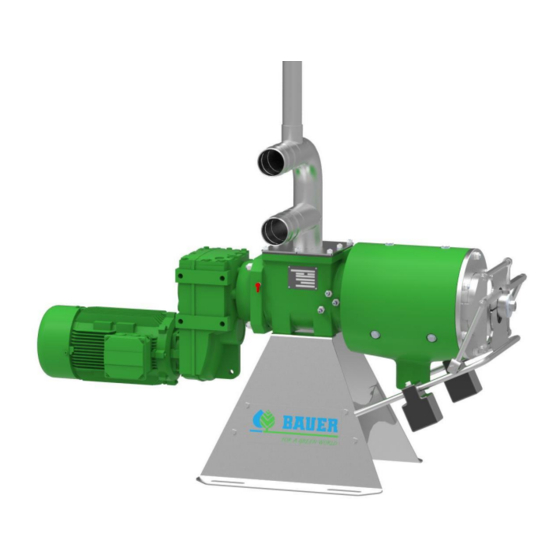

- Page 1 ORIGINAL OPERATING MANUAL SEPARATOR S300 Version: II- 2019...

- Page 3 Please make this manual available to your staff. State the pump type and serial number of your BAUER SEPARATOR in all inquiries, correspondence, warranty problems or parts orders. You will find this information on the type plate riveted onto the screen housing of the separator.

- Page 4 It is very important to include with all guarantee claims and all correspondence related with this machine the entire serial number group, including all letters, both for the machine and for its relevant components. This point cannot be stressed enough. Operating Manual for BAUER Separator S300...

-

Page 5: Table Of Contents

GENERAL INSTRUCTIONS FOR SAFETY AND ACCIDENT PREVENTION ............3 FUNCTION DESCRIPTION ............................. 6 SETUP OF THE SEPARATOR..........................7 Installation Diagram ............................7 Condition of the BAUER Separator upon Delivery .................... 7 Required Tools ..............................7 Features, Identification and Information ......................8 Type plates - Information Signs ........................9 4.5.1... - Page 6 14 PROBLEMS - TROUBLESHOOTING ........................29 Principles of a “Normal” Operating Condition ..................... 29 14.1 14.2 Troubleshooting ............................30 15 ACCESSORIES ..............................33 15.1 Separator Control ............................33 16 NOTES................................... 34 17 CONFORMITY DECLARATION ........................... 35 Operating Manual for BAUER Separator S300...

-

Page 7: General Safety Instructions

The recipient of the machine must be instructed with reference to the men- tioned regulations. Should you encounter difficulties in understanding this manual or other instructions, contact the respective dealer or the BAUER company for any necessary clarifications. PRODUCT LIABILITY According to the Product Liability Act, every farmer is an entrepreneur! In accordance with Section 9 PHG (Product Liability Act), liability for damage to physical property caused by defective products is expressly excluded. -

Page 8: Qualified Operators

The BAUER separator may be used and operated only by persons who are familiar with the system and aware of the hazards involved. All relevant rules for accident prevention as well as any other generally accepted rules and regula- tions relating to safety, occupational medicine and traffic laws must be strictly observed. -

Page 9: General Instructions For Safety And Accident Prevention

The system may only be started up if all protective and safety-related features are fully functional. This includes the fact that all removable protective features, EMERGENCY STOP buttons and covers must be present and functional. Operating Manual for BAUER Separator S300... - Page 10 Grips, steps, railings, landings, platforms and ladders must be cleaned of oil, dirt, snow and ice be- fore all activity on the system. If the BAUER separator is installed on an elevated platform, this must be equipped with a railing. The platform should be sufficiently dimensioned to allow maintenance and service work.

- Page 11 Always ensure sufficient ventilation when working with slurry! When working with biologically active materials in connection with the BAUER separator or connected compo- nents, the decomposition of these materials can lead to the production of life-threatening gases, especially in enclosed spaces.

-

Page 12: Function Description

3 FUNCTION DESCRIPTION The BAUER separator serves for separating pumpable slurry (solid-liquid mixtures with relatively low solid matter content and no foreign bodies such as metal parts, stones, wood or rags) into solid and liquid (thin slurry) fractions. As a compact device, it combines the functions of two separators, specifically the func- tions of a screen and a press. -

Page 13: Setup Of The Separator

It is recommended that the corresponding electrical con- trol for the separator or for the separator and the BAUER submersed motor pump be purchased from BAUER since it will be already adapted to the corresponding drive motors. -

Page 14: Features, Identification And Information

4.4 FEATURES, IDENTIFICATION AND INFORMATION To make it easier for you to familiarize yourself with your new BAUER separator, Fig. 4-2 shows you a longitudinal section of the internal machine design. We assist every customer in optimally selecting the right main separator components for the specific ap- plication before it is purchased, manufactured, assembled and shipped. -

Page 15: Type Plates - Information Signs

4.5 TYPE PLATES - INFORMATION SIGNS When you contact your dealer or communicate directly with BAUER GesmbH about wearing parts or for technical support for your separator, you will be asked for your serial number and machine number in or- der to ensure faster and more effective assistance. -

Page 16: Setup And Assembly

4.7 SETUP AND ASSEMBLY The basic dimensions of the BAUER separator for determining the dimensions of the setup location are shown in Fig. 4-3. The Separator S300 has a dead weight of approx. 220 kg. [mm ] 1018 1289 Ø89 Ø75... -

Page 17: Complete System

The supply line available with the BAUER separator as an accessory is a reinforced yet flexible tube. This reinforced tube is resistant to negative pressure. Ventilation openings can be added to the inflow line through the connection of a breather pipe to the inflow element. -

Page 18: Inflow Setup

Fig. 4-8 Drainage line If no FAN/BAUER pump is installed, the pump for supplying the separator should have a NOTE pump rate of at least 15 m³/h since the capacity of the separator otherwise cannot be fully utilized. To keep pressure losses due to pipe friction low, the pipes should have a diameter of at least 75 mm. -

Page 19: Electrical Connection

It is recommended that the corresponding electrical control for the separator or for the separator and the submersed motor pump be purchased from BAUER since it will be already adapted to the corresponding drive motors. -

Page 20: Setup And Operation Of The Motor

5.3 INSTALLATION WITHOUT SWITCH CABINET If the BAUER separator was delivered or ordered without a switch cabinet, a few basic rules must be followed in controlling the separator; otherwise, the warranty is void: ... -

Page 21: Preparation For Initial Startup

7.1 CONFIGURATION INSTRUCTIONS Two weight arms and weights are available to stabilize the solid cake and to adjust the dry matter content. These weights should be affixed as necessary. Fig. 7-1 Weight arms and weights Operating Manual for BAUER Separator S300... -

Page 22: Solid Cake Formation

As a suitable solid cake is formed, the output regulator arms will slowly move upwards. The pump can then be switched on without pauses Operating Manual for BAUER Separator S300... -

Page 23: Configuration To Stabilize The Solid Cake

Fig. 7-5 Cake too soft Depending on the medium, the adjustments described above must be performed multiple times upon startup until a stable condition is reached and the performance of the separator is optimized. Operating Manual for BAUER Separator S300... -

Page 24: Additional Instructions For Flawless Operation

It may be necessary to thaw the solid cake with hot water before the separator can be oper- ated normally. In order to ensure optimal operation in regions with prolonged cold periods, the separator should be in- stalled in a shelter or room protected against freezing. Operating Manual for BAUER Separator S300... -

Page 25: Test For Separation Capability

The second separator is equipped with screens of a smaller gap width than the first separator in order to achieve a further clarifying of the liquid. Inflow Fig. 10-1 Typical arrangement for the operation of 2 separators in series Operating Manual for BAUER Separator S300... -

Page 26: Important Aspects To Be Considered During Operation

If the cake is frozen solid in the separator, it must be thawed with hot water be- fore restarting. Operating Manual for BAUER Separator S300... -

Page 27: Maintenance And Inspection

Check the oil level of the gearbox roughly twice per year. Other than a regular supply of sealing medium, the BAUER separator normally requires little maintenance. 13.1.1 Supply of Sealing Medium When using sealing media and grease it must be guaranteed that they are compati- NOTE ble with the seals (material FPM). -

Page 28: Sealing

The surface of the slide ring which is in contact with the wear plate during operation and also the bushing must be greased before installation, the other surfaces of the sealing must be free of grease Abb.13-4 Sealing O-Rings slide ring Operating Manual for BAUER Separator S300... -

Page 29: Inspection Of The Screen And The Guide Rails

A plastic profile rail (T-rail) is inserted in the screen guide rails. Screen guide rail T-rail Fig. 13-6 T-rail T-rail Fig. 13-5 Housing of the Separator S300 with screen guide rails and T-rail plastic profiles Operating Manual for BAUER Separator S300... - Page 30 4 bolts located inside on the wear ring. Pull the wear ring out of the screen housing and replace it with a new one. Fig. 13-8 Wear ring bolts Operating Manual for BAUER Separator S300...

-

Page 31: Inspecting And Reinstalling The Screen

This must be checked with a thickness gage (Fig. 13-11). Fig. 13-11 Movable screen in the separator, Inspection of the floating capacity with the inspection of the floating capacity by hand thickness gage (left) Operating Manual for BAUER Separator S300... -

Page 32: Inspecting And Reinstalling The Auger

Then turn the bolts back approx. 30° and lock the lock nuts. The scraping bolts must be readjusted every 4 weeks. Fig. 13-14 Scraping bolts Operating Manual for BAUER Separator S300... -

Page 33: Evaluation Criteria For The Auger And Screen With Regard To Wear And Recoating

In principle, only the auger can be recoated to be used again; the screen cannot be recoated In order to ensure the necessary quality and precision, the recoating of the auger may only be performed by a workshop authorized by BAUER GmbH WARNING... -

Page 34: Summary Of Maintenance And Inspection Intervals

After 10.000 operating hours (no later than every 2 years) Geared motor oil change (see the gearbox and motor documen- tation for oil quantity and type) Inspect the bearing (see the gearbox and motor documentation for details) Operating Manual for BAUER Separator S300... -

Page 35: Problems - Troubleshooting

The search for possible sources of error is simpler when the principle and functioning of the BAUER separator are sufficiently well understood. 14.1 PRINCIPLES OF A “NORMAL” OPERATING CONDITION The auger of the separator has a defined diameter over its length and is adapted to the screen cylinder. -

Page 36: Troubleshooting

2. The gap width of the screen is too widths are: 0.25, 0.50, 0.75, and large 1.0 mm. After changing the gap Separator is running width, accustom yourself to a “ ” change in the normal operating condition. Operating Manual for BAUER Separator S300... - Page 37 Initial Startup. The cake may be ejected if the sol- id content in the supply medium decreases significantly. Use a finer screen. Solids are too fine and have no fibrous structure Operating Manual for BAUER Separator S300...

- Page 38 Document the symptoms and the Contact your dealer or the BAUER A problem as described measures you have taken to correct company. above cannot be corrected the problem. despite optimal configuration according to the instructions given above. Operating Manual for BAUER Separator S300...

-

Page 39: Accessories

The cable dimensions and the preliminary fuse must correspond to the power speci- fications. The BAUER separator is optionally delivered with an electrical switch cabinet that was designed for precisely your application. Normally, the switch cabinet has additional connections, e.g. for the feed pump, the fill level sensor, etc., which are controlled by the switch cabinet or which control the operation of the separator. -

Page 40: Notes

16 NOTES Operating Manual for BAUER Separator S300... -

Page 41: Conformity Declaration

This declaration becomes void in event of any changes to the machine made without the ap- proval of Bauer GmbH. Party responsible for documentation: Thomas Theissl, Kowaldstraße 2, 8570 Voitsberg, Austria Operating Manual for BAUER Separator S300...

Need help?

Do you have a question about the S300 and is the answer not in the manual?

Questions and answers